Additive for silicon nitride sintered bodies

A sintered body and additive technology, applied in the field of heating element additives, can solve the problems of high sintering temperature, increase the cost of sintering equipment, limit the mass production of sintered body, etc., and achieve the effect of improving refractoriness and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

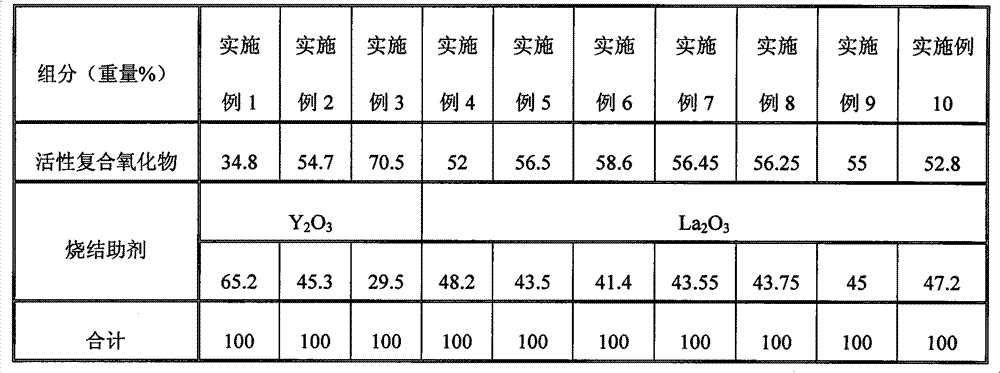

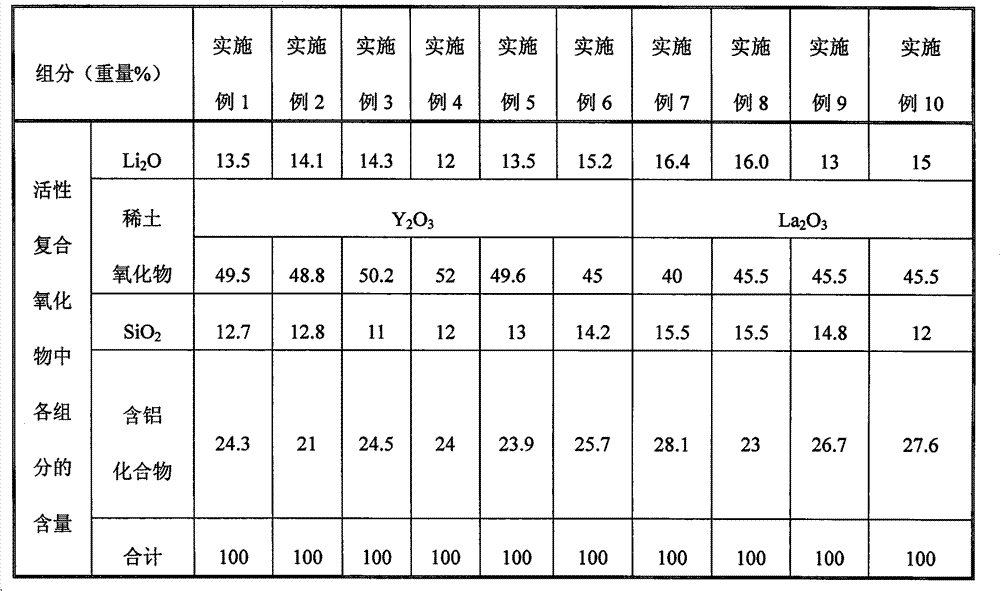

[0033] The preparation method of embodiment 1-10:

[0034] (1) Raw material configuration: According to the ingredients in Table 1, add absolute ethanol and silicon nitride balls, ball mill for 1 hour, and dry under the protection of nitrogen.

[0035] (2) Green body preparation: Process the mold according to the shape requirements of the heating element (150mm×30mm×5mm), and prepare the green body by using dry powder compression molding.

[0036] (3) Microwave sintering process: the green body enters the microwave sintering furnace continuously, and is continuously sintered under the protection of flowing nitrogen. The sintering temperature of the furnace body is shown in Table 1, and the atmosphere in the furnace is 102,325-102500Pa flowing nitrogen. The green body is sintered in this temperature range and released after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com