Urea mixing device

A mixing device and urea technology, which is applied in the direction of muffler, exhaust device, exhaust treatment, etc., can solve the problems of low crystallization risk of gas flow rate distribution uniformity, poor gas flow rate distribution uniformity, urea crystallization, and poor mixing uniformity, etc., to achieve Good mixing effect, high mixing uniformity, good swirling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

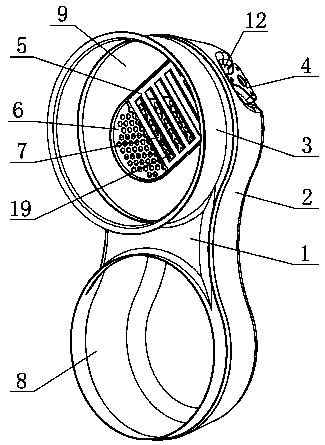

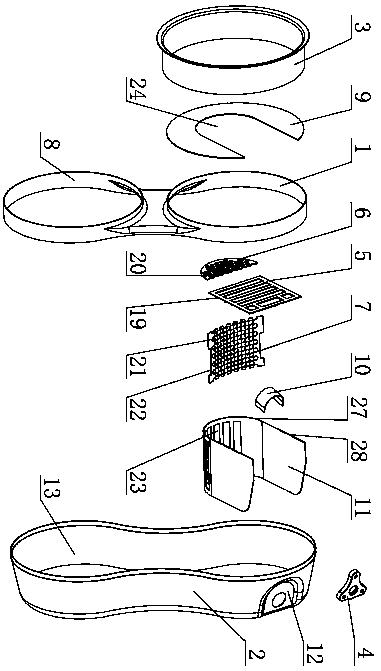

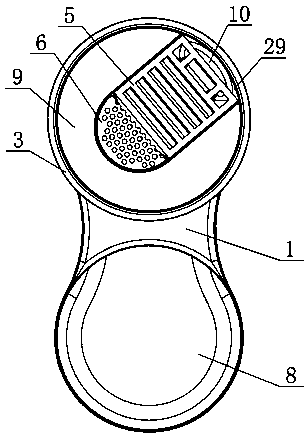

[0042] Such as figure 1 As shown, the front shell 1 of the present invention is fixed on the rear shell 2, and an internal cavity 13 is formed between the front shell 1 and the rear shell 2, and the left and right sides of the middle part of the front shell 1 and the rear shell 2 respectively face the internal cavity 13 is concave inward to form a waist structure, and the overall cross-section of the present invention along the longitudinal axis is in the shape of a peanut shell. The upper part of the front housing 1 is equipped with an air intake cylinder 3 , and the lower part has a cylindrical air outlet 8 , and the air intake cylinder 3 and the air outlet 8 communicate with the internal cavity 13 . Such as figure 2 As shown, a U-shaped partition 11 is fixed between the front casing 1 and the rear casing 2, and the partition 11 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com