Nozzle specially used for preparing transparent conductive film by using ultrasonic quick precipitation method

A technology of transparent conductive film and deposition method, which is applied in the manufacture/processing of superconductor devices, jetting devices, jetting devices, etc., can solve the problems of poor jetting uniformity, zebra strip uniformity, etc. Easy, pressure-even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

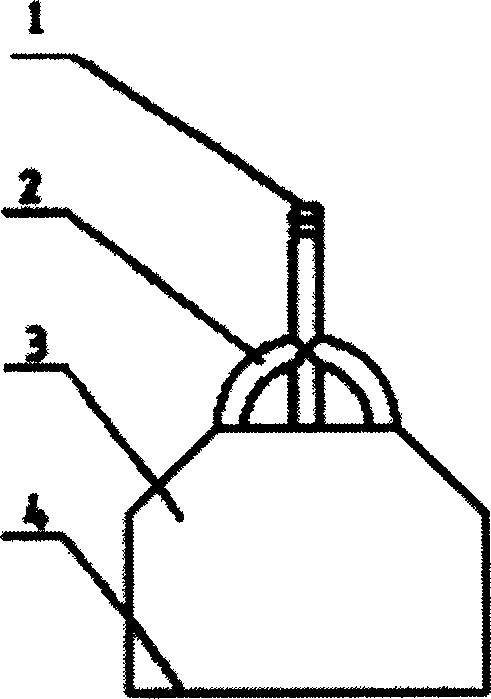

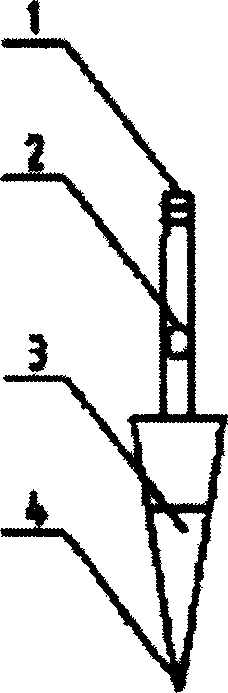

[0017] The special nozzle for preparing transparent conductive film by ultrasonic rapid deposition method, which includes air inlet, air inlet pipe, nozzle, and nozzle; out;

[0018] Its characteristic is: the chemical solution is atomized by the ultrasonic spraying method, and after entering the nozzle 3 evenly through the air inlet 1 and the air inlet pipe 2, it is finally sprayed evenly on a surface of 20×20cm through the nozzle. 2 on a large area glass substrate.

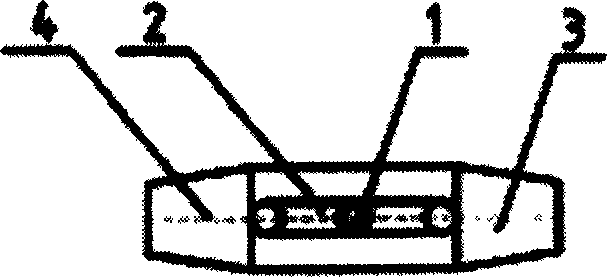

[0019] The nozzle height is 150mm, the width is 200mm, the thickness is 5mm, the nozzle is a slit orifice, and the area of the nozzle slit is 20×1.5mm 2 .

[0020] The upper part of the nozzle is designed with a slope. The ratio of the volume of the nozzle 3 to the area of the nozzle 4 determines the pressure of the nozzle 4. The atomized gas can be sprayed on a uniformly moving and heated glass substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com