Propeller blade-micropowder composite drying method for nanometer grade material

A combined drying and paddle dryer technology, applied in dryer combination, drying, dryer and other directions, can solve problems affecting technical and economic performance and promotion scope, wide product particle size distribution, uncontrollable particle agglomeration degree, etc. problems, to achieve the effect of solving the degree of agglomeration of micropowder, low operating costs, and preventing thermal denaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

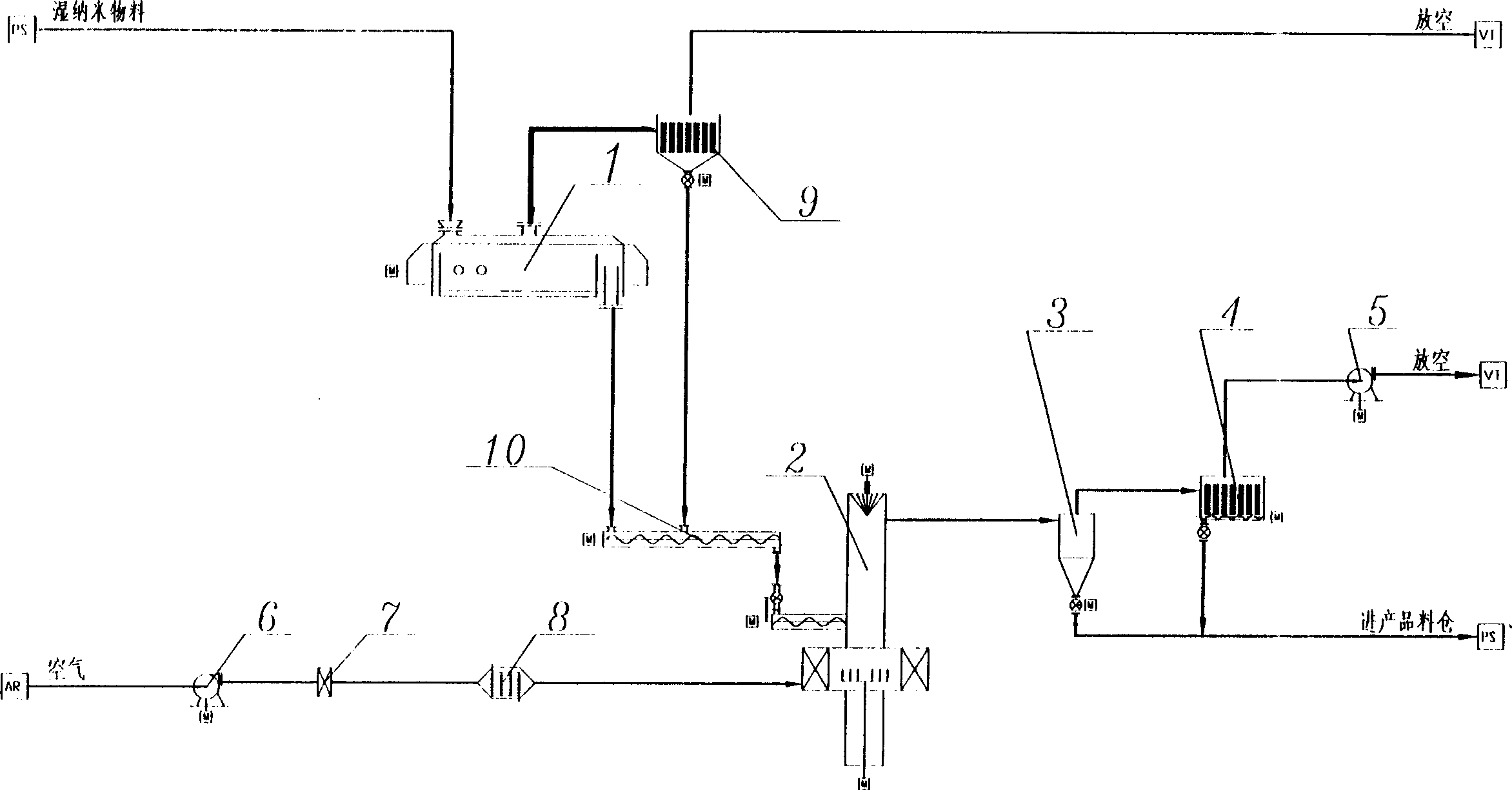

[0018] The present invention will be described in further detail in conjunction with accompanying drawing:

[0019] Nano wet materials are continuously and evenly fed into the first-stage paddle dryer 1, using steam as the heat medium, and the temperature is controlled at 150°C for pre-drying. The moisture content of the pre-drying product is controlled at 10-15%. The moisture control of the primary drying product is to control the residence time of the material in the dryer by adjusting the height of the overflow plate at the material outlet of the paddle dryer. The moisture evaporated during the primary pre-drying process enters the primary drying dust collector 9. The function of the dust collector 9 is to separate the moisture discharged from the primary paddle dryer 1 from the dust entrained in it. After passing through the primary drying dust collector 9, The moisture is evacuated and the recovered material is returned to the dryer. The dust collector can be a bag filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com