A thermal load control method for micro gas turbine cogeneration system based on robust fuzzy predictive control

A micro gas turbine, fuzzy prediction technology, applied in general control system, control/regulation system, adaptive control, etc., can solve problems such as failure to meet performance requirements, achieve fast tracking speed, enhanced degree of freedom, and small overshoot Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

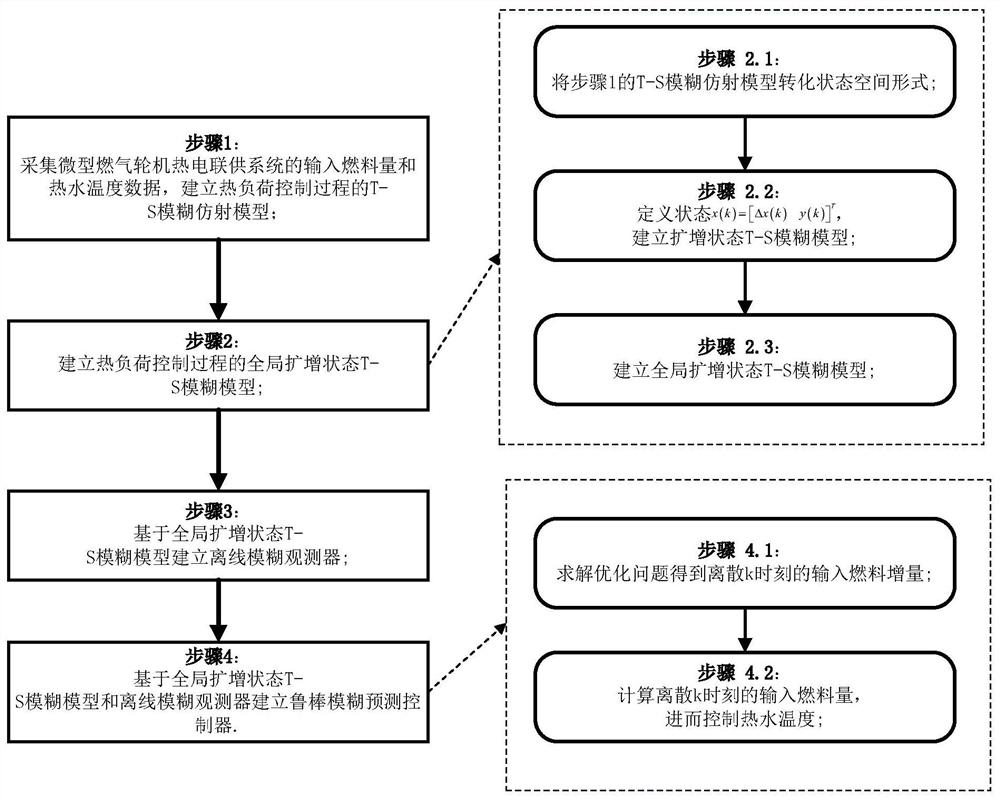

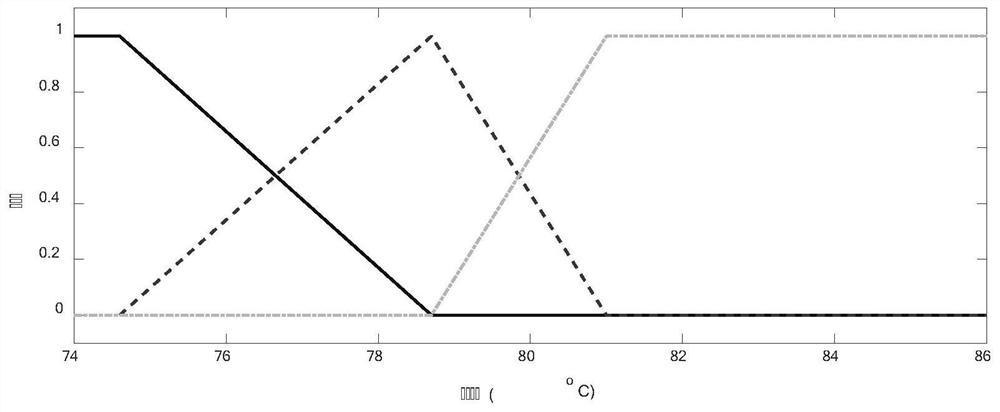

[0065] The method of the invention first approaches the dynamic characteristics of the process by establishing the T-S fuzzy affine model of the heat load control process, then promotes the design of the predictive controller through the state space transformation, and then eliminates the control deviation through the state amplification to improve the degree of freedom of the controller , and then because the state is unmeasurable, a fuzzy observer is established based on the fuzzy Lyapunov function to estimate the unmeasurable state, and finally a robust fuzzy predictive controller is established based on the augmented fuzzy model and the derivation of the fuzzy observer.

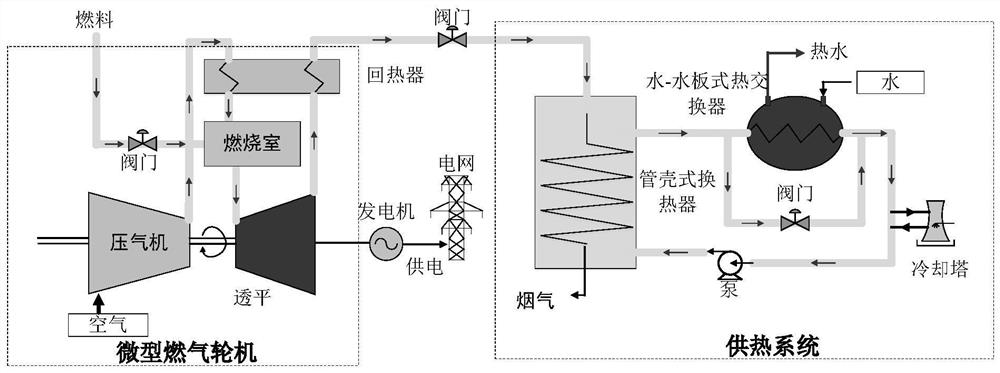

[0066] Such as figure 1 As shown, the present invention is based on a robust fuzzy predictive control micro-turbine heat and power cogeneration s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com