Preparation method of bentonite for drilling mud and device thereof

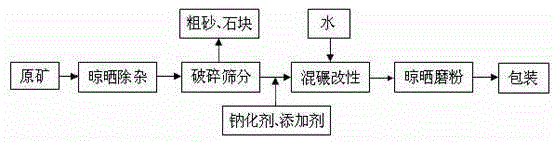

A technology for drilling mud and preparation equipment, applied in chemical instruments and methods, drilling compositions, inorganic chemistry, etc., can solve the problems of cumbersome sodium ion adjustment steps, unstable product quality, poor modification effect, etc., to achieve The effect of thickening is better, it is conducive to drying, and the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

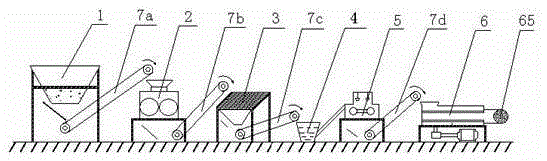

[0042] A method for preparing bentonite for drilling mud and a preparation device thereof, comprising the following steps and a device for realizing the steps:

[0043] 1. Dry and remove impurities. The calcium-based bentonite raw ore is placed in the cement drying yard for drying. During the drying process, manual selection and removal of impurities is carried out. After drying, the moisture content of the material is ≤ 20%, and the material is put into the fixed hopper 1 through the loading vehicle.

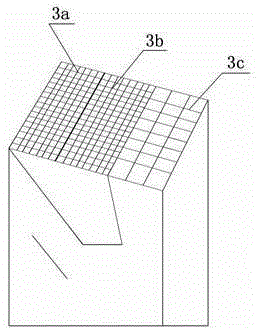

[0044] 2. Crushing and screening. After drying, the material is transported to the crusher 2 through the first belt conveyor 7a, and the crushed material is transported to the screening machine 3 through the second belt conveyor 7b for screening. The material with a particle size of less than 10mm enters the mixing and grinding process. Materials with a size of 10-25mm are returned for re-crushing or used in the production of other common products, and impurities with a partic...

Embodiment 2

[0048] A method for preparing bentonite for drilling mud and a preparation device thereof, comprising the following steps and a device for realizing the steps:

[0049] 1. Dry and remove impurities. The calcium-based bentonite raw ore is placed in the cement drying yard for drying. During the drying process, manual selection and removal of impurities is carried out. After drying, the moisture content of the material is ≤ 20%, and the material is put into the fixed hopper 1 through the loading vehicle.

[0050] 2. Crushing and screening. After drying, the material is transported to the crusher 2 through the first belt conveyor 7a, and the crushed material is transported to the screening machine 3 through the second belt conveyor 7b for screening. The material with a particle size of less than 10mm enters the mixing and grinding process. Materials with a size of 10-25mm are returned for re-crushing or used in the production of other common products, and impurities with a partic...

Embodiment 3

[0054] A method for preparing bentonite for drilling mud and a preparation device thereof, comprising the following steps and a device for realizing the steps:

[0055] 1. Dry and remove impurities. The calcium-based bentonite raw ore is placed in the cement drying yard for drying. During the drying process, manual selection and removal of impurities is carried out. After drying, the moisture content of the material is ≤ 20%, and the material is put into the fixed hopper 1 through the loading vehicle.

[0056] 2. Crushing and screening. After drying, the material is transported to the crusher 2 through the first belt conveyor 7a, and the crushed material is transported to the screening machine 3 through the second belt conveyor 7b for screening. The material with a particle size of less than 10mm enters the mixing and grinding process. Materials with a size of 10-25mm are returned for re-crushing or used in the production of other common products, and impurities with a partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com