Liquid mill

A liquid mill and cylinder technology, applied in the field of grinding machinery, can solve the problems of high cost, low mixing and grinding efficiency of colloid mill, complex rotor and stator tooth structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

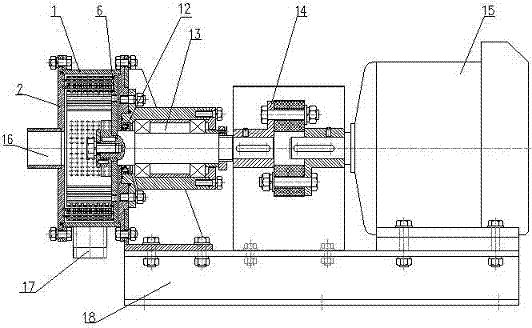

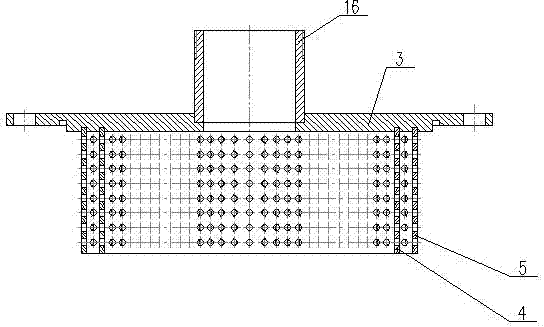

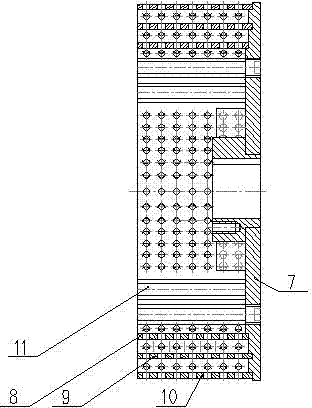

[0012] The structure of the invention is shown in the accompanying drawings.

[0013] 1 is the cylinder, 2 is the stator, 3 is the disc of the stator, 4 is the second-level ring, 5 is the fourth-level ring, 6 is the rotor, 7 is the rotor disc, 8 is the first-level ring, and 9 is the Three-stage ring, 10 is five-stage ring, 11 is stirring rod, 12 is shaft sealing device, 13, 14 is transmission device, 15 is motor, 16 is feeding pipe, 17 is discharging pipe, 18 is supporting device .

[0014] The present invention includes cylinder body 1, stator 2, rotor 6, shaft sealing device 12, transmission device 13, 14, motor 15, support device 18, and is characterized in that the disc 7 of the rotor is welded with a primary circular ring 8, a tertiary circular ring Ring 9 and five-stage ring 10, a plurality of stirring rods 11 are welded on the disc 7 of the rotor, and a secondary circular ring 4 and a fourth-stage circular ring 5 are welded on the disc 3 of the stator. The first-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com