Horizontal convection integral grain drying machine

A drying machine and grain technology, applied in the direction of drying and preserving seeds, etc., can solve the problems of low temperature, large energy consumption, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

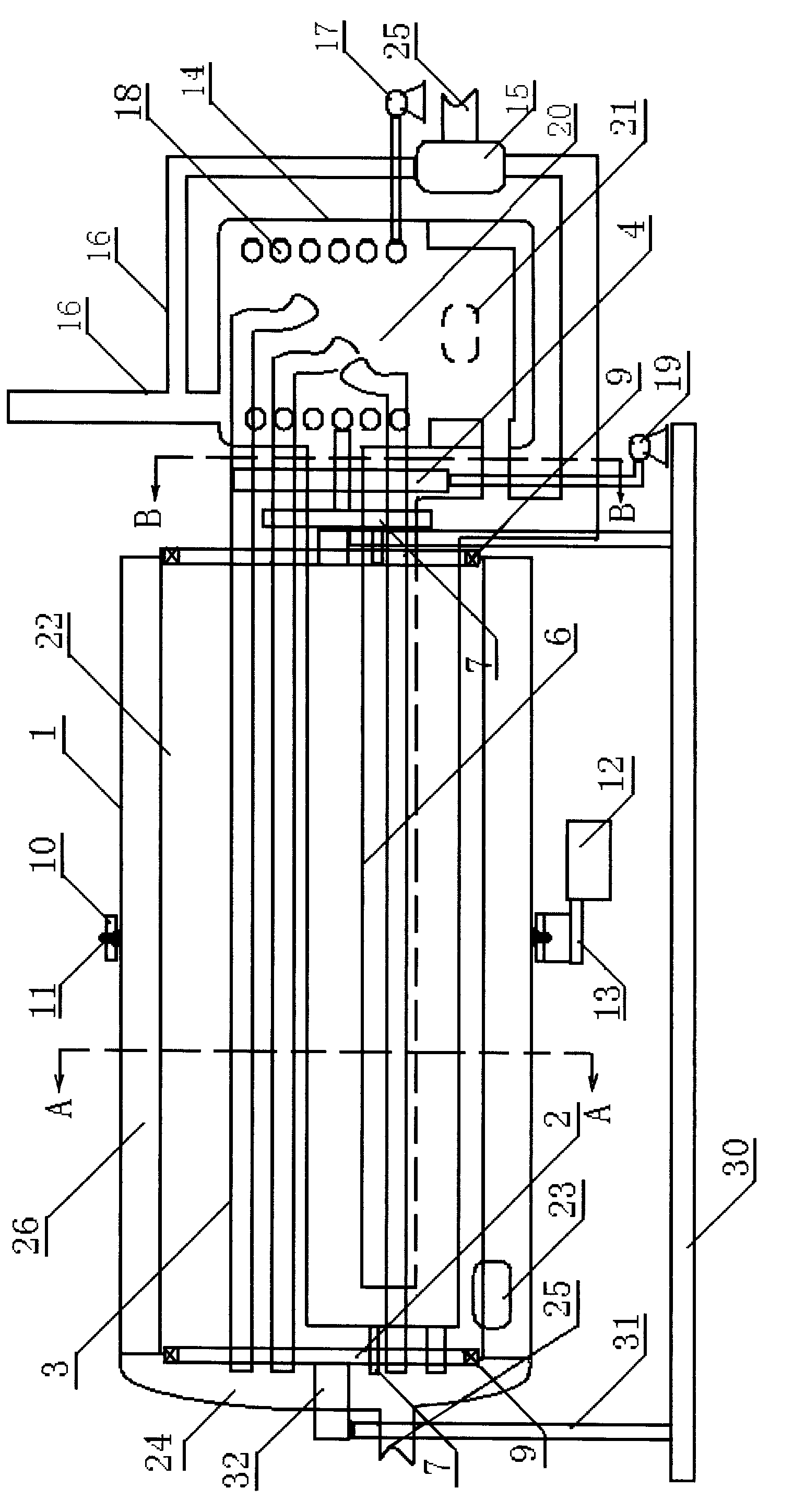

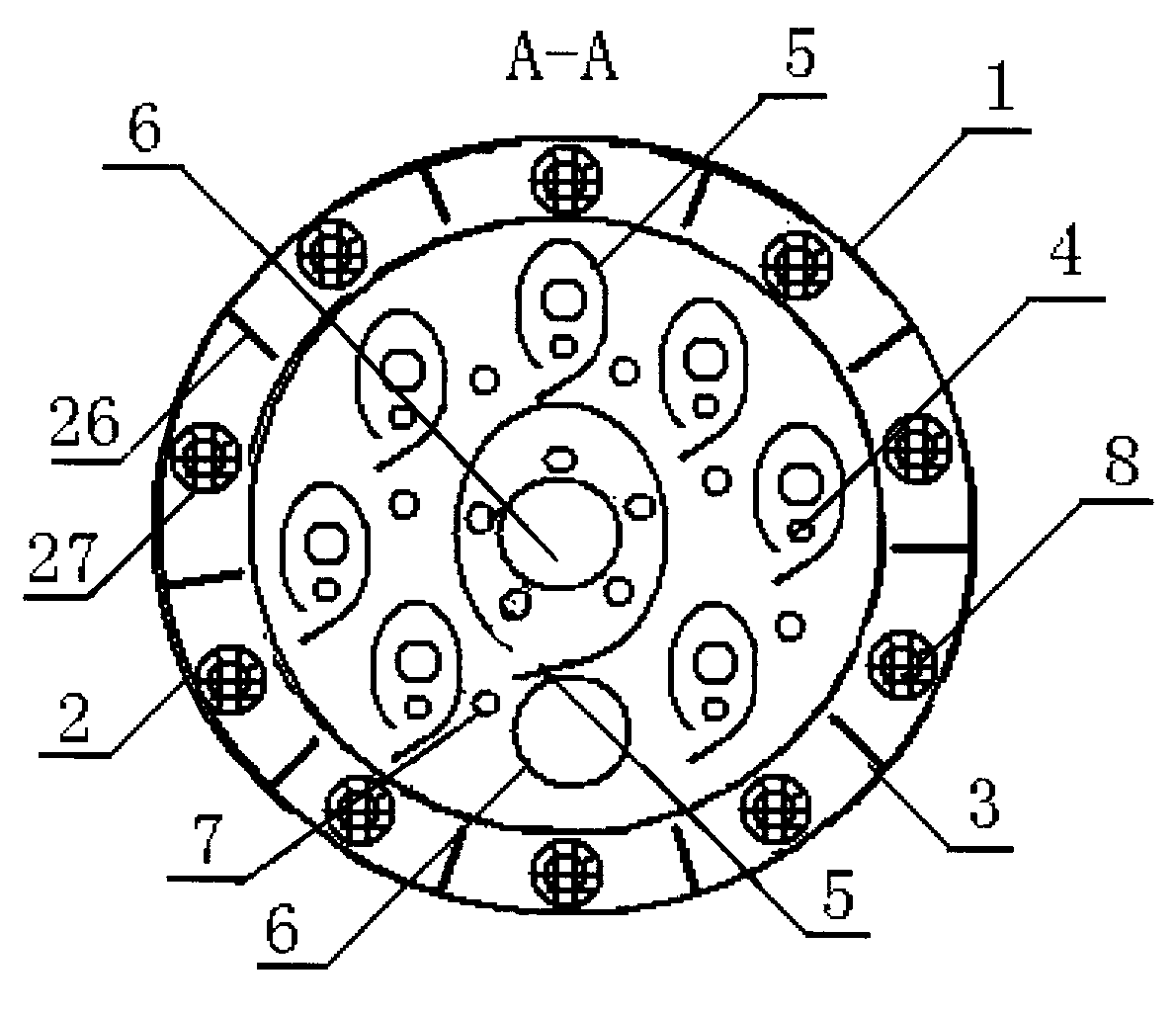

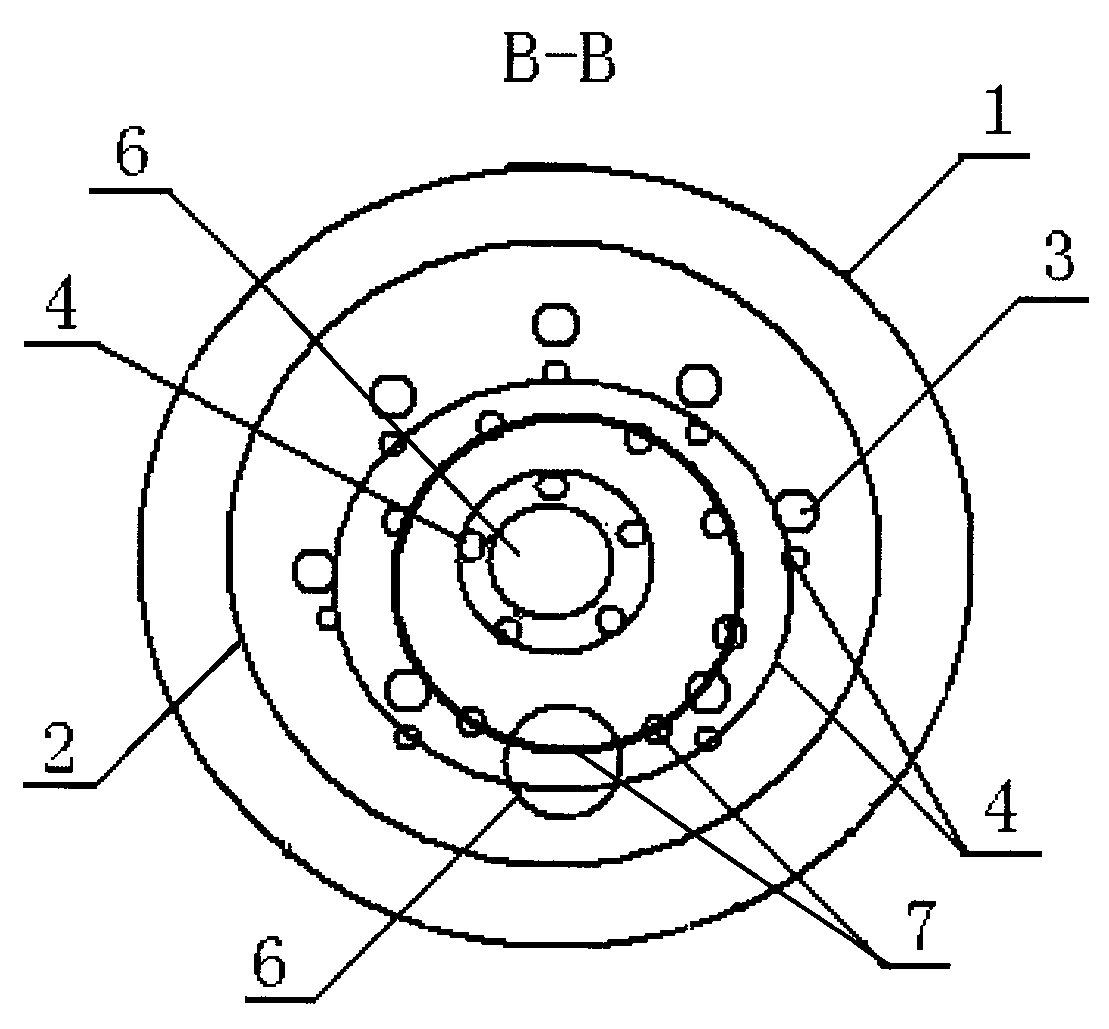

[0007] Specific implementation mode one: combine figure 1 , figure 2 , image 3 The present embodiment will be described. This embodiment consists of a drying cylinder 1, a stator shaft disk 2, a superconducting heat pipe 3, an air pipe 4, an anti-scalding cyclone cover 5, a flue 6, a hot air pipe 7, a bearing 9, a sprocket 10, a gear tooth 11, a deceleration 12, reducer output shaft 13, heating furnace 14, dust collector 15, exhaust duct 16, hot air blower 17, annular air heat pipe 18, fan 19, grain shifting plate 26 and filter screen 27, the stator shaft disk 2 is symmetrical It is arranged at both ends of the drying cylinder 1, and the end surface of the stator shaft disk 2 is provided with a bearing 9, the outer ring of the bearing 9 is connected with the drying cylinder 1, and the left ends of a plurality of superconducting heat pipes 3 are evenly arranged on the stator shaft disk at the left end 2, the right end of a plurality of superconducting heat pipes 3 is set i...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 , figure 2 , image 3 The present embodiment will be described. This embodiment also includes a base 30, a support rod 31 and a connecting shaft 32, the lower end of the supporting rod 31 is connected to the base 30, the upper end of the supporting rod 31 is connected to the connecting shaft 32, and the end of the connecting shaft 32 is connected to the stator shaft disk 2 connect. The base 30 is provided with wheels and can be moved by traction.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 The present embodiment will be described. Industrial coke is installed in the dust collector 15 of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com