Patents

Literature

30results about How to "Achieve low temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

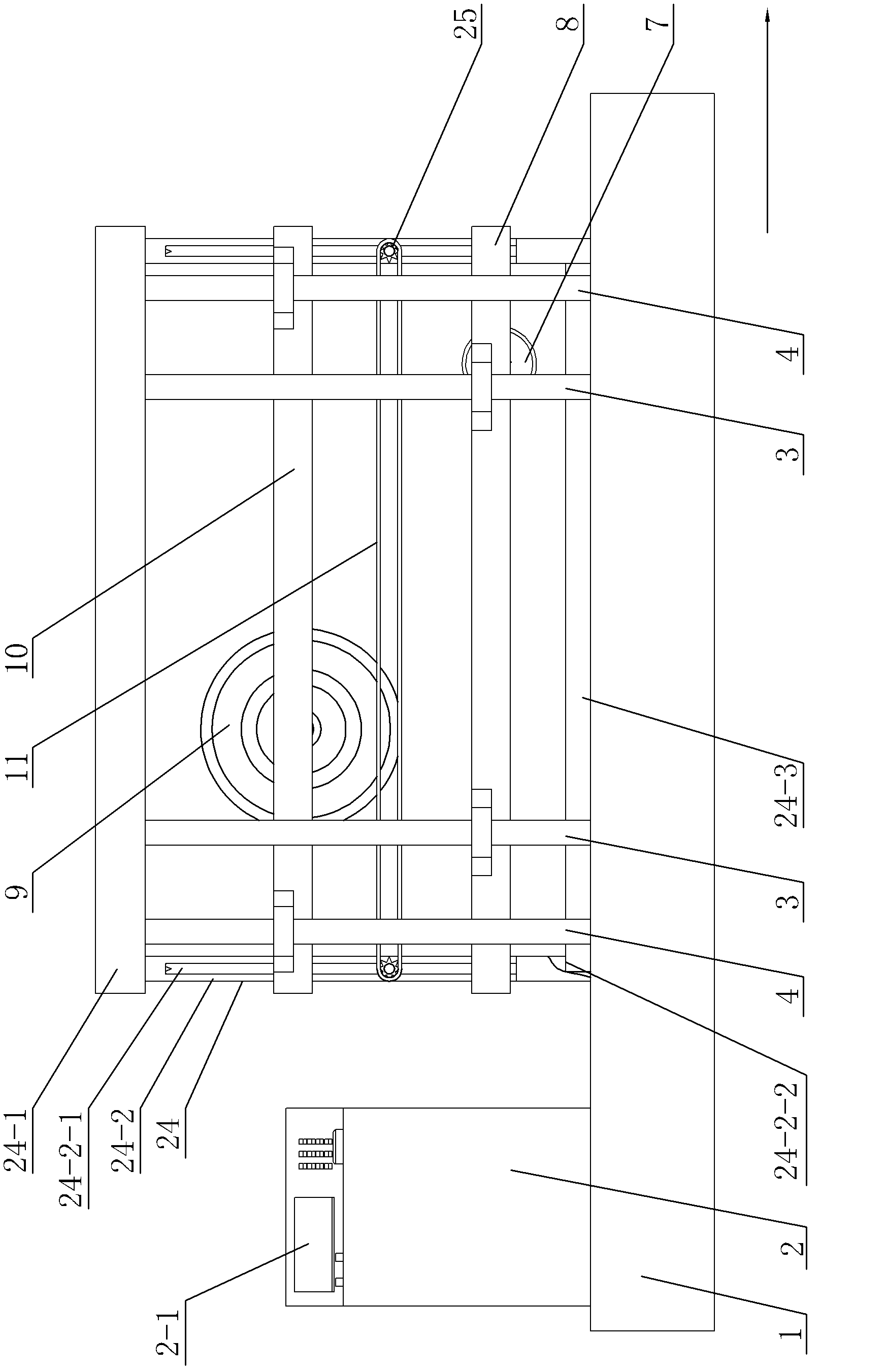

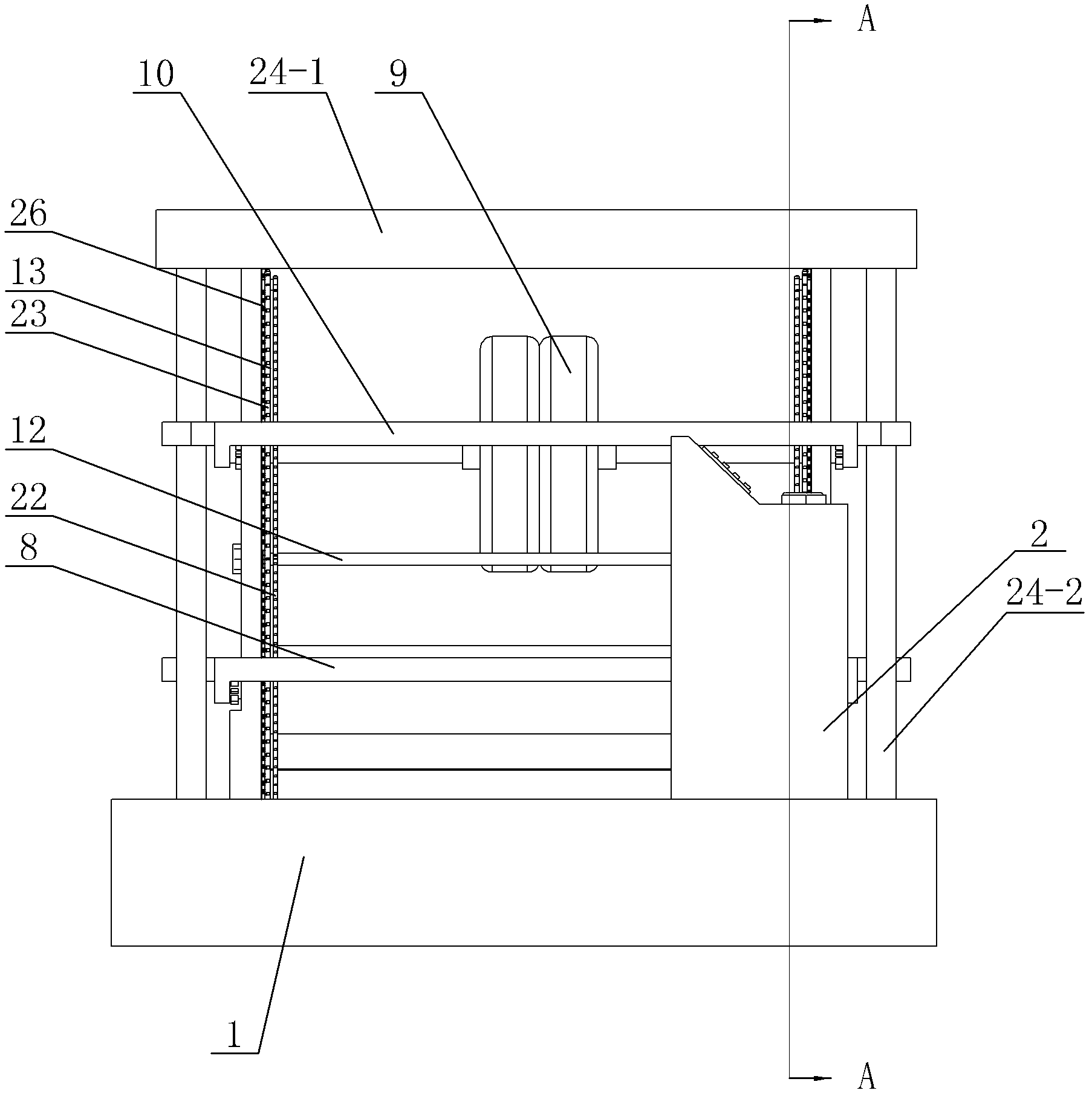

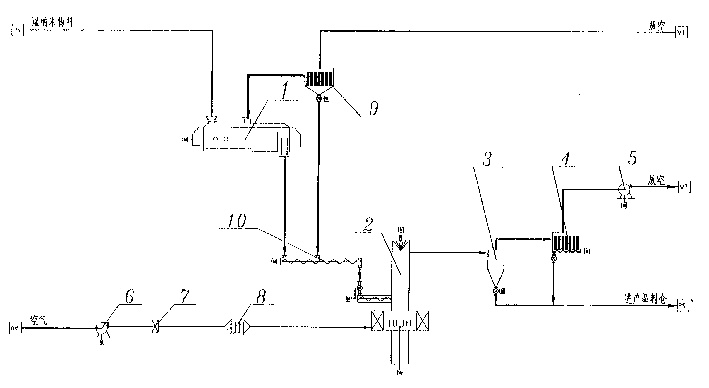

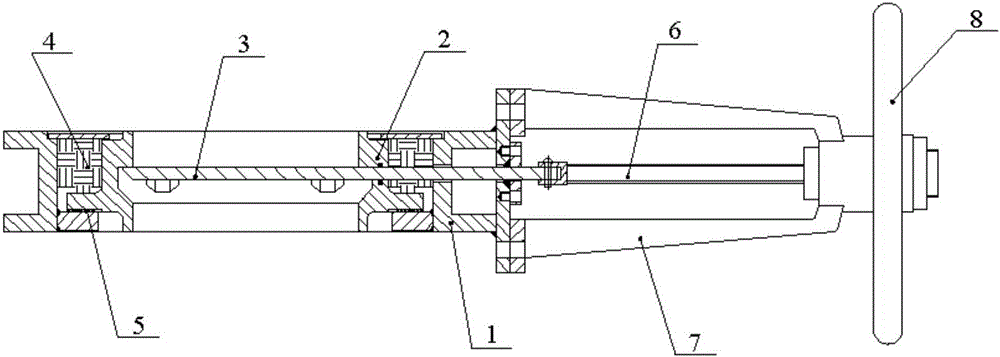

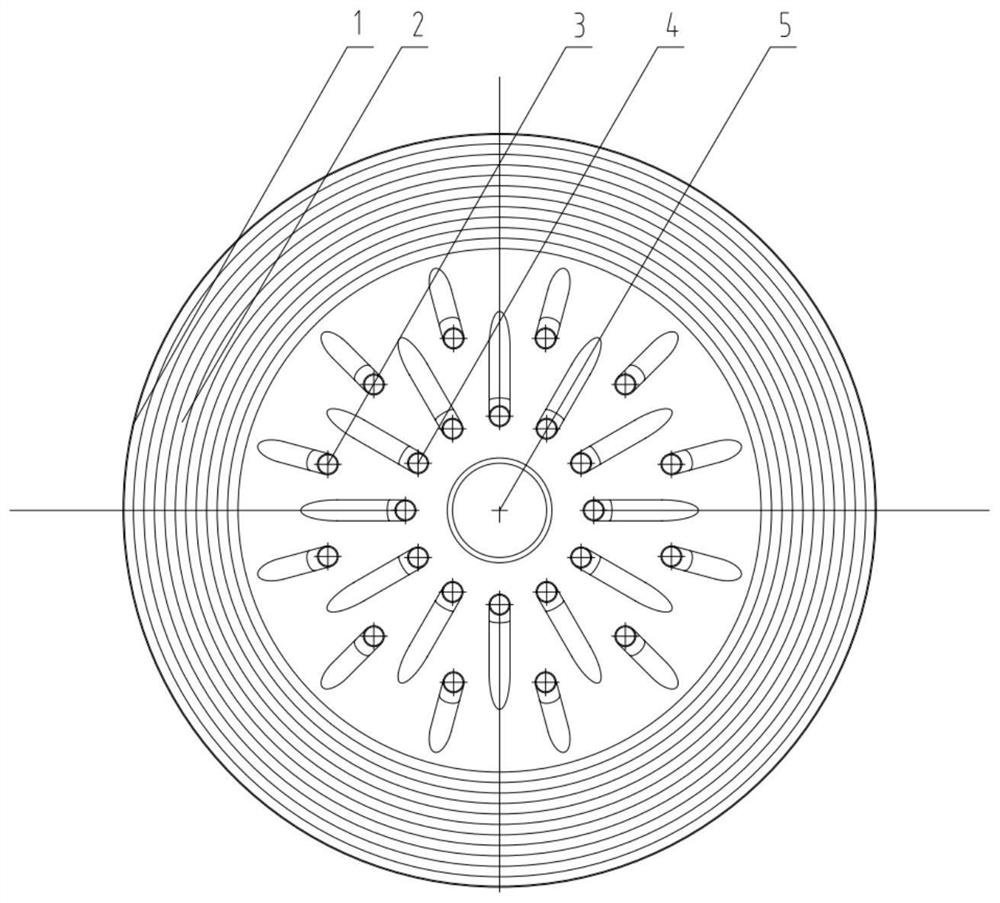

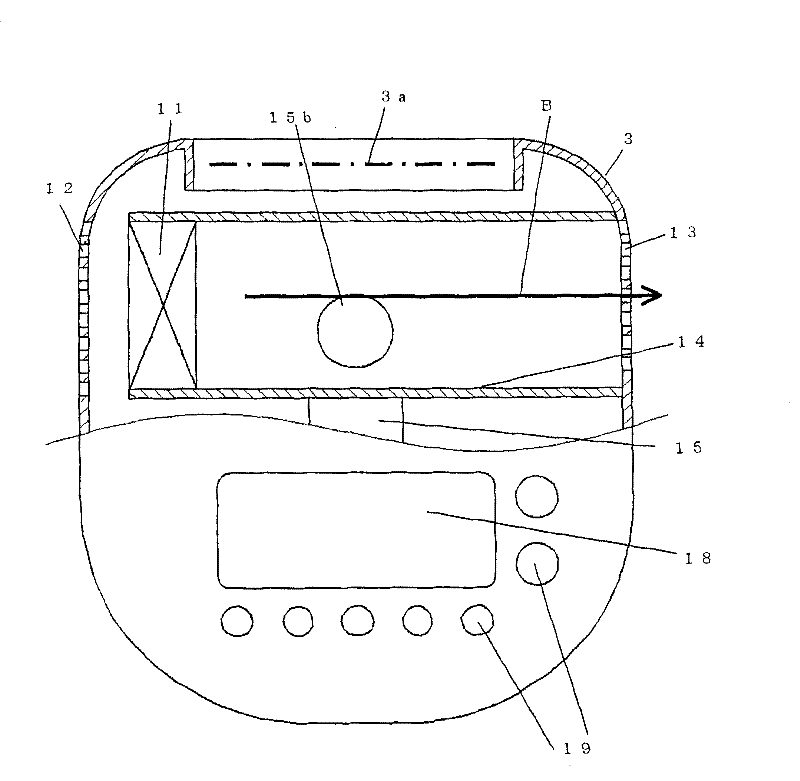

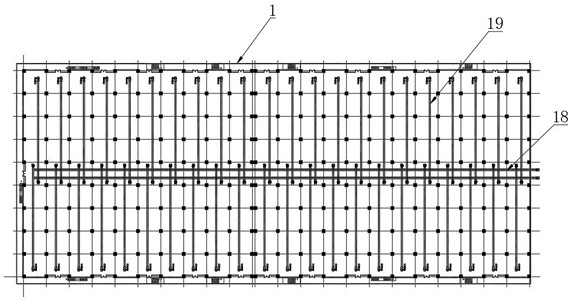

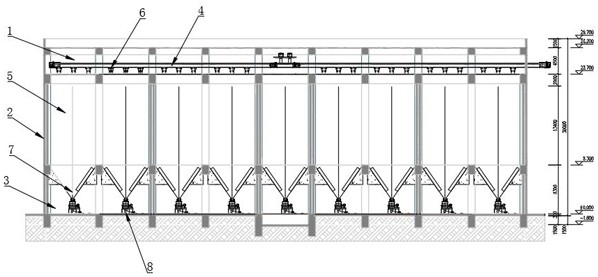

Accelerated loading test device for small full-size asphalt pavement

ActiveCN102607974AReflects anti-rutting performanceReduce trafficMaterial strength using repeated/pulsating forcesHorizontal transmissionMotor drive

An accelerated loading test device for a small full-size asphalt pavement relates to an accelerated loading test device for a full-size asphalt pavement, aiming at the problems of impossibility of accurately simulating the actual stress state of an asphalt pavement in an indoor wheel tracking test, as well as large equipment size, long test period, high test expense and complex operation process in an outdoor full-size pavement accelerated loading test. A two-way motor drives a drive big gear and a driven big gear to rotate; a transmission cross rod disposed on a rack is fixedly sleeved with a force-transferring pinion, as well as sleeved with a force-transferring big gear, a lifting gear and a transition chain wheel engaged with an annular horizontal transmission chain in a suspension manner; the force-transferring big gear and the force-transferring pinion are engaged with an annular vertical inner transmission chain and an annular vertical outer transmission chain; the lifting gear is engaged with a lifting guide rail; the movements of a rolling steel wheel and a loading wheel group are driven via the annular horizontal transmission chain; the up-and-down movement of a rectangular-frame steel wheel loading beam is driven via an inner oil pressure pump; and the up-and-down movement of a rectangular-frame wheel group loading beam is driven via an outer oil pressure pump. The invention is used for the accelerated loading test for the full-size asphalt pavement.

Owner:HARBIN INST OF TECH

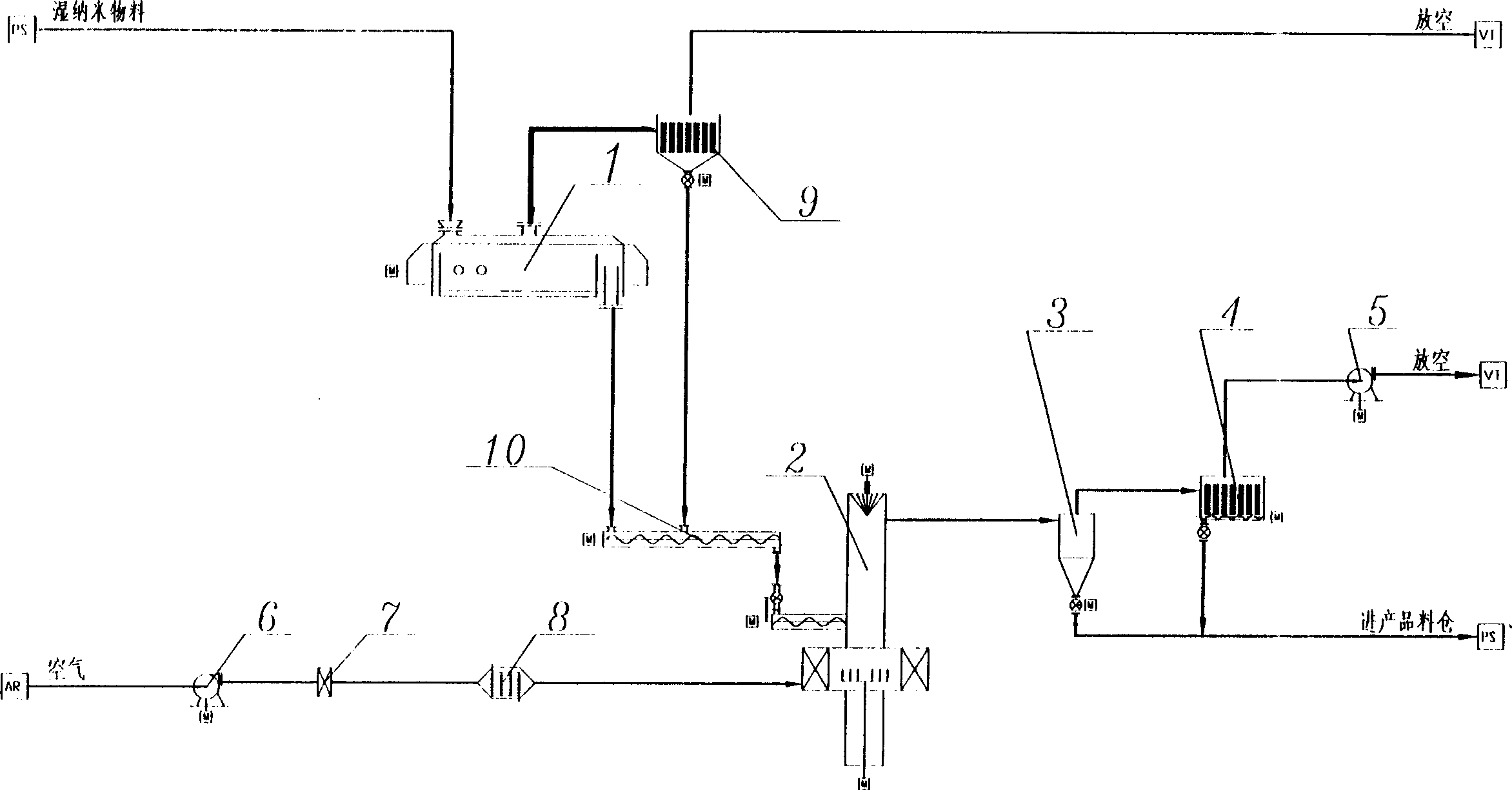

Propeller blade-micropowder composite drying method for nanometer grade material

InactiveCN1517657ASolve technical problems of reunionSolve the problem of high humidity and high viscosityDrying machine combinationsGranularityPropeller

A method for drying the nano-class material features the combination of paddle-type drier with microparticle drier. Said paddle-type drier is used for pre-drying at temp lower than 150 deg.C to remove the most of moisture. Said microparticle driver is used for drying, pulverizing, classifying and pneumatic delivering. Its advantages are high granularity uniformity and low energy consumption.

Owner:LANZHOU RUIDE DRYING TECH

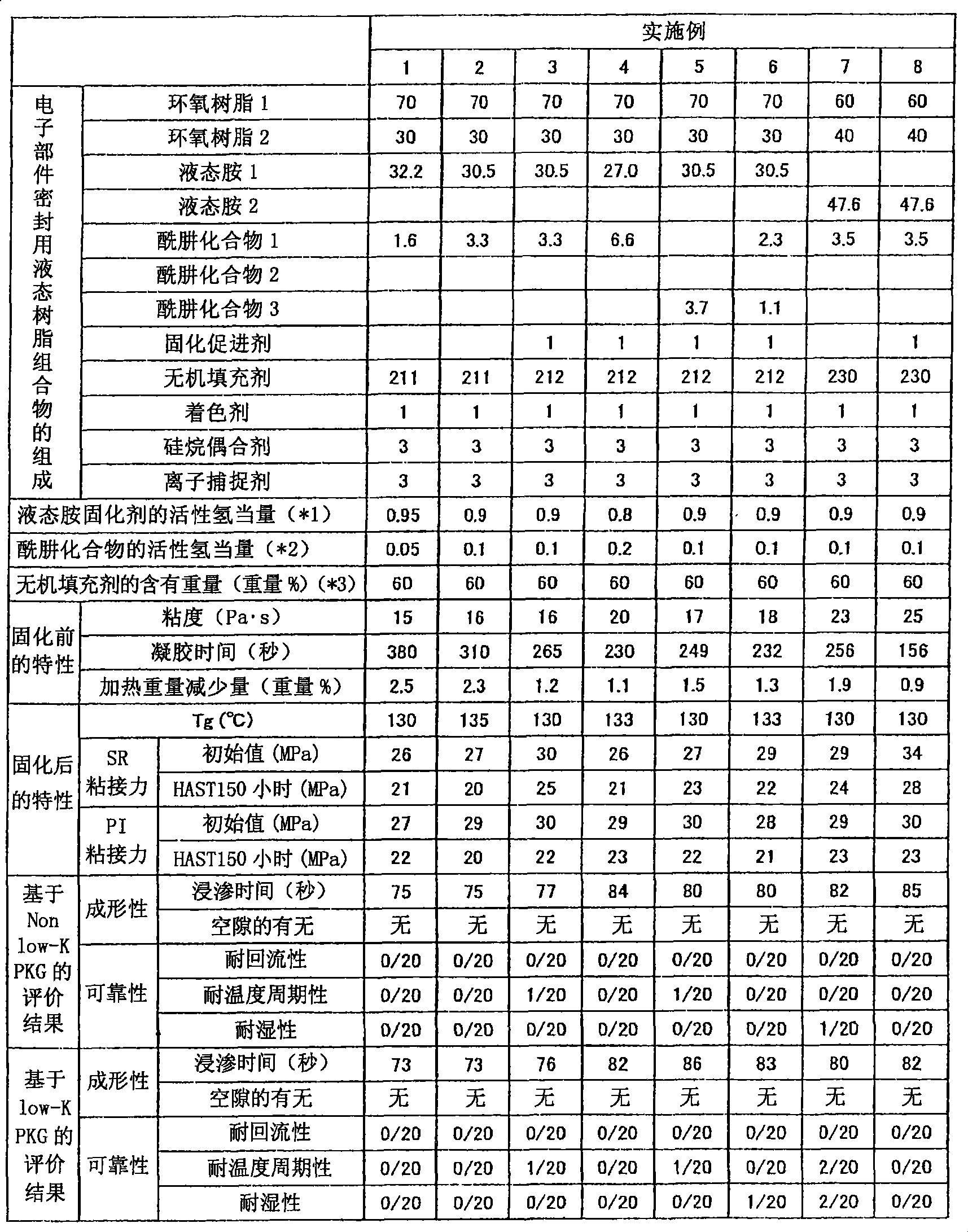

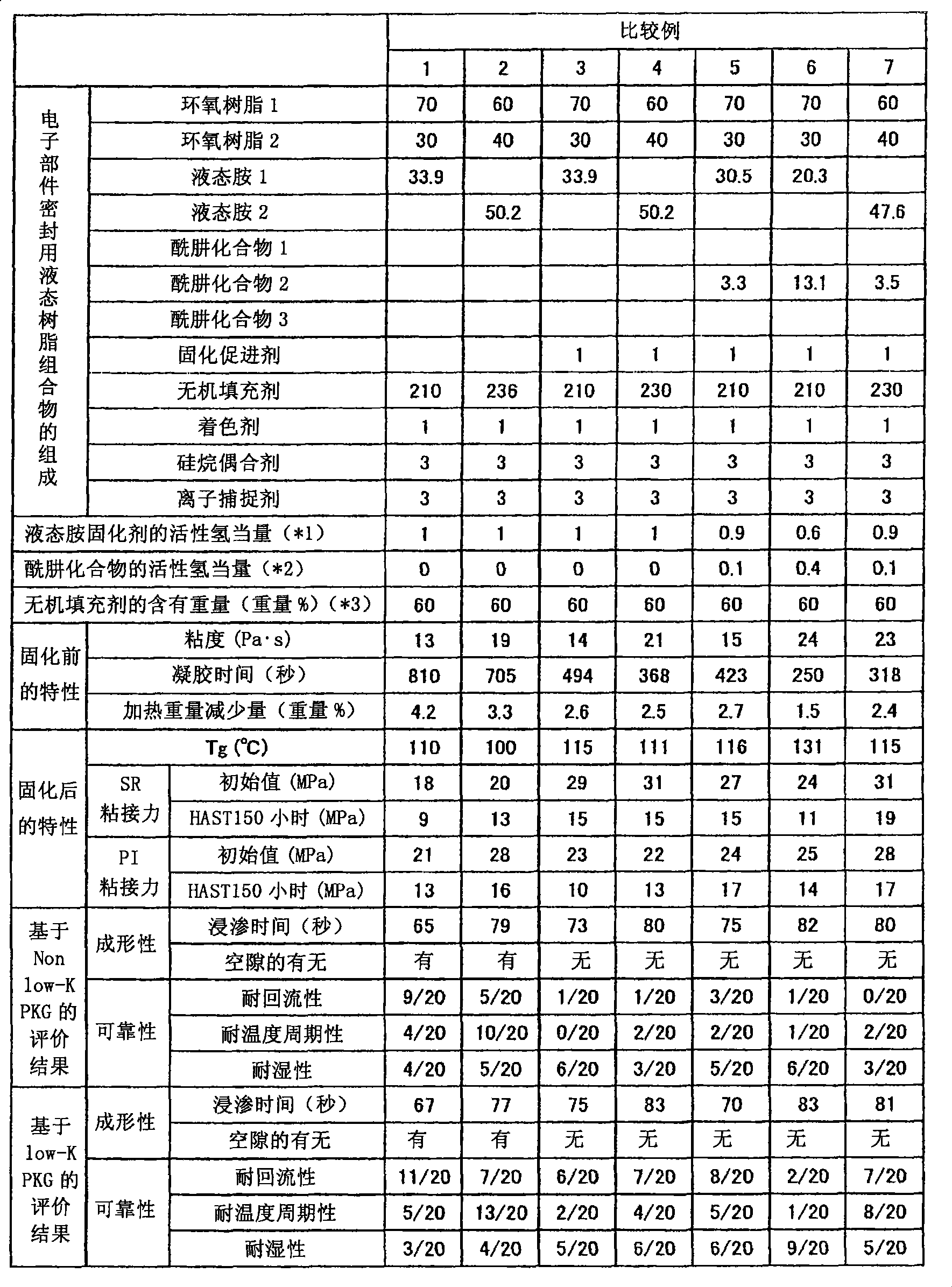

Liquid resin composition for electronic part sealing and electronic part apparatus utilizing the same

InactiveCN101522751AImprove moisture resistanceImprove thermal shock resistanceSemiconductor/solid-state device detailsSolid-state devicesEpoxyLiquid state

The invention provides a liquid resin composition for electronic part sealing that is good in fluidity in a narrow gap, being free from void generation, and that excels in fillet formation; and an electronic part apparatus sealed thereby of high reliability (moisture resistance and thermal shock resistance). The liquid resin composition for electronic part sealing is characterized by containing (A) epoxy resin including a liquid epoxy resin, (B) hardening agent including a liquid aromatic amine, (C) hydrazide compound of less than 2 [mu]m average particle diameter and (D) inorganic filler of less than 2 [mu]m average particle diameter.

Owner:RESONAC CORP

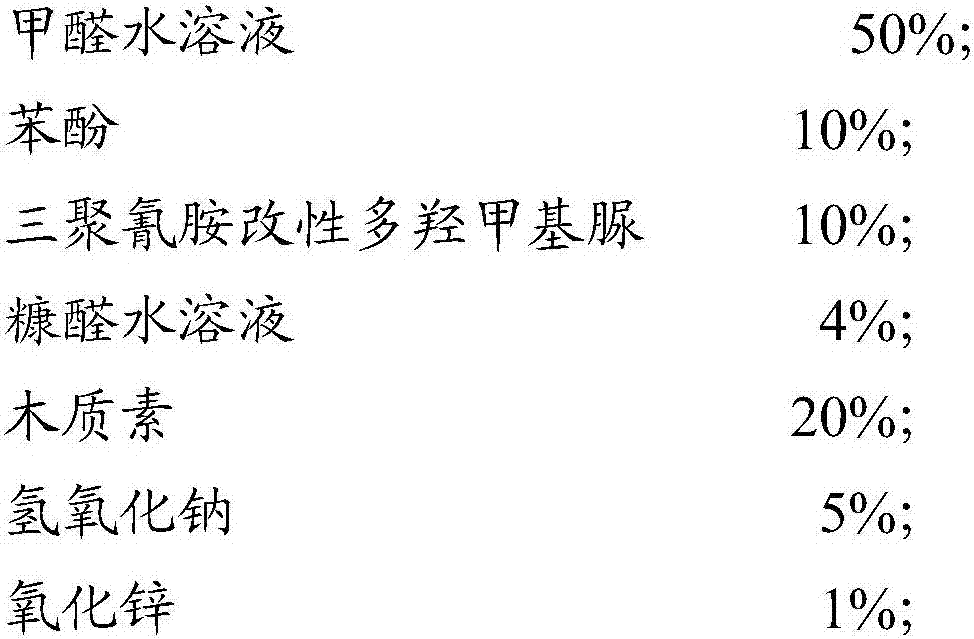

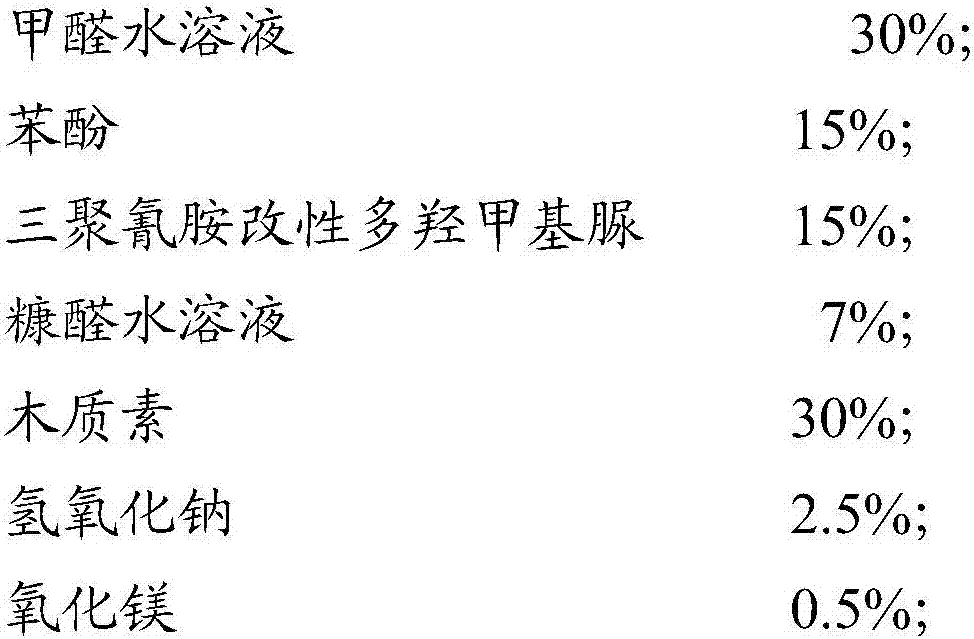

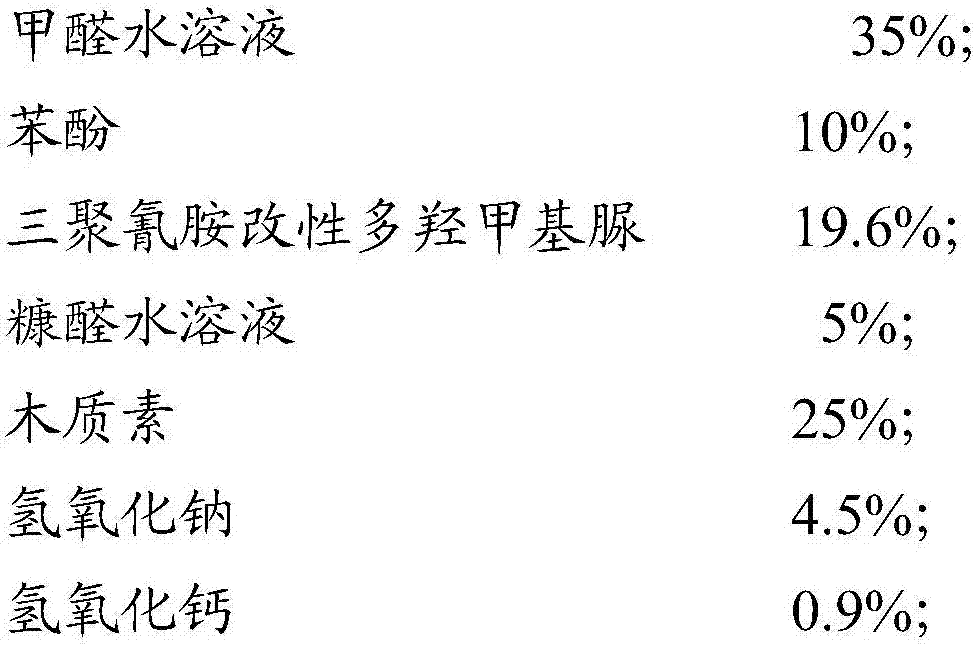

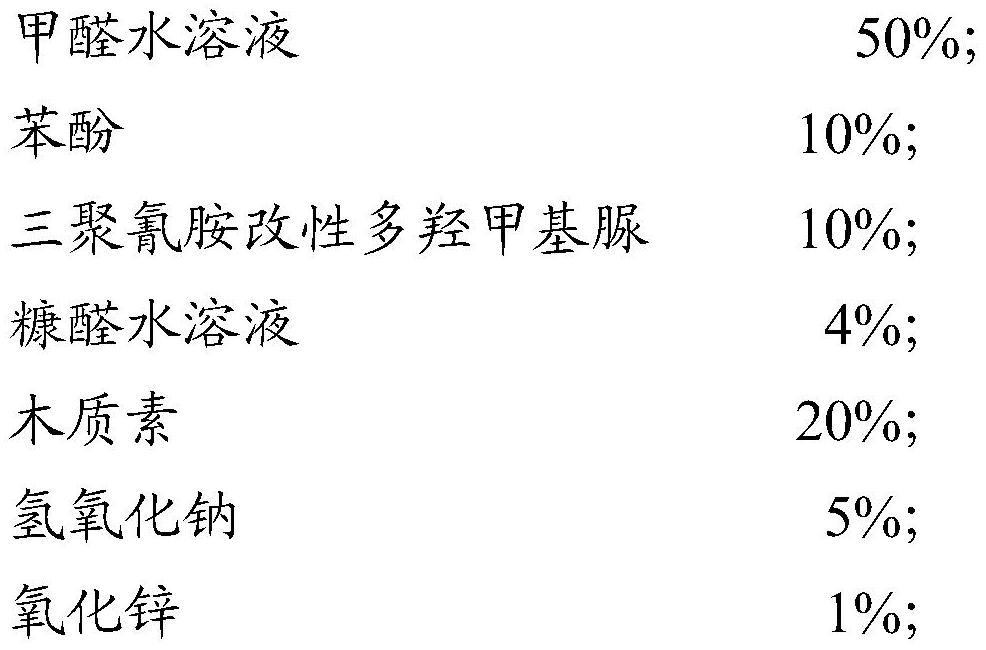

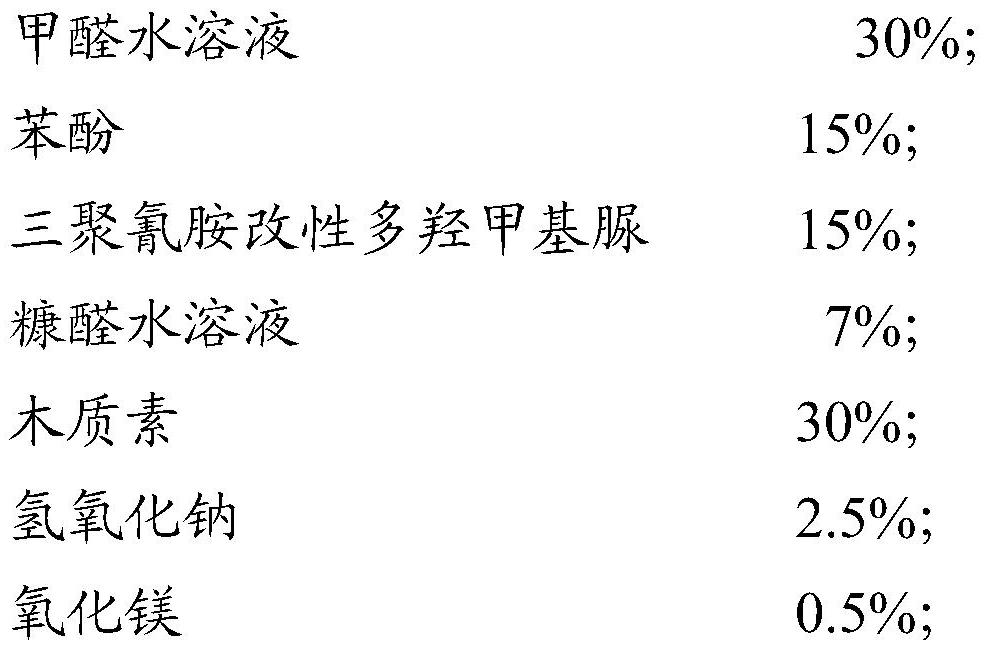

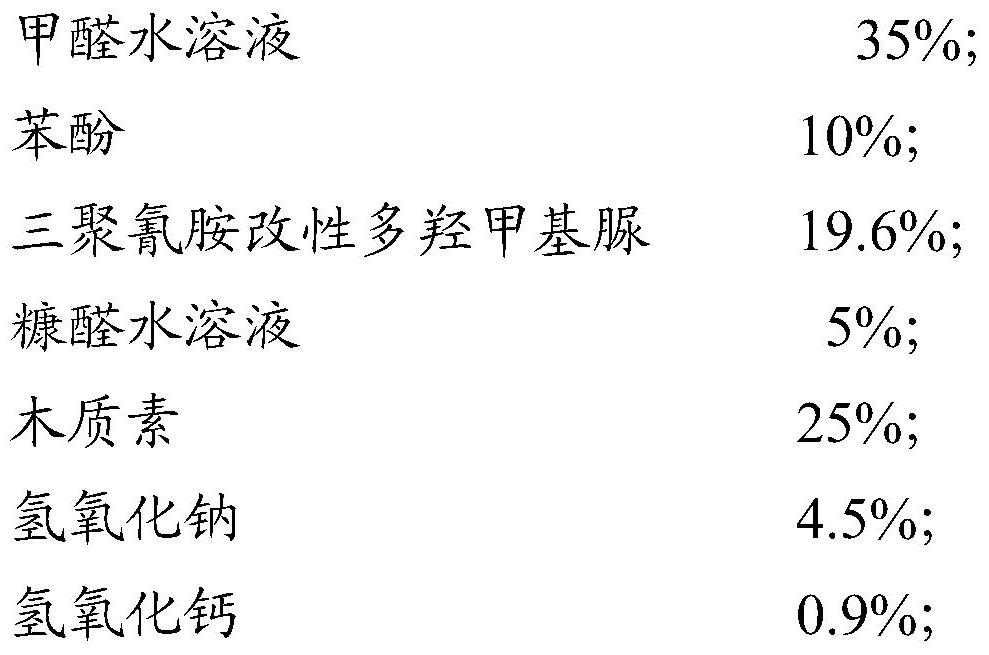

Resin adhesive and preparation method thereof

ActiveCN106883800AImprove uniformityIncrease crosslink densityAldehyde/ketone condensation polymer adhesivesUreaChemistry

The invention provides a resin adhesive and a preparation method thereof. The resin adhesive is prepared from the following raw materials in percentages by weight: 30-50% of a formaldehyde solution, 10-25% of phenol, 10-20% of melamine-modified polyhydroxymethyl urea, 20-40% of lignin, 5-10% of a polyaldehyde cross-linking agent and 3-6% of a composite catalyst, wherein the mass concentration of the formaldehyde solution is 35-40%; and the composite catalyst comprises a mixture of one of zinc oxide, magnesium oxide, calcium hydroxide, barium hydroxide, potassium hydroxide and potassium carbonate, and sodium hydroxide. With the melamine-modified polyhydroxymethyl urea as the raw material, the storage stability of methylol urea is improved, the storage period of the resin adhesive is prolonged, the polymerization reaction of an ortho-response point with relatively poor activity in a phenol structure in the lignin is directionally promoted by the composite catalyst, and low-temperature fast solidification of the resin adhesive is achieved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

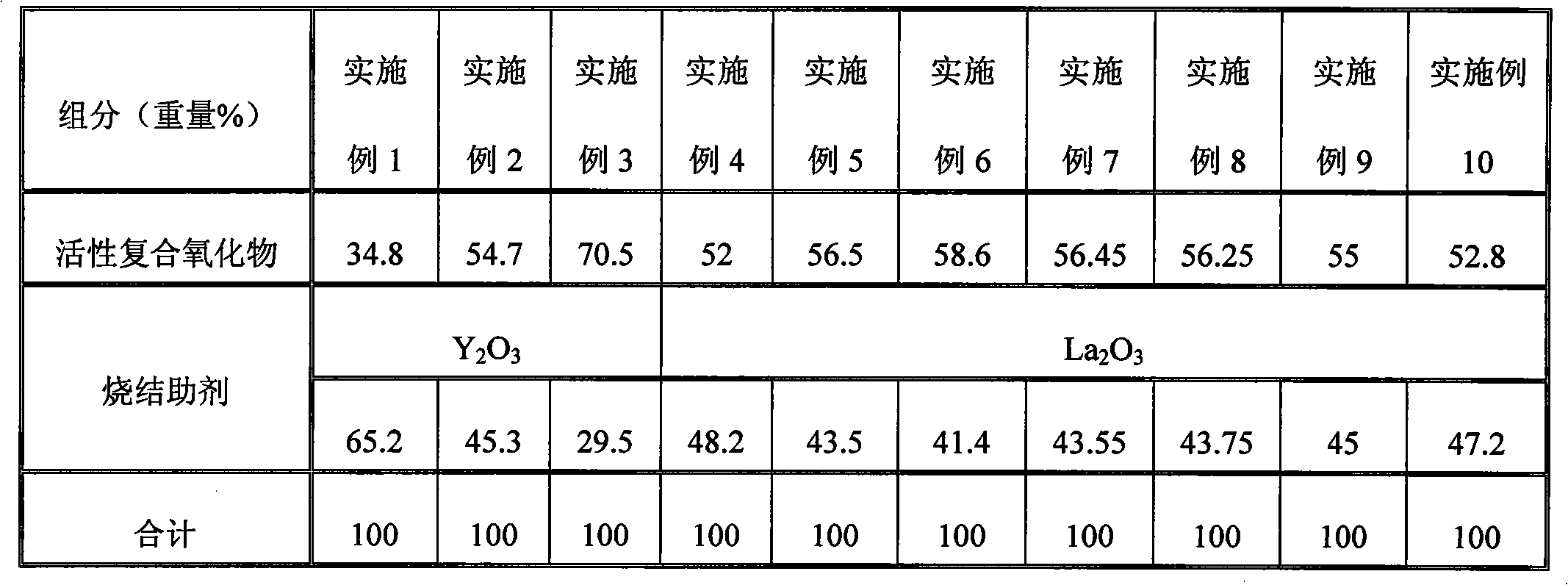

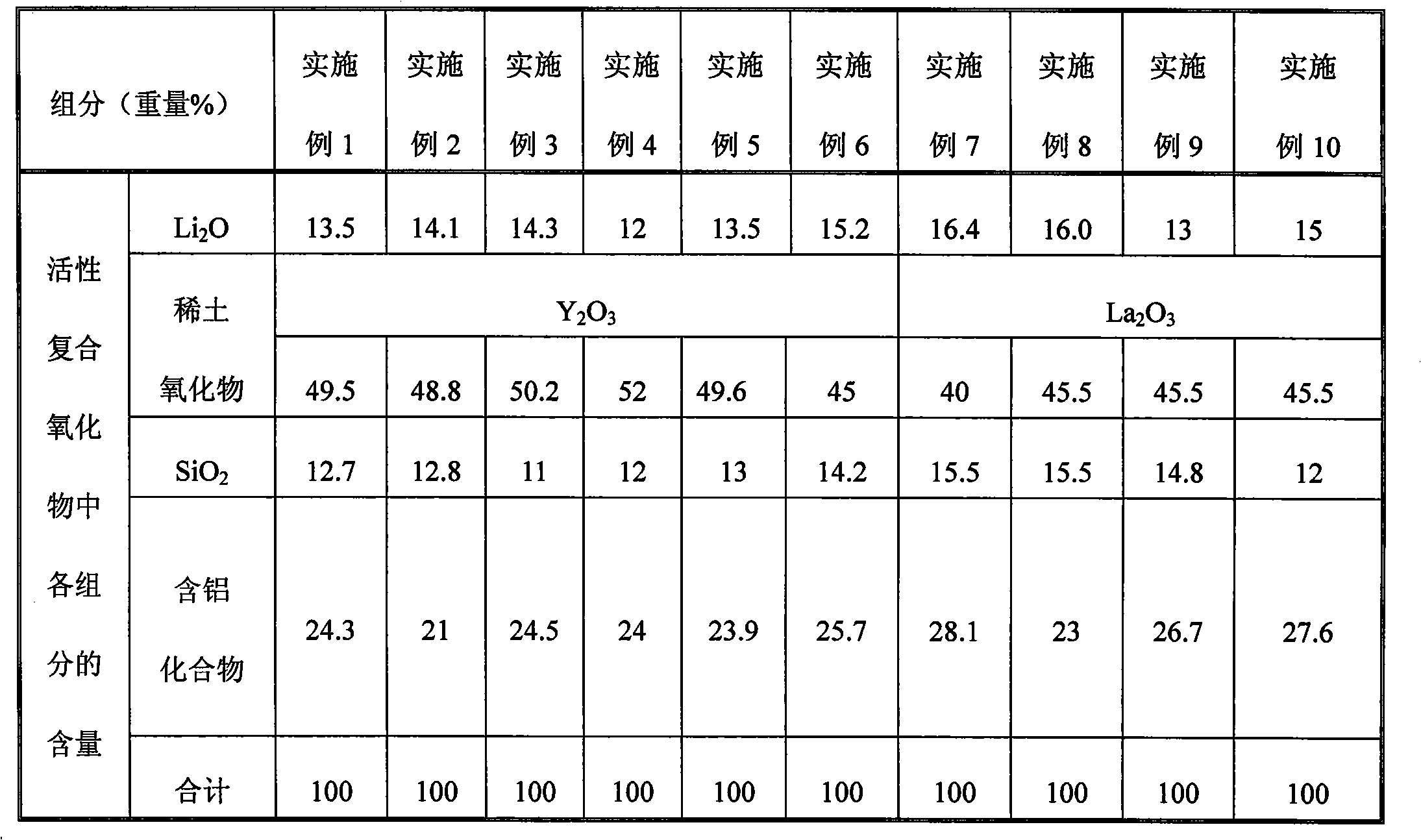

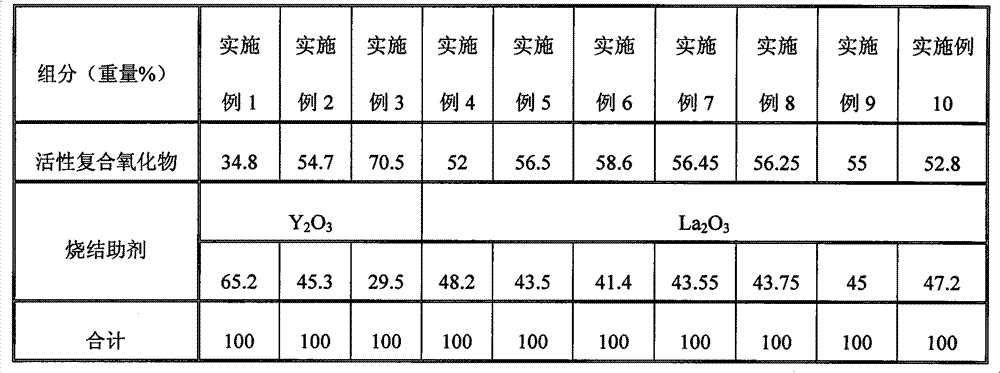

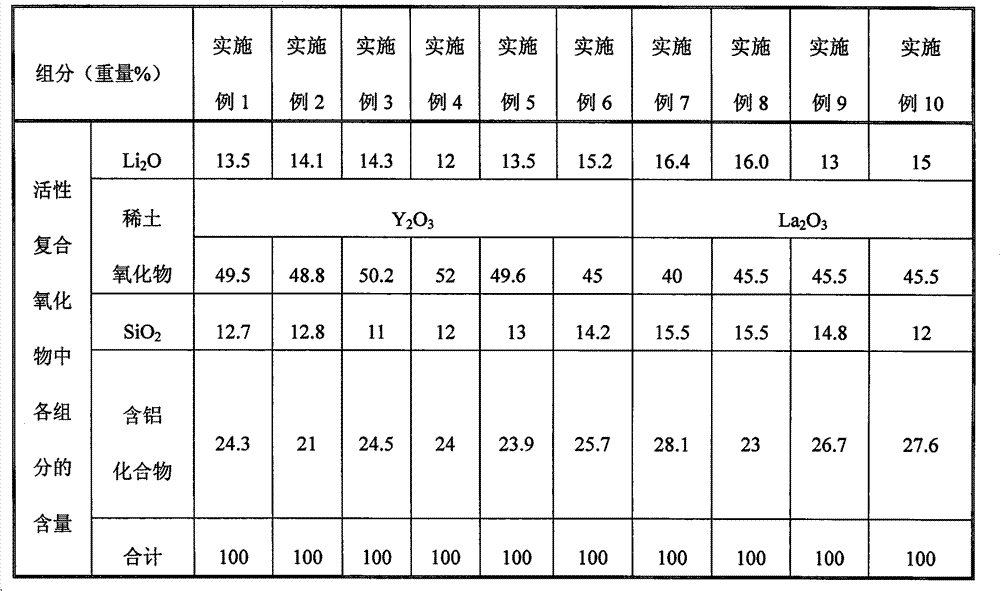

Additive for silicon nitride sintered bodies

The invention discloses an additive for silicon nitride sintered bodies, which is prepared from the following components by weight percent: 29.5-65.2 percent of sintering aid and 34.8-70.5 percent of activating composite oxide, wherein the activating composite oxide is a compound formed by combining lithium oxide (Li2O), yttrium oxide (Y2O3), silicon dioxide (SiO2) and aluminium-containing compound. After the additive is added into a silicon nitride sintered body, the inter-granular phase components of a silicon nitride heating element is changed, the refractoriness of the silicon nitride sintered body sintered at normal pressure is enhanced, the mechanical property of the heating element at high temperature is improved and a heating element of the silicon nitride sintered body with the use temperature of 1,200-1,400 DEG C is obtained, the thermoconductivity is 21-32 W*m <-1>*K<-1>, the linear expansibility is 3.1*10<-6>-3.8*10<-6> / DEG C(40-800DEG C) and the density is over 98 percent. The invention realizes the normal-pressure low-temperature rapid-firing sintering of the silicon nitride heating element.

Owner:CHANGSHA SYNO THERM

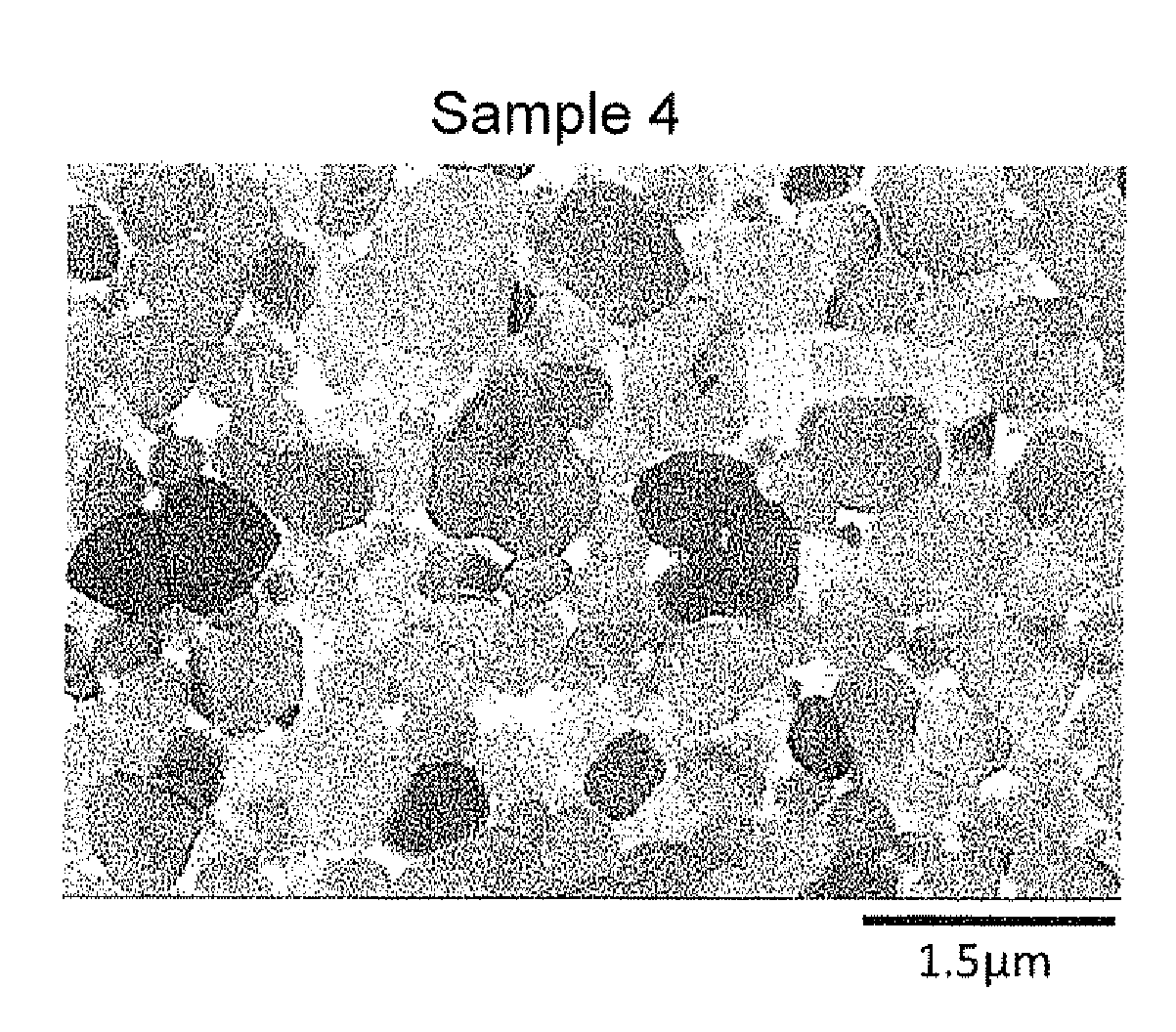

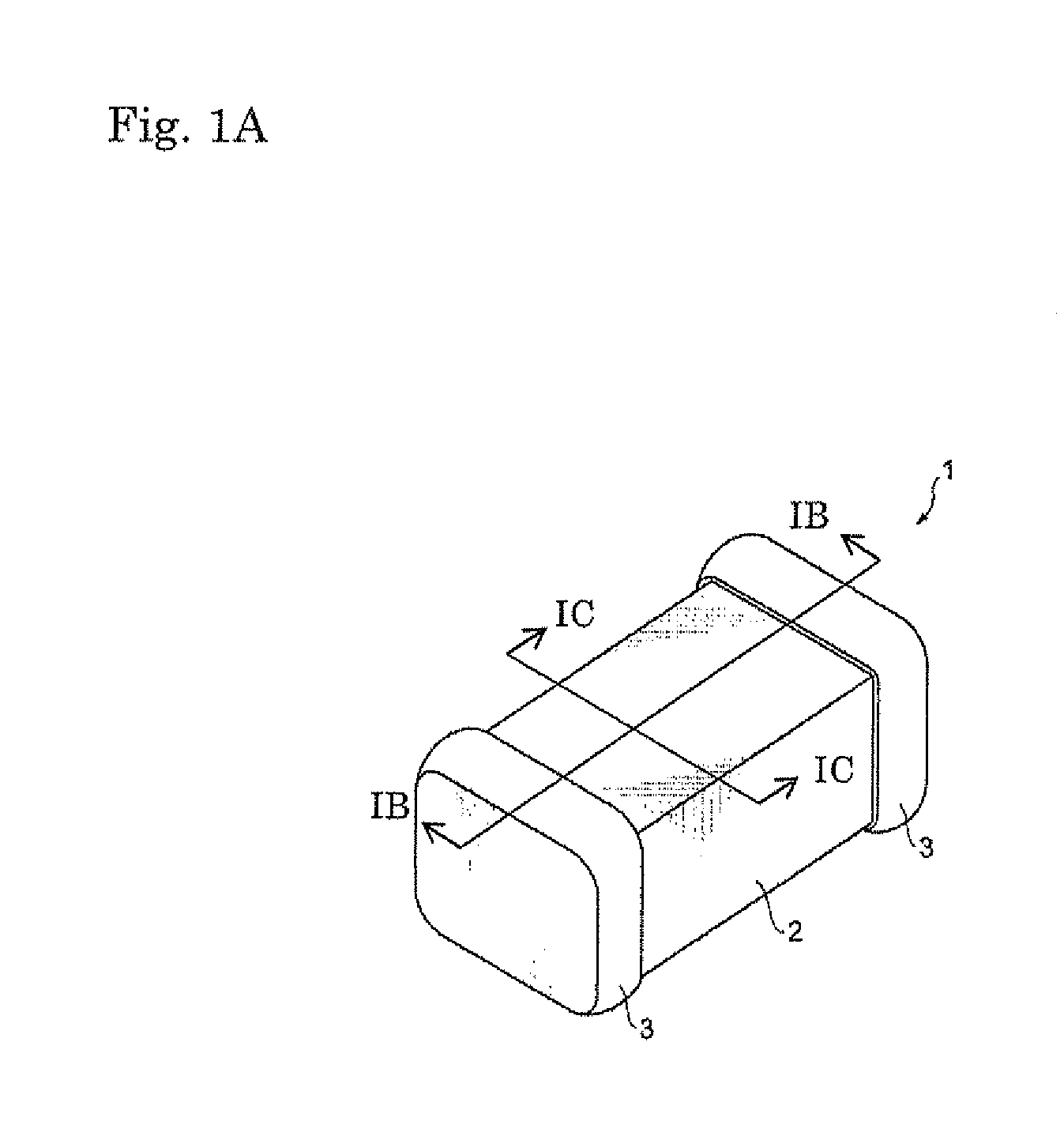

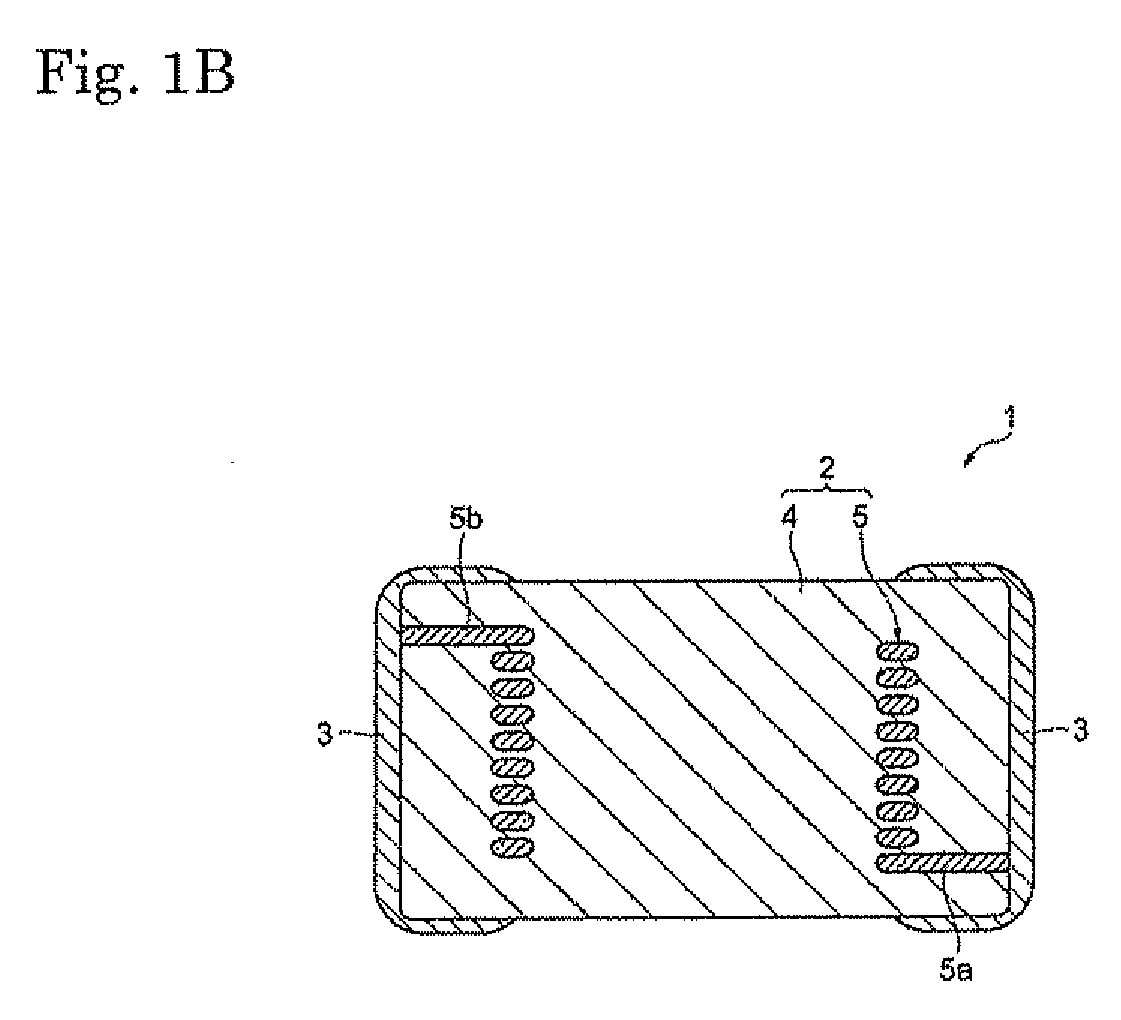

Ferrite composition and electronic component

InactiveUS20110226982A1Improve breathabilityHigh currentMaterial nanotechnologyInorganic material magnetismInitial permeabilityCopper oxide

A ferrite composition includes a main component having 46.0 to 49.8 mol % of an iron oxide in terms of Fe2O3, 5.0 to 14.0 mol % of a copper oxide in terms of CuO and 6.0 to 32.0 mol % of a zinc oxide in terms of ZnO, and a remainder of the main component is composed of a nickel oxide; and as subcomponents, with respect to 100 wt % of the main component, 0.5 to 6.0 wt % of a silicon oxide in terms of SiO2 and 0.01 to 2.0 wt % of a boron oxide in terms of B2O3. Further, as a subcomponent, 0.01 to 0.17 wt % of potassium oxide in terms of K2O or 0.3 to 2.0 wt % of tin oxide in terms of SnO2 may be included. According to the present invention, the ferrite composition having good initial permeability, good superposed direct current characteristic and comparatively good temperature characteristic of the initial permeability, and achieving low temperature firing; and an electronic component having the ferrite composition can be provided.

Owner:TDK CORPARATION

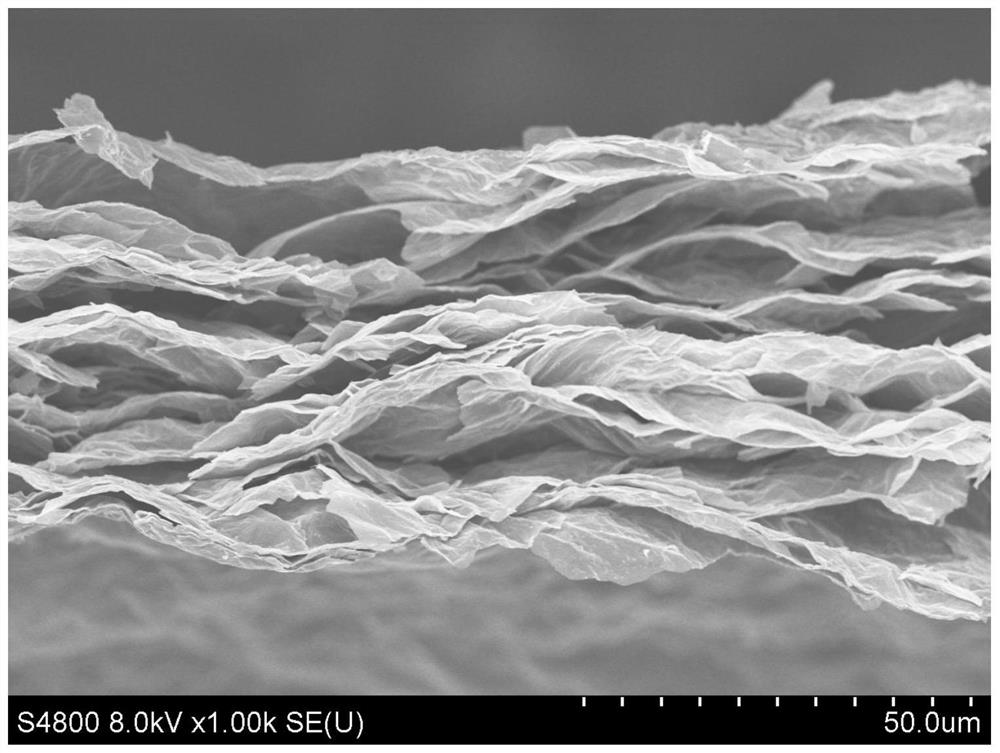

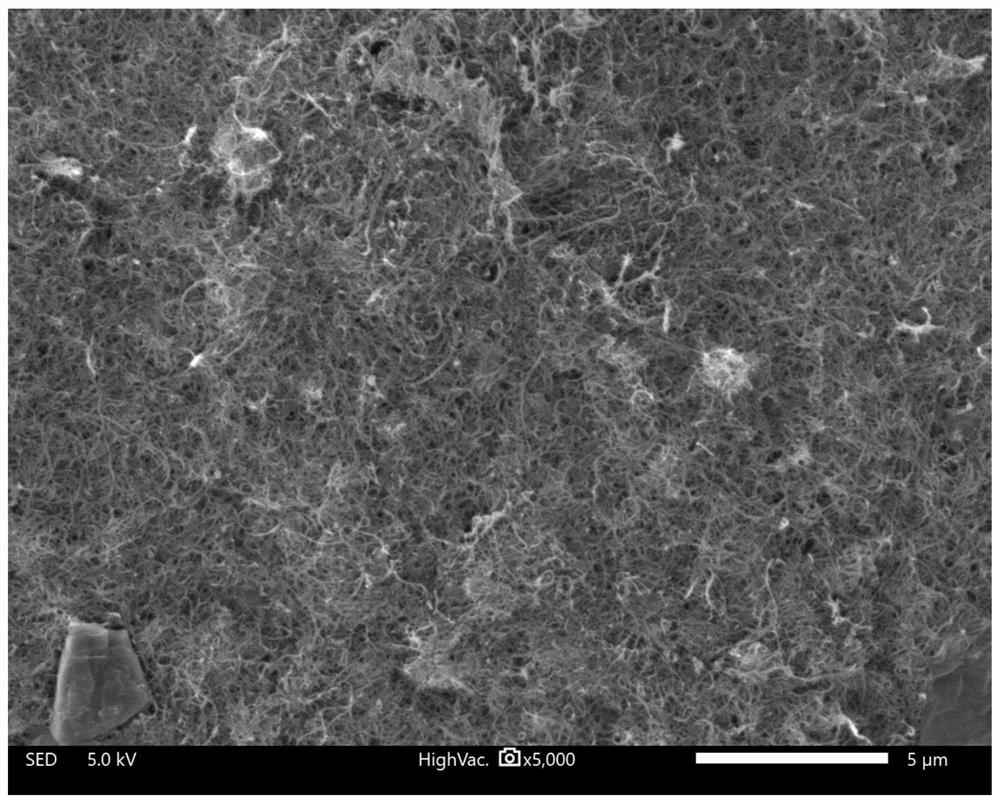

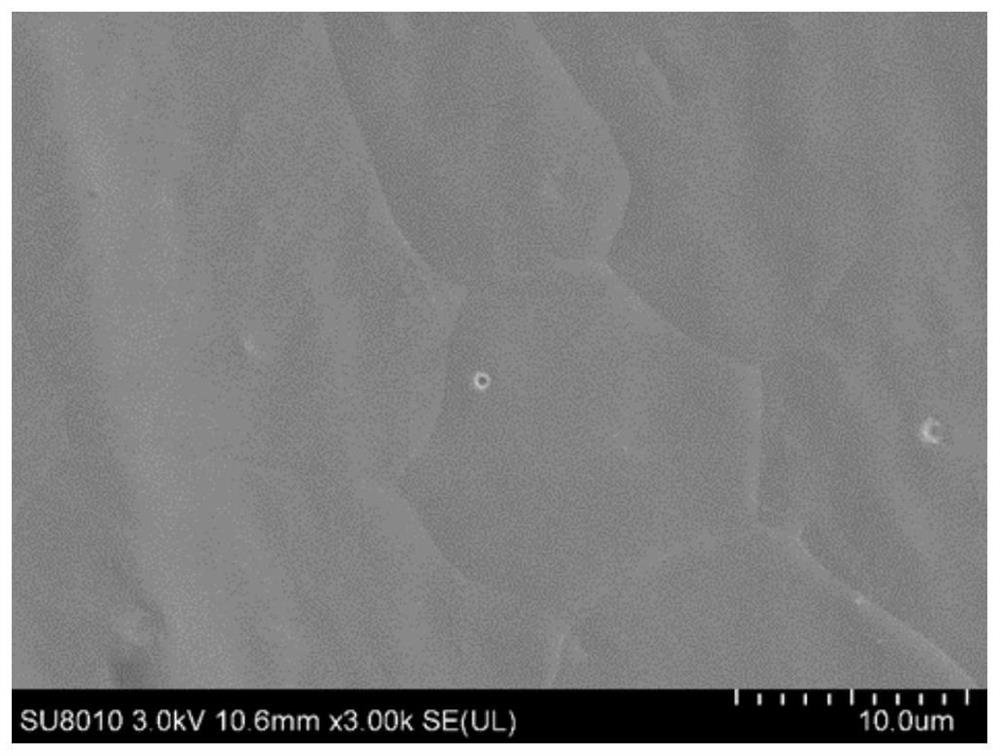

Preparation method and application of graphene/carbon nanotube composite porous membrane

InactiveCN111615318AAchieve low temperatureUniform/non-uniform dispersionMagnetic/electric field screeningGrapheneMicrospherePorous membrane

The invention discloses a preparation method and application of a graphene / carbon nanotube composite porous membrane, and relates to the technical field of preparation of composite porous membranes. The preparation method comprises the steps of (1) dispersing crosslinked polystyrene (PS) microspheres, graphene oxide and carboxylated carbon nanotubes in a solvent to obtain a suspension; (2) carrying out suction filtration on the suspension to obtain a filter membrane; (3) drying the filter membrane to obtain a graphene oxide / carbon nanotube / PS microsphere composite membrane; and (4) clamping the graphene oxide / carbon nanotube / PS microsphere composite membrane between graphite plates, and performing carbonization treatment in an atmosphere furnace to obtain the required graphene / carbon nanotube composite porous membrane. According to the preparation method, polystyrene microspheres are taken as a template, uniform and non-uniform dispersion of the polystyrene microspheres in the graphene / carbon nanotube composite membrane is realized through suction filtration, and then the template is removed through low-temperature carbonization, so that low-temperature and simple preparation of the graphene / carbon nanotube composite porous membrane is realized.

Owner:HUANGHUAI UNIV

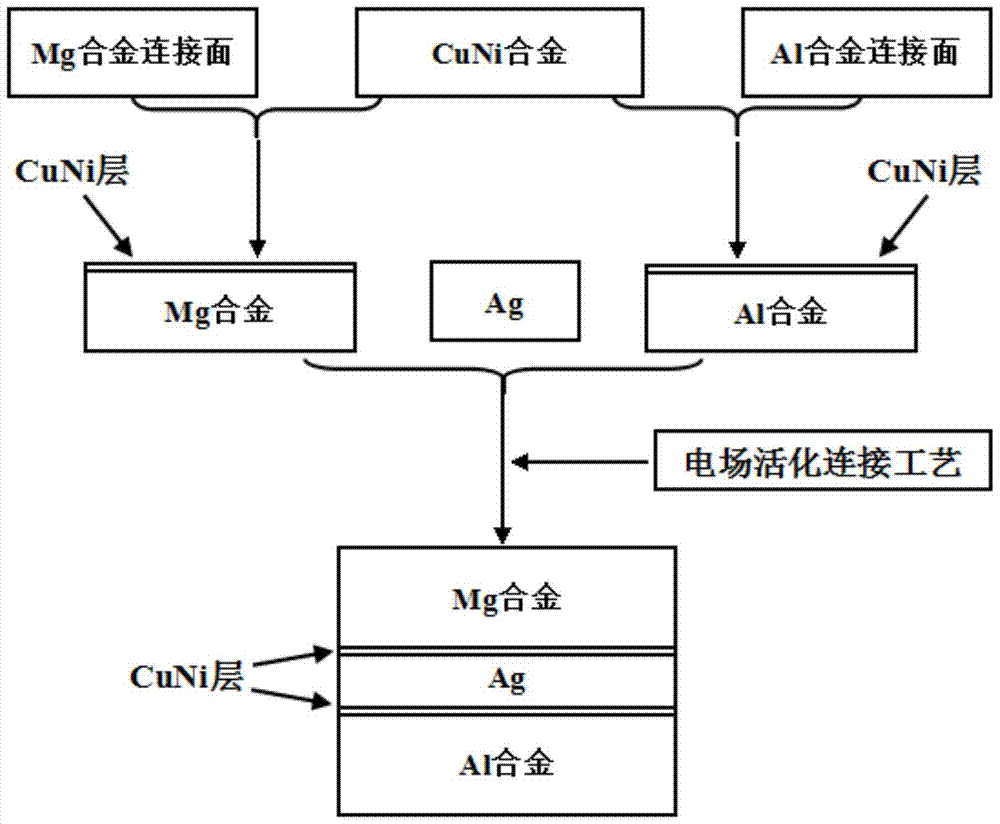

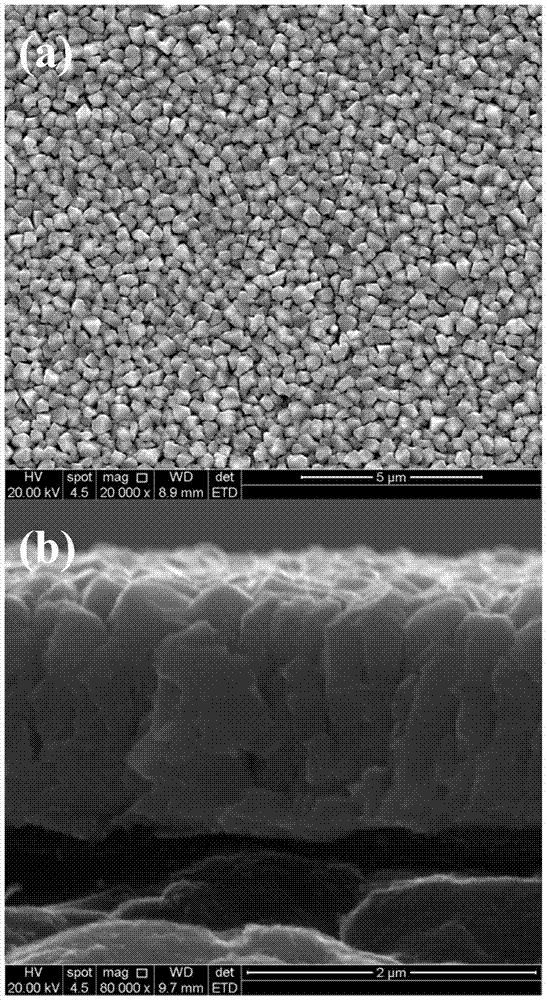

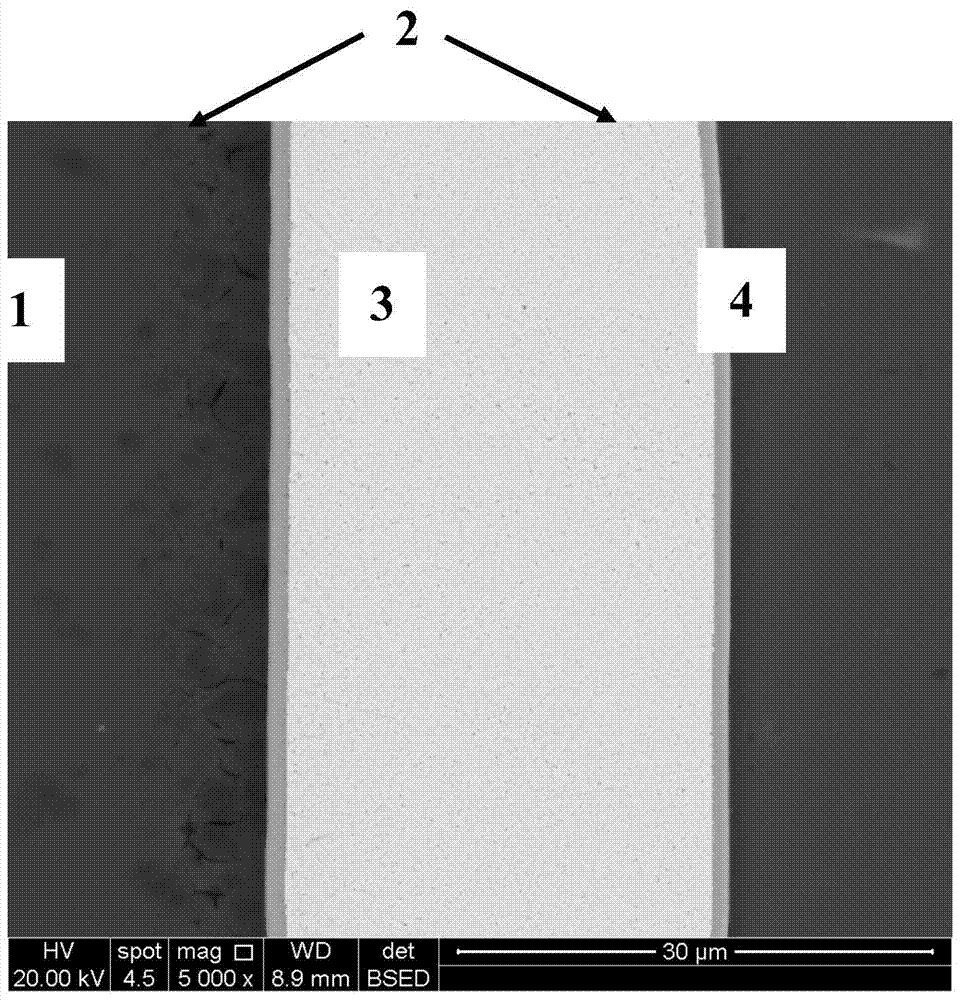

The design of laminated composite interlayers introduces a method for joining magnesium alloys to aluminum alloys

ActiveCN105149769BReduce oxidationIncrease contactWelding/soldering/cutting articlesNon-electric welding apparatusSurface oxidationAlloy thin film

The invention provides a method for introducing the design of laminated compound interlayers to enable magnesium alloy and aluminium alloy to be connected. The method comprises the steps that first, CuNi alloy thin films are deposited on the surface of the magnesium alloy and the surface of the aluminium alloy to be used as obstructing interlayers for preventing surface oxidation of aluminium and magnesium matrixes and intermetallic compound generation; then Ag is added between CuNi alloy thin film layers to lower the connecting temperature of a CuNi interlayer, and a CuNi-Ag-CuNi laminated compound interlayer is formed; and then a to-be-connected magnesium alloy piece and a to-be-connected aluminium alloy piece of the compound interlayer are assembled and are subjected to heat preservation for 0-750 s at the temperature of 380-420 DEG C. According to the method, the compound interlayer avoids the generation of Mg-Al-based intermetallic compounds with connecting interface brittleness and other intermetallic compounds; an electric field activation connecting technology is adopted, so that quick low-temperature and high-strength welding of the magnesium alloy and the aluminium alloy is achieved under vacuum, the connecting temperature is lowered, the connecting technology cycle is shortened, and the reliability of connecting joints is improved.

Owner:WUHAN UNIV OF TECH

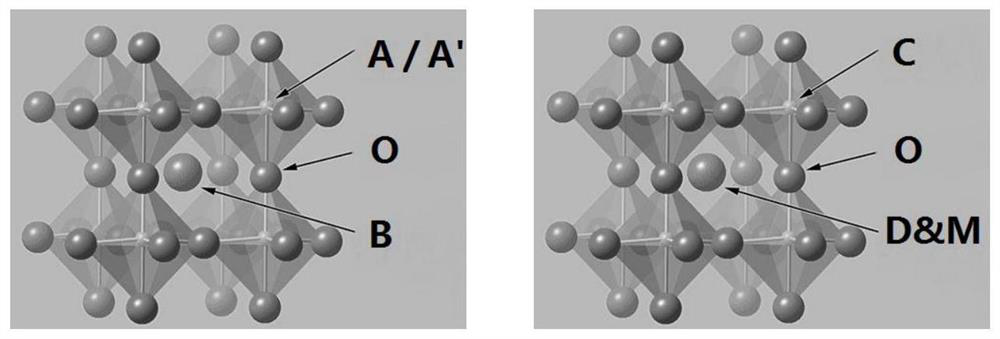

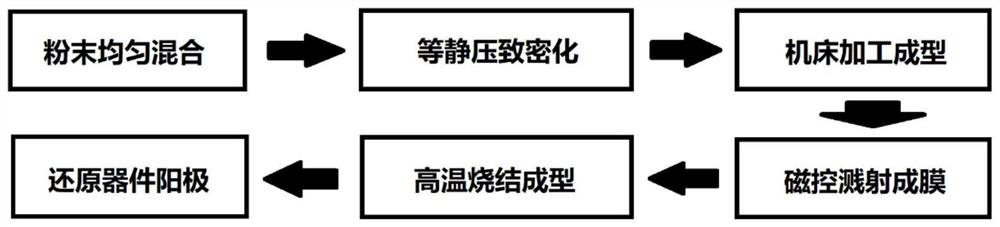

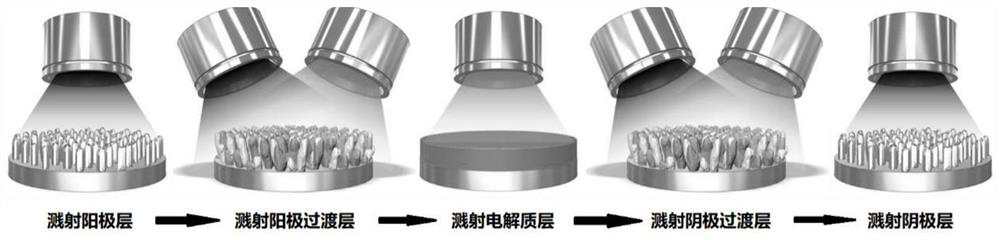

Solid oxide fuel cell based on proton conduction type electrolyte and preparation method

ActiveCN112768704AAchieve low temperatureWell matched thermal expansionCell electrodesSolid electrolyte fuel cellsSputteringFuel cells

The invention discloses a solid oxide fuel cell based on proton conduction type electrolyte and a preparation method of the solid oxide fuel cell. An electrolyte material in a traditional SOFC single cell is replaced by a CD<1-x>M<x>O<3-delta> type perovskite structure proton conduction type electrolyte material; acathode material of an AA'B2O6-delta type double-layer perovskite structure is also adopted; the anode layer and the cathode layer of the SOFC single cell are both prepared from a metal oxide target material containing a pore-forming agent through magnetron sputtering; and an electrolyte layer is prepared from the metal oxide target material without the pore-forming agent through magnetron sputtering. The method is wide in material selection and simple in preparation process; organic solvents, binders, plasticizers, activators, other organic auxiliaries and the like are not used in the whole process; and the method belongs to environment-friendly processing preparation means and technological processes.

Owner:WANHUA CHEM (SICHUAN) CO LTD +1

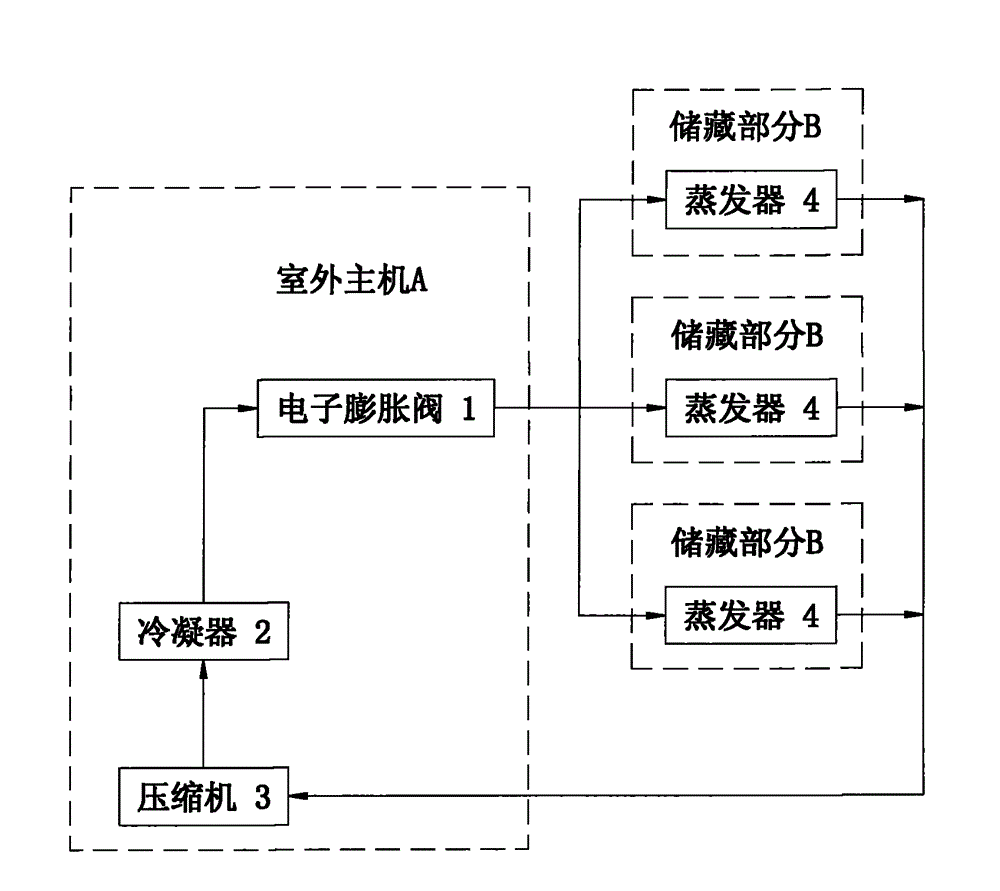

Central refrigerator

InactiveCN102748909AUse maximizedImprove energy efficiency ratioLighting and heating apparatusDomestic refrigeratorsBusiness efficiencyEngineering

The invention discloses a central refrigerator and relates to the technical field of electric appliances. The central refrigerator comprises an outdoor main machine (A) and storage parts (B); the outdoor main machine (A) is connected with a plurality of storage parts (B); the outdoor main machine (A) comprises an electronic expansion valve (1), a condenser (2) and a compressor (3); the compressor (3) is connected with the condenser (2); the condenser (2) is connected with the electronic expansion valve (1); and the storage parts (B) comprise evaporators (3) and storage spaces. The central refrigerator only utilizes one main machine which is arranged outdoors, the noise is reduced obviously; the energy efficiency ratio can be improved greatly by adopting an air cooling or water cooling technology and other technologies; the power can be far less than the power sum of the original single refrigerator, the energy utilization maximization is achieved, energy is saved effectively, and low temperature preservation and high temperature preservation can be realized.

Owner:宋校良

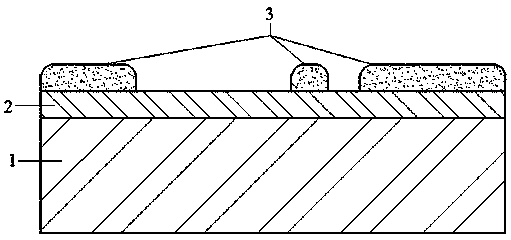

Laser doping method for polycrystalline silicon film

PendingCN112103368AReduce energy consumptionLocalized dopingFinal product manufactureSemiconductor/solid-state device manufacturingThin membraneSilicon chip

The invention discloses a laser doping method for a polycrystalline silicon film. The laser doping method comprises the following steps: growing a silicon oxide layer on a surface of a silicon wafer substrate; depositing a polycrystalline silicon film on the silicon oxide layer, wherein the polycrystalline silicon film is an in-situ doped polycrystalline silicon film or an intrinsic polycrystalline silicon film, and if the polycrystalline silicon film is the intrinsic polycrystalline silicon film, a doping source is introduced on the intrinsic polycrystalline silicon film; and irradiating thepolycrystalline silicon film by a laser. For the in-situ doped polycrystalline silicon film, the laser is adopted to irradiate the polycrystalline silicon film so as to activate doped atoms. And if the polycrystalline silicon film needing to be externally introduced with the doping source is irradiated by the laser, a doping agent is pushed into the polycrystalline silicon film to realize doping.According to the invention, low-temperature doping of the polycrystalline silicon film can be realized, and local doping of the polycrystalline silicon film can be realized too.

Owner:TRINASOLAR CO LTD

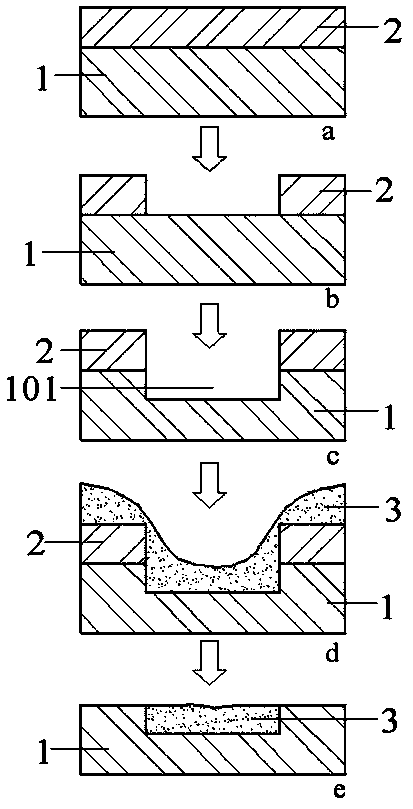

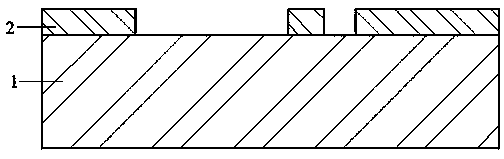

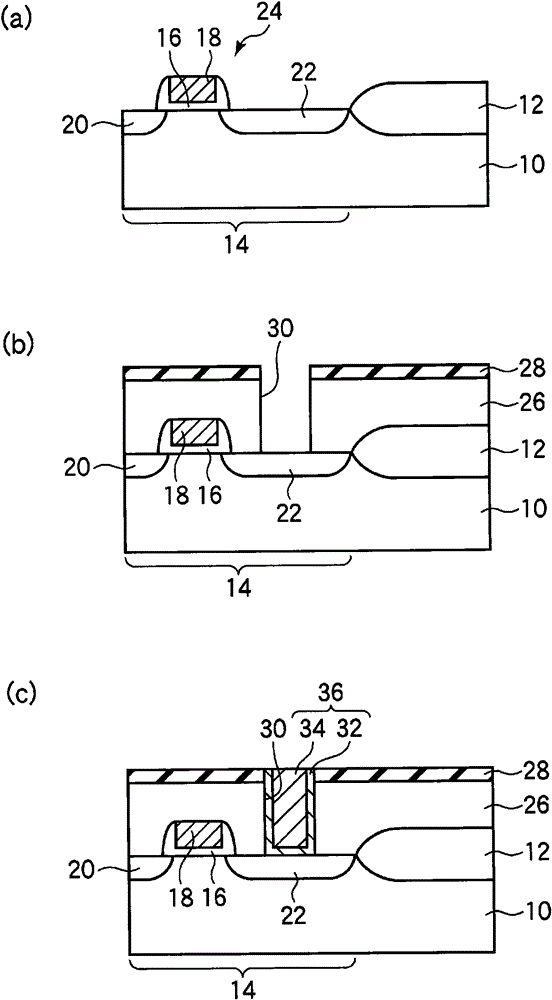

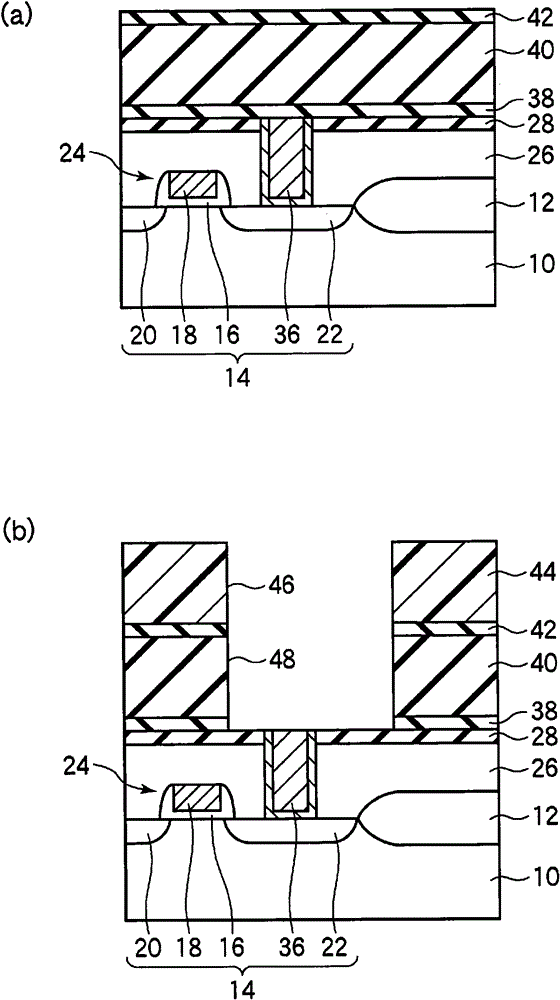

Low-temperature oxidation isolation technology for field isolation

InactiveCN109950196AAchieve low temperatureSimple processSemiconductor/solid-state device manufacturingCooking & bakingEtching

The invention relates to a low-temperature oxidation isolation technology for field isolation, and belongs to the technical field of electronic device and integrated circuit processing technologies. The low-temperature oxidation isolation technology comprises that the channel position in a substrate is determined in a photo-etching method, a channel is etched in the channel position by etching, and filled with a spacer, and a residue of photo-etching and superfluous spacer are removed. The photo-etching method comprises that the substrate is smeared with a photoresist, and a photoresist layeris formed on the substrate; the photoresist layer is covered with a masking plate to define the position of a concave area, and exposure is carried out; and post-baking and development are carried outto prepare the concave area on the photoresist layer, the channel to be filled is etched, the channel is filled, and the residue of photo-etching and superfluous spacer are removed. The processing technology can be completed in the low-temperature environment, the optical technology is simple and easy to realize, the cost is reduced, relatively more materials can be selected, and application is wider.

Owner:SHENZHEN UNIV

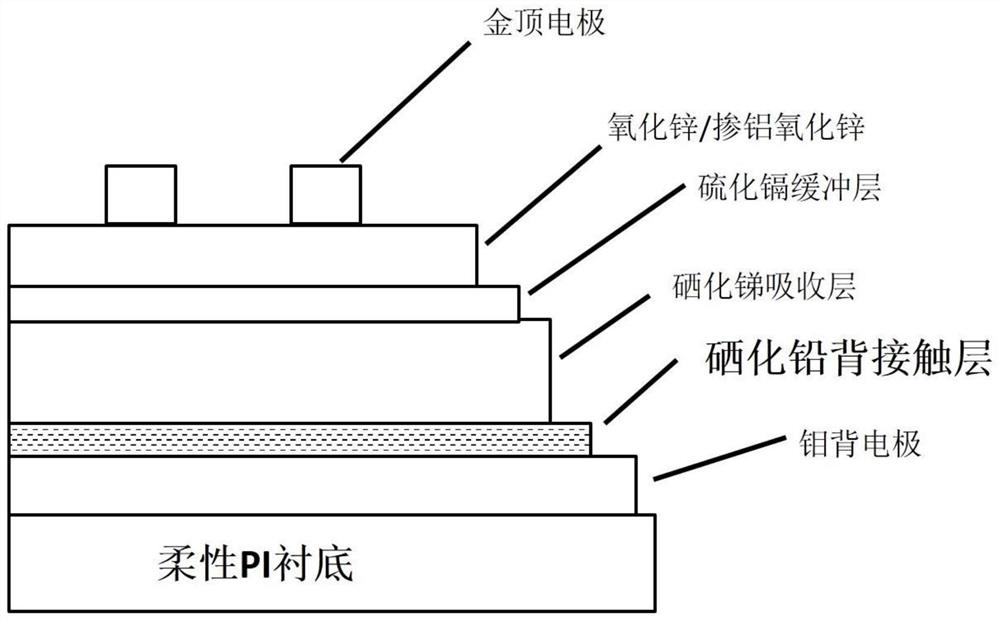

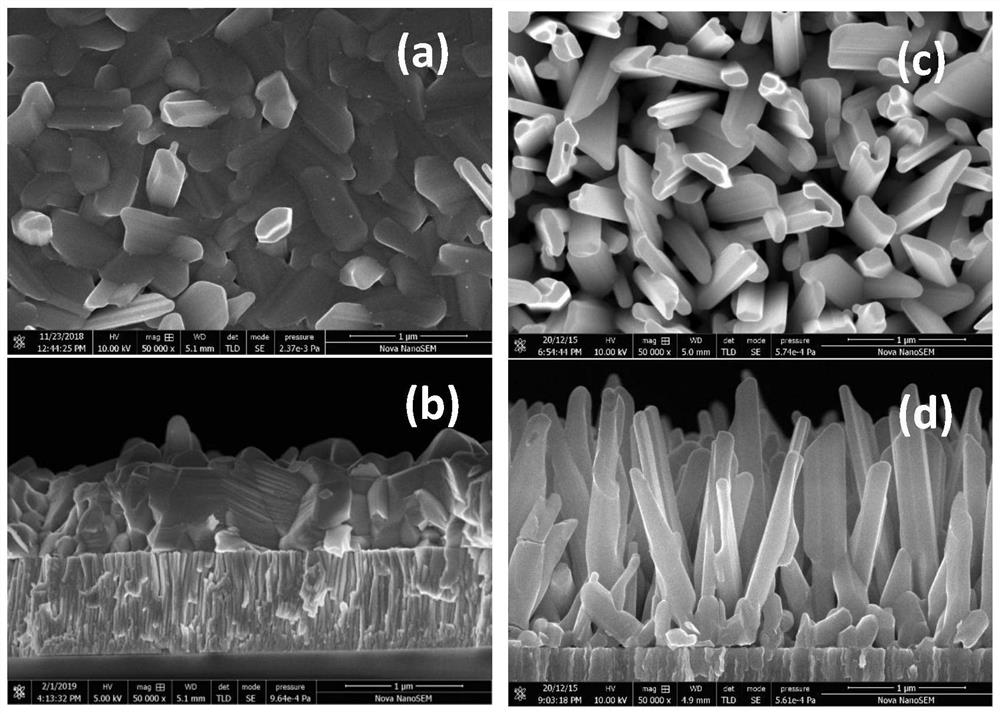

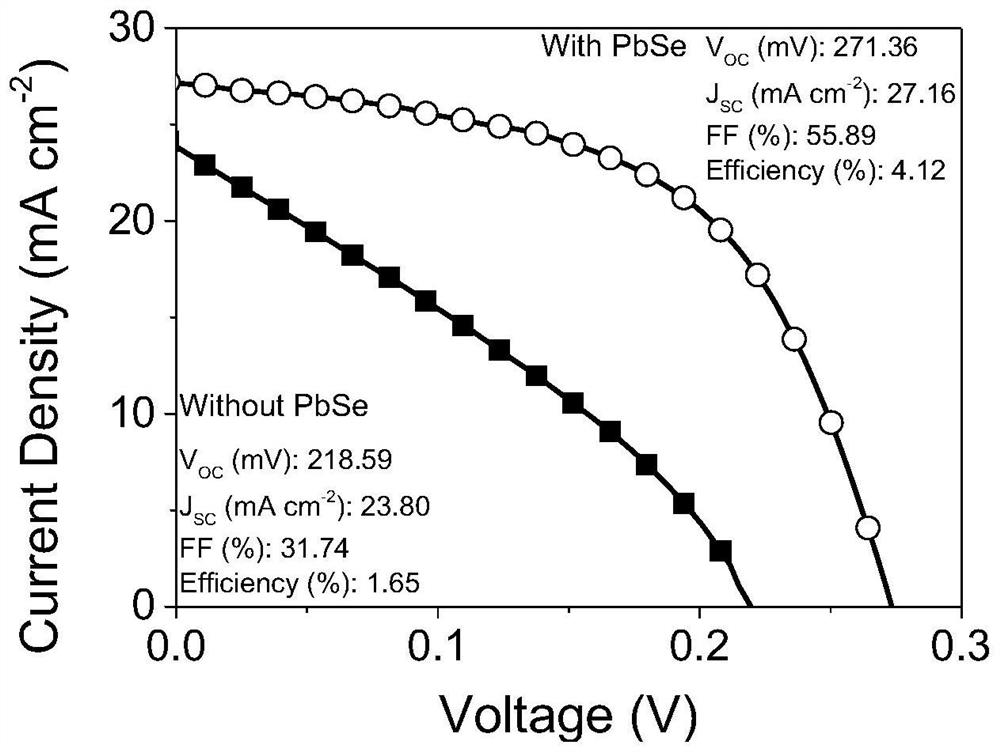

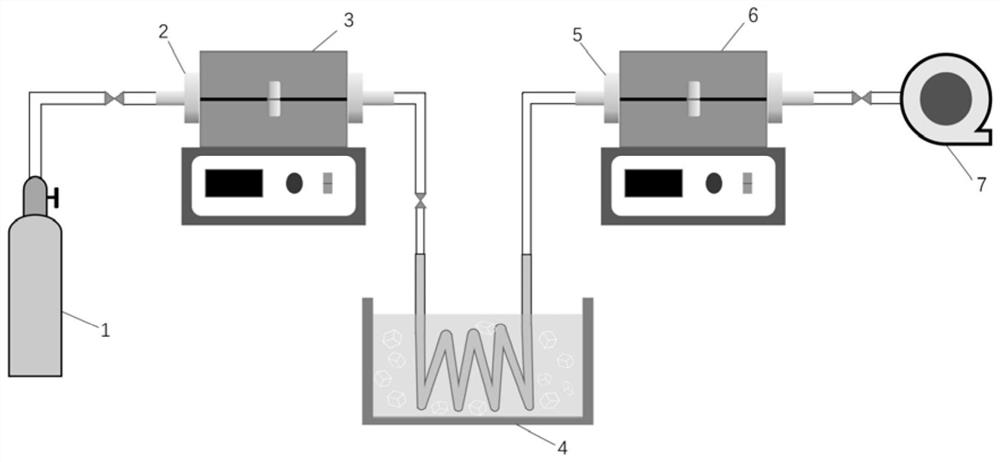

Flexible antimony selenide solar cell and preparation method thereof

ActiveCN114203848ACrystal Orientation OptimizationLower contact barrierFinal product manufactureVacuum evaporation coatingCrystal growthMaterials science

The invention provides a flexible antimony selenide solar cell and a preparation method thereof. According to the method, a lead selenide back contact layer is prepared on a back electrode through a low-temperature magnetron sputtering method, then subsequent preparation of an antimony selenide absorption layer, a buffer layer, a window layer and a top electrode is carried out, crystal growth of subsequently deposited antimony selenide is optimized through the lead selenide back contact layer, meanwhile, the contact barrier of a back contact interface is reduced, and the service life of the back contact interface is prolonged. And the preparation of the flexible, low-temperature and efficient antimony selenide thin film solar cell is realized. The invention provides a novel preparation method of the low-temperature flexible back contact layer, effectively optimizes the growth of the antimony selenide absorption layer, reduces the back contact potential barrier of the device, improves the performance of the device, and realizes the preparation of the flexible antimony selenide solar cell.

Owner:HEBEI UNIVERSITY

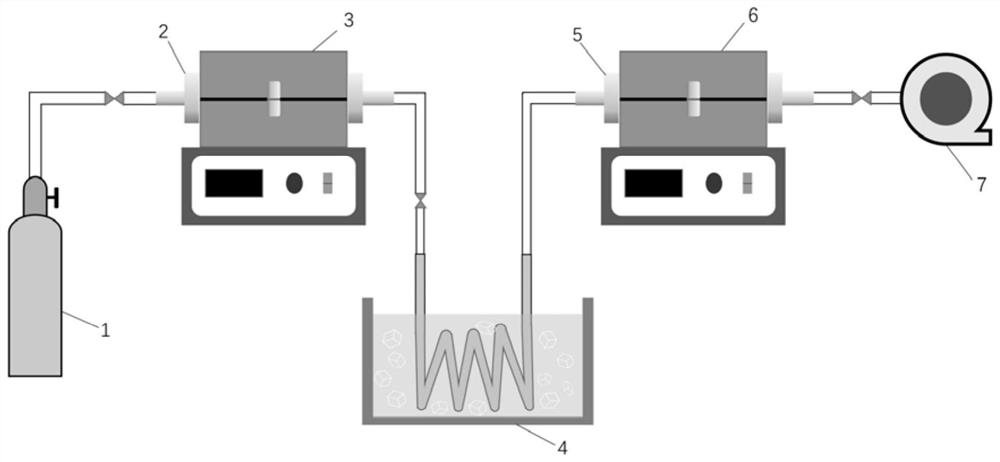

Preparation method of low-energy-consumption graphene film

ActiveCN111847431AReduce energy consumptionAchieve low temperatureChemical industryGraphenePhysical chemistryGraphite

The invention discloses a preparation method of a low-energy-consumption graphene film. The preparation method comprises the following steps of: (1) converting coal into semicoke and a high-temperature volatile product under an oxygen-free atmosphere high-temperature condition through coal grading conversion; (2) carrying out separation pretreatment on the high-temperature volatilization product to obtain gas-phase light components; and (3) enabling the gas-phase light components to enter a graphene growth reaction system based on a chemical vapor deposition method, diffusing the gas-phase light components to the surface of a growth substrate in the system, and synthesizing and growing graphene on the surface of the growth substrate at a set temperature by taking a light aromatic compoundcomponent in the gas-phase light components as a carbon source and taking a hydrogen-rich gas component in the gas-phase light components as a production atmosphere. According to the method, coal serves as a carbon source, a gas-phase light compound is obtained through a coal grading conversion technology, meanwhile, a carbon precursor and a reducing growth atmosphere are provided for growth of CVD graphene, low-temperature and low-energy-consumption growth of the graphene is achieved, and a scheme reference is provided for high-added-value utilization of the coal.

Owner:ZHEJIANG UNIV

High-temperature thermal insulation ash valve

InactiveCN105736817AAchieve low temperatureGuaranteed opening and closing functionOperating means/releasing devices for valvesThermal insulationThermal insulationEngineering

The invention provides a high-temperature thermal insulation ash valve. The high-temperature thermal insulation ash valve comprises an outer valve body with a cylinder structure, and an inner valve body with a cylinder structure and arranged in the outer valve body; a thermal insulation layer is arranged between the inner wall of the outer valve body and the outer wall of the inner valve body; and a guide groove is arranged in the inner valve body in the center axis direction. The high-temperature thermal insulation ash valve further comprises a valve plate capable of sliding along the guide groove. The temperature resistance of the inner valve body is transferred to the outer valve body through conduction and radiation, so that the low temperature of the outer valve body is realized, the outer valve body is not deformed under the condition of high temperature, and the normal work is guaranteed; and the whole device is excellent in generality and high in practicability.

Owner:SICHUAN LONGLINKECHUANG ENERGY SAVING & ENVIRONMENT PROTECTING CO LTD

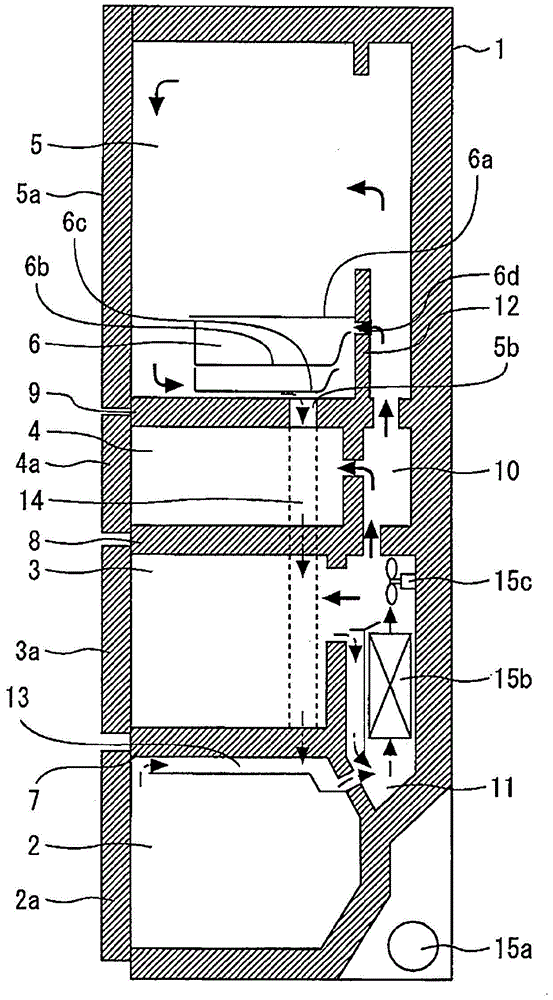

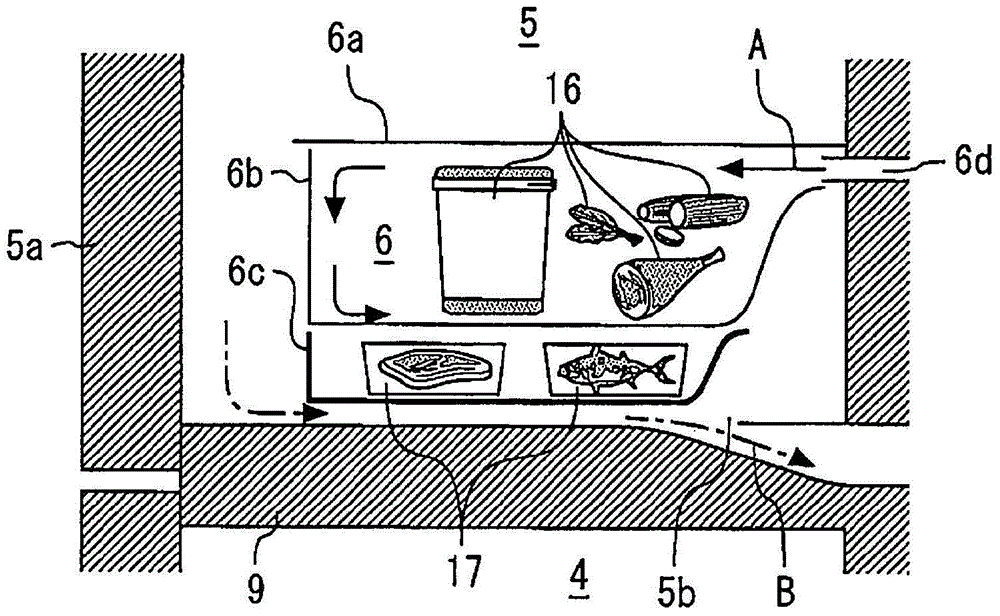

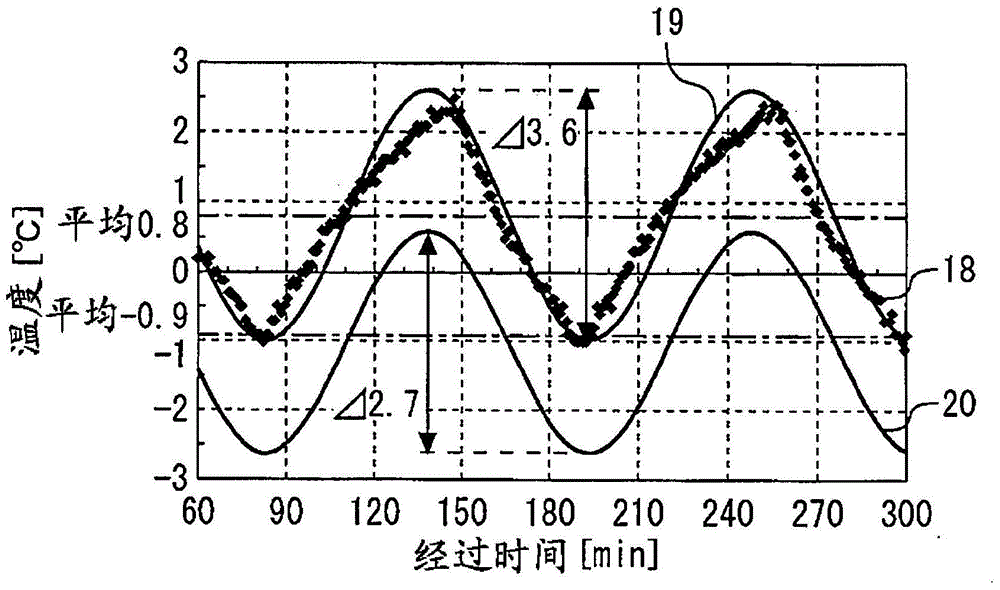

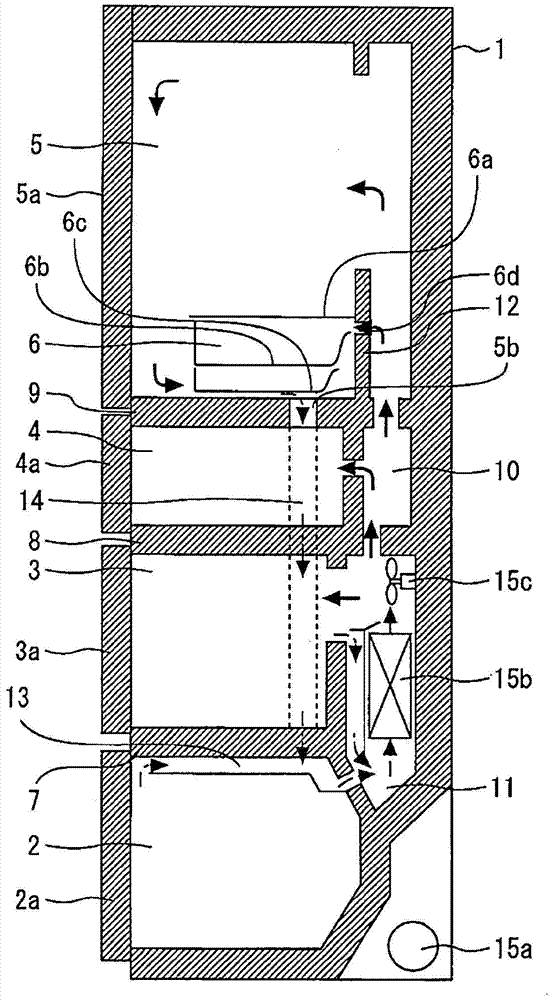

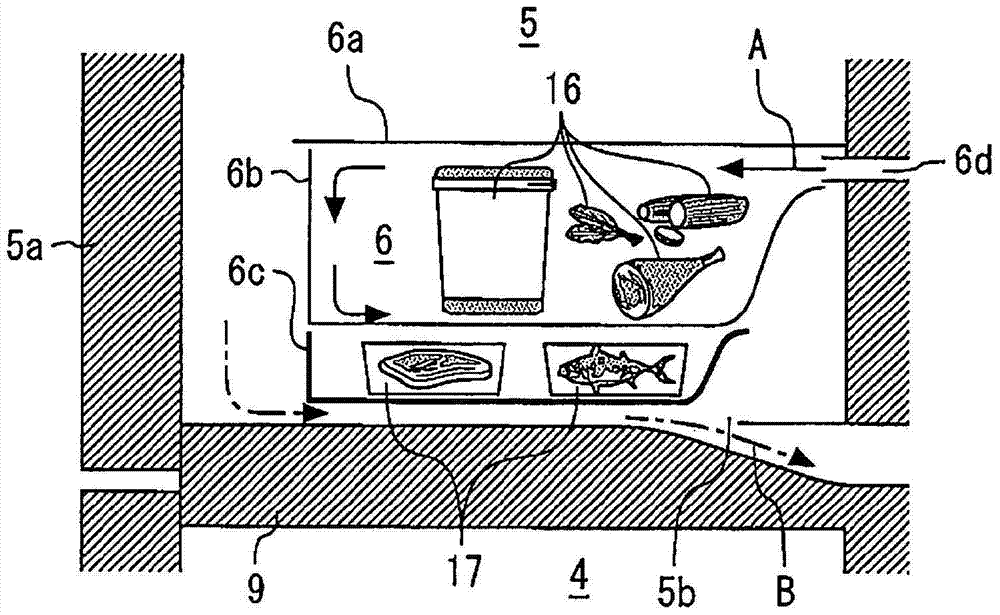

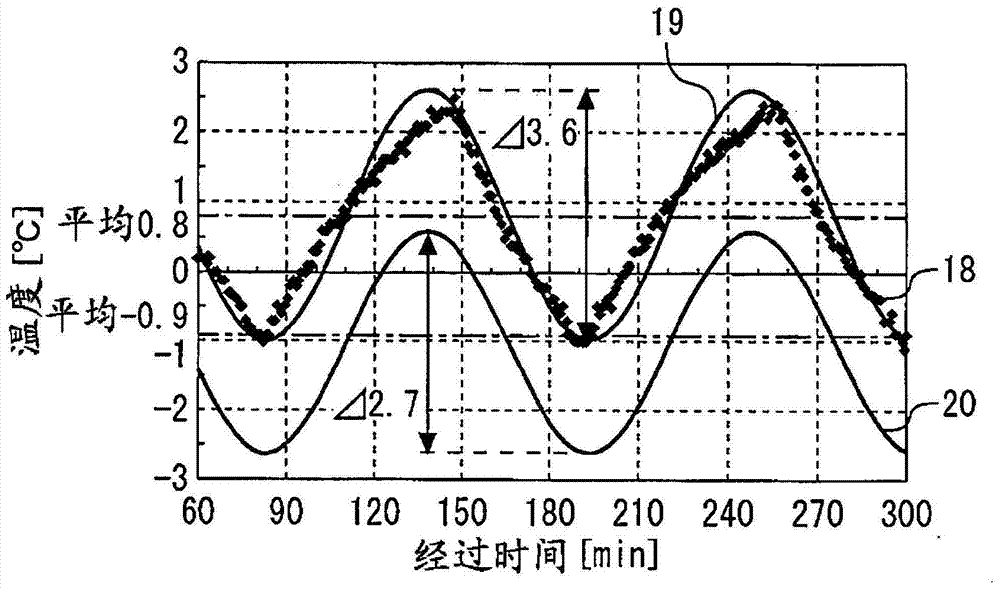

Refrigerator

ActiveCN104969017AAchieve low temperatureLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

Provided is a refrigerator that can lower temperature and keep temperature constant. The refrigerator comprises a freezing storage chamber set to a freezing temperature range, a first accommodating container provided so as to be adjacent to the freezing storage chamber and formed so that cold air is supplied, and a second accommodating container provided so as to be adjacent to the freezing storage chamber and the first accommodating container and formed so that cold air is not supplied. Due to having this configuration, the refrigerator can lower the temperature and keep the temperature constant in the second accommodating container.

Owner:MITSUBISHI ELECTRIC CORP

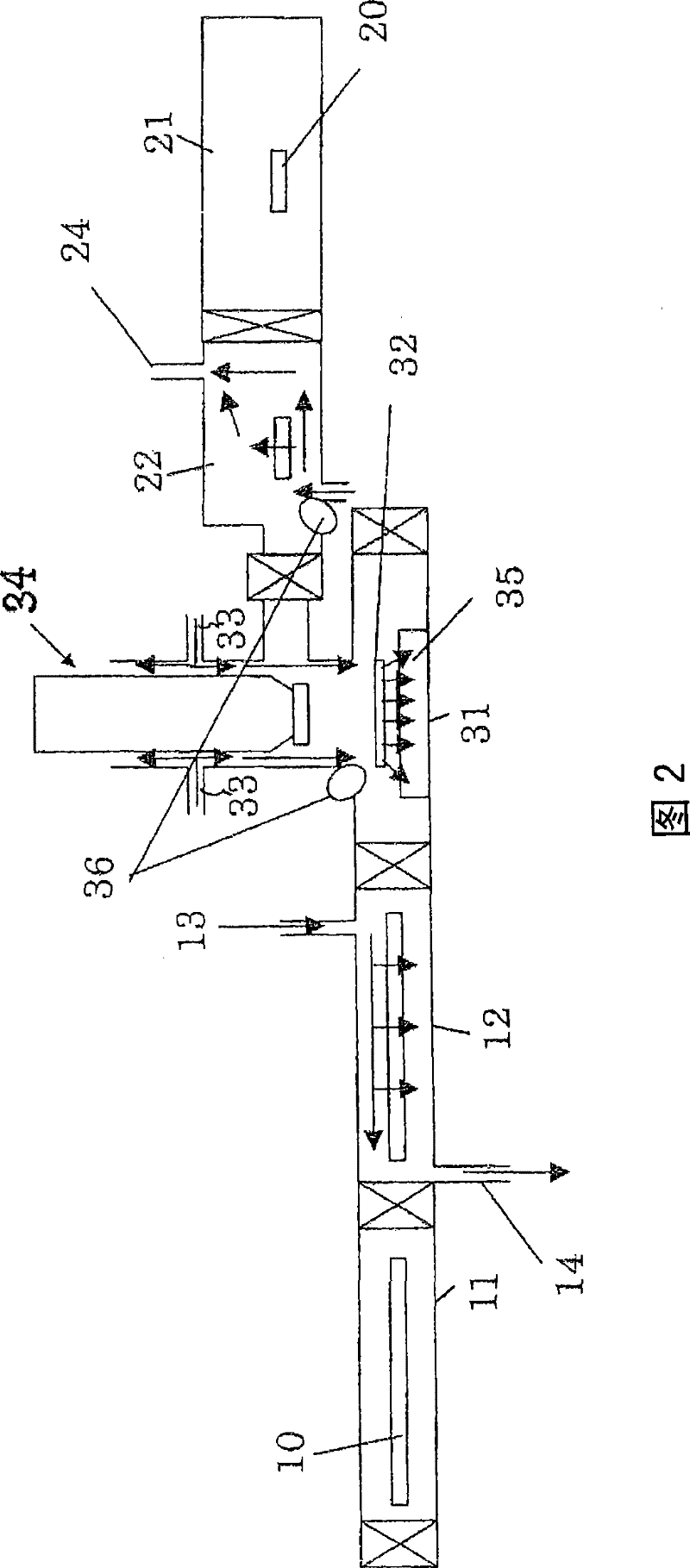

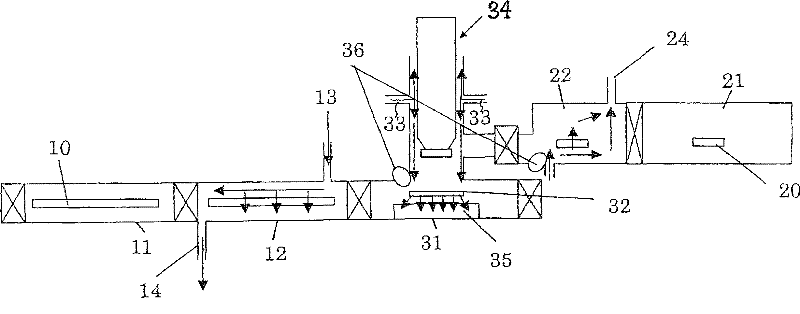

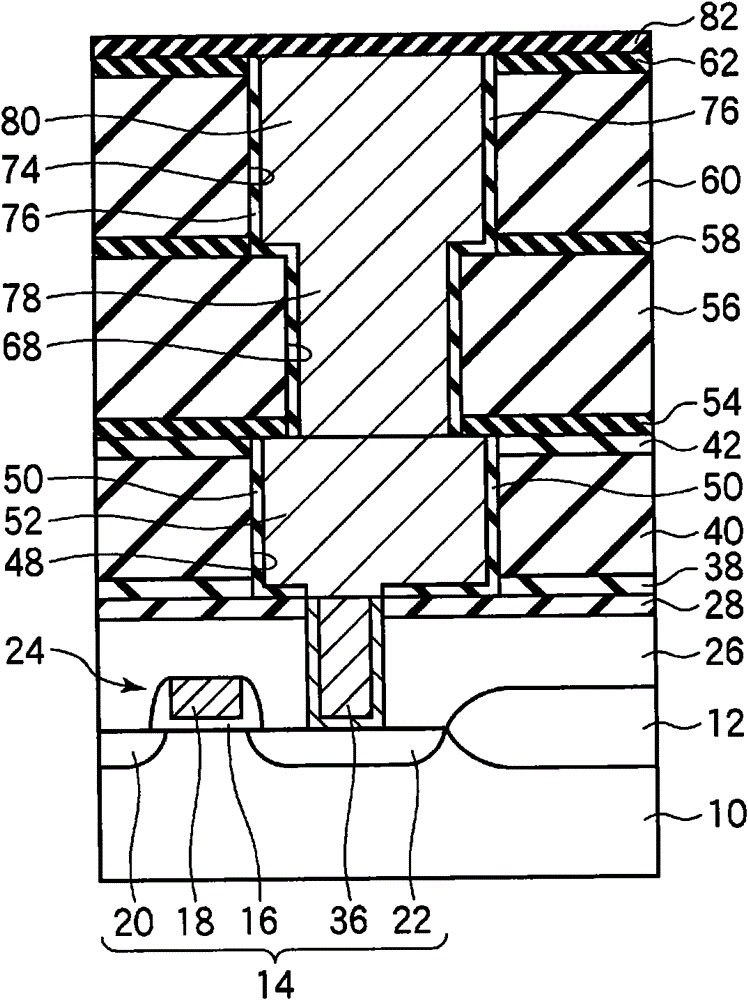

Atmosphere controlled joint device, method and electronic device

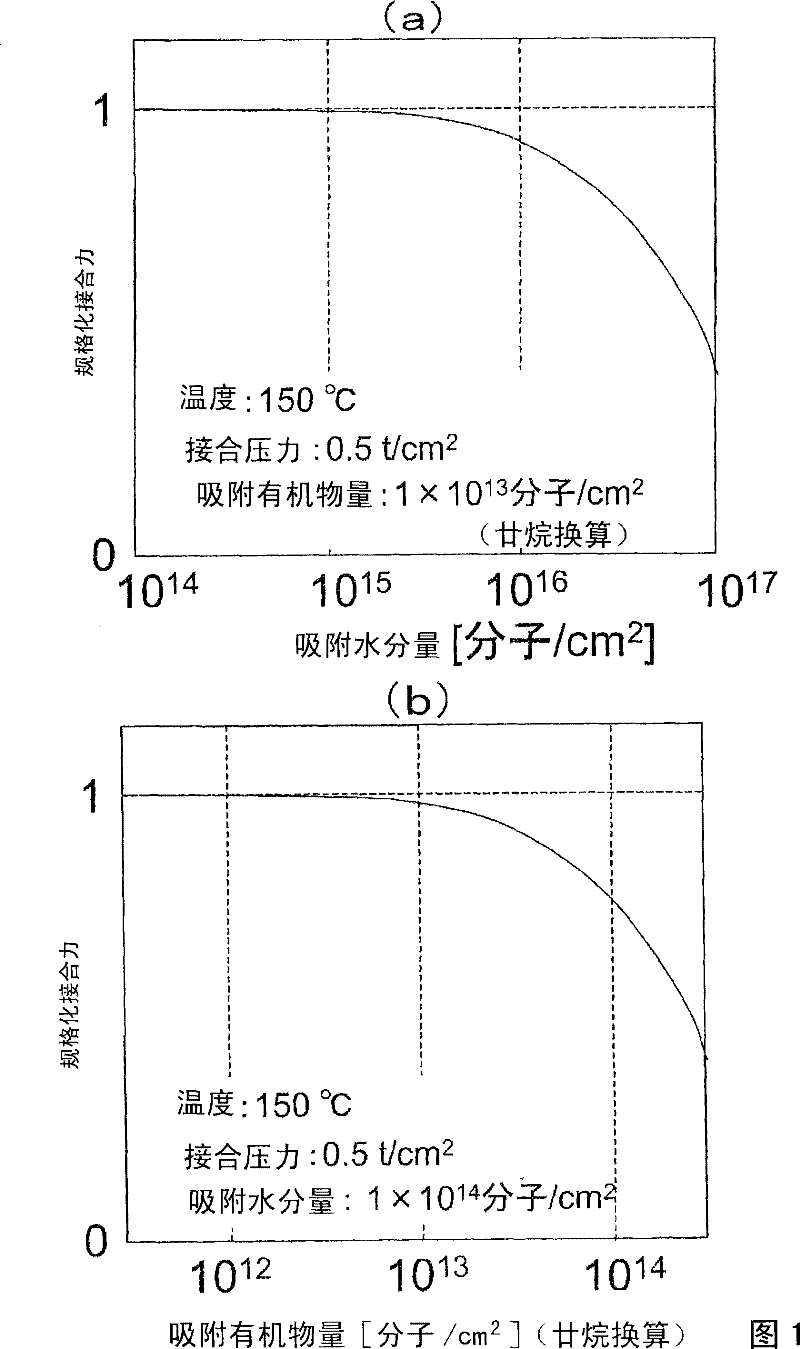

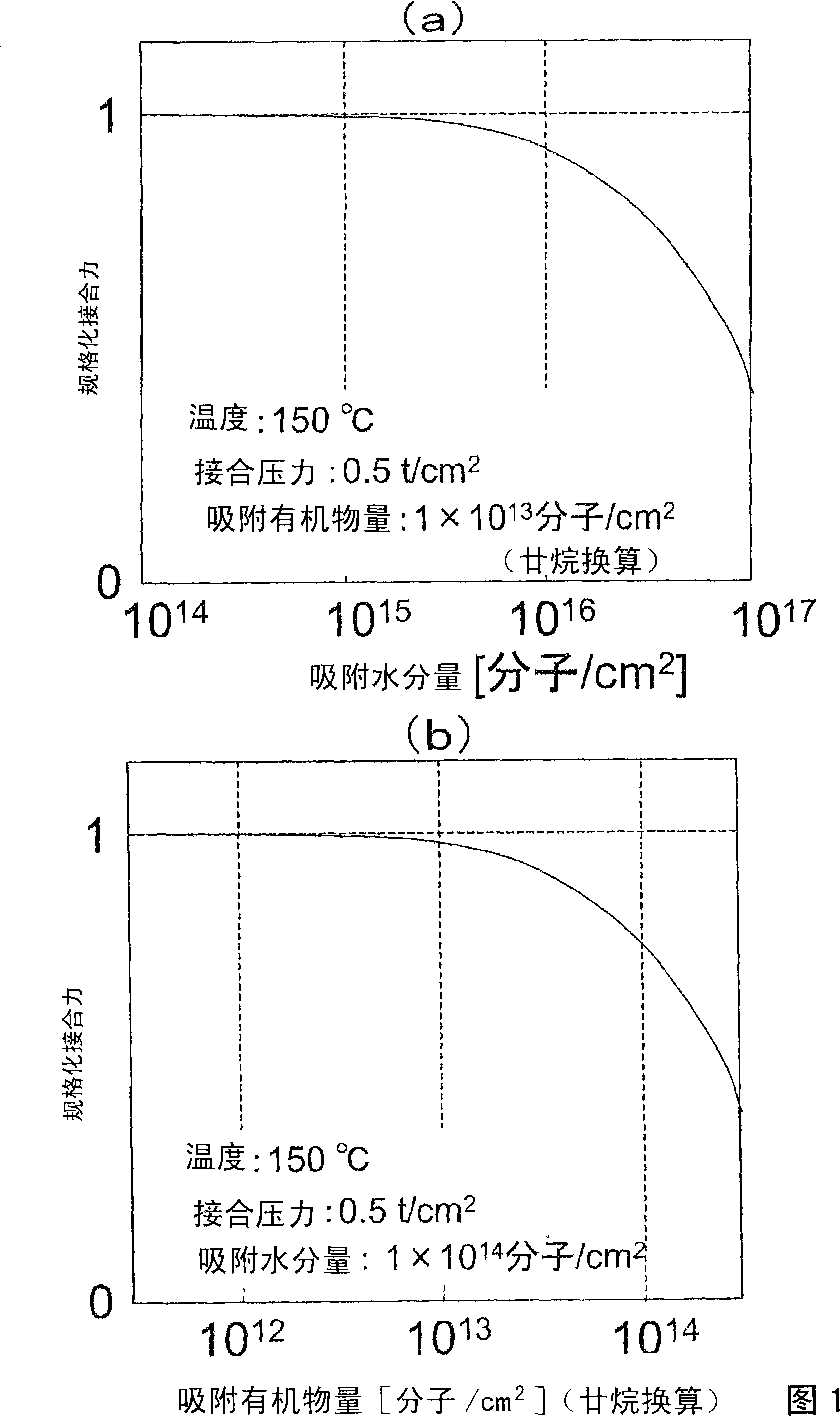

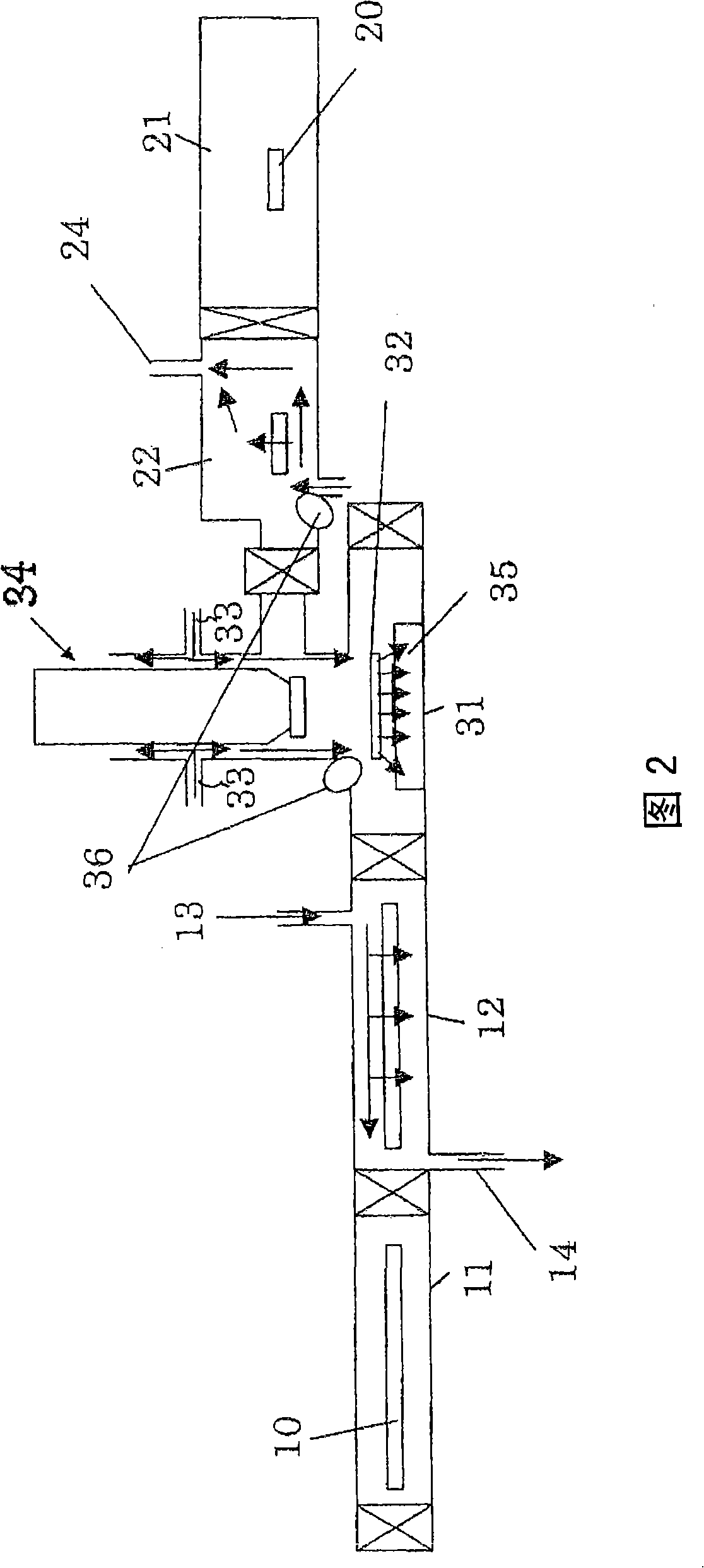

InactiveCN101273445BInhibition of thermal deteriorationAvoid deformationPrinted circuit assemblingSolid-state devicesEngineeringMoisture

This invention provides a joining device for pressure welding a pressure welding part that can realize pressure welding under low temperature and low pressure conditions by rendering the moisture content of the pressure welding part atmosphere within the device relatively smaller than the moisture content of the atmosphere outside the device. In this case, the amount of water adsorbed on each surface of a joining metal terminal and a metal terminal to be joined constituting the pressure welding part is brought to not more than 1 10<16> molecules / cm<2>.

Owner:大见忠弘

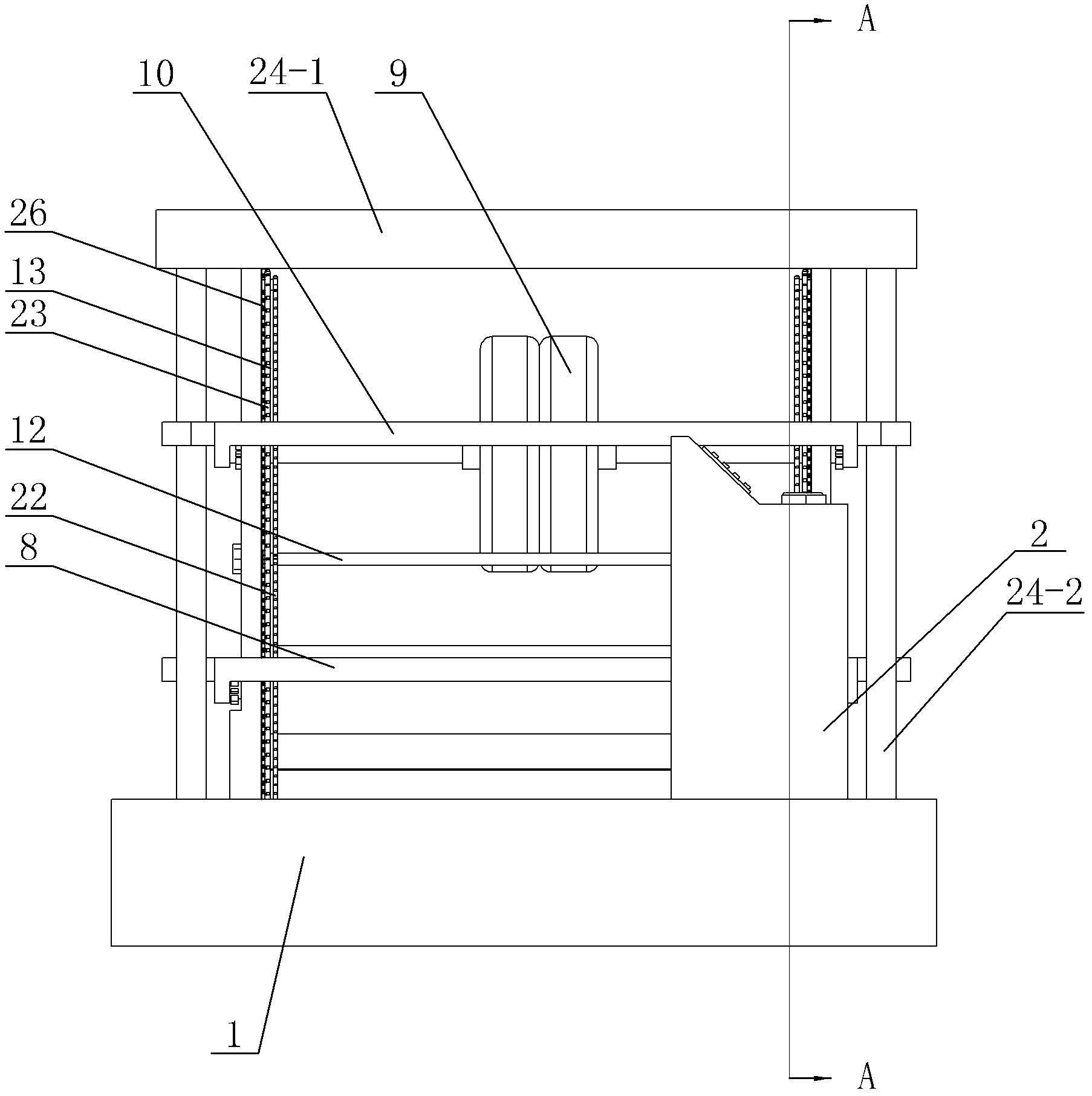

Accelerated loading test device for small full-size asphalt pavement

ActiveCN102607974BReflects anti-rutting performanceReduce trafficMaterial strength using repeated/pulsating forcesHorizontal transmissionMotor drive

An accelerated loading test device for a small full-size asphalt pavement relates to an accelerated loading test device for a full-size asphalt pavement, aiming at the problems of impossibility of accurately simulating the actual stress state of an asphalt pavement in an indoor wheel tracking test, as well as large equipment size, long test period, high test expense and complex operation process in an outdoor full-size pavement accelerated loading test. A two-way motor drives a drive big gear and a driven big gear to rotate; a transmission cross rod disposed on a rack is fixedly sleeved with a force-transferring pinion, as well as sleeved with a force-transferring big gear, a lifting gear and a transition chain wheel engaged with an annular horizontal transmission chain in a suspension manner; the force-transferring big gear and the force-transferring pinion are engaged with an annular vertical inner transmission chain and an annular vertical outer transmission chain; the lifting gear is engaged with a lifting guide rail; the movements of a rolling steel wheel and a loading wheel group are driven via the annular horizontal transmission chain; the up-and-down movement of a rectangular-frame steel wheel loading beam is driven via an inner oil pressure pump; and the up-and-down movement of a rectangular-frame wheel group loading beam is driven via an outer oil pressure pump. The invention is used for the accelerated loading test for the full-size asphalt pavement.

Owner:HARBIN INST OF TECH

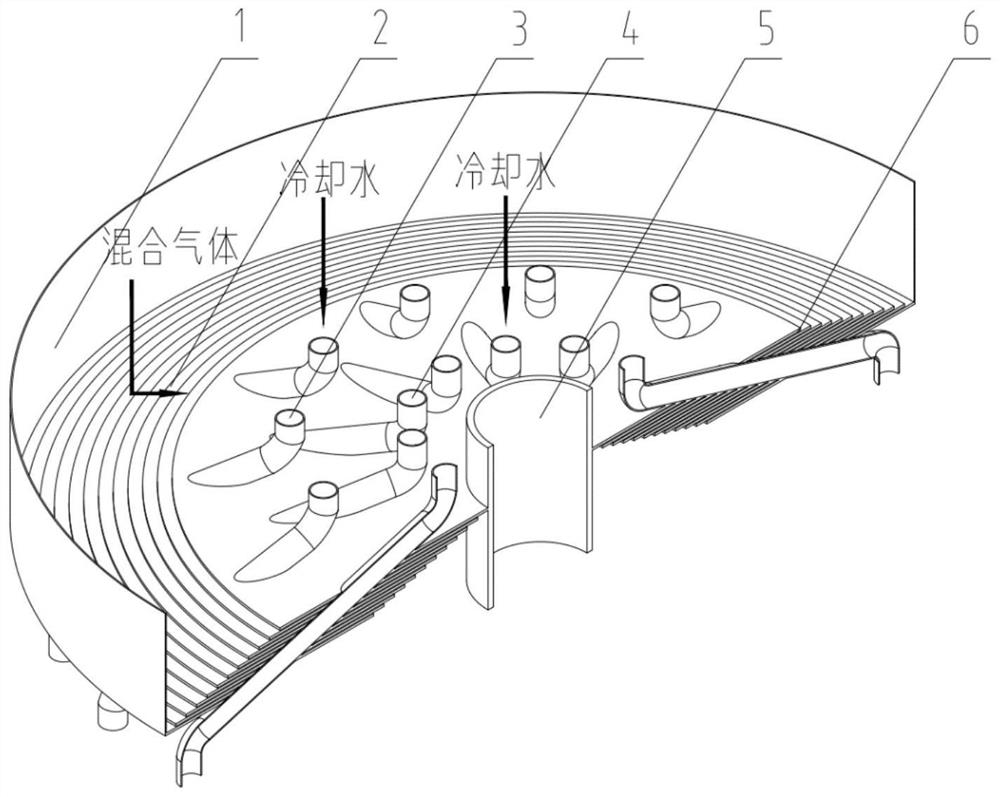

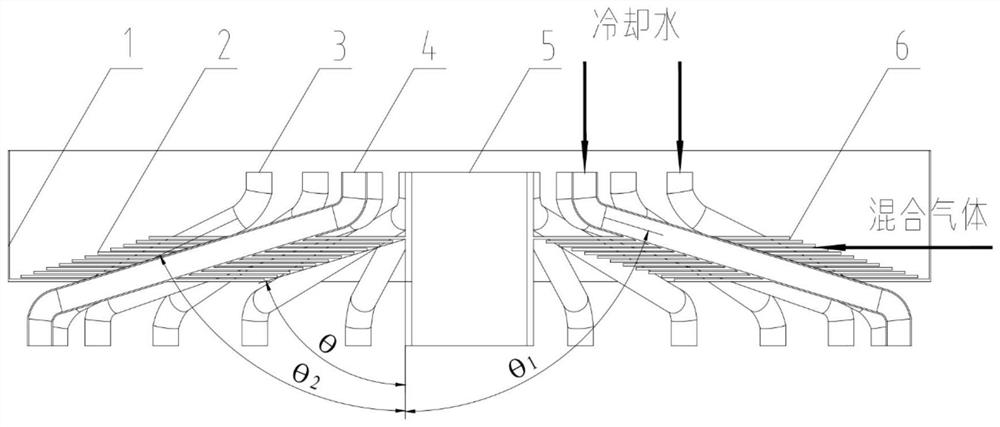

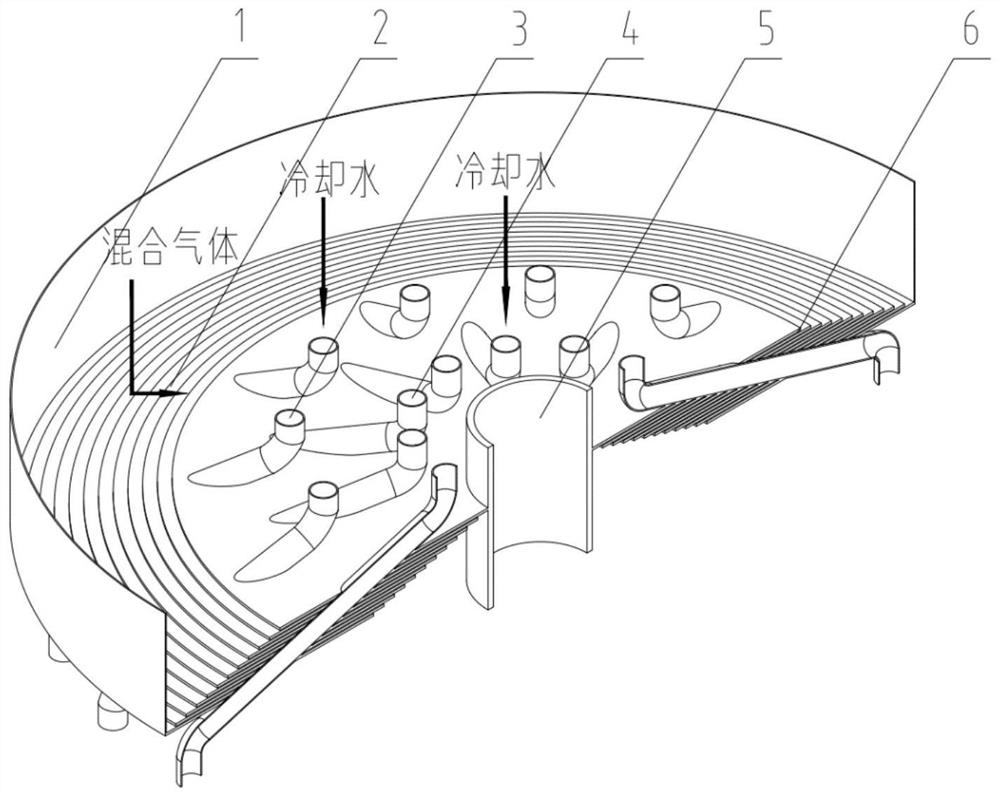

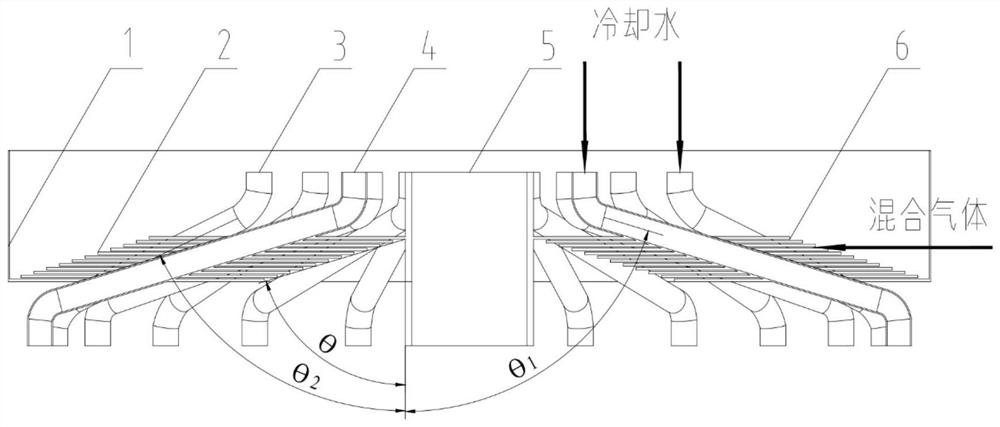

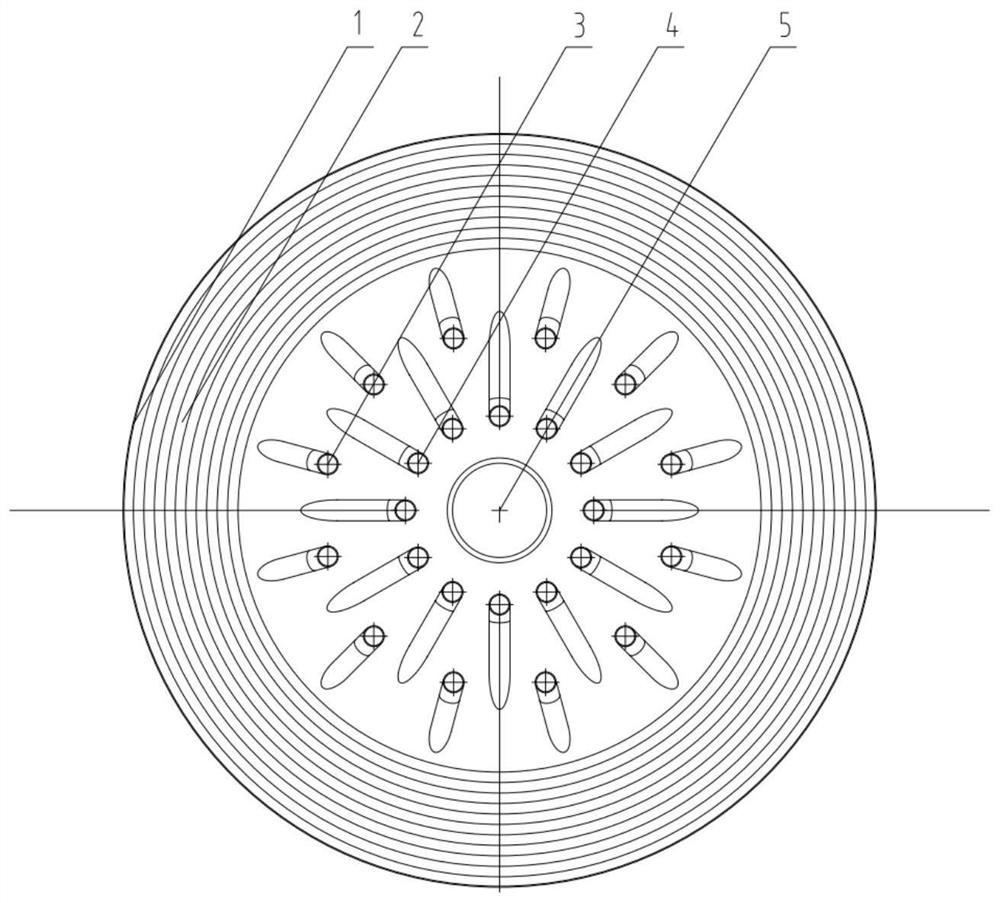

Reducing ring rib water-cooling type surface combustion gas appliance

ActiveCN113432121AUniform air intakeUniform surface burnBurner ignition devicsNon-combustible gases/liquids supplyThermodynamicsCombustor

The invention discloses a reducing ring rib water-cooling type surface combustion gas appliance. The gas appliance comprises reducing ring ribs, first-stage annular cooling water pipes and second-stage annular cooling water pipes, wherein the first-stage annular cooling water pipes and the second-stage annular cooling water pipes are arranged on the reducing ring ribs; a gas inlet cylinder is arranged on the outer side of the ring rib with the maximum diameter of the reducing ring ribs; an ignition gun hole / central secondary air pipeline is arranged on the inner side of the ring rib with the minimum diameter of the reducing ring ribs; a certain angle theta is formed between the multiple groups of reducing ring ribs and the axis of a combustor, so that a stepped gas inlet surface is formed, and isobaric gas inlet is formed; and the flow area of anti-backfire gas inlet micro-channels formed by the reducing ring ribs and the annular cooling water pipes is gradually reduced in the gas inlet direction, and in addition, an outlet forms a continuous stepped combustion plane. According to the gas appliance, isobaric gas inlet, uniform low-temperature low-NOx surface combustion of gas can be realized, meanwhile, backfire can be effectively prevented, and stable, efficient, clean and safe combustion of gas fuel is ensured; and meanwhile, the structure is simple, manufacturing is convenient, and the gas appliance is suitable for batch production.

Owner:XI AN JIAOTONG UNIV

refrigerator

ActiveCN104969017BAchieve low temperatureLighting and heating apparatusDomestic refrigeratorsCold airEngineering

Provided is a refrigerator that can lower temperature and keep temperature constant. The refrigerator comprises a freezing storage chamber set to a freezing temperature range, a first accommodating container provided so as to be adjacent to the freezing storage chamber and formed so that cold air is supplied, and a second accommodating container provided so as to be adjacent to the freezing storage chamber and the first accommodating container and formed so that cold air is not supplied. Due to having this configuration, the refrigerator can lower the temperature and keep the temperature constant in the second accommodating container.

Owner:MITSUBISHI ELECTRIC CORP

Atmosphere controlled joint device, method and electronic device

InactiveCN101273445AInhibition of thermal deteriorationAvoid deformationPrinted circuit assemblingSolid-state devicesEngineeringMoisture

This invention provides a joining device for pressure welding a pressure welding part that can realize pressure welding under low temperature and low pressure conditions by rendering the moisture content of the pressure welding part atmosphere within the device relatively smaller than the moisture content of the atmosphere outside the device. In this case, the amount of water adsorbed on each surface of a joining metal terminal and a metal terminal to be joined constituting the pressure welding part is brought to not more than 1 10<16> molecules / cm<2>.

Owner:大见忠弘

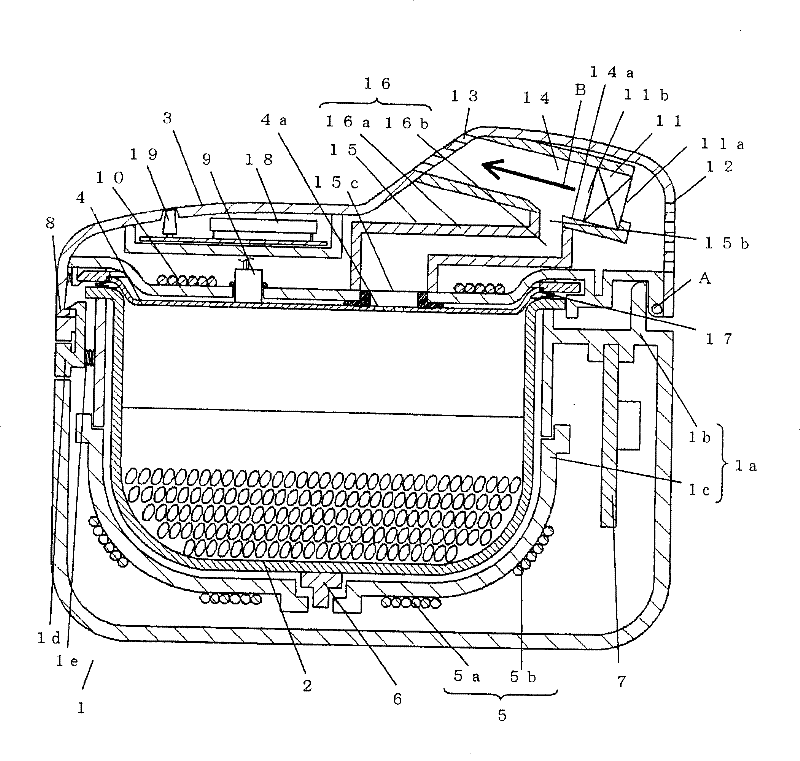

Electric cooker

ActiveCN101336797BReduce the phenomenon of entering the potWell mixedCooking vesselsDistilled waterRoom temperature

Owner:PANASONIC CORP

Method for forming field isolation

InactiveCN109920726AAchieve low temperatureLow costSemiconductor/solid-state device manufacturingIsolation layerElectron

The invention relates to the technical field of electronic devices and integrated circuit technology and relates to a method for forming field isolation. The method comprises the steps of preparing anisolation layer, wherein the isolation layer is prepared on the surface of a substrate through a thin film growth method or a precipitation method after the substrate is cleaned and dried; determining a trench of an active area, and marking the position of the trench of the active area on the isolation layer through a photoetching method; etching the trench of the active area, and removing the isolation layer covered on the position of the trench of the active area through an etching method in the position of the trench of the active area, wherein the thickness of the isolation layer is 1 nm-1 mm. According to the method in the invention, low temperature and low cost of production and processing of integrated boards can be realized, and industrialization is facilitated.

Owner:SHENZHEN UNIV

A water-cooled surface combustion gas device with different diameter ring ribs

ActiveCN113432121BUniform air intakeUniform surface burnBurner ignition devicsNon-combustible gases/liquids supplyThermodynamicsCombustor

The invention discloses a water-cooled surface combustion gas device with different-diameter ring ribs, which comprises a different-diameter ring rib, a first-stage ring-mounted cooling water pipe and a second-stage ring-mounted cooling water pipe arranged on the different-diameter ring rib. The air intake tube is arranged outside the largest diameter ring rib of the radial ring rib, and the ignition gun hole / central secondary air duct is arranged inside the smallest diameter ring rib of the different diameter ring rib; The angle θ is arranged to form a "ladder"-shaped air intake surface, forming an equal-pressure air intake; the flow area of the anti-tempering air intake micro-channel formed by the different-diameter ring ribs and the ring-mounted cooling water pipes gradually decreases along the air intake direction, and the outlet forms a continuous The "ladder" shaped burning plane. The invention can realize isobaric air intake, uniform gas, low temperature and low NO x Surface combustion can effectively prevent tempering and ensure stable, efficient, clean and safe combustion of gas fuel; meanwhile, the structure is simple and easy to manufacture, which is suitable for mass production.

Owner:XI AN JIAOTONG UNIV

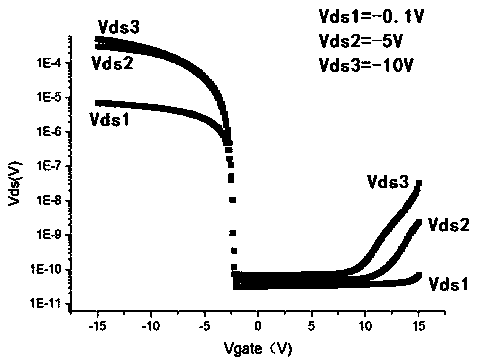

Semiconductor device and manufacturing method thereof

ActiveCN102047411BImprove performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesInterconnectionCopper

The method of manufacturing a semiconductor device includes forming an insulating film of a silicon compound-group insulation film; forming an opening in the insulation film, applying an active energy beam in an atmosphere containing hydrocarbon gas to form a barrier layer of a crystalline SiC, and forming an interconnection structure of copper in the opening with the barrier layer formed in.

Owner:FUJITSU LTD

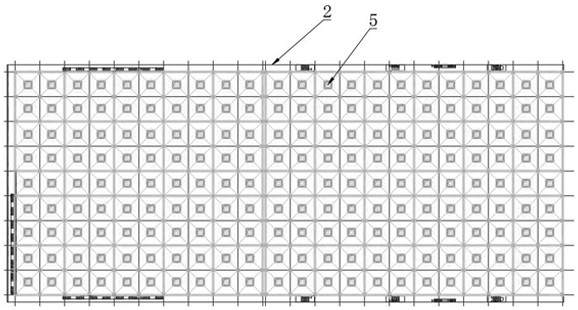

Low-temperature grain storage double-layer wall square silo and silo entering and exiting method

PendingCN114651611ACang Rong XiaoEasy to rotate outAgriculture tools and machinesHarvested fruit hanging devicesStructural engineeringElectrical and Electronics engineering

The invention discloses a low-temperature grain storage double-layer wall square silo, and relates to the technical field of grain storage, the low-temperature grain storage double-layer wall square silo comprises a warehousing equipment layer, a grain storage layer and a delivery equipment layer, and the warehousing equipment layer is provided with a grain conveyor; the grain storage layer comprises a plurality of vertically and horizontally arranged grain storage units, each grain storage unit is a conical bottom bin, a bin inlet is formed in the top of each grain storage unit, a bin outlet is formed in the bottom of each grain storage unit, a plurality of scrapers are arranged in the bin outlet equipment layer, and the scrapers are in lap joint with a conveying belt to a belt conveyor in the middle of the bin outlet equipment layer; a discharge port of the grain conveyor is communicated with the warehouse inlet, and a warehouse outlet is communicated with the scraper conveyor; a waterproof layer I is arranged on the inner wall of the grain storage unit, and a waterproof layer II is arranged on the outer wall of the grain storage unit; the bottoms of the grain storage units are provided with first air openings, the upper portions of the grain storage units are provided with second air openings, and ventilation pipes communicated with the first air openings are distributed at the bottoms of the grain storage units. The square silo is convenient to go out in turns, higher in adaptability, large in overall grain storage capacity and high in land utilization efficiency; the waterproof and heat-insulating performance is excellent; and in-out bin and ventilation are all automatically operated, so that the cost is relatively low.

Owner:河南工大设计研究院

A kind of resin adhesive and preparation method thereof

ActiveCN106883800BExtended shelf lifeAchieve low temperatureAldehyde/ketone condensation polymer adhesivesPtru catalystOrtho position

The invention provides a resin adhesive and a preparation method thereof. The resin adhesive is prepared from the following raw materials in percentages by weight: 30-50% of a formaldehyde solution, 10-25% of phenol, 10-20% of melamine-modified polyhydroxymethyl urea, 20-40% of lignin, 5-10% of a polyaldehyde cross-linking agent and 3-6% of a composite catalyst, wherein the mass concentration of the formaldehyde solution is 35-40%; and the composite catalyst comprises a mixture of one of zinc oxide, magnesium oxide, calcium hydroxide, barium hydroxide, potassium hydroxide and potassium carbonate, and sodium hydroxide. With the melamine-modified polyhydroxymethyl urea as the raw material, the storage stability of methylol urea is improved, the storage period of the resin adhesive is prolonged, the polymerization reaction of an ortho-response point with relatively poor activity in a phenol structure in the lignin is directionally promoted by the composite catalyst, and low-temperature fast solidification of the resin adhesive is achieved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

A kind of preparation method of graphene film with low energy consumption

ActiveCN111847431BReduce energy consumptionAchieve low temperatureChemical industryGrapheneGas phasePhysical chemistry

The invention discloses a preparation method of a graphene film with low energy consumption: (1) coal is converted into semi-coke and high-temperature volatile products through coal classification conversion under high temperature conditions in an oxygen-free atmosphere; (2) the high-temperature volatile products are separated and pre-processed (3) The gas-phase light component enters the graphene growth reaction system based on chemical vapor deposition method, and diffuses to the surface of the growth substrate in the system, and the light aromatic components in the gas-phase light component are obtained. The compound component is the carbon source, and the hydrogen-rich gas component in the gas phase light component is used as the production atmosphere to realize the synthetic growth of graphene on the surface of the growth substrate at a set temperature. The method uses coal as a carbon source, uses coal graded conversion technology to obtain gas-phase light compounds, and provides carbon precursors and a reducing growth atmosphere for the growth of CVD graphene, so that graphene can grow at low temperature and low energy consumption. Value-added utilization provides program reference.

Owner:ZHEJIANG UNIV

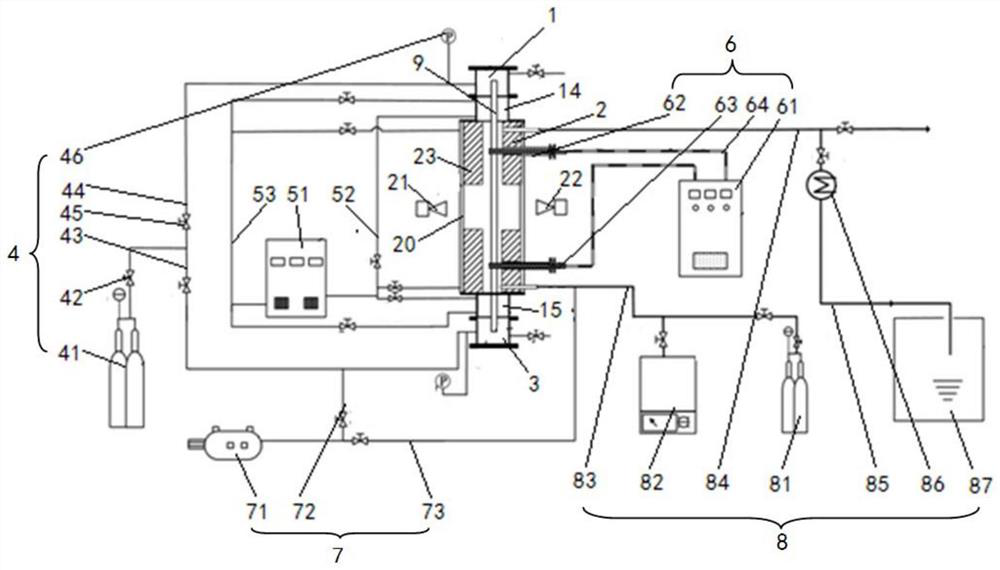

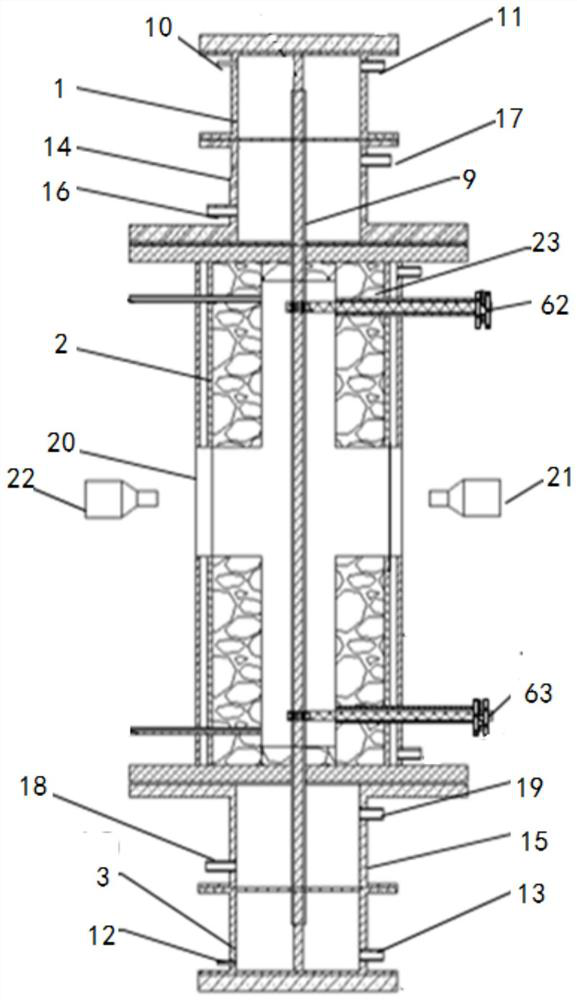

Reactor cladding blasting experiment system and experiment method

PendingCN114088540ARealize blasting experimentRealize any preset pressureMaterial strength using tensile/compressive forcesThermodynamicsWater vapor

The invention discloses a reactor cladding blasting experiment system and an experiment method. The system comprises a top gas chamber, a heating furnace, a bottom gas chamber, an inert gas pressurization unit, a water cooling unit, a heating unit, a vacuum unit and an atmosphere supply unit. The blasting experiments of the cladding in different environments, such as inert gas, water vapor, air, vacuum, etc., are achieved through the coordinated work of all the parts in the system, the blasting data of the cladding in different environments can be provided, and powerful data support is provided for the establishment of a cladding blasting criterion model.

Owner:NORTHWEST INST OF NUCLEAR TECH

Additive for silicon nitride sintered bodies

The invention discloses an additive for silicon nitride sintered bodies, which is prepared from the following components by weight percent: 29.5-65.2 percent of sintering aid and 34.8-70.5 percent of activating composite oxide, wherein the activating composite oxide is a compound formed by combining lithium oxide (Li2O), yttrium oxide (Y2O3), silicon dioxide (SiO2) and aluminium-containing compound. After the additive is added into a silicon nitride sintered body, the inter-granular phase components of a silicon nitride heating element is changed, the refractoriness of the silicon nitride sintered body sintered at normal pressure is enhanced, the mechanical property of the heating element at high temperature is improved and a heating element of the silicon nitride sintered body with the use temperature of 1,200-1,400 DEG C is obtained, the thermoconductivity is 21-32 W*m <-1>*K<-1>, the linear expansibility is 3.1*10<-6>-3.8*10<-6> / DEG C(40-800DEG C) and the density is over 98 percent. The invention realizes the normal-pressure low-temperature rapid-firing sintering of the silicon nitride heating element.

Owner:CHANGSHA SYNO THERM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com