Preparation method of low-energy-consumption graphene film

A graphene film and low energy consumption technology, applied in the field of graphene film preparation, can solve the problems of increasing the technological complexity of the graphene growth process, equipment investment costs, and high graphene energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

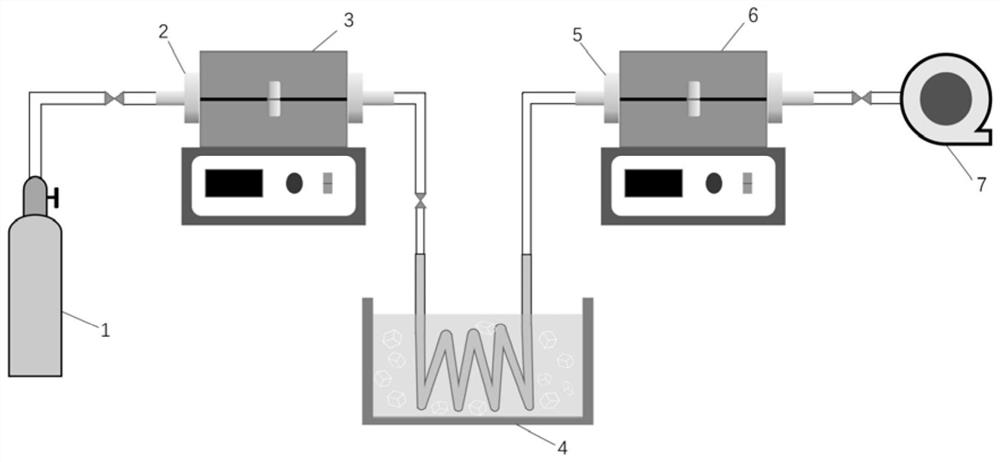

[0034] 1. Place the bituminous coal with a particle size of 6-8mm and the Cu thin substrate of graphene growth in the fixed bed reactor 2 for coal graded conversion in tube furnace and the graphene growth reactor 5 based on chemical vapor deposition (CVD).

[0035] 2. Configure cold trap cooling medium. The cold trap 4 uses a mixture of ethanol and dry ice as the cooling medium, pours the ethanol solution into the cold trap, adds dry ice to the ethanol solution in the cold trap, and adjusts the temperature of the cooling medium in the cold trap to -30°C by adding the amount of dry ice .

[0036] 3. Select the condensate recovery device for liquid phase heavy components and liquid phase light components in the bituminous coal graded conversion volatile products by the serpentine tube, and place the fixed bed reactor 2 with bituminous coal, the serpentine tube and the The graphene growth reactors on the base Cu foil were connected sequentially with flexible pipes, and the airti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com