Resin adhesive and preparation method thereof

A technology of resin adhesives and composite catalysts, applied in adhesives, adhesive types, aldehyde/ketone condensation polymer adhesives, etc., can solve problems such as high curing temperature, short storage period, and low production efficiency, and achieve The effect of increasing adhesive performance, increasing cross-linking density, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a preparation method of the resin adhesive described in the above technical solution, comprising the following steps:

[0060] (1) phenol, melamine-modified polymethylol urea and part of the composite catalyst are mixed, and the addition reaction obtains the mixture;

[0061] (2) the mixture that described step (1) obtains is mixed with formaldehyde aqueous solution and remaining composite catalyst, and condensation reaction obtains polymer;

[0062] (3) mixing the polymer obtained in the step (2) with lignin, and performing a polymerization reaction to obtain a resin;

[0063] (4) Mix the resin obtained in the step (3) with a polyaldehyde cross-linking agent, and perform a cross-linking reaction to obtain a resin adhesive.

[0064] In the present invention, there is no special limitation on the preparation device of the resin adhesive, and a reaction vessel well known to those skilled in the art can be used. In the embodiment of th...

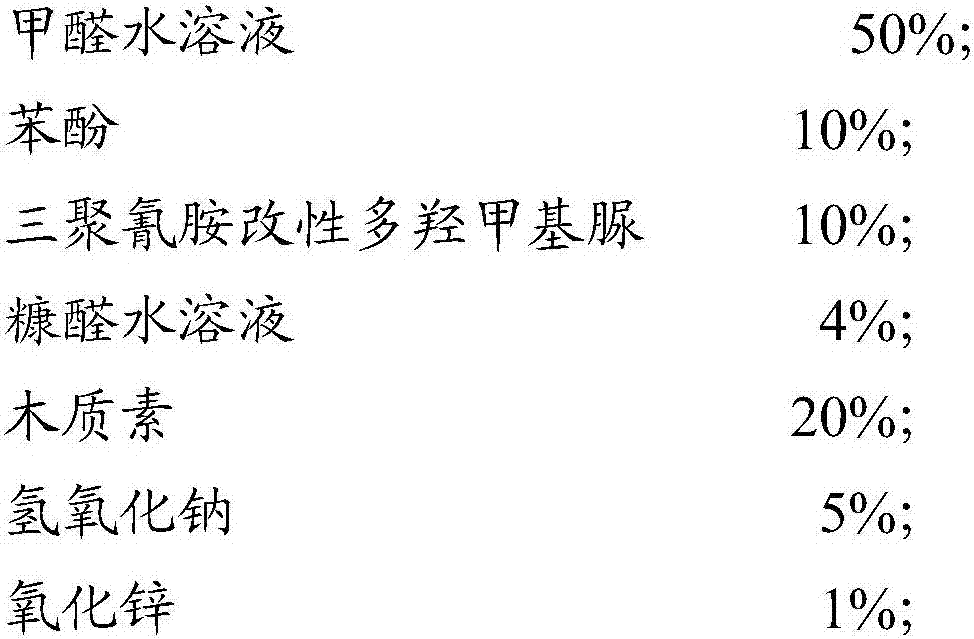

Embodiment 1

[0074] Taking the total mass of the adhesive raw material as 100%, the components and mass percentages in the raw material are as follows:

[0075]

[0076] The specific steps of preparation are as follows:

[0077] (1) Mix 10kg of urea, 21kg of formaldehyde and 0.5kg of polyvinyl alcohol evenly, add a 30% formic acid aqueous solution, adjust the pH value to 6.5, supplement the stirring mode speed and time value with mechanical stirring at a speed of 80r / min for 5min; Heat to 90°C, keep warm for 1 hour, add 6 kg of melamine, keep warm at 75°C until the viscosity of Tu 4 is 10 seconds, slowly cool down to 50°C, add 20% sodium hydroxide aqueous solution, adjust the pH value to 8.0, and react After 5 minutes, the temperature was lowered to 30° C., and the material was discharged to obtain polymethylol urea;

[0078] (2) Put 10kg of phenol and 10kg of polymethylol urea into the reactor, mix evenly, add 4kg of sodium hydroxide and 0.8kg of zinc oxide, react for 10 minutes and gra...

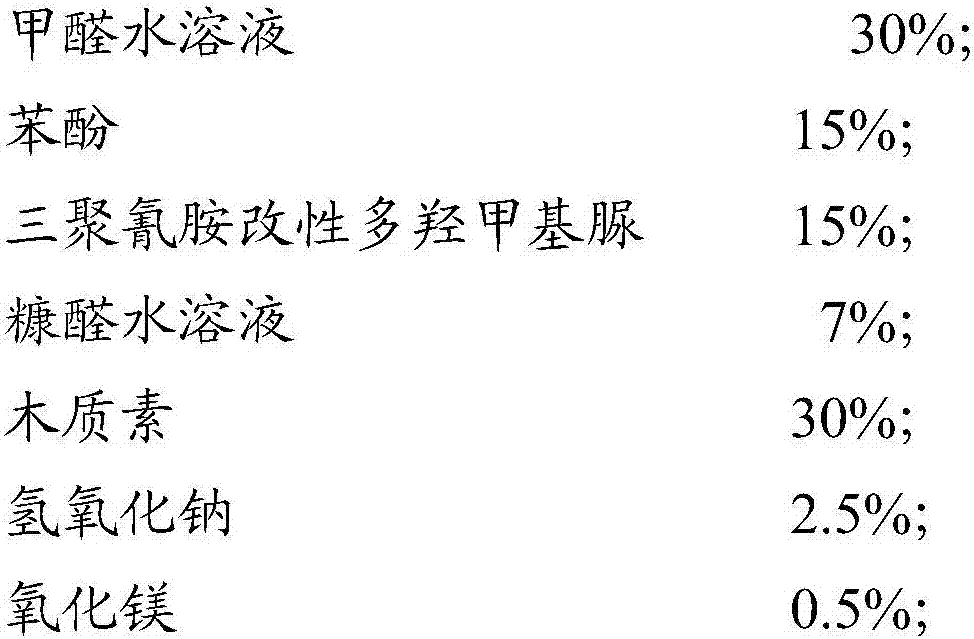

Embodiment 2

[0086] Taking the total mass of the adhesive raw material as 100%, the components and mass percentages in the raw material are as follows:

[0087]

[0088] The specific steps of preparation are as follows:

[0089] (1) Mix 10kg urea, 21kg formaldehyde and 0.5kg polyvinyl alcohol evenly, add 30% formic acid aqueous solution, adjust the pH value to 6.5, stir mechanically at a speed of 80r / min for 5min; heat to 90°C, and keep warm for reaction 1h, add 6kg of melamine, keep warm at 75°C until the viscosity of Tu 4 is 13 seconds, slowly cool down to 50°C, add 20% sodium hydroxide aqueous solution, adjust the pH value to 8.0, react for 5min, cool down to 30°C, Discharge, obtain polymethylol urea;

[0090] (2) 15kg of phenol and 15kg of polymethylol urea were put into the reactor, mixed evenly, 2kg of sodium hydroxide and 0.4kg of magnesium oxide were added, and after 10 minutes of reaction, the temperature was gradually raised to 90°C, and the reaction was kept for 20 minutes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com