Cereal drying control system

A technology of grain drying and control system, applied in the direction of drying solid materials, drying, lighting and heating equipment, etc., can solve the problems of complex operation, high cost, complex structure, etc., to achieve the effect of economical flexibility and intelligent control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment the present invention is further described in detail:

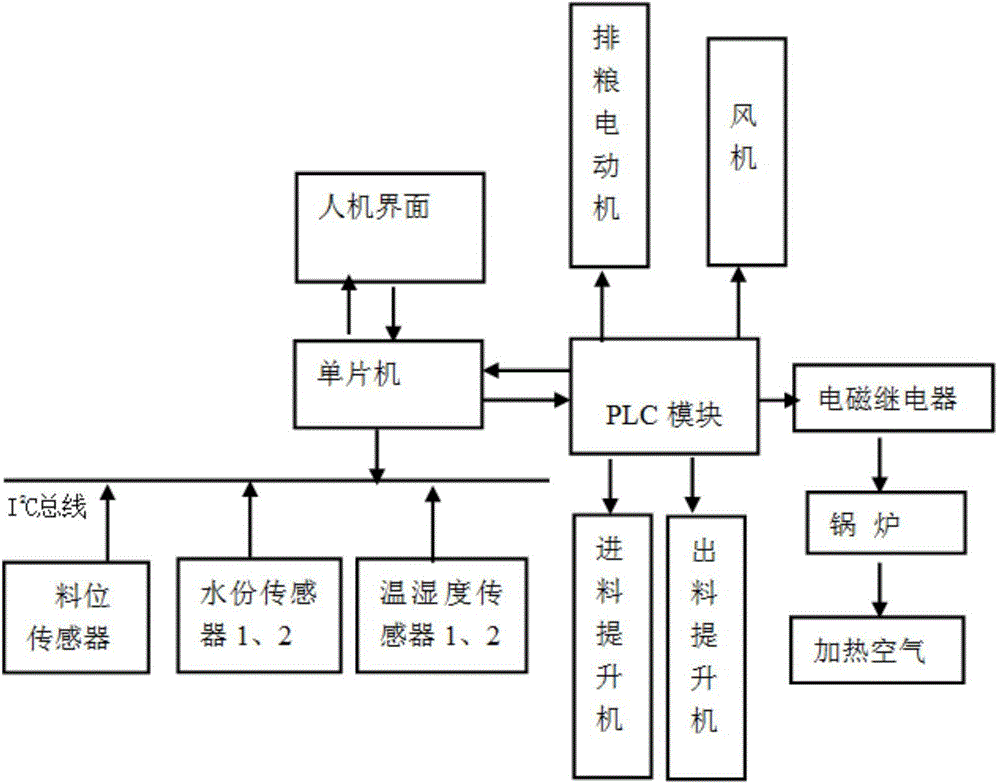

[0014] Such as figure 1 Shown, a kind of grain drying control system is characterized in that: comprise man-machine interface, single-chip microcomputer, sensor and PLC module, man-machine interface and sensor connect single-chip microcomputer, sensor comprises material level sensor, moisture content sensor and temperature and humidity sensor, PLC module Connect the boiler with the single-chip microcomputer, grain discharge motor, fan, feed hoist, discharge hoist, electromagnetic relay, and electromagnetic relay;

[0015] The single-chip microcomputer is the core of the control system of the grain dryer, and the sensor passes through the I 2 The C bus communicates with the single-chip microcomputer; all programs and data are stored on the single-chip microcomputer, and the initial data of the startup is transmitted to the human-machine interface by the single-chip microcomputer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com