Fuzzy prediction control system of power supply for electrostatic dust collection and control method of fuzzy prediction control system

A technology of electrostatic dust removal and fuzzy prediction, which is applied in the field of high-voltage electrostatic dust removal, can solve the problems of low controller design cost and difficulty in establishing accurate mathematical models, and achieve the effects of enhanced self-adaptive ability, good adaptability, and reduced dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

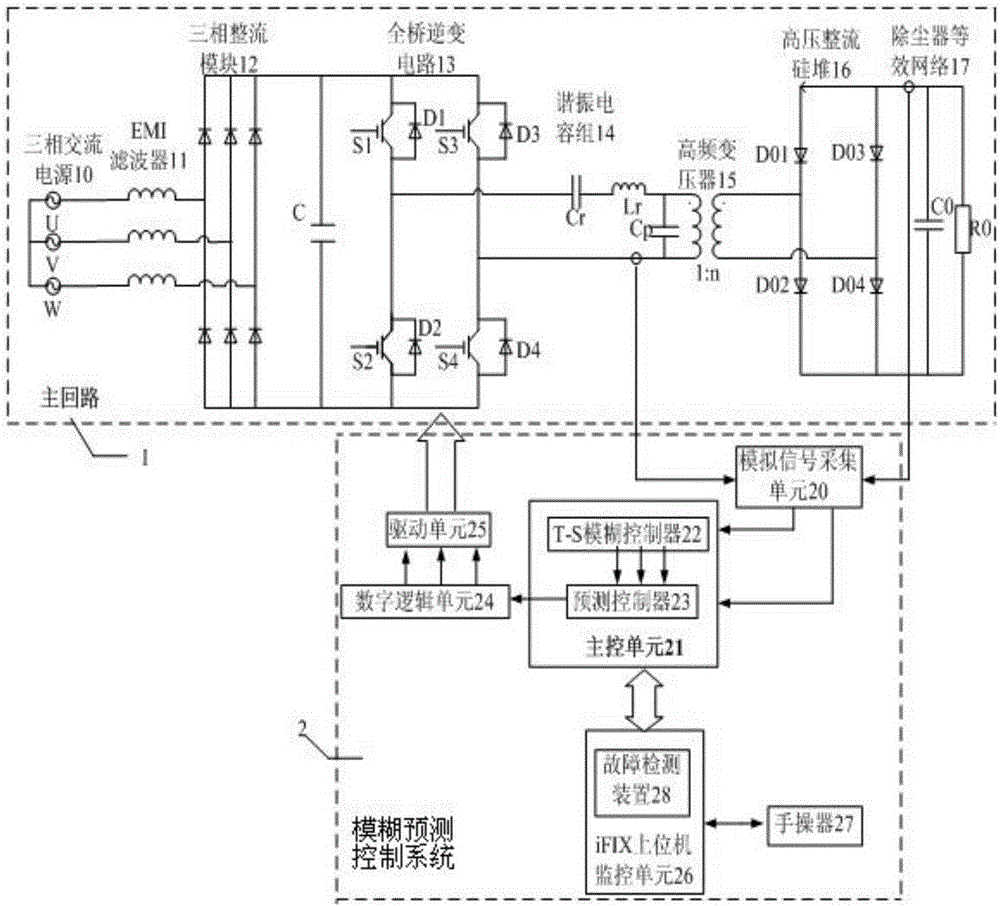

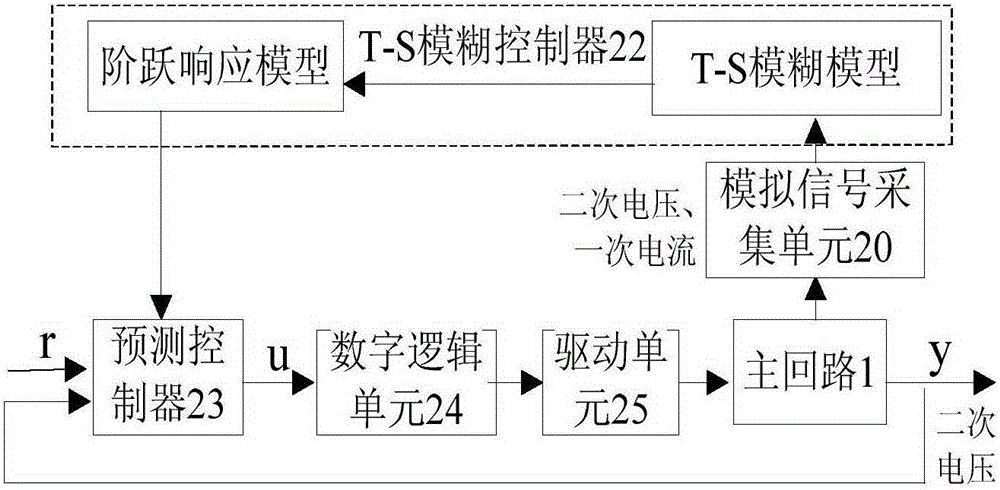

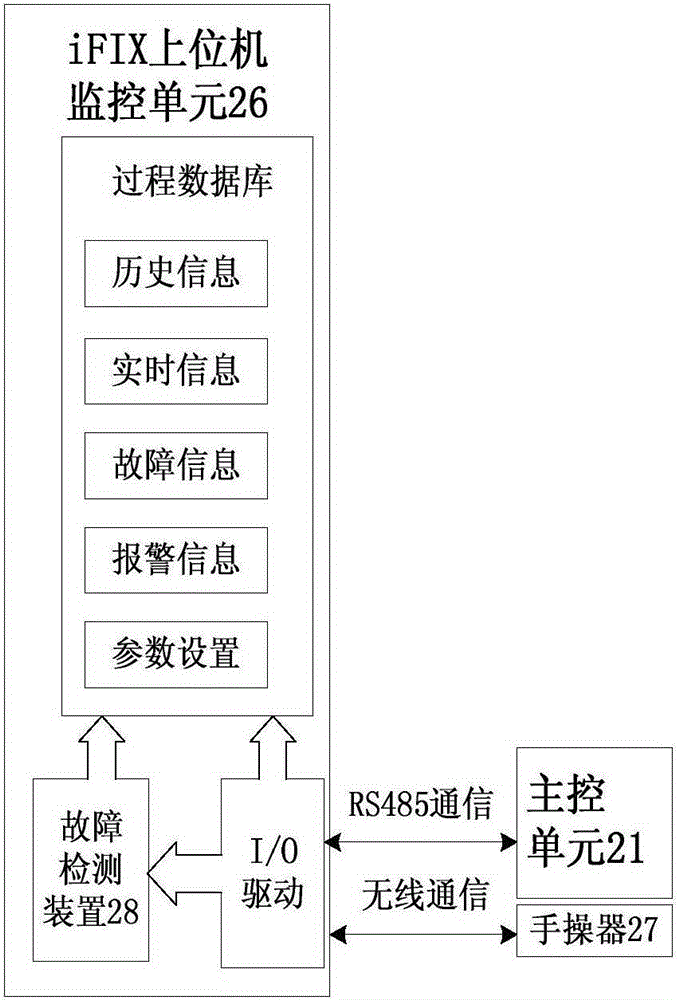

[0023] see figure 1 , the fuzzy predictive control system 2 of the power supply for electrostatic precipitator of the present invention is connected to the main circuit 1 of the power supply system for electrostatic precipitator. The main circuit 1 of the power supply system for electrostatic dust removal includes three-phase AC power supply (U, V, W) 10, EMI filter 11, three-phase rectification module 12, full-bridge inverter circuit 13, resonant capacitor group 14, high Frequency transformer 15 and high voltage rectifier silicon stack 16. The three-phase rectification module 12 adopts a three-phase bridge rectification method. The series-parallel resonant network is composed of the resonant capacitor group 14, the equivalent leakage inductance of the high-frequency transformer 15, and the distributed capacitance. The high-frequency transformer 15 is a high-turn-ratio high-frequency step-up transformer. The output of the high-voltage silicon rectifier stack 16 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com