Liquid resin composition for electronic part sealing and electronic part apparatus utilizing the same

A technology of electronic components and liquid resins, applied in the direction of electrical components, electrical solid devices, semiconductor/solid device parts, etc., can solve the problems of reduced adhesion, difficulty in adjusting curing, accelerating curing, etc., and achieve thermal shock resistance Excellent performance, excellent fillet weld formation, shortening gel time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

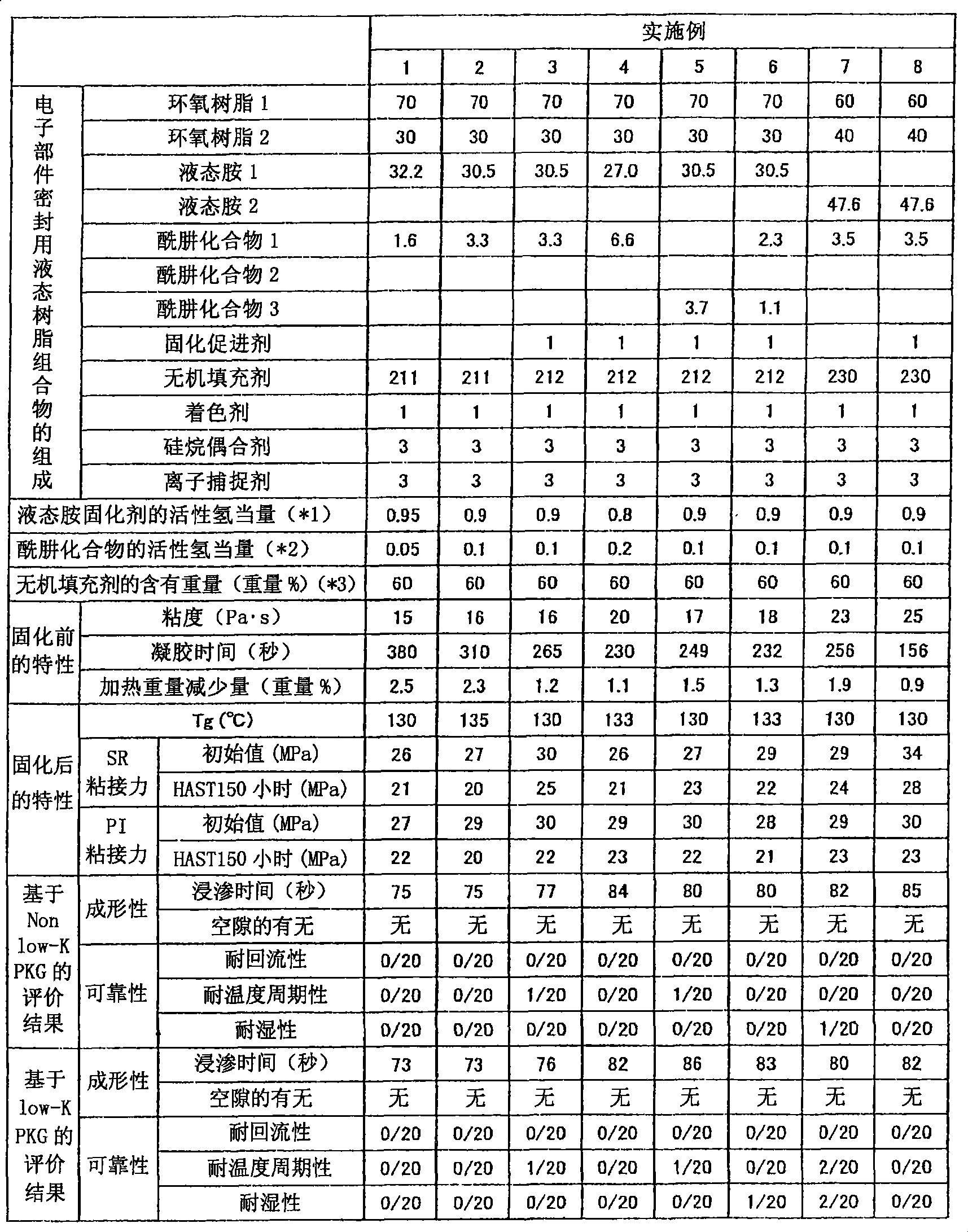

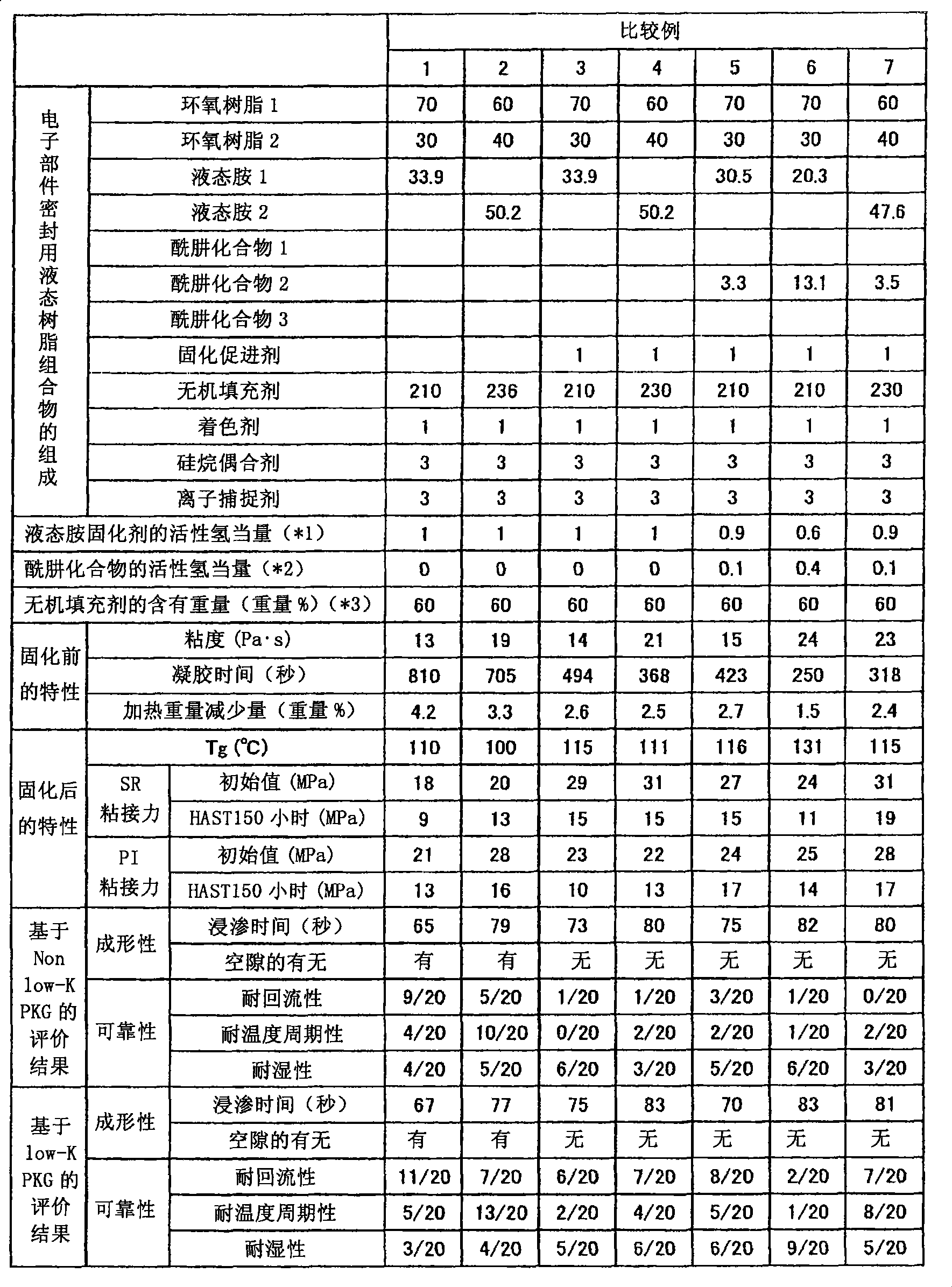

Embodiment 1~8、 comparative example 1~7

[0119] Mix the following ingredients according to the compositions (parts by weight) shown in the following Tables 1 to 2 respectively, knead and disperse them with three rollers and a vacuum attritor, and then prepare electronic components of Examples 1 to 8 and Comparative Examples 1 to 7. Liquid resin composition for sealing parts.

[0120] The liquid resin compositions for electronic component sealing of Examples 1-8 and Comparative Examples 1-7 were evaluated by various characteristic tests of said (1)-(11). The evaluation results are shown in Tables 1 to 2 below. Also, blank columns in the table indicate no fit.

[0121] For each component in the table, the following substances were used.

[0122] (epoxy resin)

[0123] Epoxy resin 1: a liquid diepoxy resin having an epoxy equivalent of 160 obtained by epoxidizing bisphenol F (manufactured by Tohto Chemical Co., Ltd., trade name "YDF-8170C")

[0124] Epoxy resin 2: a trifunctional liquid epoxy resin (manufactured by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com