Grain drying and storing granary

A technology for storage bins and grain outlets, applied in fruit hanging devices, household heating, lighting and heating equipment, etc., can solve unsatisfactory problems, achieve simple and practical structure, maintain original flavor, reduce labor intensity of farmers and economical burden effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

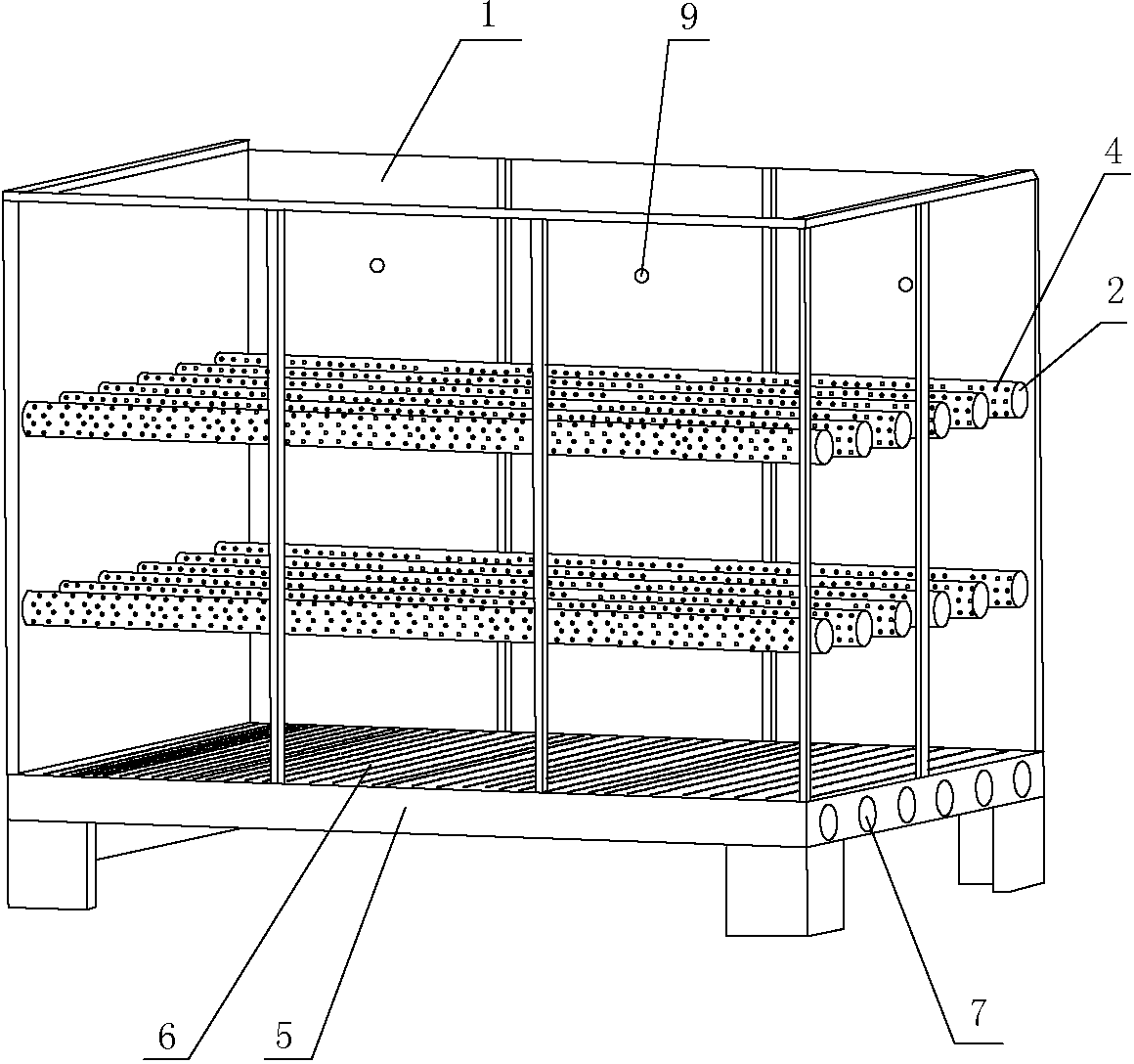

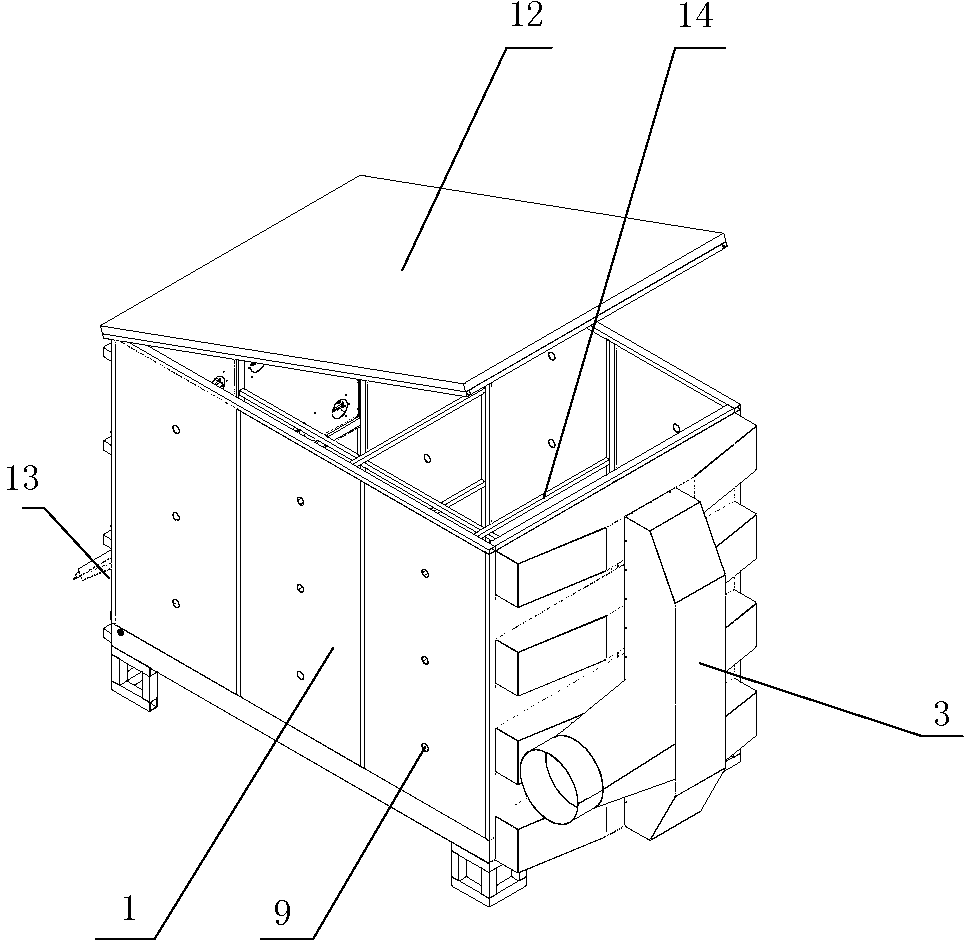

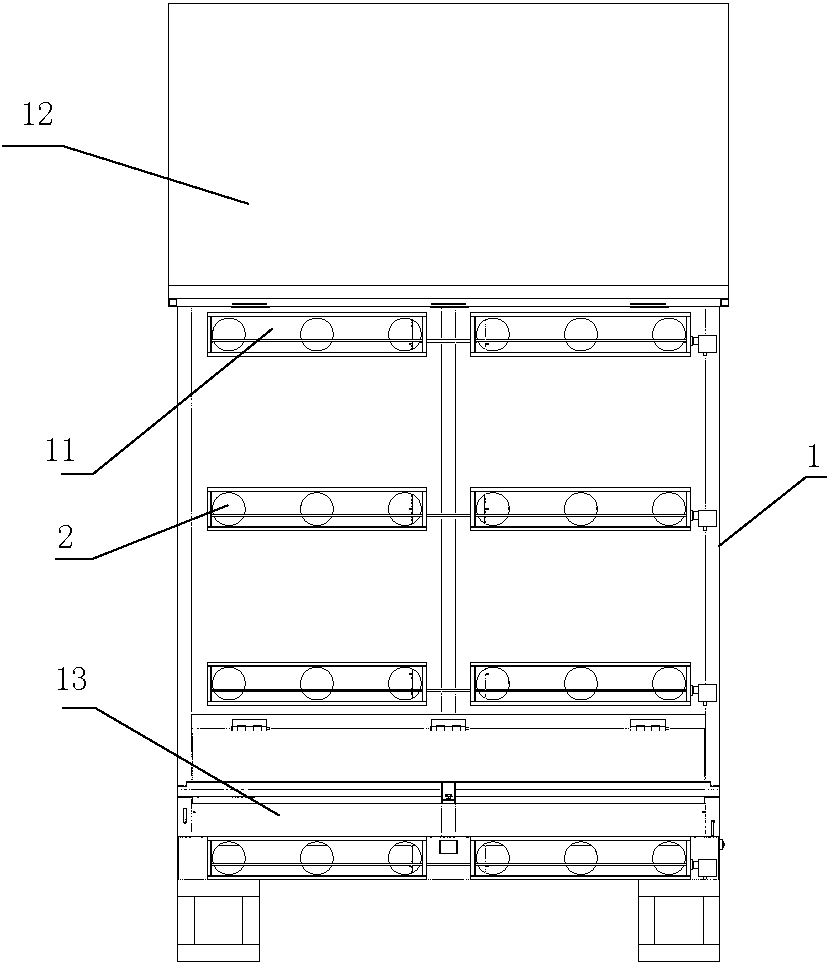

[0038] as attached figure 1 As shown, the present invention includes a grain storage box 1, and the grain storage box 1 is provided with a plurality of air ducts 2 arranged in layers, and the distance between two adjacent layers is no more than 1m. , preferably the distance between two adjacent layers of the air duct 2 is 60cm, and the effective volume of the grain storage box 1 is improved under the premise of ensuring the drying effect. One end of the air pipe 2 is connected with the ventilation pipe 3, and can be connected with the hot blast stove through the pipe 3 to provide the hot air needed for drying the grain, and can also be connected with the air cooler or the medicine delivery device according to different functional needs. A plurality of ventilation holes 4 are arranged on the air duct 2. The air duct 2 is made of a PVC pipe or a metal pipe with a diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com