Polycarboxylic acid high-performance water reducing agent production and synthesis device and production process thereof

A synthesis device and water reducing agent technology, applied in the direction of feeding device, chemical/physical/physicochemical process, chemical/physical/physicochemical fixed reactor, etc. The quality of the water reducing agent, the molecular structure of the water reducing agent is not flexible, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

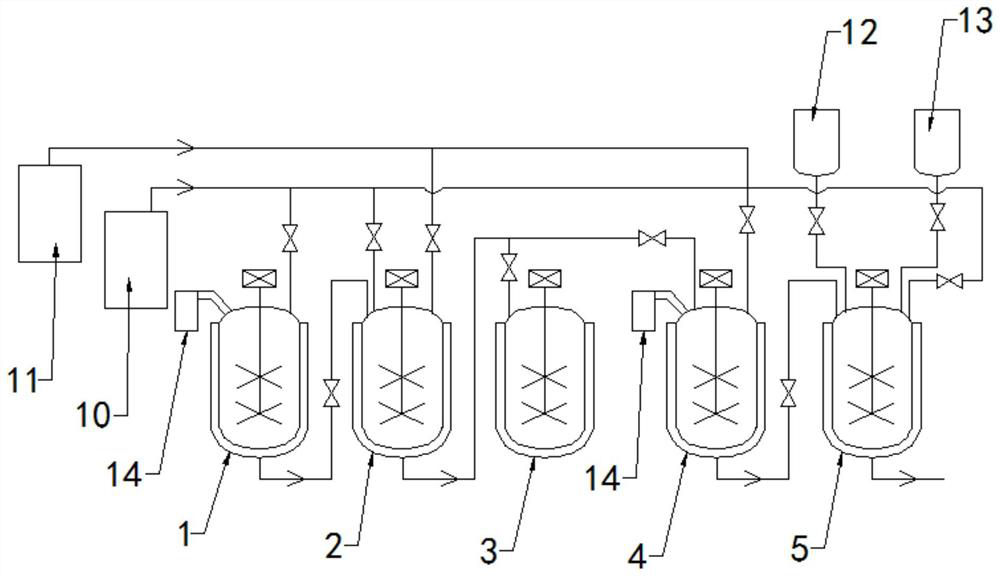

[0044] Such as figure 1 As shown, the present invention discloses a polycarboxylate high-performance water reducer production and synthesis device. In a specific embodiment of the present invention, it includes a polyether primary reaction kettle 1 and a polyether primary reaction kettle 2 connected in sequence. , polyether secondary reaction kettle 3, polyether secondary reaction kettle 4 and water reducer reaction kettle 5, and the polyether primary reaction kettle 1, polyether primary reaction kettle 2, polyether secondary The reactor 3, the polyether secondary reactor 4 and the water reducer reactor 5 are equipped with a stirring device for stirring materials and a temperature control device for controlling the reaction temperature, and also includes a storage tank for 4-hydroxybutyl vinyl ether. 4-hydroxybutyl vinyl ether storage tank 10 and ethylene oxide and butylene oxide storage tank 11 storing ethylene oxide and butylene oxide, the polyether primary pre-reactor 1, po...

Embodiment 2

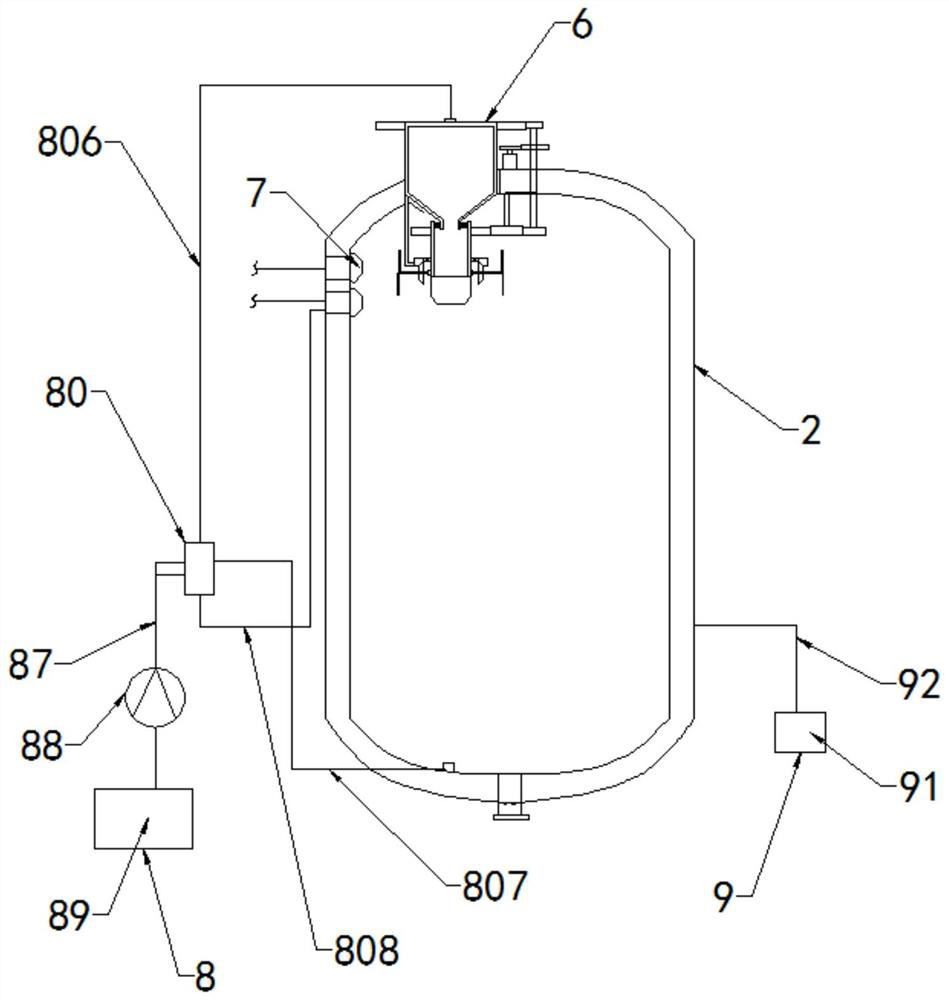

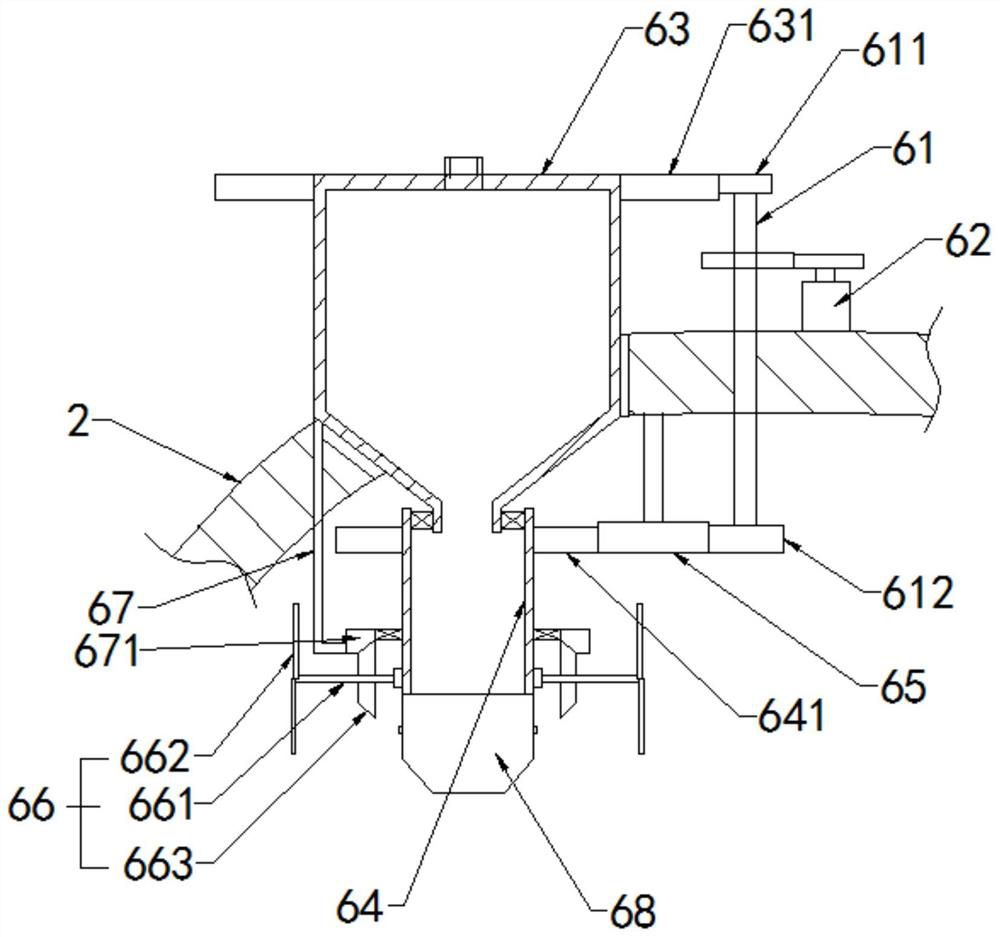

[0056] like figure 2 , Figure 9 and Figure 10 As shown, the difference between this embodiment and the above embodiment is that in this embodiment, a nitrogen replacement device is provided on the polyether primary reactor 2, and the nitrogen replacement device includes an air intake unit 8 and a pumping unit 8. Gas unit 9, the air intake unit 8 includes a nitrogen storage tank 89 storing nitrogen, a nitrogen delivery pipe 87 connecting the nitrogen storage tank 89 and the polyether primary reactor 2, and a delivery pump 88 installed on the nitrogen delivery pipe 87 And the quick exhaust valve 80 installed on the nitrogen delivery pipe 87, the output end of the quick exhaust valve 80 is multiple and communicated with the feed cylinder 63 and the spray nozzle 71 respectively; The suction pump 91 and the suction pipe 92 of the polyether primary reactor 2.

[0057] In this embodiment, the quick exhaust valve 80 is provided with a first valve port 801, a second valve port 80...

Embodiment 3

[0063] The invention also discloses a production process of polycarboxylate high-performance water reducer. In a specific embodiment of the invention, the following steps are included:

[0064] S1, primary synthesis, synthesis of 4-hydroxybutyl vinyl polyoxyethylene polyoxybutylene ether oligomer, specifically: open the discharge output end of the 4-hydroxybutyl vinyl ether storage tank, and feed polyether- Add a certain amount of 4-hydroxybutyl vinyl ether into the first-level pre-reactor, turn on the stirring device to stir, use the catalyst continuous feeder to add catalyst metal sodium into the first-level pre-reactor, and keep the temperature at a constant temperature through the temperature control device At room temperature, the primary pre-reactant is obtained; the original gas in the polyether primary reaction kettle is extracted by an air pump, and the temperature of the polyether primary reaction kettle is controlled by a temperature control device to rise to 90 ° C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com