Reducing ring rib water-cooling type surface combustion gas appliance

A surface combustion and gas device technology, applied in the direction of burner ignition device, burner, burner, etc., can solve the problems of poor low-nitrogen combustion effect, high cost, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

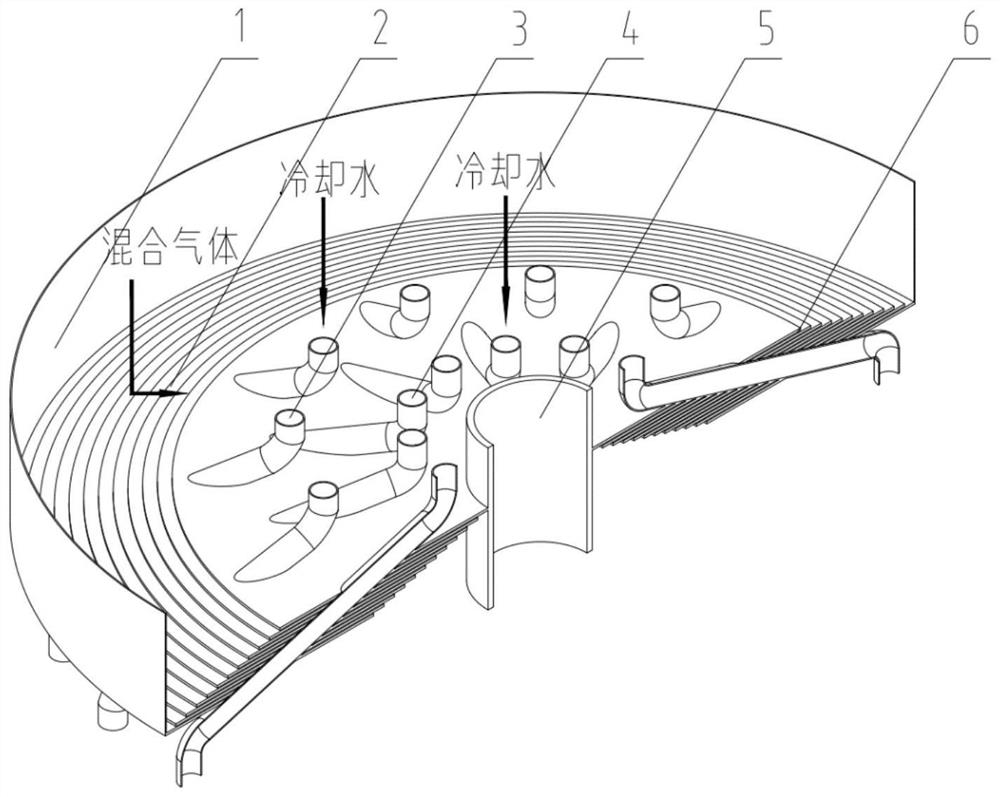

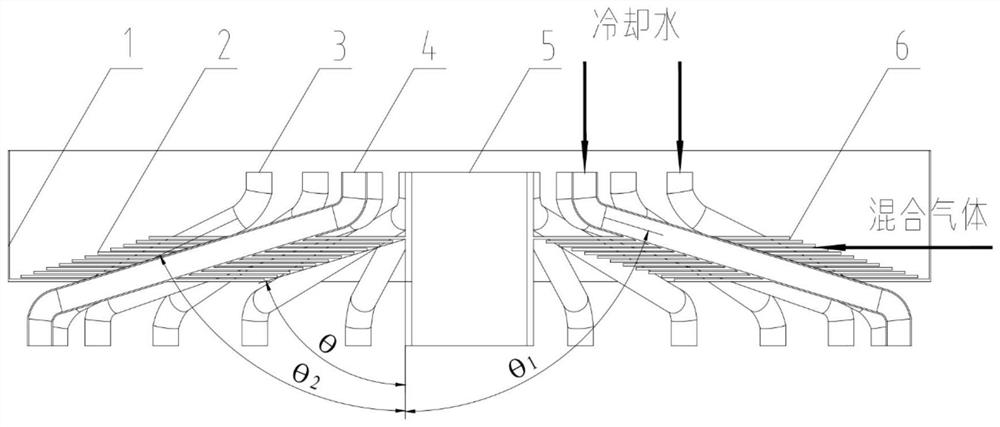

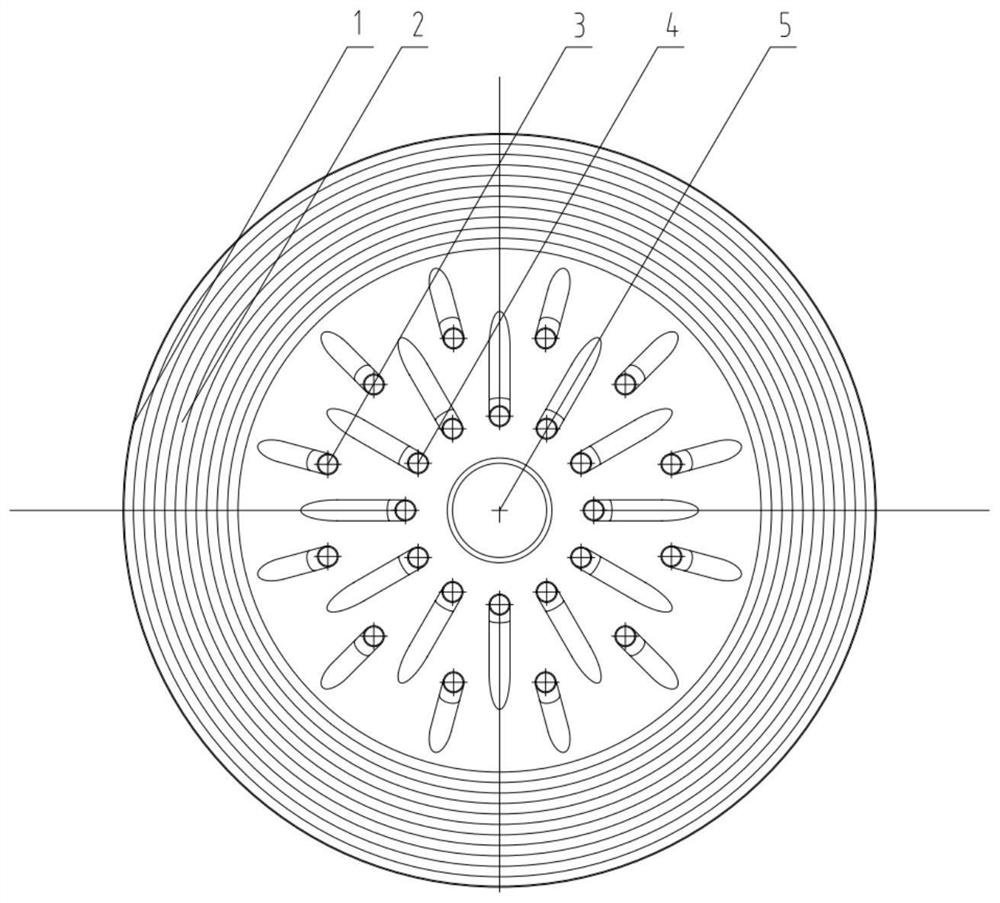

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Such as Figure 1-Figure 3 As shown: the water-cooled surface combustion gas device with ring ribs of different diameters, its main structure is that the mixed gas enters through the "ladder" shaped mixed gas inlet formed by multiple groups of ring ribs 2 of different diameters in the air intake cylinder 1, and then enters The gas cylinder 1 is installed outside the ring rib with the largest diameter; the first-stage ring cooling water pipe 4 and the second-stage ring cooling water pipe 3 are connected to multiple sets of different-diameter ring ribs 2 by welding to form a ribbed cooling system. Water pipes, the multiple groups of ring ribs 2 with different diameters are arranged at an angle of θ with the axis of the burner; the first-stage ring cooling water pipes 4 are arranged obliquely at equal intervals along the circumferential direction, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com