Leak-proof bottle cap

An anti-leakage, bottle cap technology, applied in the directions of bottle/container cap, capping, bottle filling, etc., can solve the problems of inner plug plastic hardening, wine leakage, and wine fluctuation, so as to improve strength and reduce alcohol consumption. Fluid fluctuation and the effect of ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

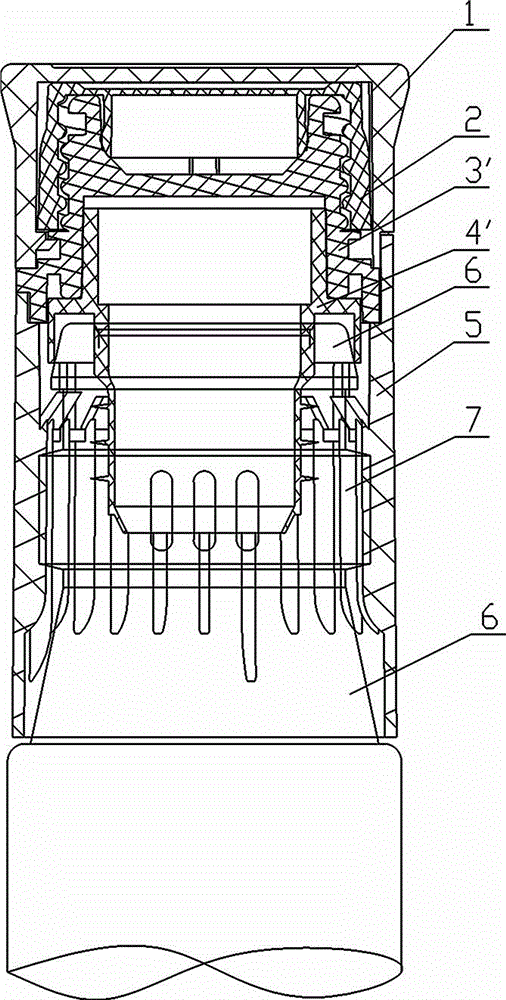

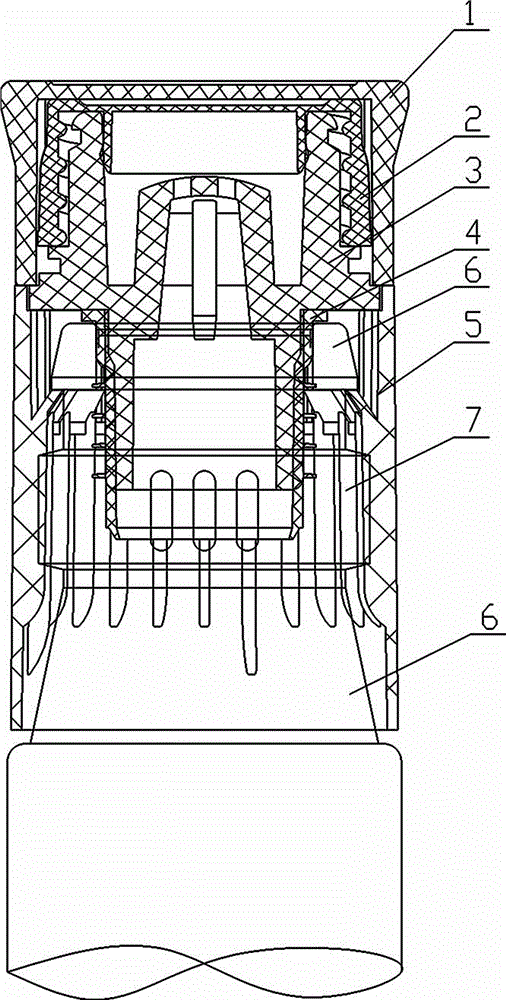

[0021] Such as figure 2 , 3 Among them, a leak-proof bottle cap includes a lower cap 5 fixed on the bottle mouth of the bottle body 6. In this example, the lower cap 5 is hooked on the bottle by a plurality of limit barbs 7 located in the lower cap 5. The step at the lower end of the outer wall of the mouth, so that the lower cover 5 cannot be disassembled after being installed, and it is not easy to rotate.

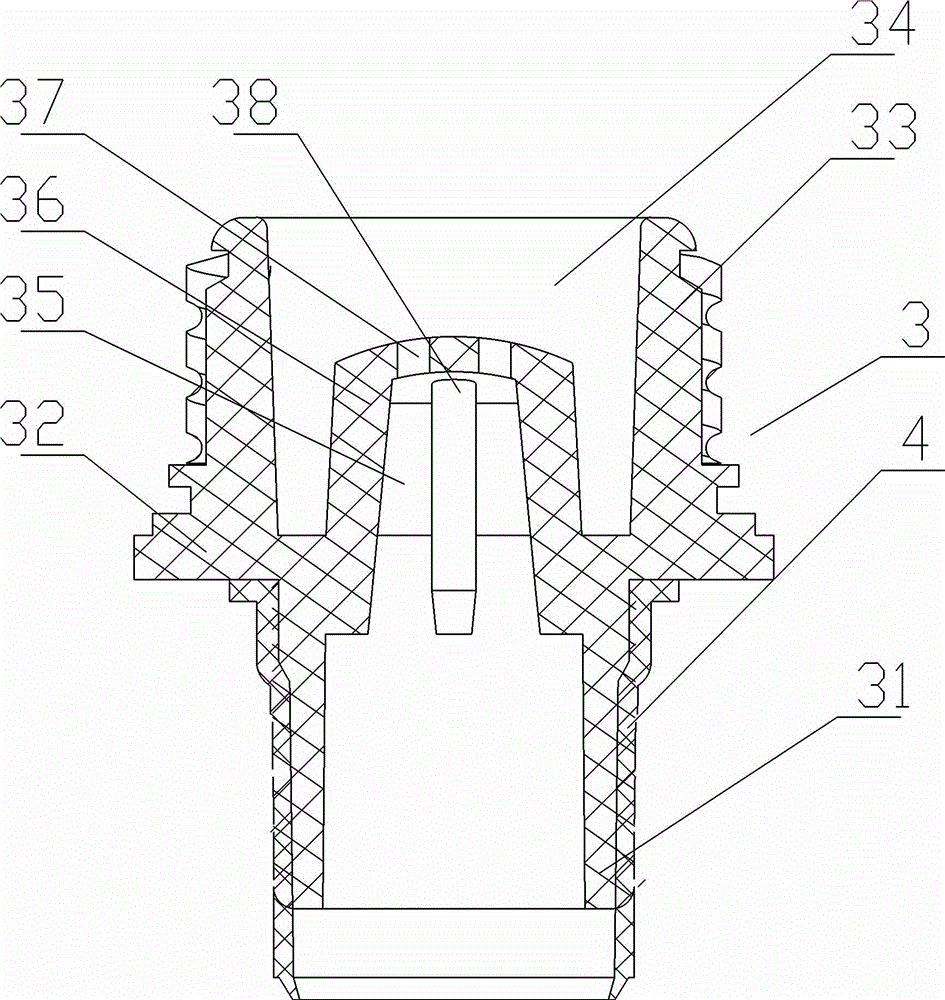

[0022] There is also an inner plug 4 located in the bottle mouth, and a through hole is provided in the inner plug 4. The extension 31 at the bottom of the bottle mouth 3 extends into the inner plug 4, and is interference fit with the inner plug 4. Preferably, the The outer wall of the inner plug 4 is provided with a plurality of sealing rings, and the depth of the extending portion 31 protruding into the inner plug 4 is at least greater than the depth of the inner plug 4 provided with the sealing rings. To ensure that the inner plug 4 is pressed against the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com