Patents

Literature

95results about How to "Less supporting equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

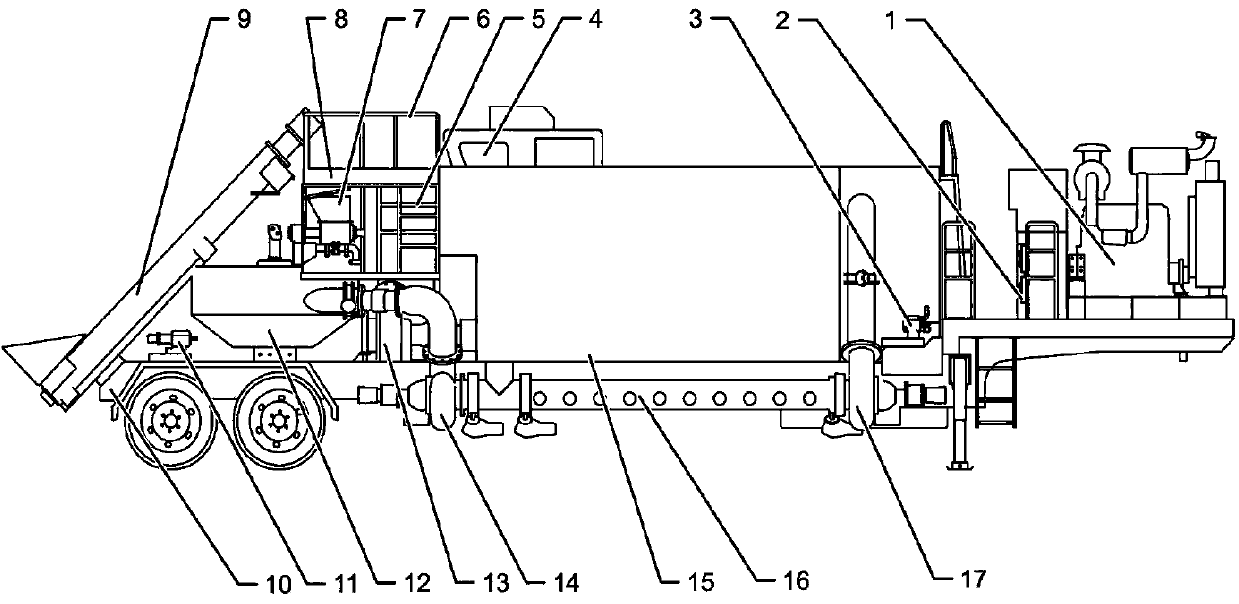

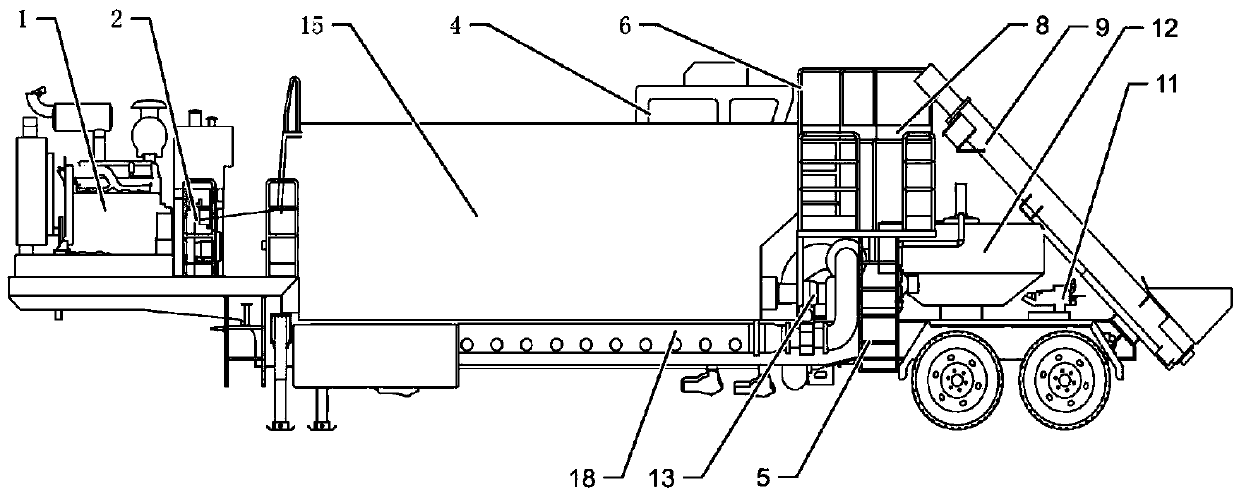

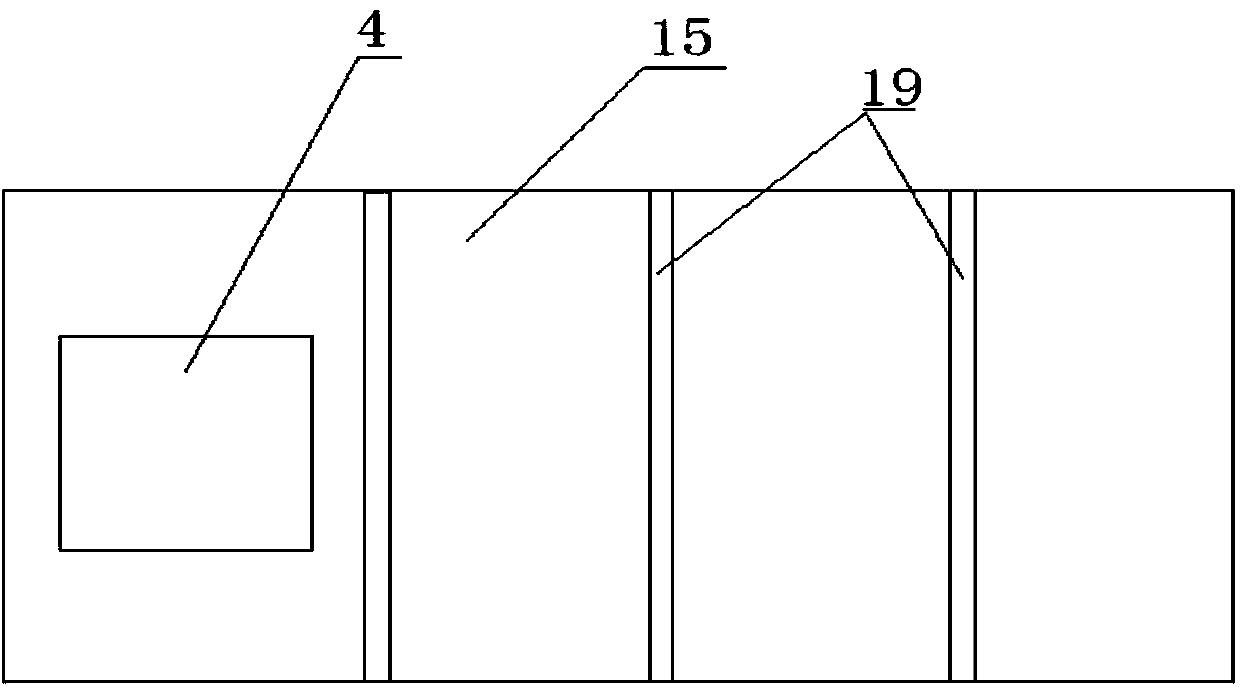

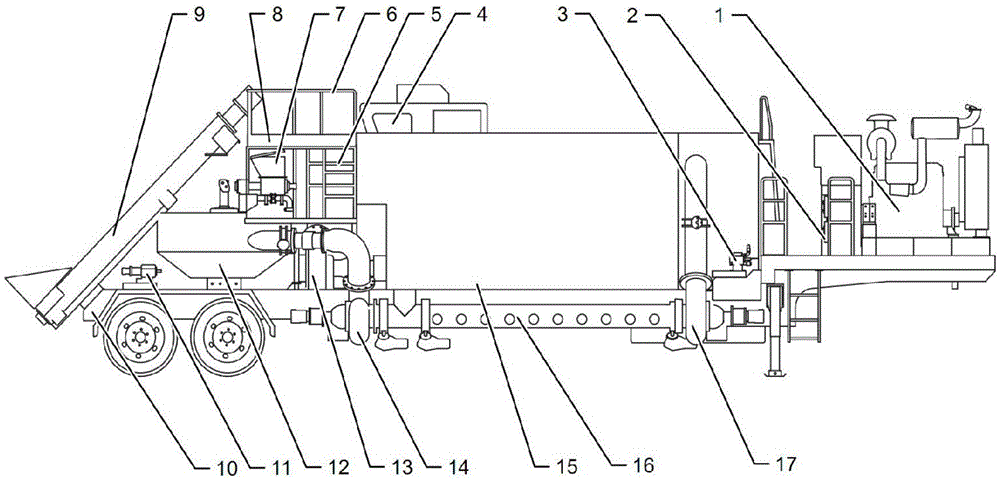

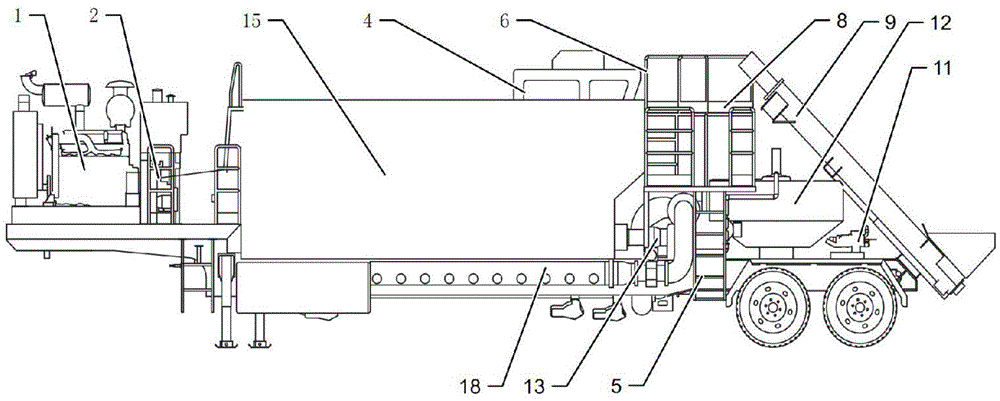

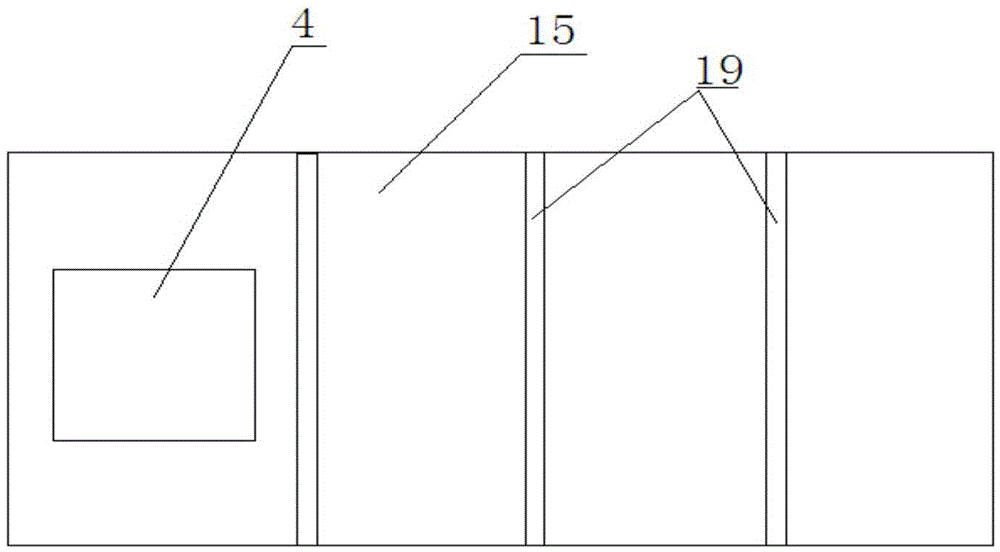

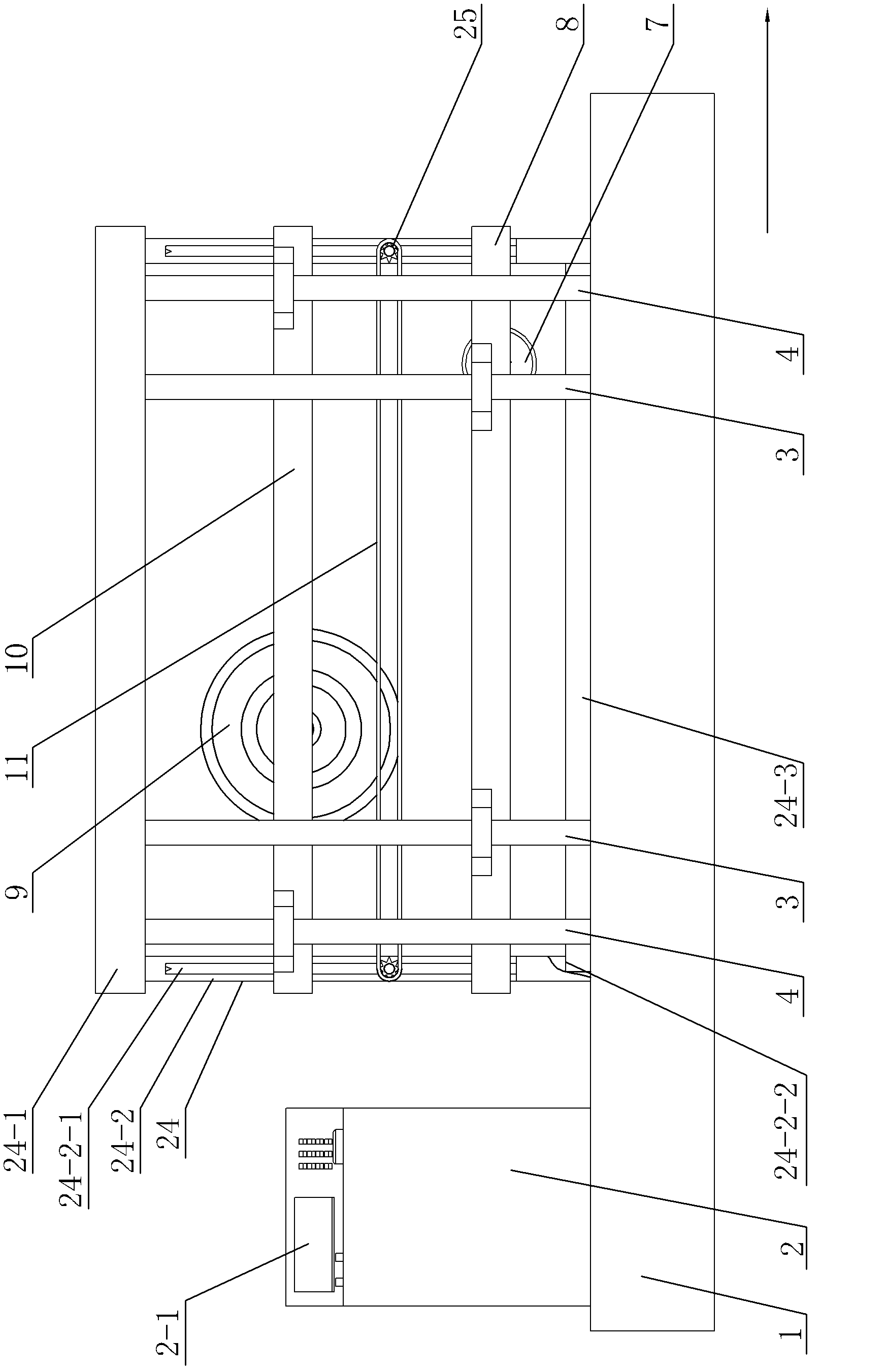

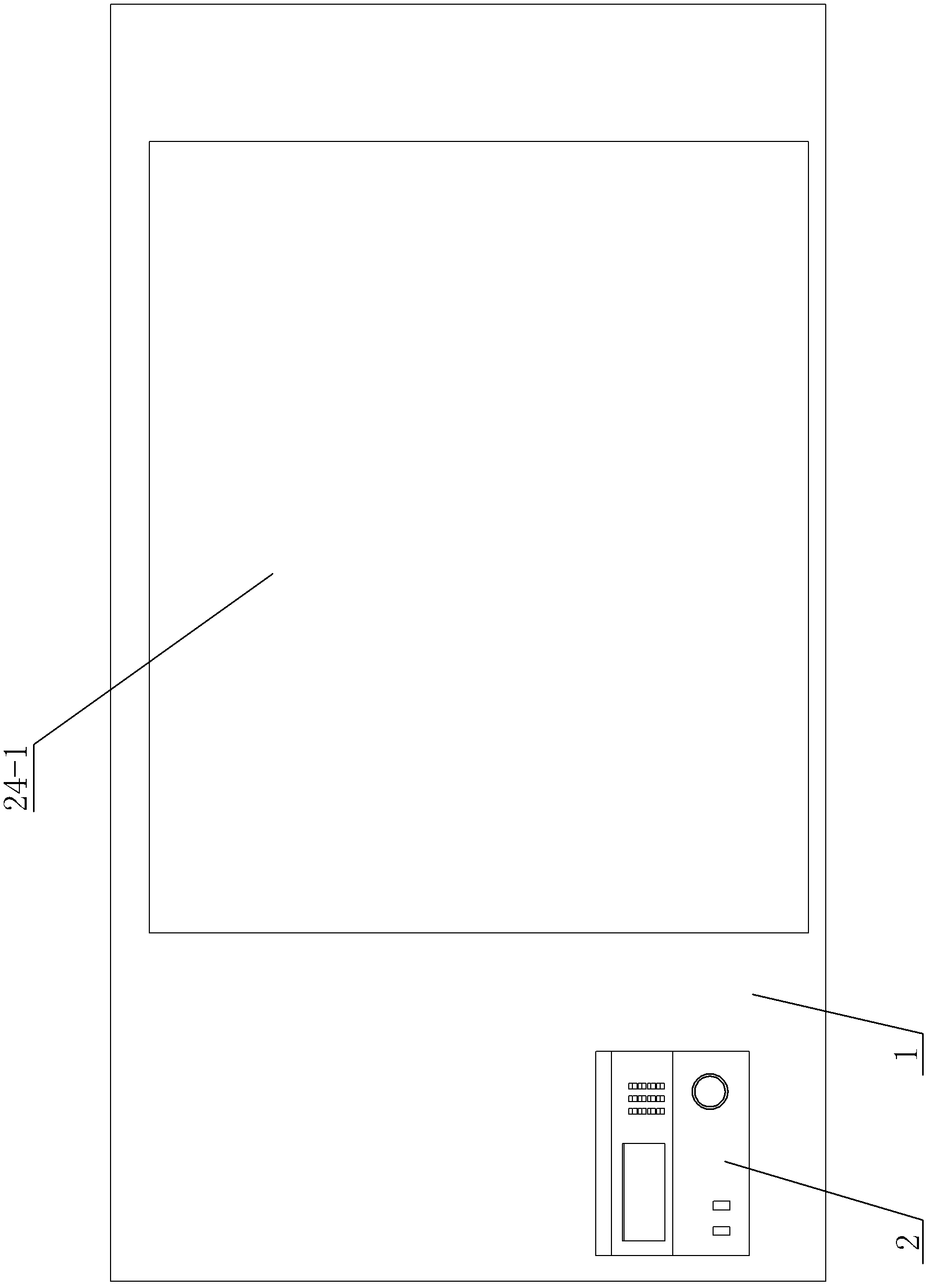

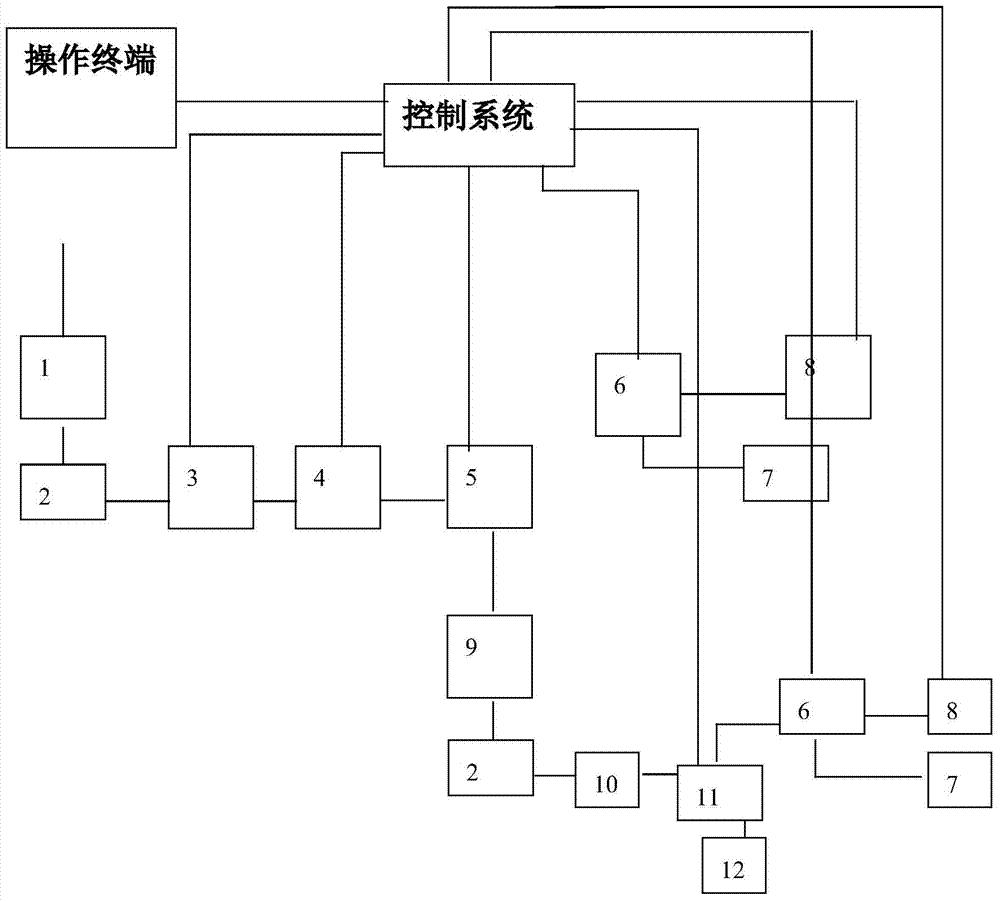

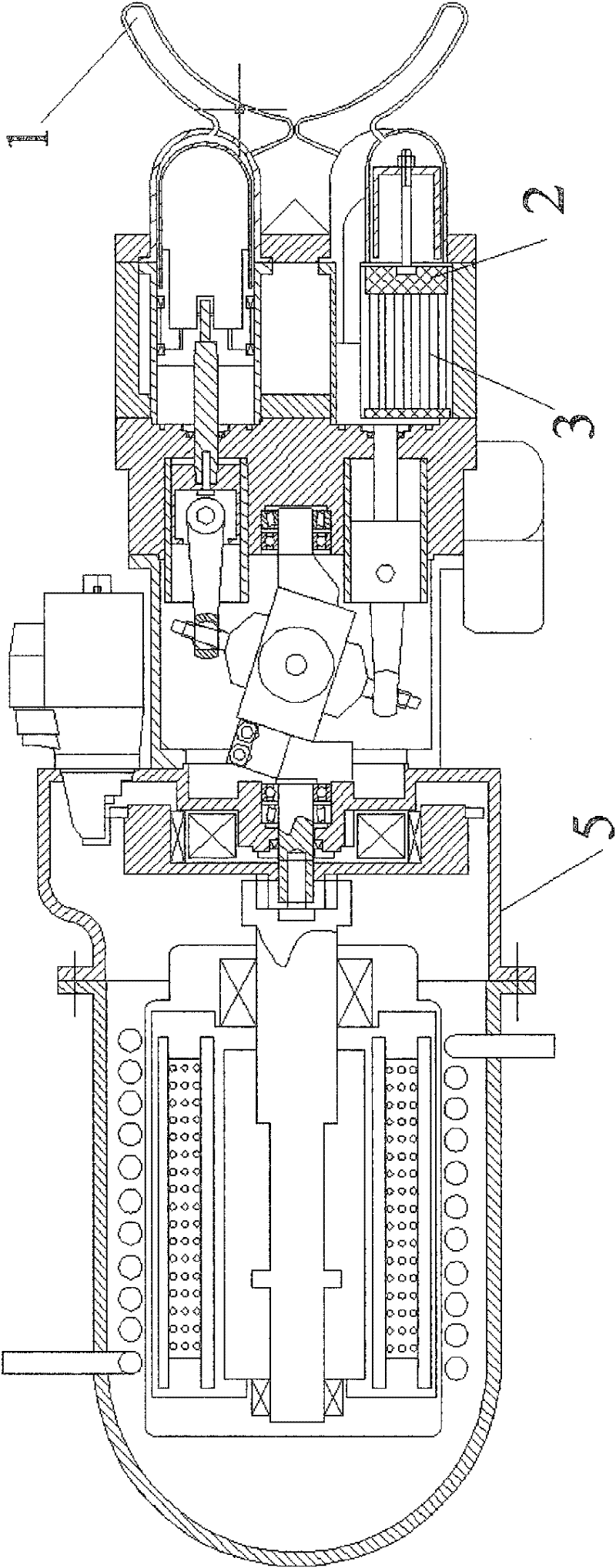

Fracturing fluid mixing and sand mixing semitrailer

ActiveCN103993869ALess supporting equipmentReduce workloadFluid removalTractor-trailer combinationsFracturing fluidHydraulic pump

The invention relates to a fracturing fluid and sand mixing semitrailer, and belongs to the field of fracturing devices for oil field work. The fracturing fluid and sand mixing semitrailer comprises a semitrailer body, a hydraulic system and an electrical control system. The hydraulic system comprises a hydraulic oil tank, at least one hydraulic pump and a hydraulic multi-way valve. An engine, the hydraulic system, the electrical control system, a lifting control chamber, a spiral conveyor, a clean water suction centrifugal pump, a fracturing fluid suction centrifugal pump, a stirring machine, a discharge centrifugal pump, a liquid adding pump, a dry powder adding device and a concentrated guanidine gum adding pump are integrated on the semitrailer body. The work steps of conducting glue solution mixing after fracturing liquid mixing is conducted and discharging the glue solution to a downward fracturing device can be conducted by operating the electrical control system to drive the hydraulic pump through an operator, and therefore work steps of oil field work are highly integrated, matched devices are reduced, workloads of working staff are reduced, and construction quality is ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

A fracturing fluid mixing sand mixing semi-trailer

ActiveCN103993869BReduce workloadLess supporting equipmentFluid removalTractor-trailer combinationsFracturing fluidHydraulic pump

The invention relates to a fracturing fluid and sand mixing semitrailer, and belongs to the field of fracturing devices for oil field work. The fracturing fluid and sand mixing semitrailer comprises a semitrailer body, a hydraulic system and an electrical control system. The hydraulic system comprises a hydraulic oil tank, at least one hydraulic pump and a hydraulic multi-way valve. An engine, the hydraulic system, the electrical control system, a lifting control chamber, a spiral conveyor, a clean water suction centrifugal pump, a fracturing fluid suction centrifugal pump, a stirring machine, a discharge centrifugal pump, a liquid adding pump, a dry powder adding device and a concentrated guanidine gum adding pump are integrated on the semitrailer body. The work steps of conducting glue solution mixing after fracturing liquid mixing is conducted and discharging the glue solution to a downward fracturing device can be conducted by operating the electrical control system to drive the hydraulic pump through an operator, and therefore work steps of oil field work are highly integrated, matched devices are reduced, workloads of working staff are reduced, and construction quality is ensured.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

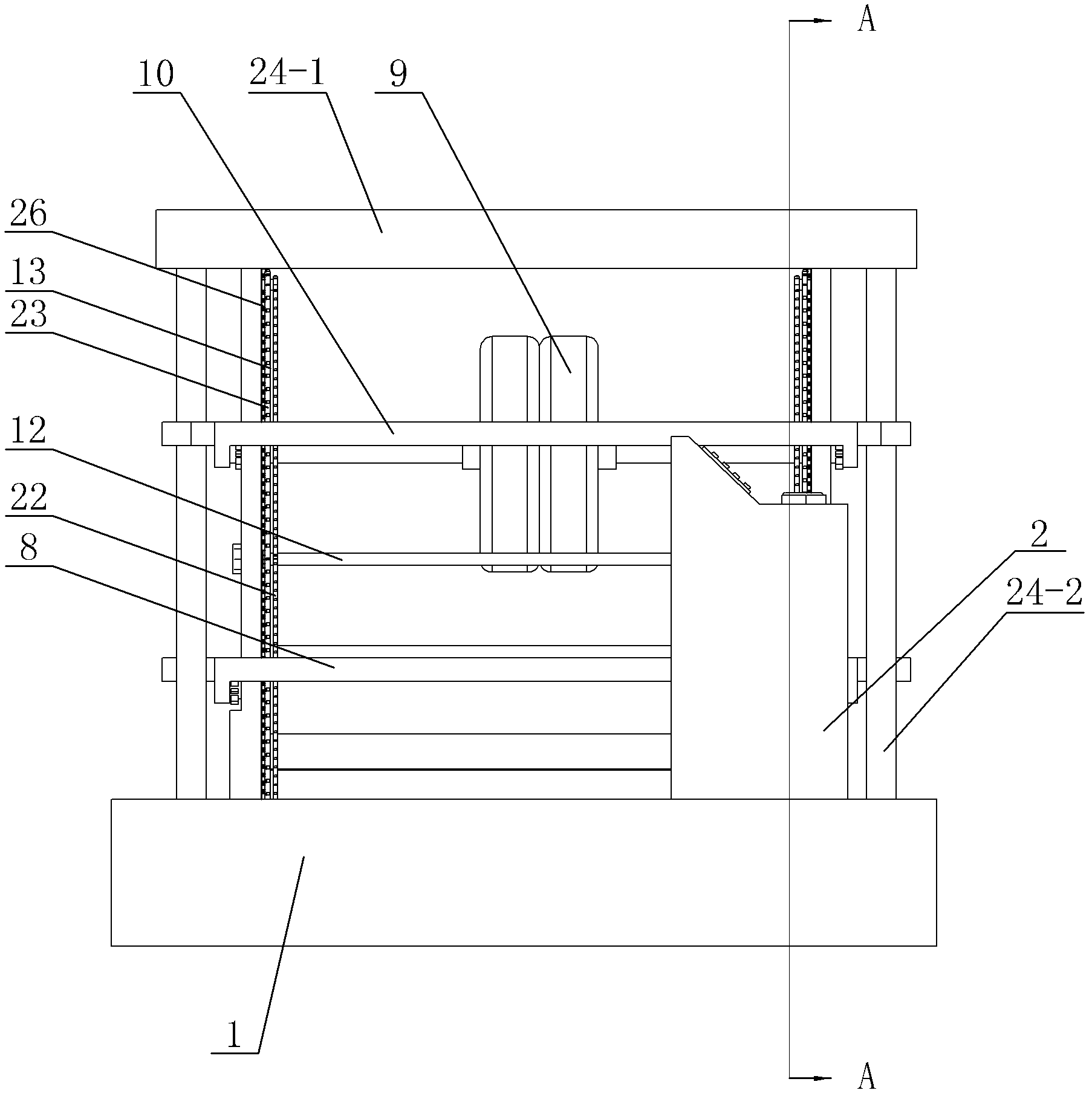

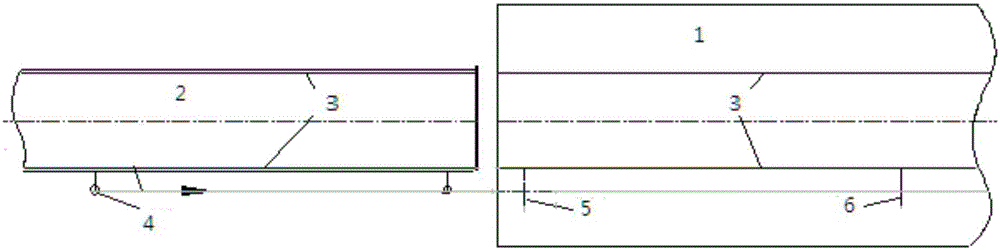

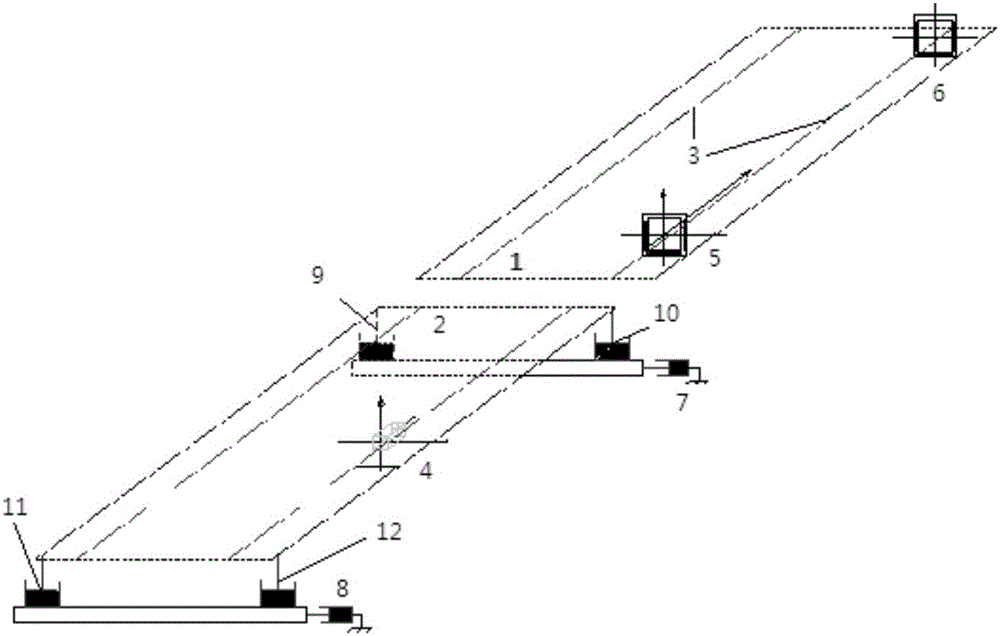

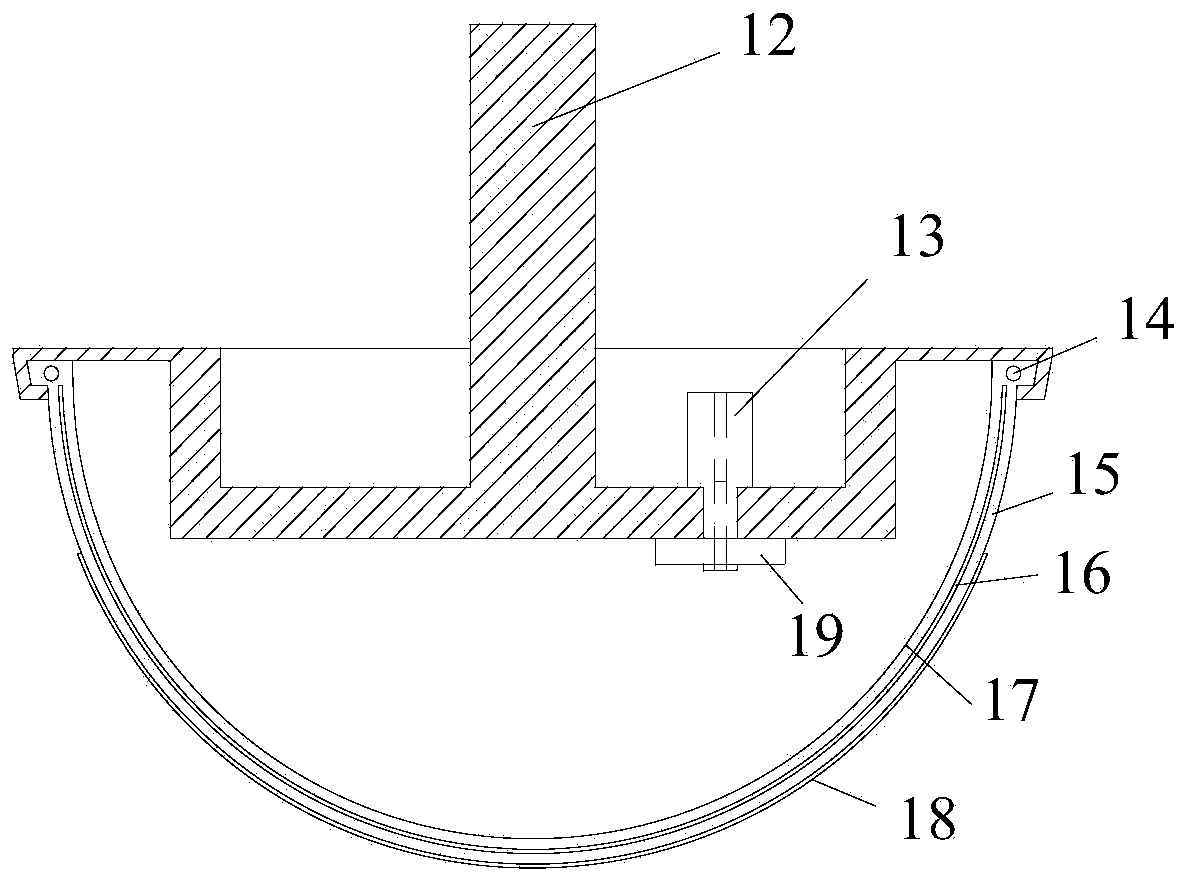

Accelerated loading test device for small full-size asphalt pavement

ActiveCN102607974AReflects anti-rutting performanceReduce trafficMaterial strength using repeated/pulsating forcesHorizontal transmissionMotor drive

An accelerated loading test device for a small full-size asphalt pavement relates to an accelerated loading test device for a full-size asphalt pavement, aiming at the problems of impossibility of accurately simulating the actual stress state of an asphalt pavement in an indoor wheel tracking test, as well as large equipment size, long test period, high test expense and complex operation process in an outdoor full-size pavement accelerated loading test. A two-way motor drives a drive big gear and a driven big gear to rotate; a transmission cross rod disposed on a rack is fixedly sleeved with a force-transferring pinion, as well as sleeved with a force-transferring big gear, a lifting gear and a transition chain wheel engaged with an annular horizontal transmission chain in a suspension manner; the force-transferring big gear and the force-transferring pinion are engaged with an annular vertical inner transmission chain and an annular vertical outer transmission chain; the lifting gear is engaged with a lifting guide rail; the movements of a rolling steel wheel and a loading wheel group are driven via the annular horizontal transmission chain; the up-and-down movement of a rectangular-frame steel wheel loading beam is driven via an inner oil pressure pump; and the up-and-down movement of a rectangular-frame wheel group loading beam is driven via an outer oil pressure pump. The invention is used for the accelerated loading test for the full-size asphalt pavement.

Owner:HARBIN INST OF TECH

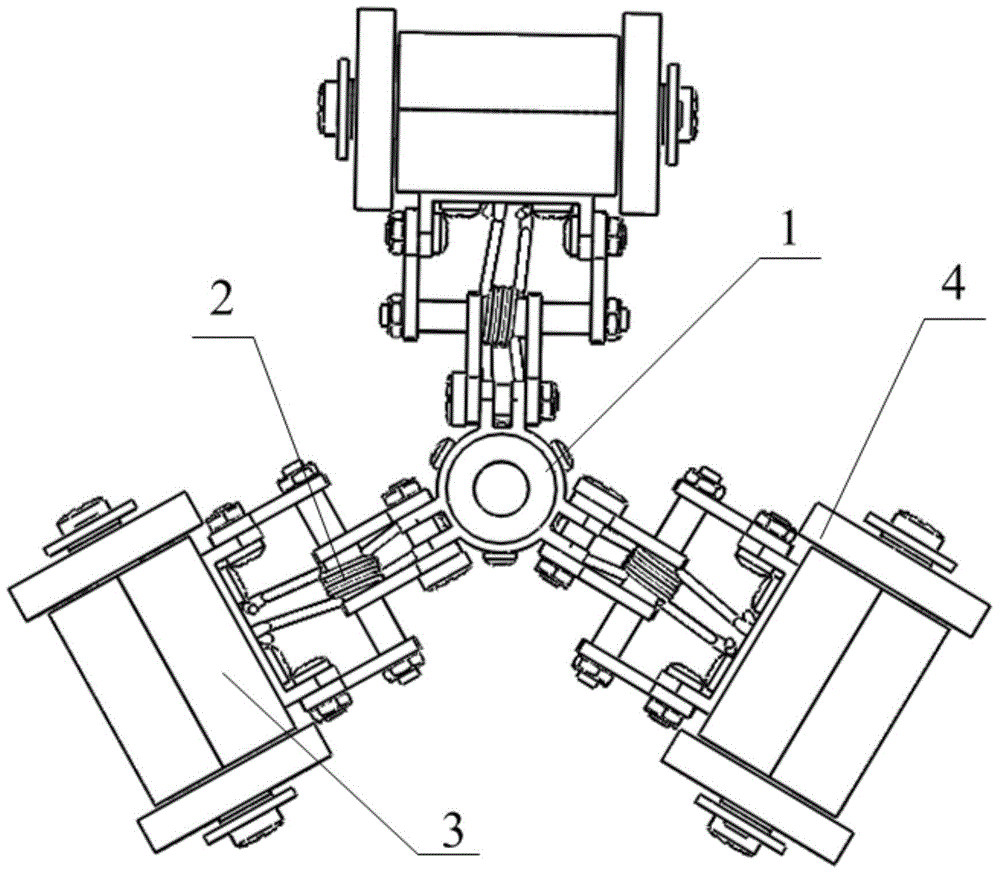

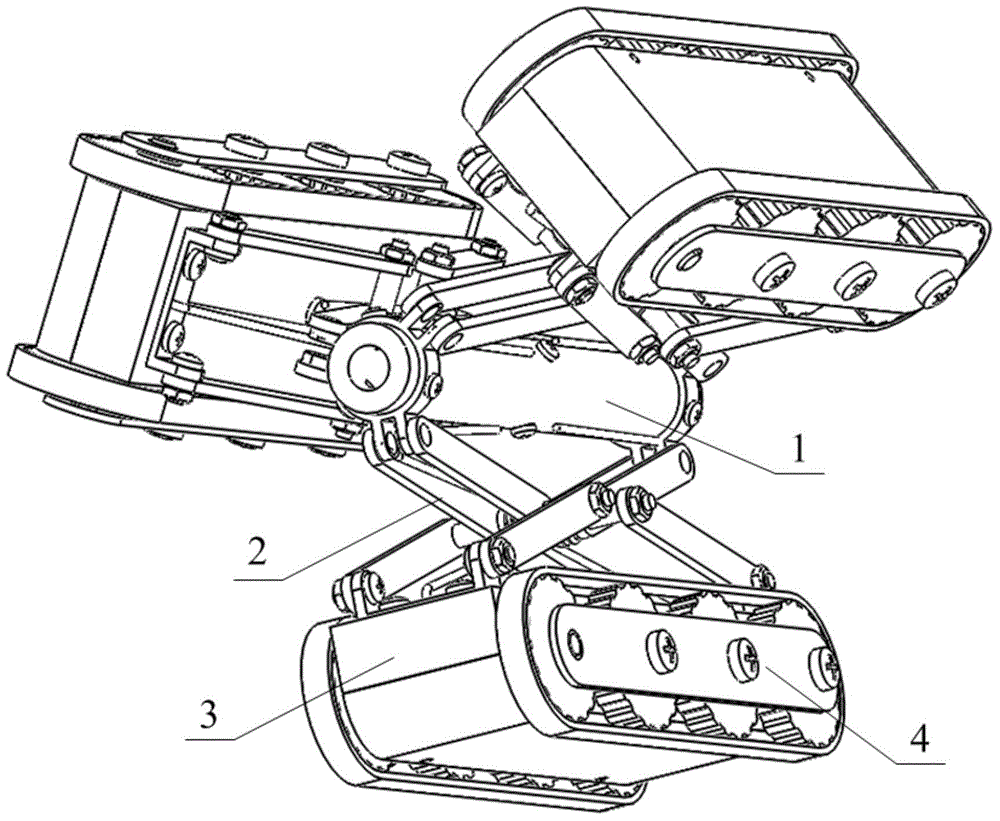

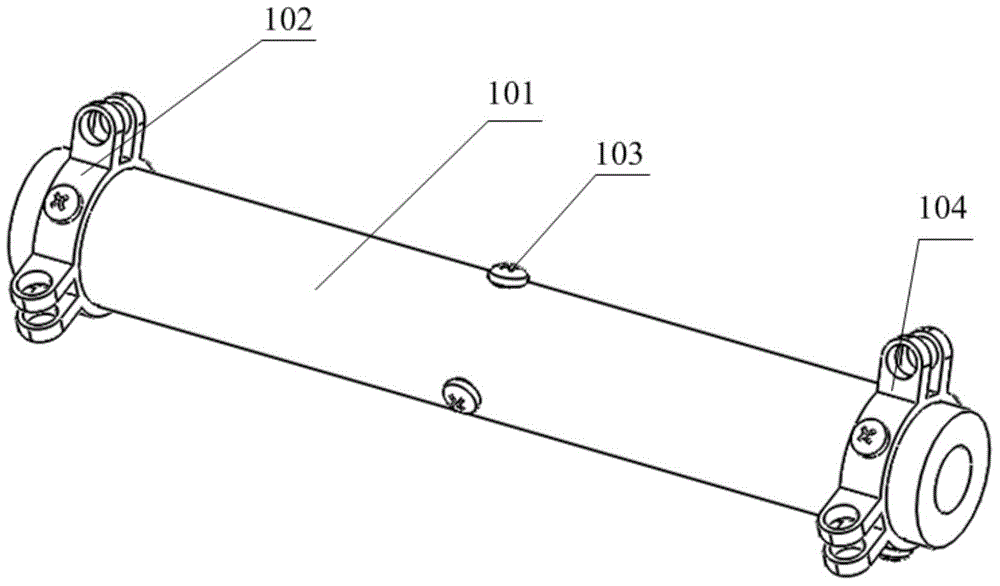

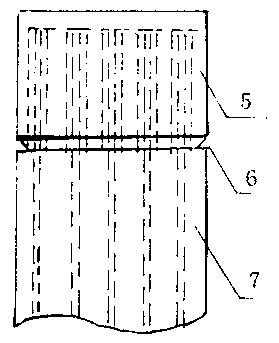

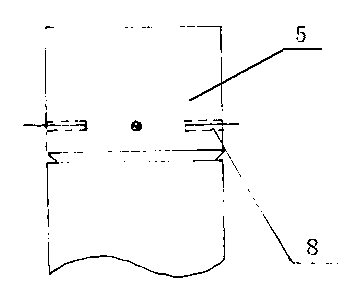

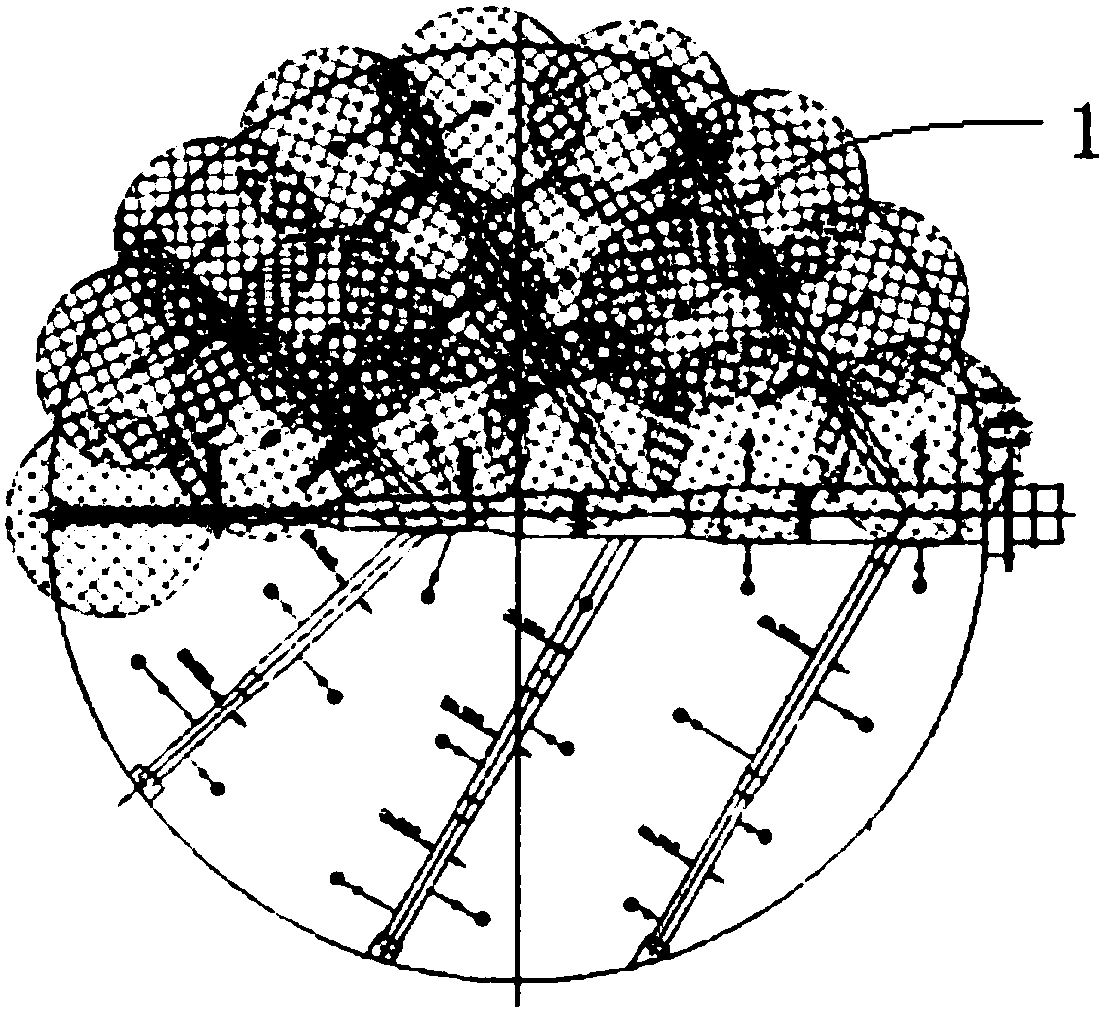

Pipeline moving mechanism with self-adaption function

The invention belongs to the field of mechanical automation engineering, and particularly relates to a pipeline moving mechanism with a self-adaption function. A plurality of motor driving mechanisms are distributed uniformly on the circumference of a central fixing component; each motor driving mechanism is connected with the central fixing component through a spring folding mechanism; driving module pedrail wheel systems are installed on both sides of each motor driving mechanism; the radial distance between the motor driving mechanisms and the central fixing component is changed through extension and extraction of the spring folding mechanism so as to adapt pipelines of different diameters; the pipeline moving mechanism moves in pipelines of different diameters under the driving of the motor driving mechanisms; and the driving module pedrail wheel systems on two sides of at least one motor driving mechanism abut against the inner wall of a pipeline in the moving process all the time. According to the pipeline moving mechanism with the self-adaption function, the structure is simple and compact; few corollary devices are required and the operation is easy; and the pipeline moving mechanism can adapt pipelines of different diameters, advance and retreat in the pipelines and sheer as the pipelines bend.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

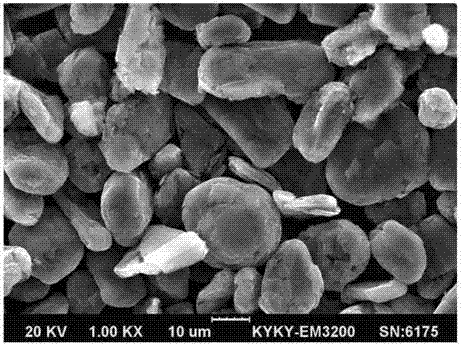

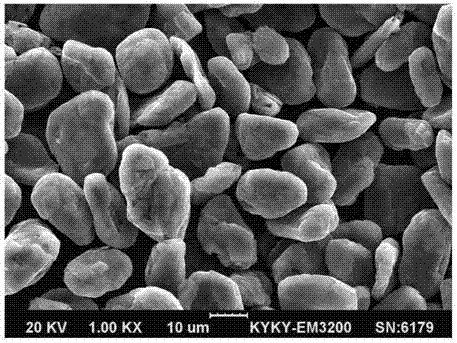

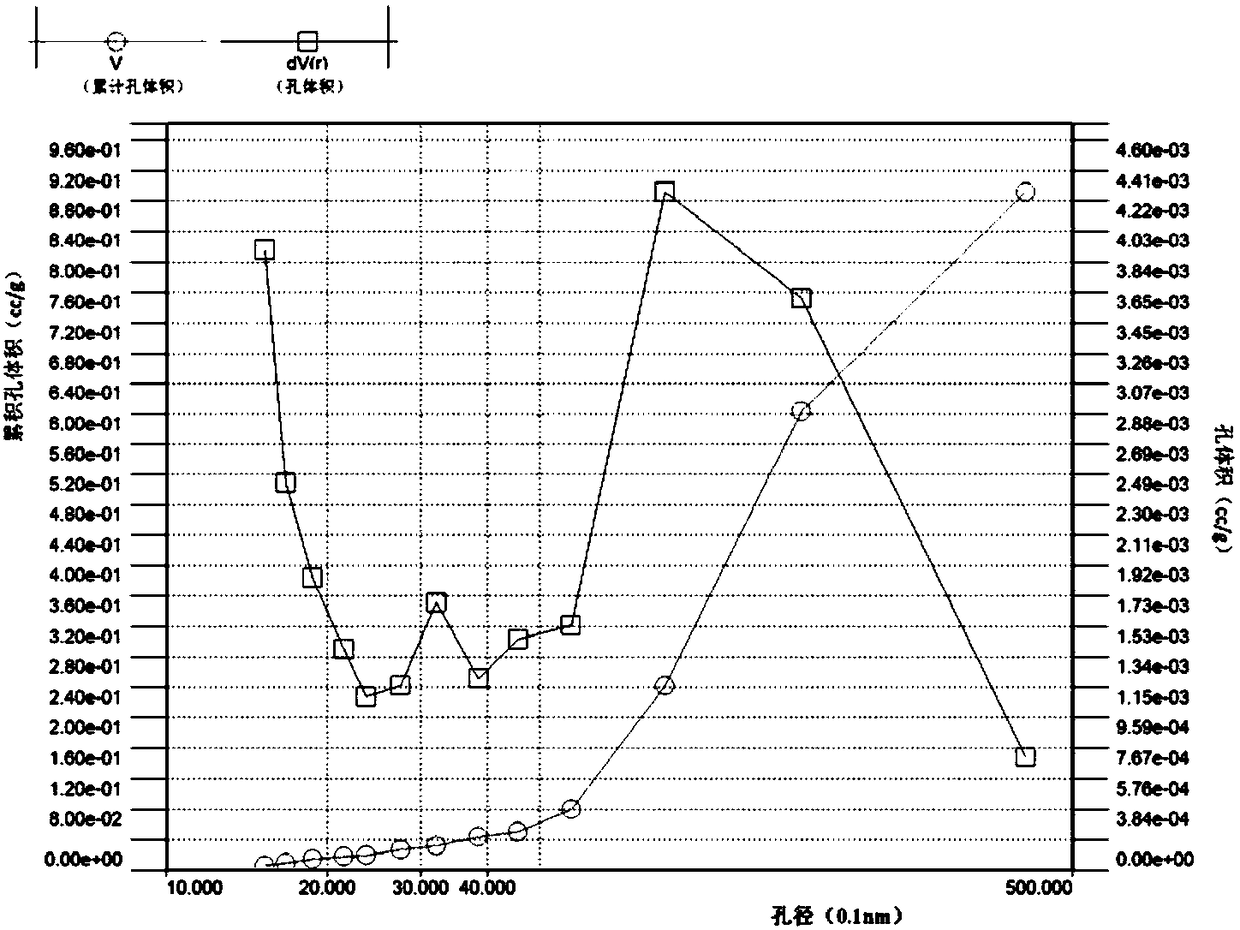

Lithium ion battery carbon negative electrode material grinding shaping technological process and production system thereof

ActiveCN103904302AHigh degree of automationIncrease productivityElectrode manufacturing processesCarbon compoundsElectrical batteryPulverizer

The invention provides a lithium ion battery carbon negative electrode material grinding shaping technological process. The process comprises the following steps: step one, feeding graphite in an inner grading ultra-fine grinding pulverizer, wherein particles with qualified sizes automatically flow out along with airflow under the rotation of an inner grading turbine, and coarse particles fall in a pulverizing area for continuous pulverizing until the particle sizes are qualified; and step two, enabling graphite powder with qualified particle diameters obtained in the step one to flow in a centrifugal classifier along with the airflow, wherein the powder with the particle size of smaller than 35 microns is discharged to a cyclone batcher from an airflow classifier material exhaust hole for collection, and coarse powder is discharged out from a return feeding hole. The ultra-fine grinding pulverizer with an inner grading device is adopted for replacing a plurality of airflow pulverizers to realize ultra-fine grinding, so that qualified fine powder is classified and extracted in time, over crushing is prevented, the product yield is improved, and the production yield is more than 90%.

Owner:ZHANJIANG JUXIN NEW ENERGY +1

Method for recovering alkali and organic substance from pomace and waste liquid

InactiveCN1450227ADischarge volume reductionReduce total pollutionRegeneration of alkali lyeLiquid wasteAdditional values

The method for covering alkali and organic substance from pulp waste liquor includes the following steps: under the condition of that temp. is 20-60 deg.c and pressure is 1.5-3.0 MPa the pulp waste liquor is passed through the fixed membrane separation system to make separation to obtain the trapped liquor in which the concentration of organic substance is 90g / l and transmitted liquor containing sodium hydroxide, said transmitted liquor containing sodium hydroxide can be recovered, and can be used in pulp production, and the described trapped liquor containing organic substance can be evaporated and concentrated, and can be used for preparing products with high additional value after it is treated by means of modification process.

Owner:凯能高科技工程(上海)有限公司

Processing process of squid rings

The invention belongs to the food processing field, and specifically relates to a processing process of squid rings. The processing process of the squid rings with delicious taste and rich nutrition is provided. The processing process comprises the steps of checking and accepting raw material squids, unfreezing, removing heads, removing hearts, washing, cutting into rings, shaping, starching, powdering, arranging in a plate, freezing, packaging to obtain a finished product and warehousing for storing.

Owner:廖雨薇

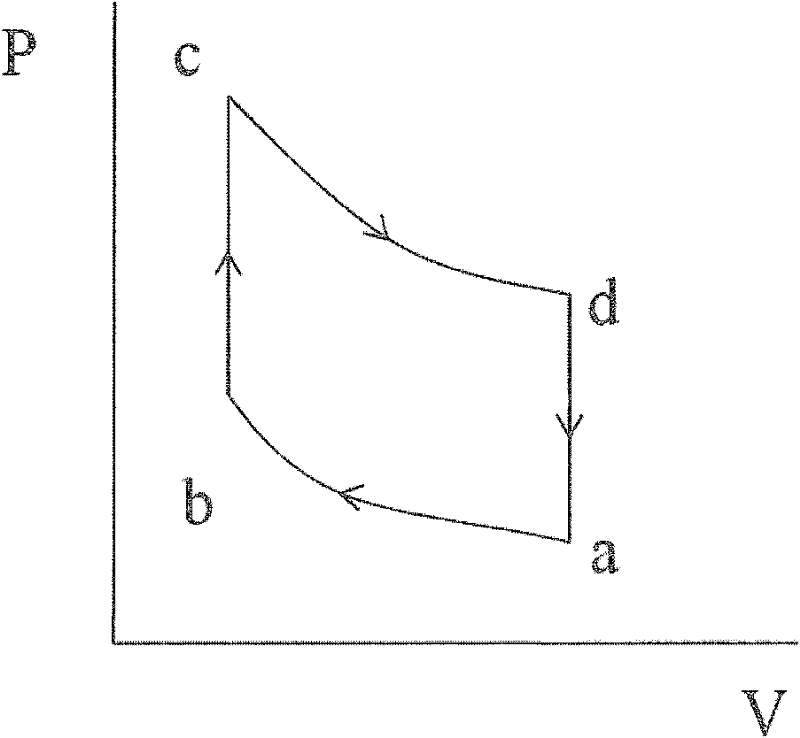

Waste heat power generation method of Stirling engine

InactiveCN102536367AReduce the temperatureCompact structureSteam engine plantsHot gas positive displacement engine plantsThermal energyMechanical energy

The invention discloses a waste heat power generation method of a Stirling engine, relating to a waste heat power generation technology. A heat absorber of the Stirling engine is arranged in a gas-collecting cavity, and the top of the heat absorber is vertical to an incoming direction of waste heat. The waste heat power generation method comprises the following steps: helium or hydrogen is filled in the heat absorber to be as an acting medium of the Stirling engine and drives a piston of the Stirling engine to move forth and back to generate mechanical energy after being heated to expand, and the Stirling engine drives a power generator connected with the Stirling engine to generate power; and waste heat gas in the gas-collecting cavity heats the helium or hydrogen in the heat absorber and then is exhausted into environment. A device for converting the waste heat into the mechanical energy through the Stirling engine is a special component applied to the waste heat power generation method disclosed by the invention, and comprises the Stirling engine, heat collecting tubes, the gas-collecting cavity and the power generator. According to the waste heat power generation method of the Stirling engine, disclosed by the invention, heat is converted to the mechanical energy, and the mechanical energy is also converted to electric energy, thus waste heat power generation with the advantages of compact structure, good economical efficiency, convenience for using and no need of additional heating is realized; and the conversion from low-grade waste heat to high-grade electric energy is realized.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

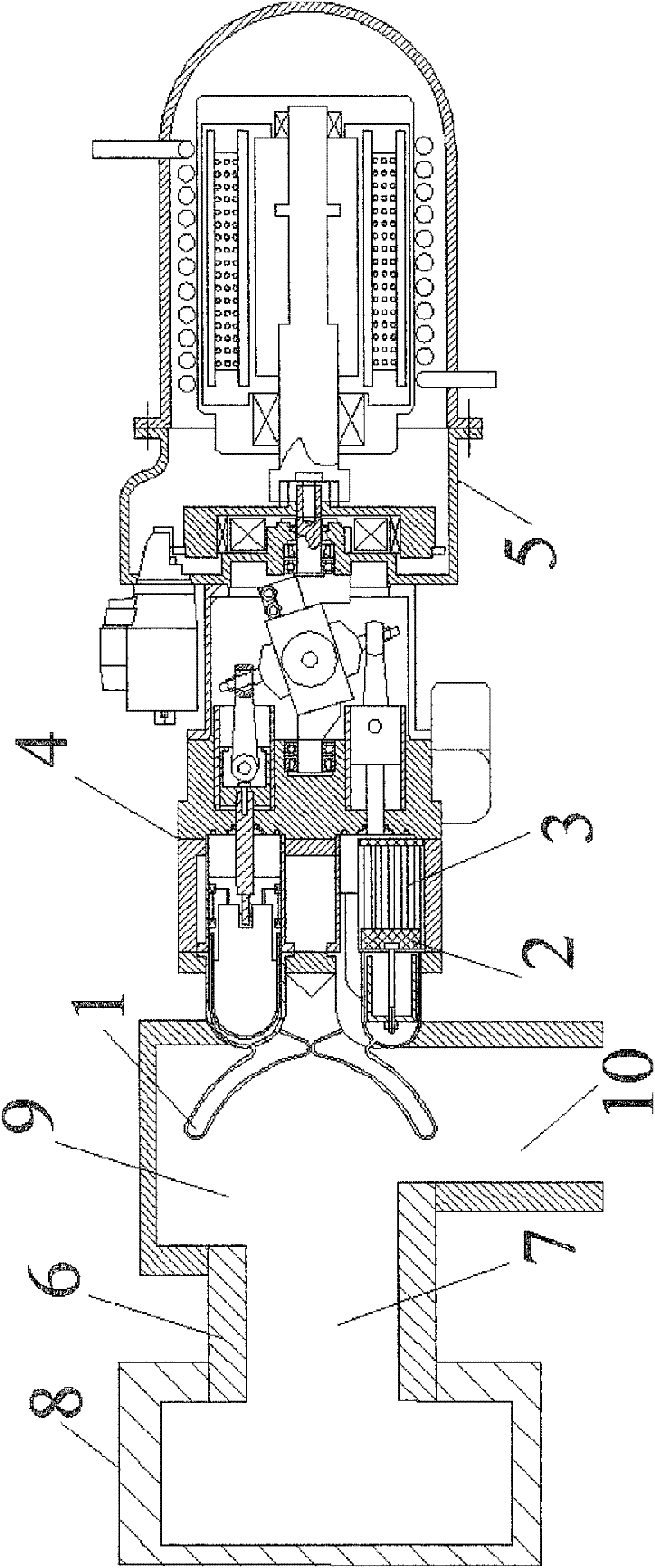

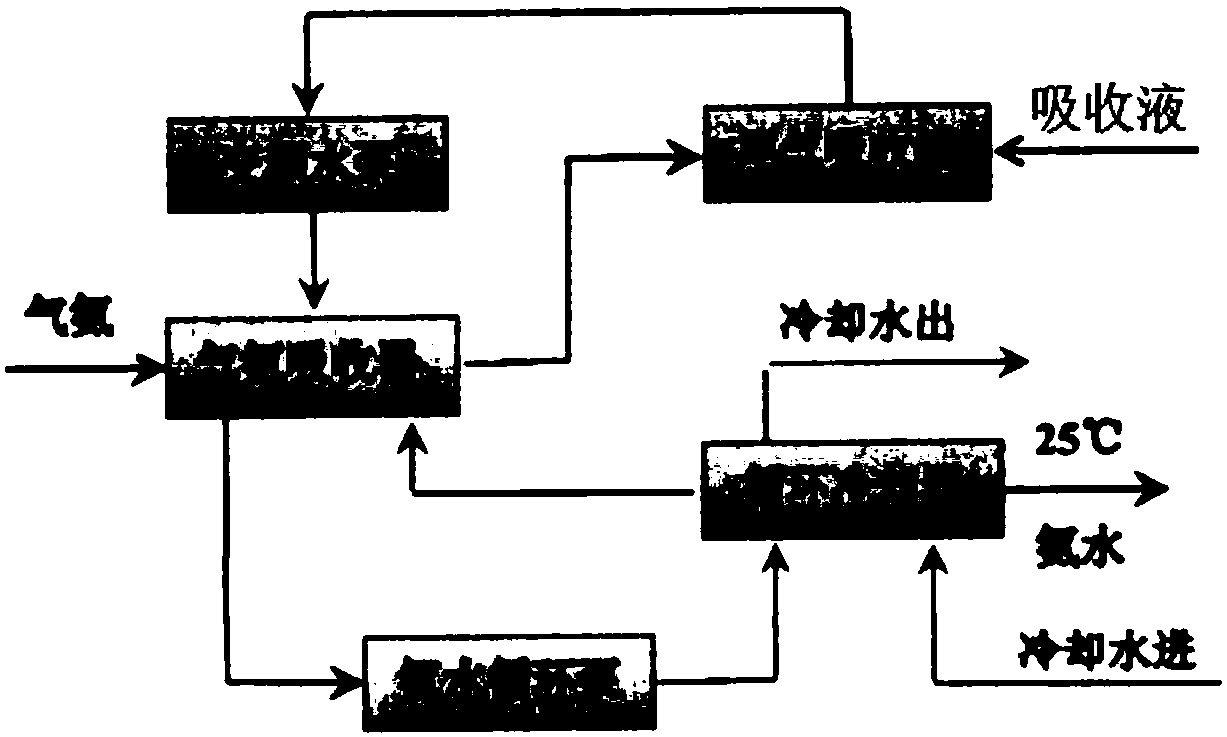

Production process and thermal recovery process of multi-element hot fluid used for thickened oil storage

ActiveCN102606122AImplement separate injectionPlay the role of annular heat insulationInsulationFluid removalNitrogenNitrogen gas

The invention relates to a production process of a multi-element hot fluid used for thickened oil storage and a thermal recover process of the multi-element hot fluid. The production process of the multi-element hot fluid comprises the steps of pressurizing and separating air to obtain high-purity nitrogen and oxygen-enriched air; pressurizing the obtained oxygen-enriched air to generate a part of the multi-element hot fluid; and mixing the generated part of multi-element hot fluid with the obtained high-purity nitrogen. The production process of the multi-element hot fluid has the advantage that components are adjustable, multi-element hot fluids with different components can be designed according to different oil storage characteristics, and the application range of the thermal recovery process of the multi-element hot fluid is widened.

Owner:CHINA NAT OFFSHORE OIL CORP +1

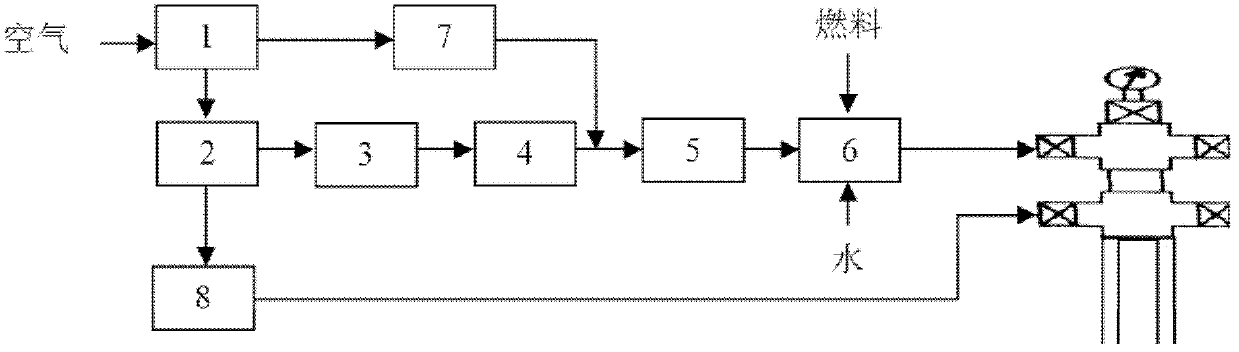

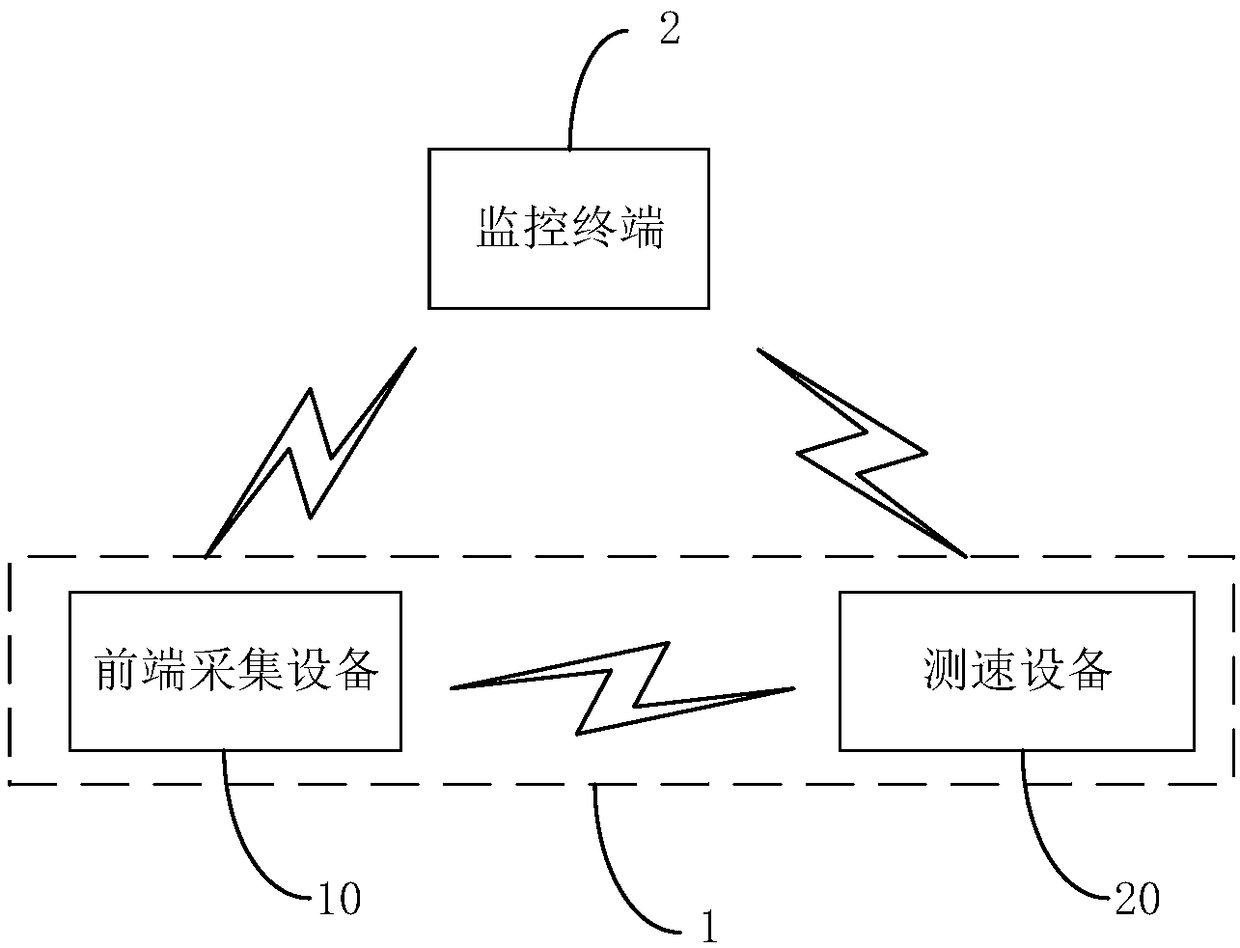

Speed measuring equipment and speed measuring system

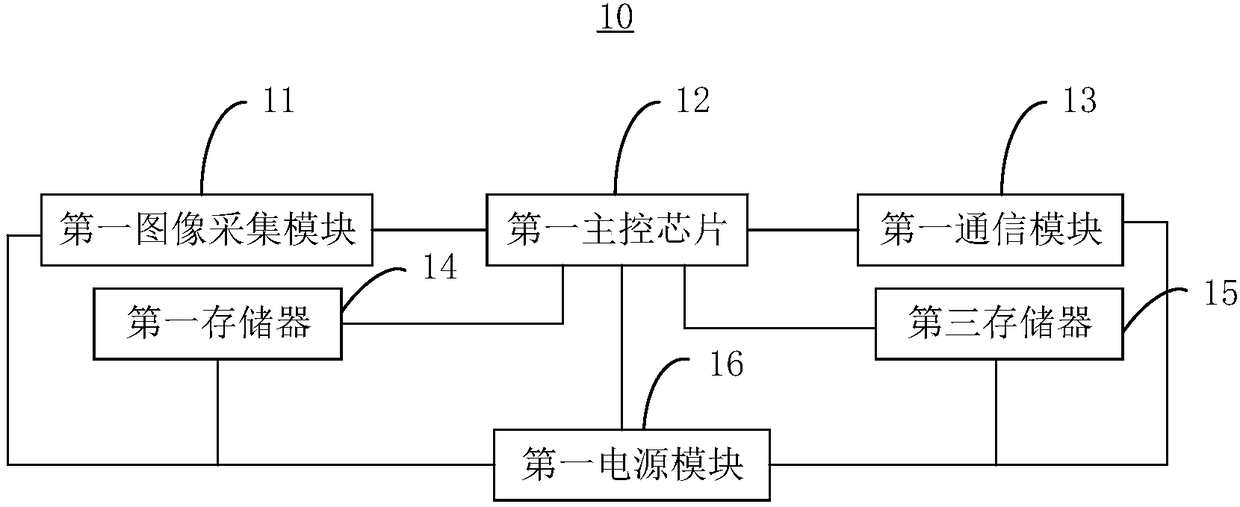

PendingCN108320531AHighly integratedReduce volumeRoad vehicles traffic controlAcquisition timeComputer terminal

The embodiment of the invention provides speed measuring equipment and a speed measuring system, and relates to the technical field of electronic control. Front-end acquisition equipment acquires first image information of a first monitored area, and recognizes first license plate information in the first image information; the speed measuring equipment receives the first license plate informationand the first image information, acquires the receiving time of the first license plate information, acquires second image information of a second monitored area, recognizes second license plate information in the second image information, and acquires the acquisition time of the second license plate information; if the second license plate information is the same as the first license plate information, according to the time difference between the receiving time and the acquisition time and the distance between the front-end acquisition equipment and the speed measuring equipment, the vehiclespeed of a vehicle corresponding to the second license plate information is calculated; if the vehicle speed exceeds a set vehicle speed, the image information and the license plate information of the overspeed vehicle and the vehicle speed are sent to a monitoring terminal. Through the speed measuring equipment and the speed measuring system, license plate information recognition, vehicle speedcalculation and vehicle overspeed judgment are achieved, and a product is high in integration degree, small in volume and low in cost.

Owner:武汉市技领科技有限公司

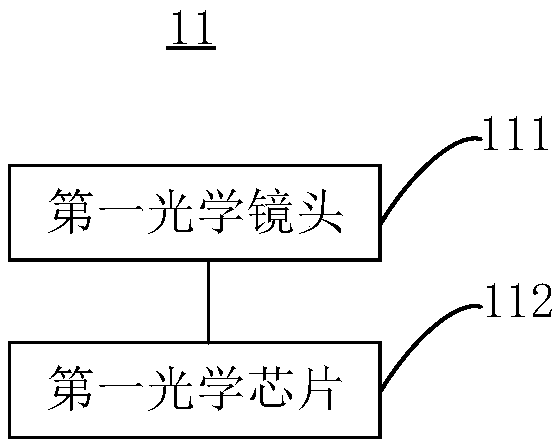

Machining method of small titanium and titanium alloy rod wire

ActiveCN108202088AReduce lossReduce energy consumptionFurnace typesMetal rolling arrangementsHigh surfaceTitanium alloy

The invention provides a machining method of a small titanium and titanium alloy rod wire, and belongs to the field of heat treatment of metal materials. According to the machining method, a single customized two-roll mill or a plurality of customized two-roll mills in series connection are used for cold rolling to prepare titanium and titanium alloy, and the single two-roll mill or the multiple two-roll mills in series connection are provided with holes located on the same axis, and a motor drives rolls to rotate to roll the rod wire. By adoption of the machining method, the labor intensity in the production process is low, auxiliary lubricating agents are not needed, and pollution to the field environment is avoided. In the rolling process, a matched heating furnace does not need to be heated, a matched wire drawing machine for traction is not needed, energy consumption is low, surface defects of products are few, and a lubricating agent-polluted layer is avoided. A finished productdoes not need to be processed by a peeling machine, the bright rod wire without a polluted layer can be directly produced, and the product has the characteristics of high yield, high surface quality,high machining efficiency and the like.

Owner:宁夏中色金航钛业有限公司

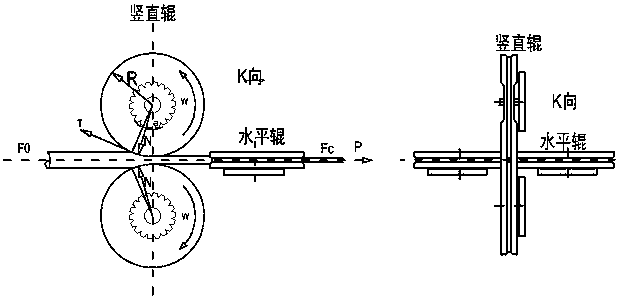

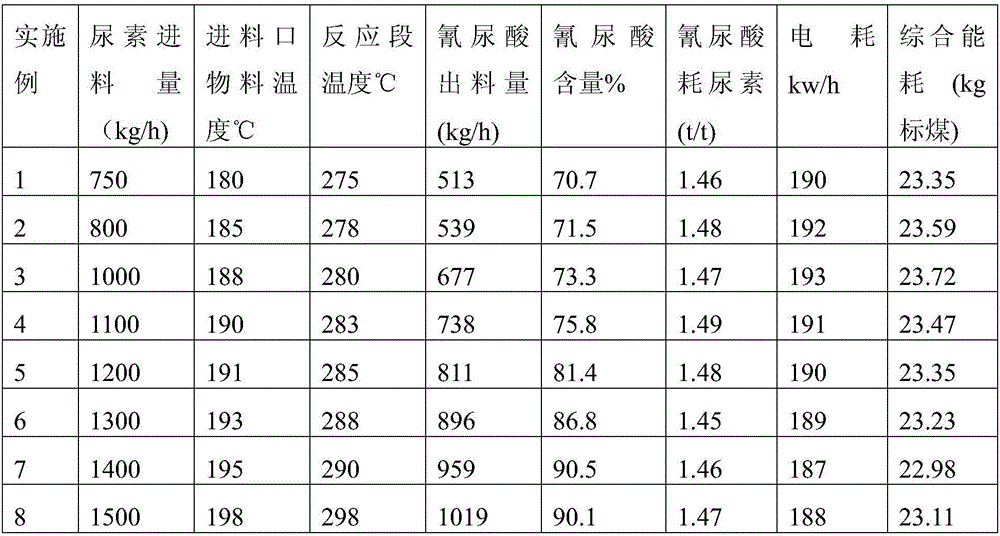

System and method for preparing crude cyanuric acid continuously by using urea

ActiveCN106008383AReduced granulation processReduce the heating and melting process of urea particlesOrganic chemistryTemperature controlWorking environment

The invention discloses a system and method for preparing crude cyanuric acid continuously by using urea. The system comprises: a differential stirring reactor for receiving urea melt and for deaminating it to produce crude cyanuric acid; a heating device disposed outside a reaction barrel of the differential stirring reactor and used for heating the reaction barrel; an ammonia recycling device connected with a gas outlet of the differential stirring reactor and used for recycling ammonia as a material for urea synthesis. The system and method enable continuous feeding, automated temperature control and automated discharging, rarely cause equipment blockage and blocking, reduce operation intensity of workers and improve work environment, optimize an operation process, and provide an organic integrity of human, machinery, material, process and environment.

Owner:河北冀衡集团有限公司

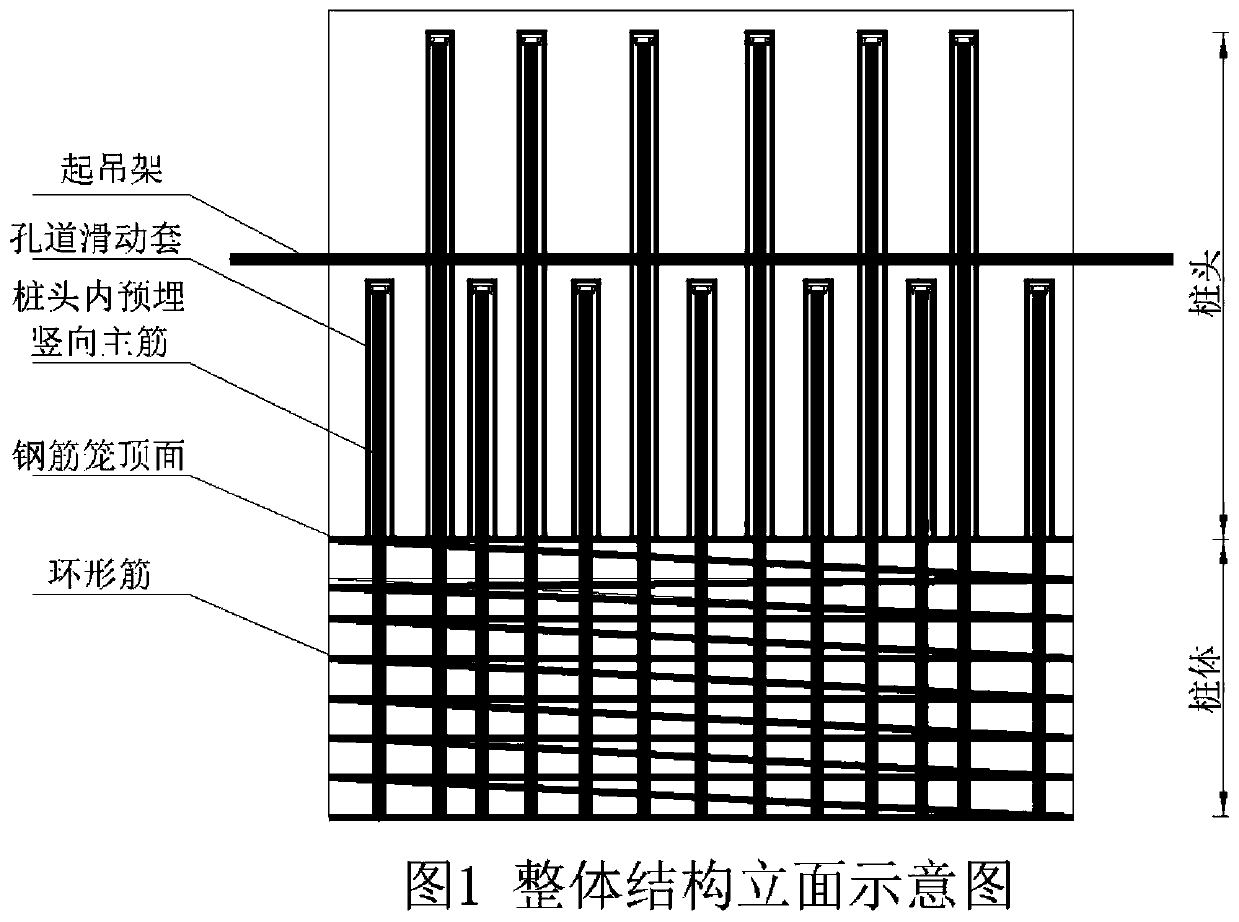

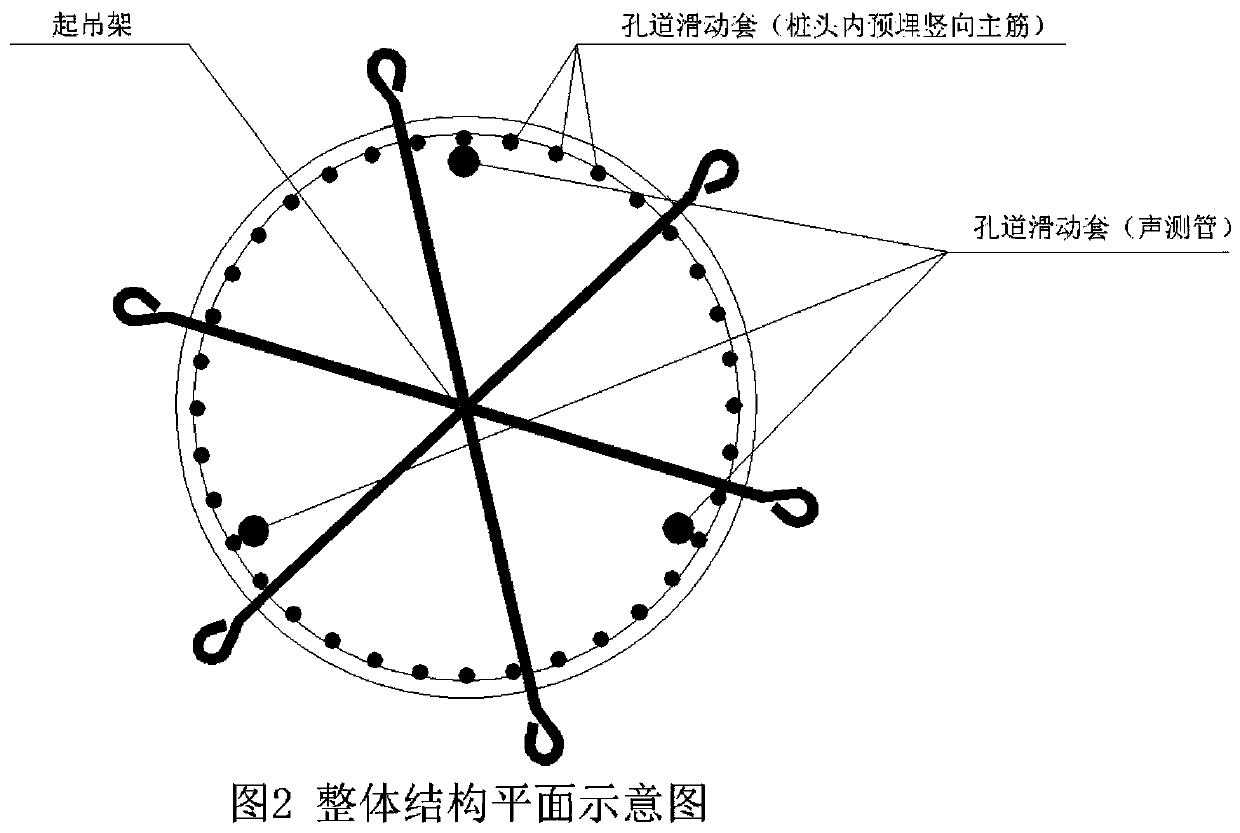

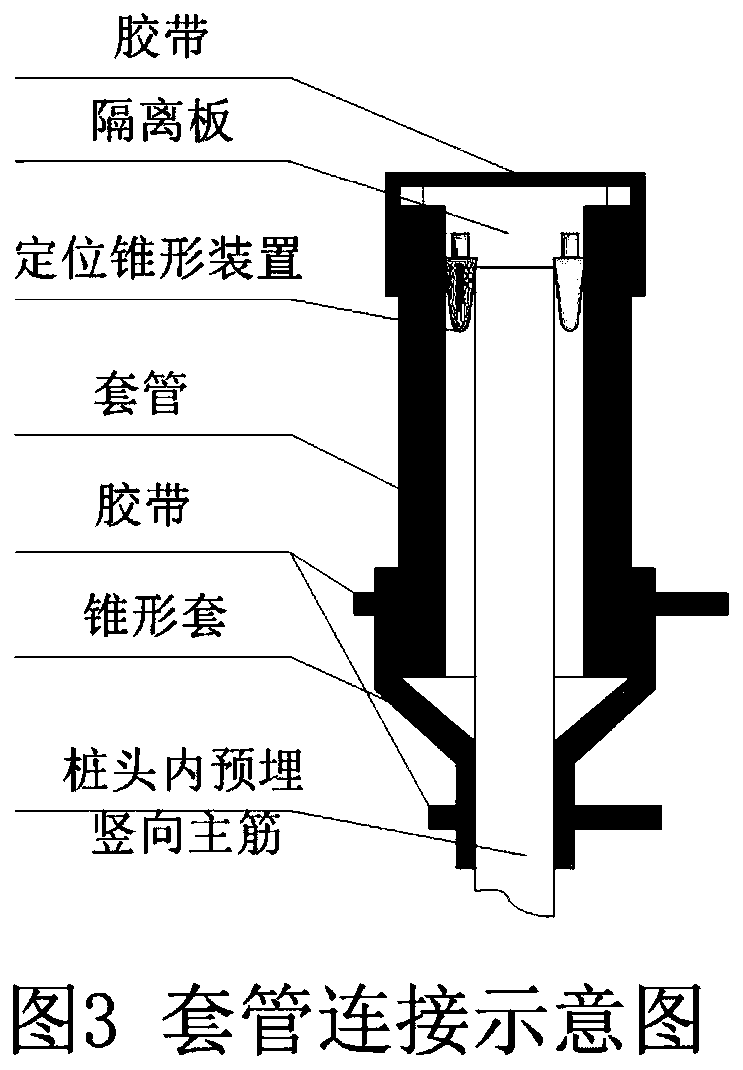

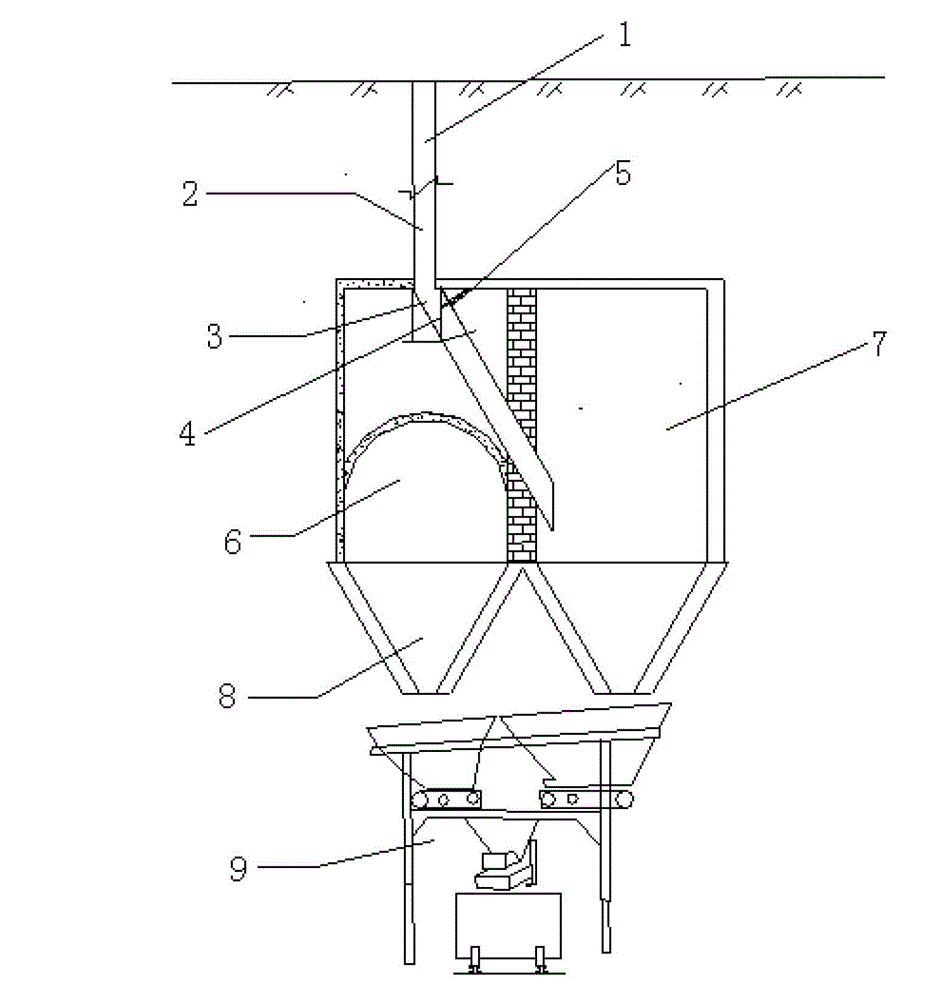

Construction method for quickly and non-destructively breaking pile heads

InactiveCN111218936AEasy to removeGood for guaranteed removalBulkheads/pilesAdhesive beltArchitectural engineering

The invention discloses a construction method for quickly and non-destructively breaking pile heads. In the construction method, a pile body is included. A reinforced cage is arranged inside the pilebody; vertical main reinforcements are reserved in a pile head of the reinforced cage; a pore passage sliding sleeve is arranged on the outer surface of a sound measuring pipe; an isolation plate anda tapered sleeve are separately arranged at the upper and lower ends of the pore passage sliding sleeve; the upper and lower ends of the pore passage sliding sleeve are bonded and sealed with an adhesive tape; a lifting frame (the whole pile head is used as a marking rod before lifting) is arranged at a position where the vertical main reinforcements reserved in the pile head of the reinforced cage are not smaller than 30 cm from the top surface of the reinforced cage; and a concrete pouring pile head is within the range of the vertical main reinforcements reserved in the pile head of the reinforced cage. After the construction of the pile head is completed, a high-pressure water jet technology (also known as hydraulic breaking technology) is used for properly removing concrete from the lifting frame to the top surface of the reinforced cage, and finally the pile head is integrally hoisted by a crane, thereby completing the quick and non-destructive breaking of the whole pile head.

Owner:SHANDONG LUQIAO CONSTR

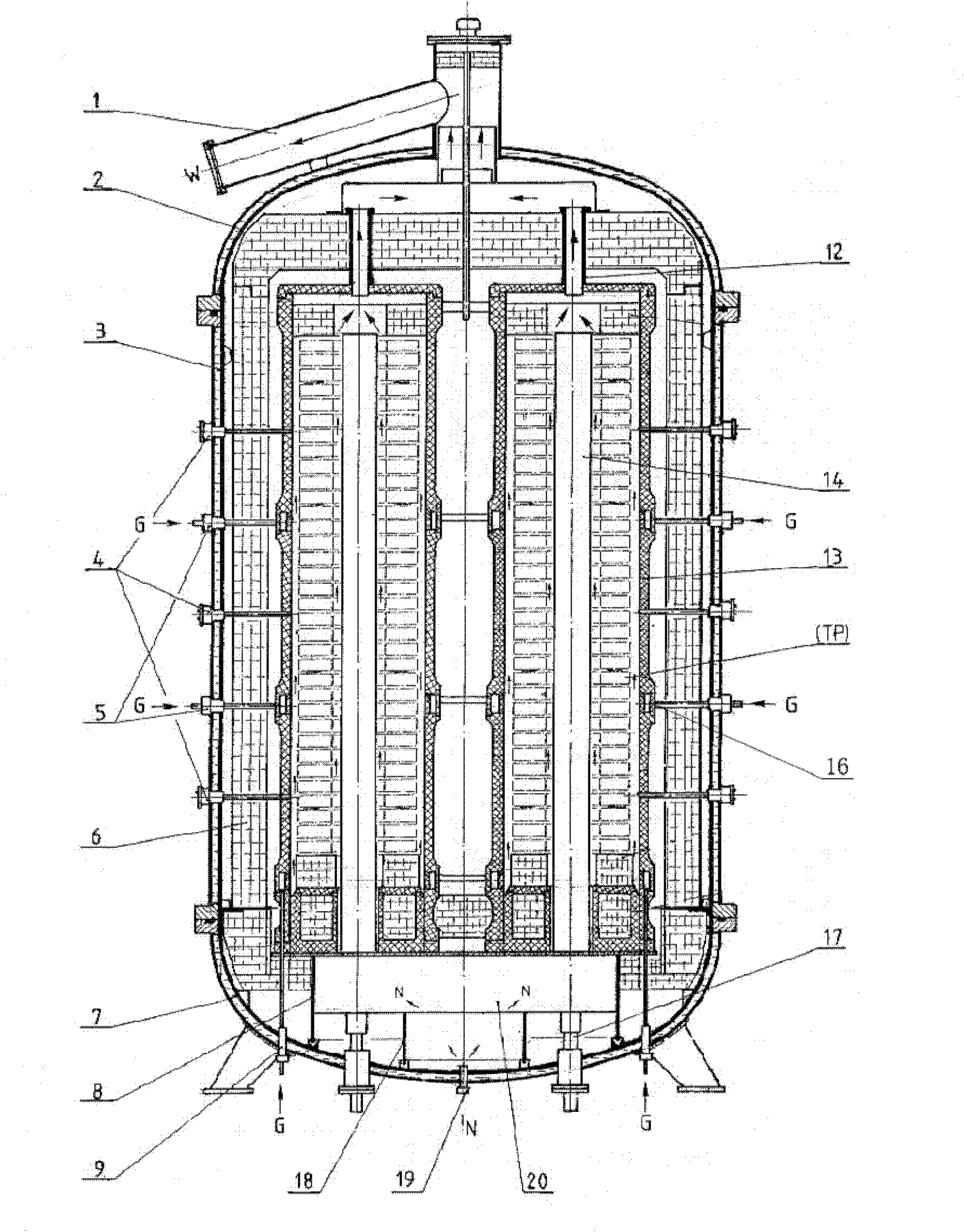

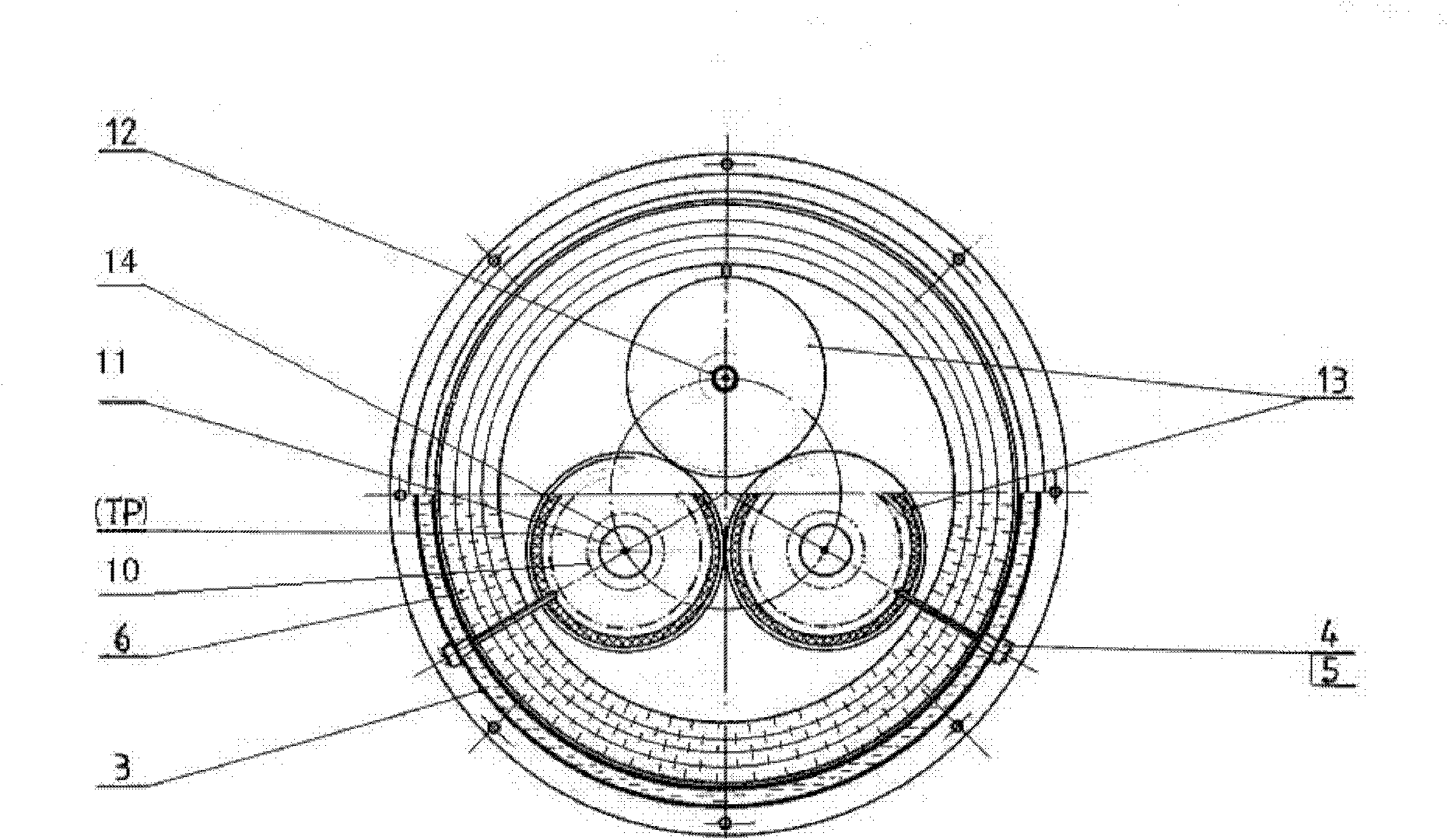

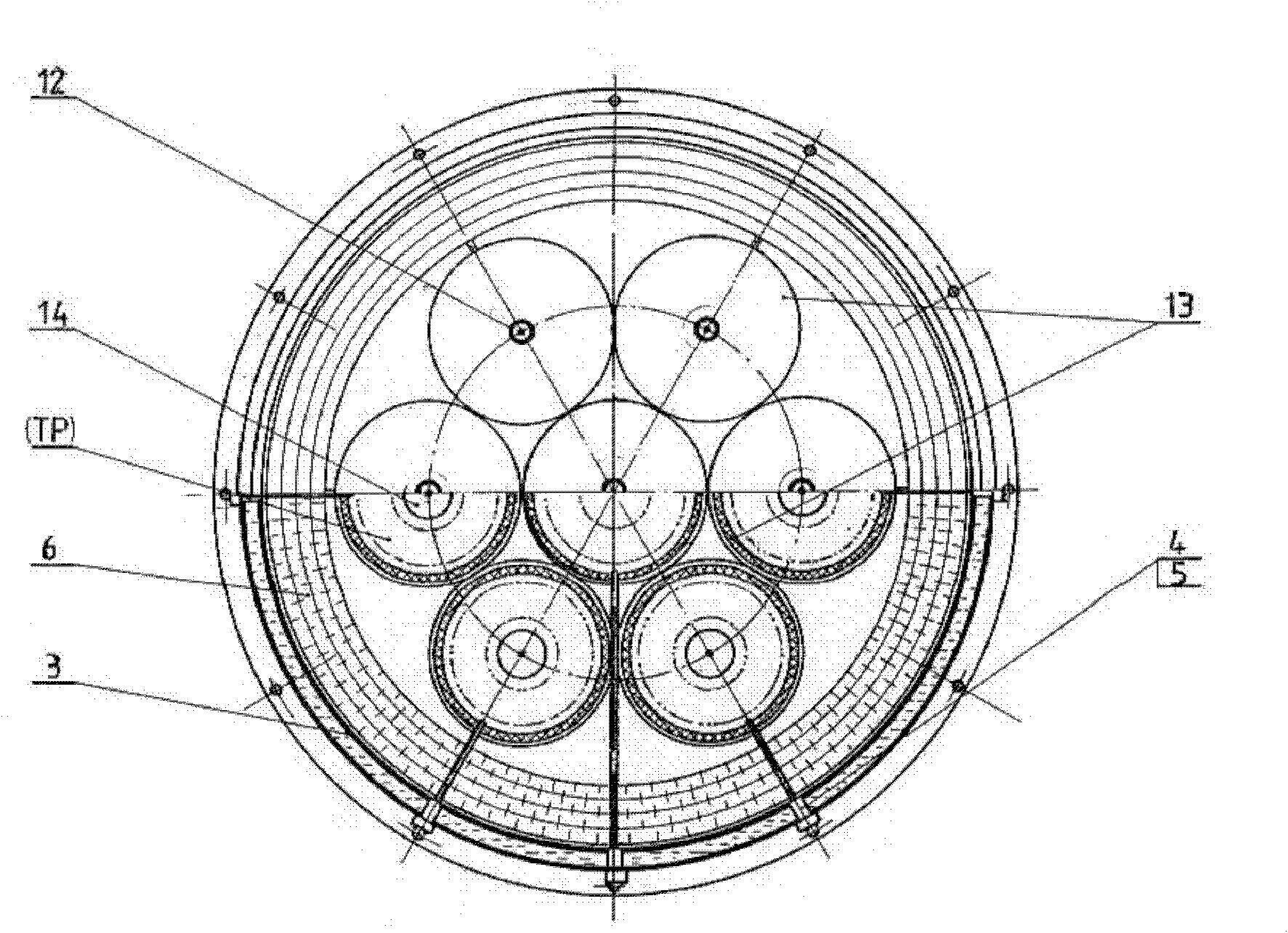

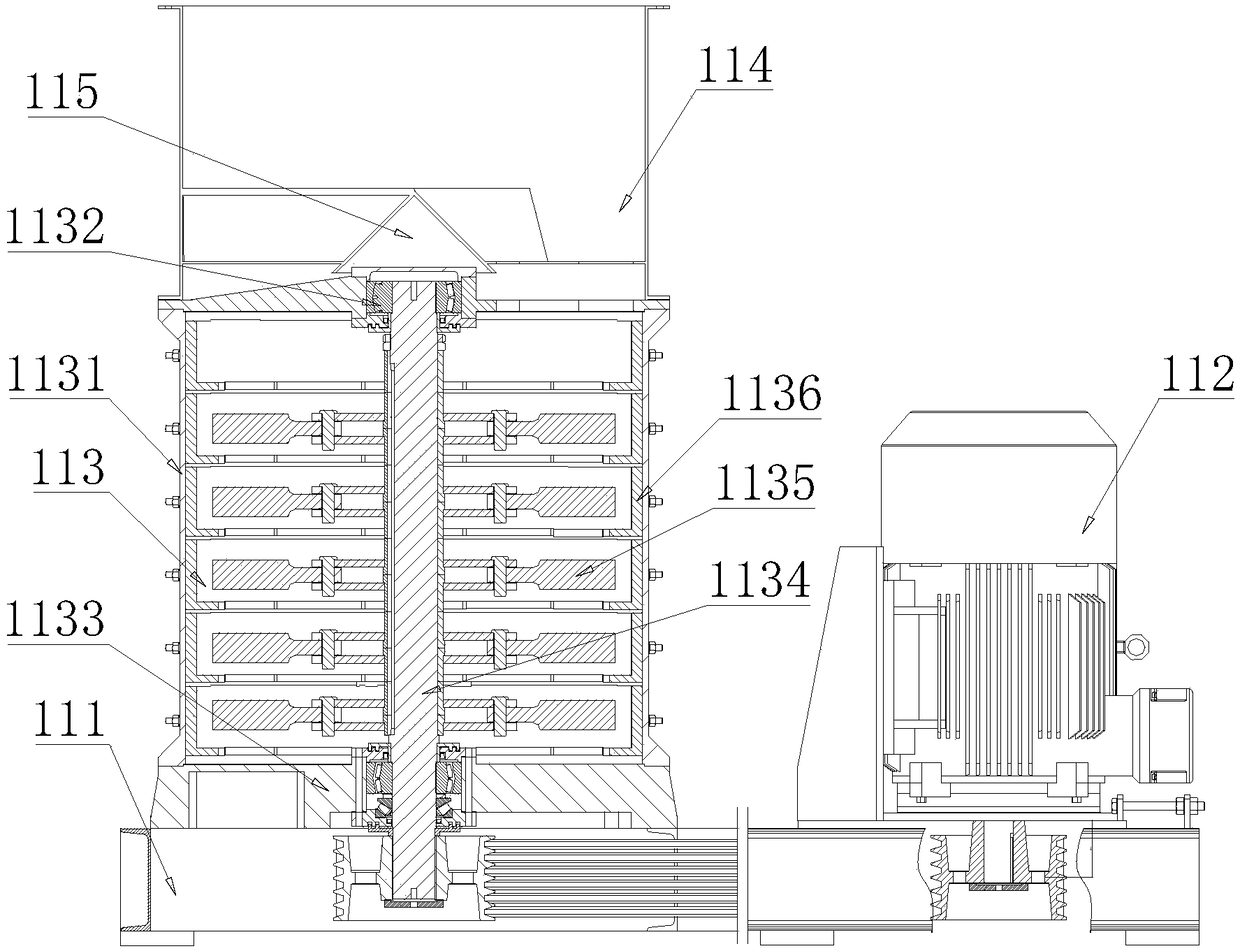

Multi-stock-column type industrial furnace for chemical vapour infiltration densification

ActiveCN102212800AThe heating conditions are the sameUniform distanceChemical vapor deposition coatingCeramic compositePhysical field

The invention discloses a multi-stock-column type industrial furnace for chemical vapour infiltration densification. The multi-stock-column type industrial furnace comprises a furnace cover, a furnace body and a furnace base. The furnace cover and the furnace body are connected integrally. Heat insulation covers are arranged in the furnace cover and the furnace body to form a bell type structure, so that the bell type structure is integrally arranged on the furnace base. Three or six upright rod type heating bodies, which are uniformly distributed co-circumferentially, are arranged on the furnace base. Stock column chambers matched with the heating bodies in number are arranged in the heat insulation covers. Air distribution rings are arranged on the stock column chambers. The multi-stock-column type industrial furnace disclosed by the invention is rational in structure, low in energy consumption and high in yield. An internally heating type three-phase balance combination structure with a plurality of heating bodies is used. The furnace is structured compactly and can save energy. The thermal gradient can be controlled effectively. The couplings of related physical fields are realized. The quality and the efficiency of CVD (Chemical Vapour Deposition) are improved. Air is supplied through multi-layer pre-heating ring type rotational flow so that the atmosphere evenness of a reaction chamber is improved. The capacity and the thermal efficiency of the furnace are greatly improved by charging through multiple stock columns of the independent reaction chamber. The multi-stock-column type industrial furnace is applicable to densification of C / C (Carbon / Ceramic) composite material brake discs and a plurality of carbon / ceramic composite annular work-pieces.

Owner:CENT SOUTH UNIV +1

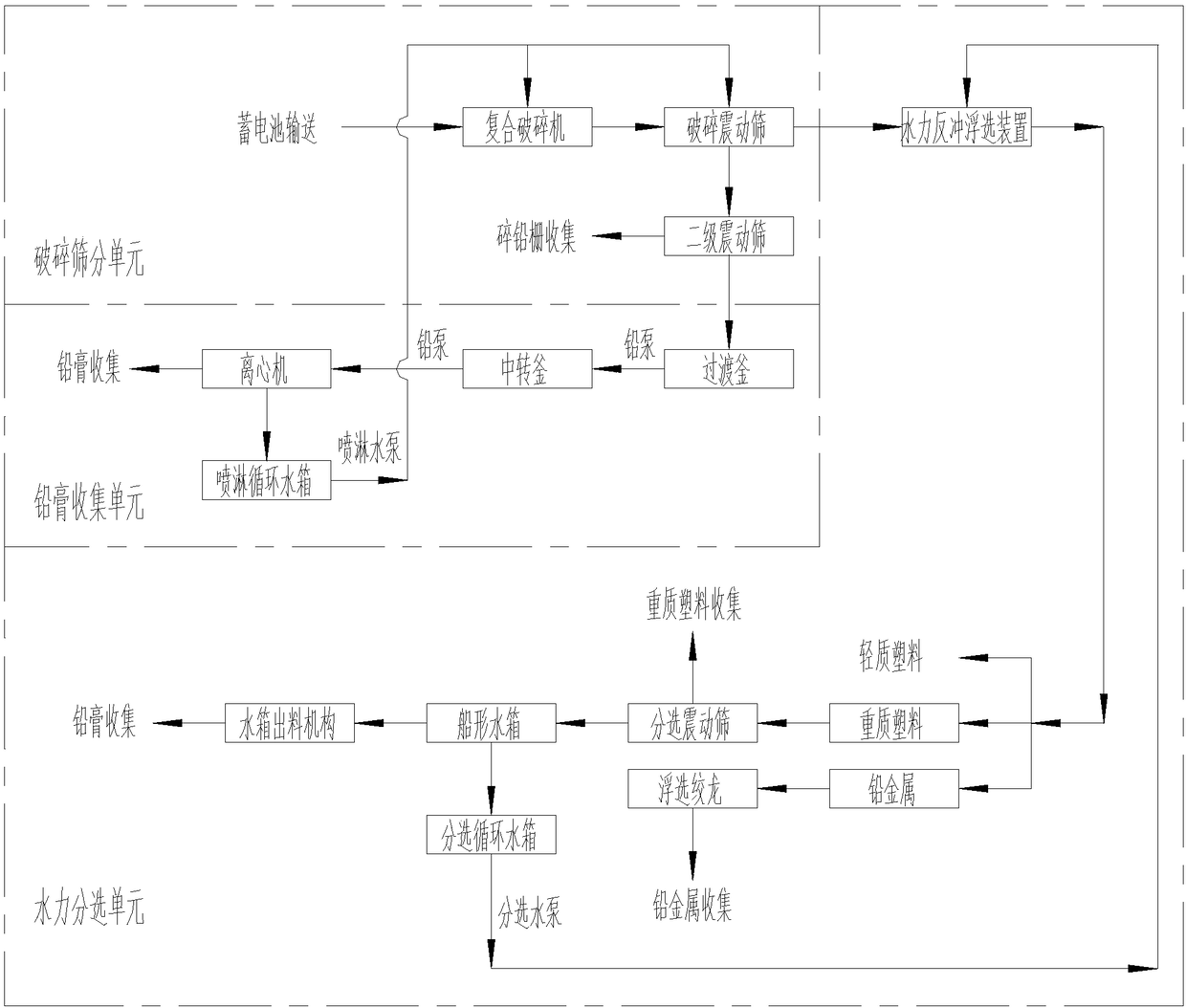

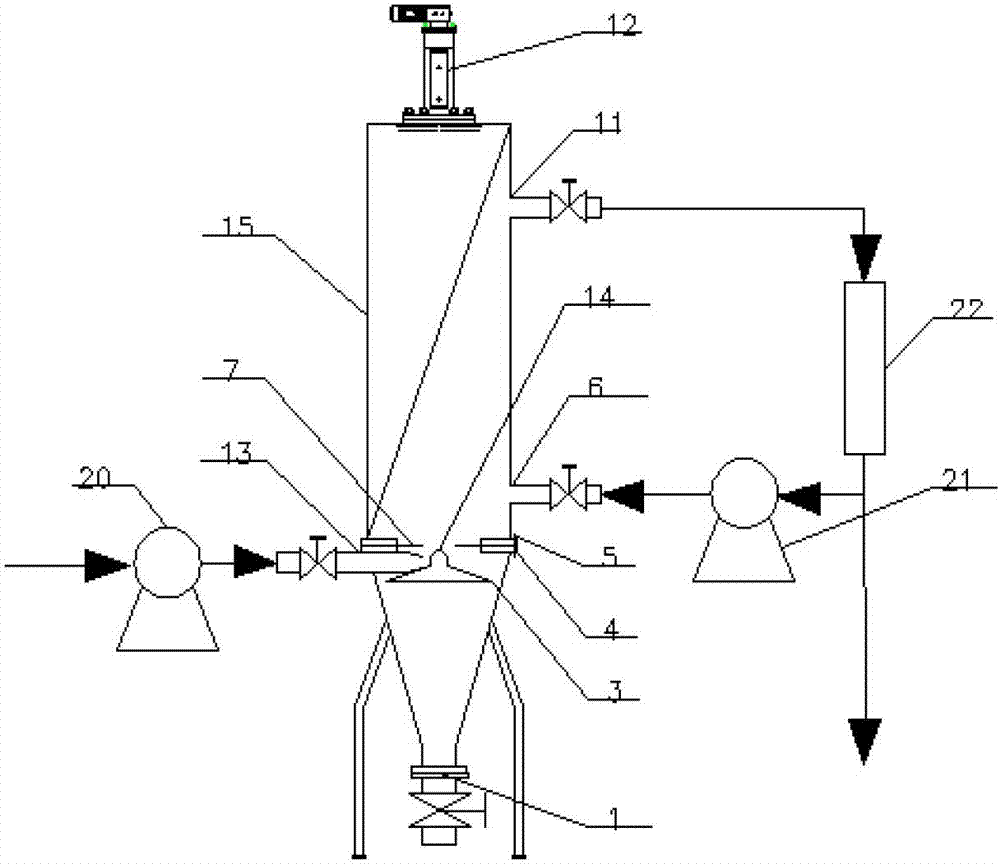

Crushing and sorting system for lead-acid storage battery

ActiveCN108465518AHigh recovery rateLess investmentWaste accumulators reclaimingGrain treatmentsEngineeringCrusher

The invention discloses a crushing and sorting system for a lead-acid storage battery, and belongs to the technical field of recovery of lead-acid storage batteries. The crushing and sorting system comprises a crushing and sieving unit, a lead plaster collection unit and a hydraulic sorting unit. The crushing and sieving unit is used for crushing and sieving a to-be-recovered lead-acid storage battery. The lead plaster collection unit is used for separating and collecting undersizes obtained through separation of the crushing and sieving unit. The hydraulic sorting unit is used for separatingand collecting the undersizes obtained through separation of the crushing and sieving unit. According to the crushing and sorting system, the lead-acid storage battery is crushed by a compound crusherinnovatively, the lead-acid storage battery is crushed only by one compound crusher, lead metals, heavy plastics and light plastics are separated simultaneously by a hydraulic back flushing flotationdevice, not only is the recovery rate of the lead-acid storage battery up to more than 98%, but also the whole crushing and sorting system is greatly simplified, and required support devices are reduced; and compared with the prior art, the crushing and sorting system has the advantages that the occupied area can be reduced by more than 60%, the power consumption can be reduced by more than 40%,and the operation cost is lowered when the investment of enterprise devices is reduced.

Owner:襄阳远锐资源工程技术有限公司

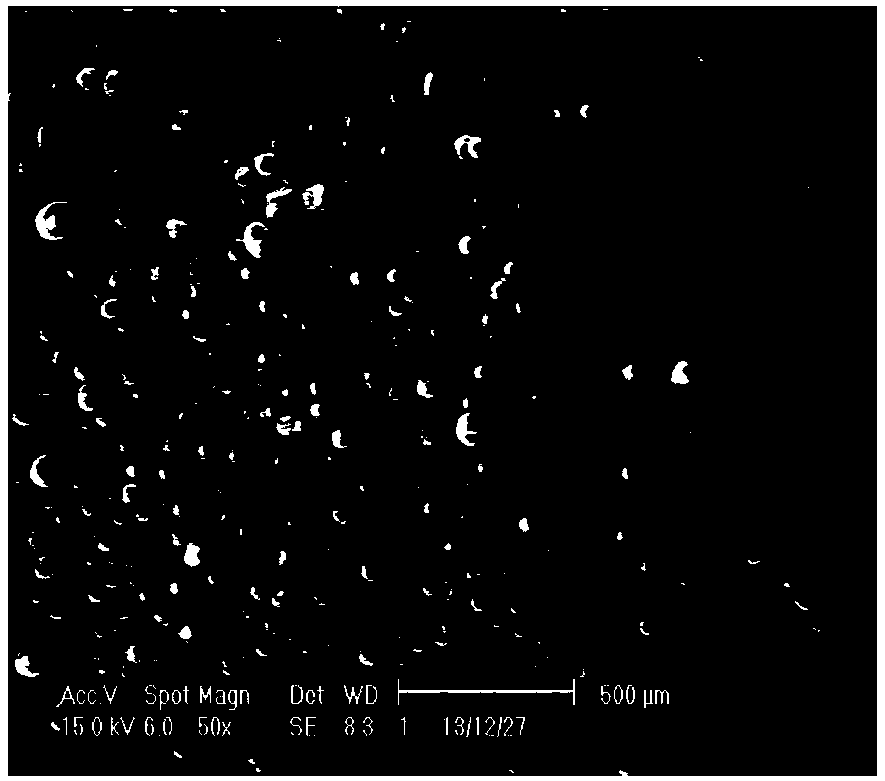

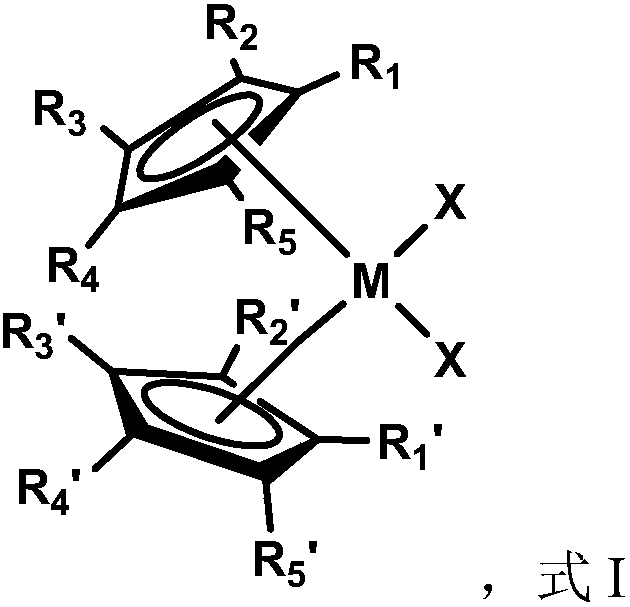

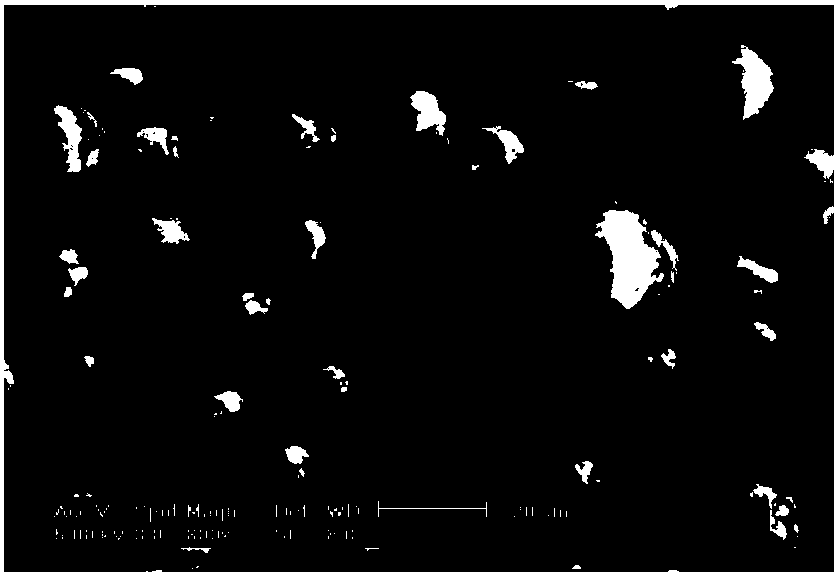

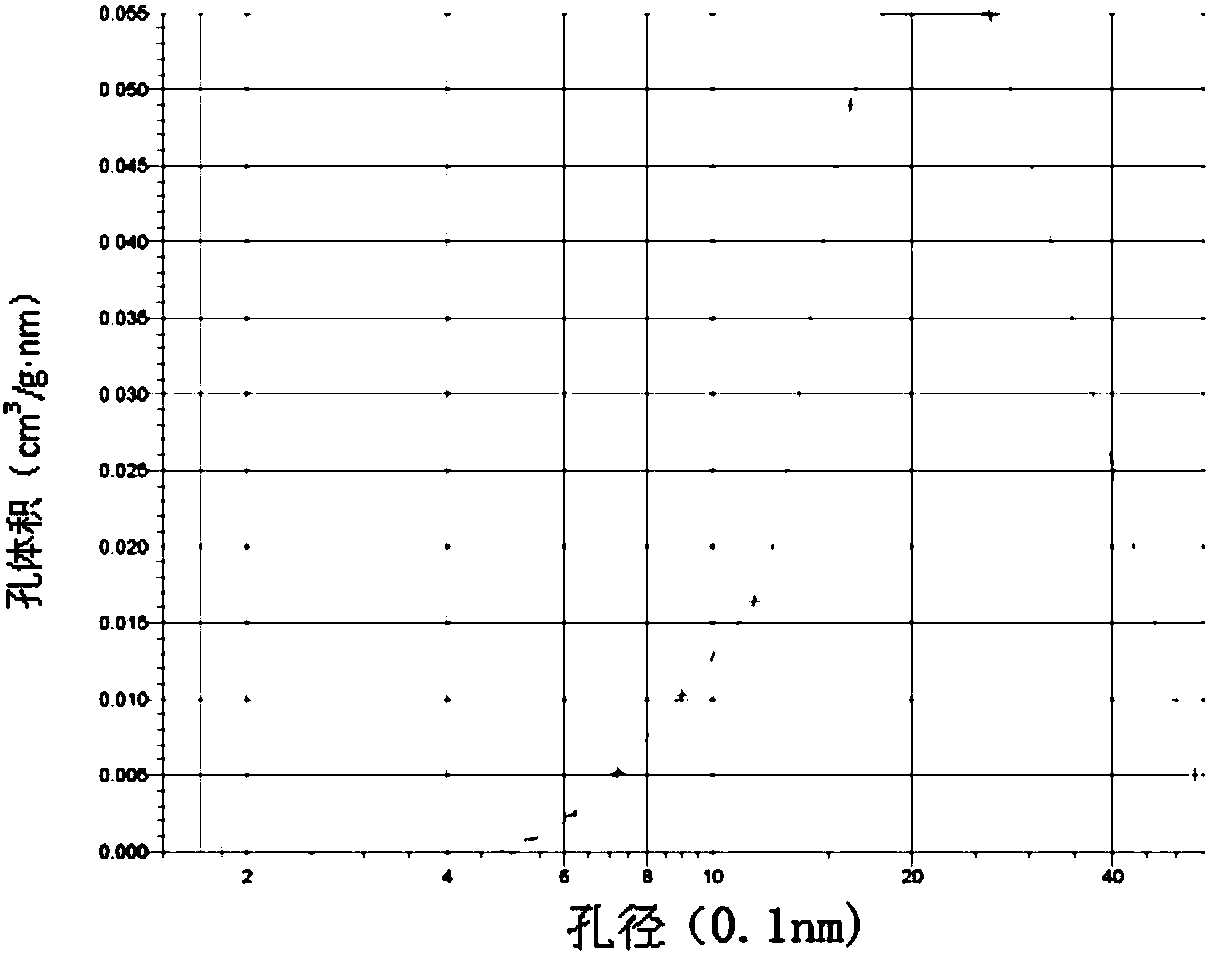

Supported metallocene catalyst, preparation method and application thereof and methyl acrylate preparation method

ActiveCN108786919AGood chemical stabilityReduce accumulationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSilica gelN-Butyl Alcohol

The invention relates to the field of supported metallocene catalysts and discloses a supported metallocene catalyst, a preparation method and application thereof and a methyl acrylate preparation method. The supported metallocene catalyst comprises a silica gel supporter and metallocene supported on the silica gel supporter. A preparation method of the silica gel supporter includes the steps of firstly, mixing sodium silicate, polyol, n-butyl alcohol and inorganic acid to obtain a mixture, and using a ceramic membrane filter to perform filtering and / or washing on the obtained mixture to obtain silica gel filter cake; secondly, subjecting the silica gel filter cake obtained in the first step to ball milling, and performing spray drying to obtain the silica gel supporter. The supported metallocene catalyst has the advantages that the supported metallocene catalyst is good in catalytic performance when being used in esterification reaction, the supported metallocene catalyst is recyclable and simple in recycling process, and the recycled catalyst is still high in reaction activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

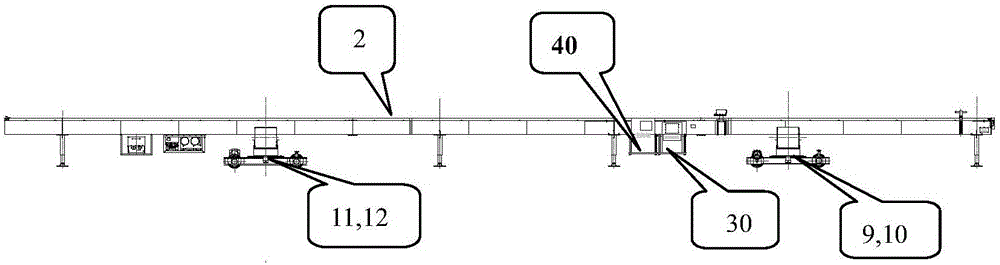

Large-scale equipment automatically centering method

ActiveCN105059564ASolve the large measurement errorThe principle is simpleAircraft assemblyObservational errorControl system

The present invention discloses a large-scale equipment automatically centering method. The method comprises a step of placing centering equipment and target equipment into place; a step of inputting deviation measurement data of a measuring system into a control system; a step that the control system judges if rolling, swaying, pitching, lateral moving and lifting adjustments are needed, calculates an adjustment amount after the adjustments are judged to be needed, drives adjusting devices to complete corresponding adjustment actions, and sends a next-time measuring command to the measuring system according to an adjustment in-place signal until criteria are met; and a step of completing butt joint of the centering equipment and the target equipment after centering. The large-scale equipment automatically centering method is advantageous in that a straight line centering method is adopted, thereby solving the problem of large measuring errors of end face centering adopted by large-scale equipment with small end faces. The method is simple in principle, few in assorted equipment, easy to realize, automatic in execution of all links such as deviation measurement, recognition, resolving, execution, control and feedback, free of manual intervention in the whole process, and high in centering efficiency.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

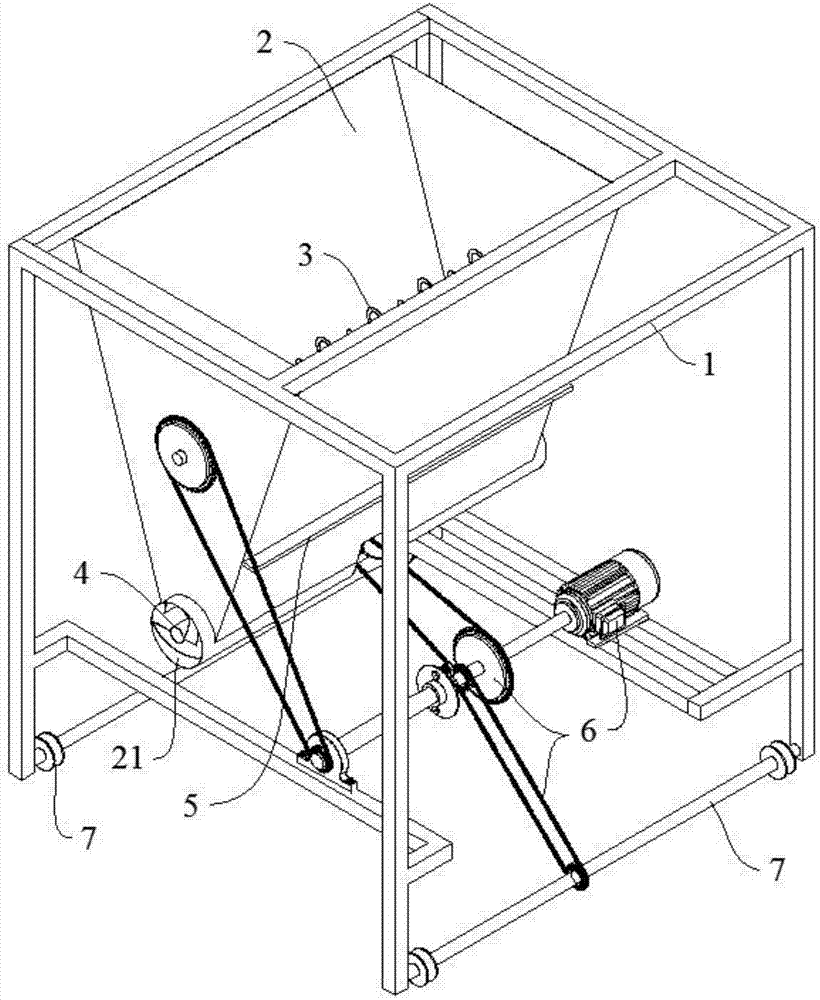

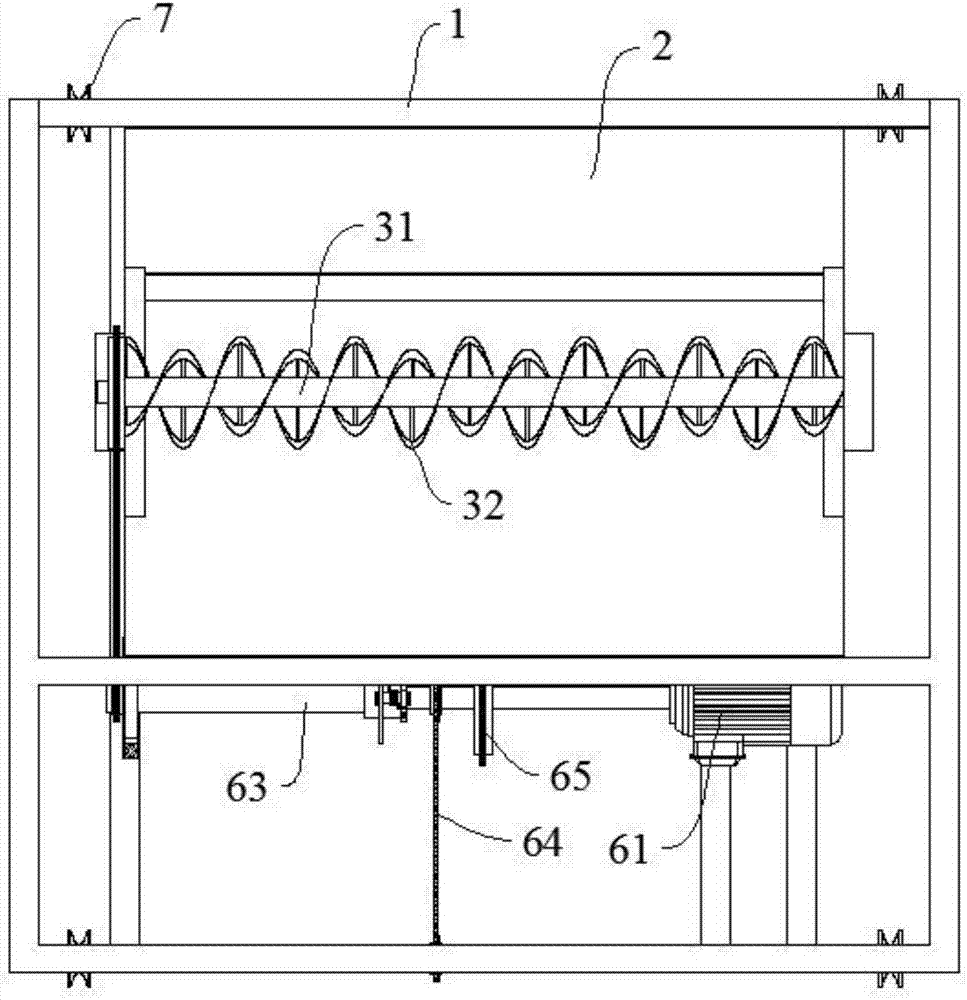

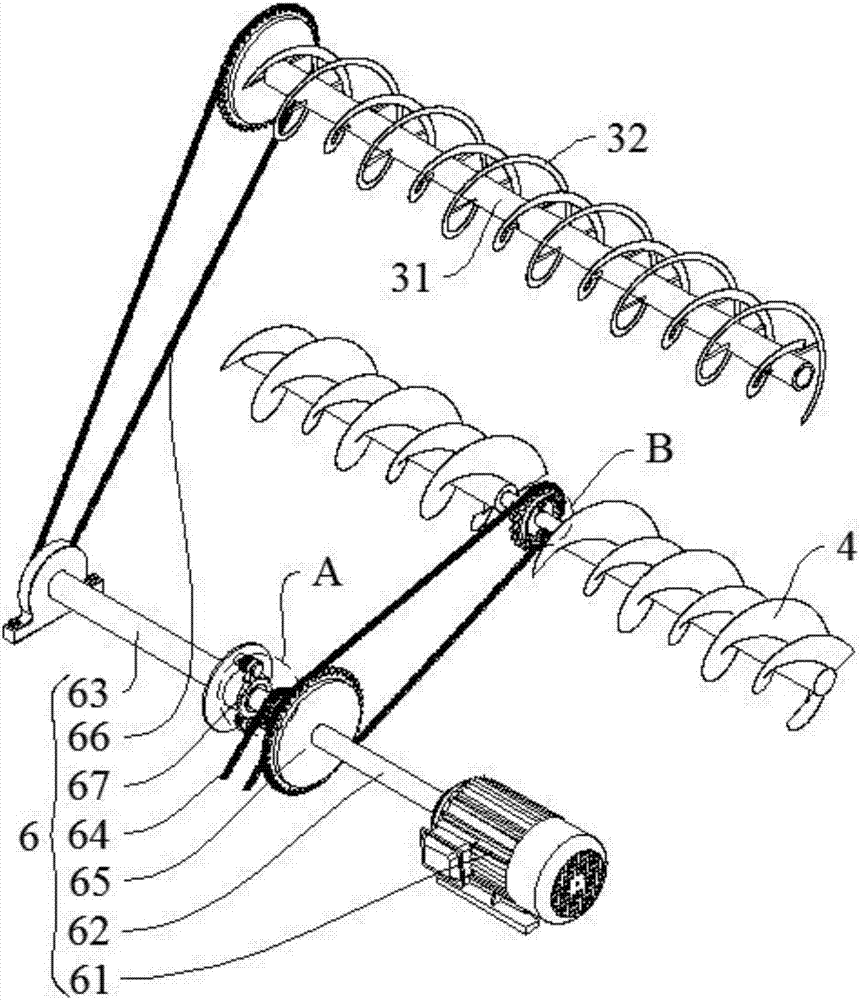

Visualized remote control feeder

PendingCN107466886AReasonable reuseLess supporting equipmentAnimal feeding devicesControl systemRemote control

Disclosed is a visualized remote control feeder. The feeder mainly comprises a hopper, a stirring mechanism, a discharging mechanism, a water adding system, a gate, a weighing system, cameras, a control system, a driving mechanism and a walking mechanism. The stirring mechanism is arranged in the middle of the hopper, discharging outlets are formed in the two sides of the lower portion of the hopper, the discharging mechanism is arranged at the lower portion of the hopper, the gate is arranged between the stirring mechanism and the discharging mechanism, the walking mechanism is arranged at the lower portion of the machine frame, the driving mechanism provides power for the stirring mechanism, the discharging mechanism and the walking mechanism, the cameras are arranged at the front and back ends of a machine frame, the weighing system is arranged on a machine frame stand column, the weighing system, the cameras and the control system are electrically connected, and the control system comprises a wireless signal transceiving module. By reasonably adopting the feeder hopper, the previous stirrer-conveyor links are omitted, and corollary equipment is omitted, so that the occupied place is saved; unattended remote control is achieved through the weighing system, the cameras and the control system.

Owner:郝巴雅斯胡良

Method and system for treating high-concentration phosphating wastewater

ActiveCN110092524AGood adsorption effectReduce usageSpecific water treatment objectivesWater contaminantsMagnetic powderPolyacrylamide

The invention relates to the field of wastewater treatment, in particular to a method for treating high-concentration phosphating wastewater, and the method comprises the following steps: (1) adding coagulant PAC (polyaluminium chloride) and magnetic powder into the phosphating wastewater, stirring and mixing to obtain a first-level mixing system; (2) adding coagulant aid PAM (polyacrylamide) intothe first-level mixing system, stirring and mixing to obtain a secondary mixing system; (3) adopting an air floatation machine to carry out air floatation separation on the secondary mixing system toobtain effluent and scum, and by combining magnetic coagulation and air floatation technology, the method not only reduces the usage amount of medicaments, but also reduces the treatment time and occupied area, and improves the treatment efficiency.

Owner:CHONGQING UNIV

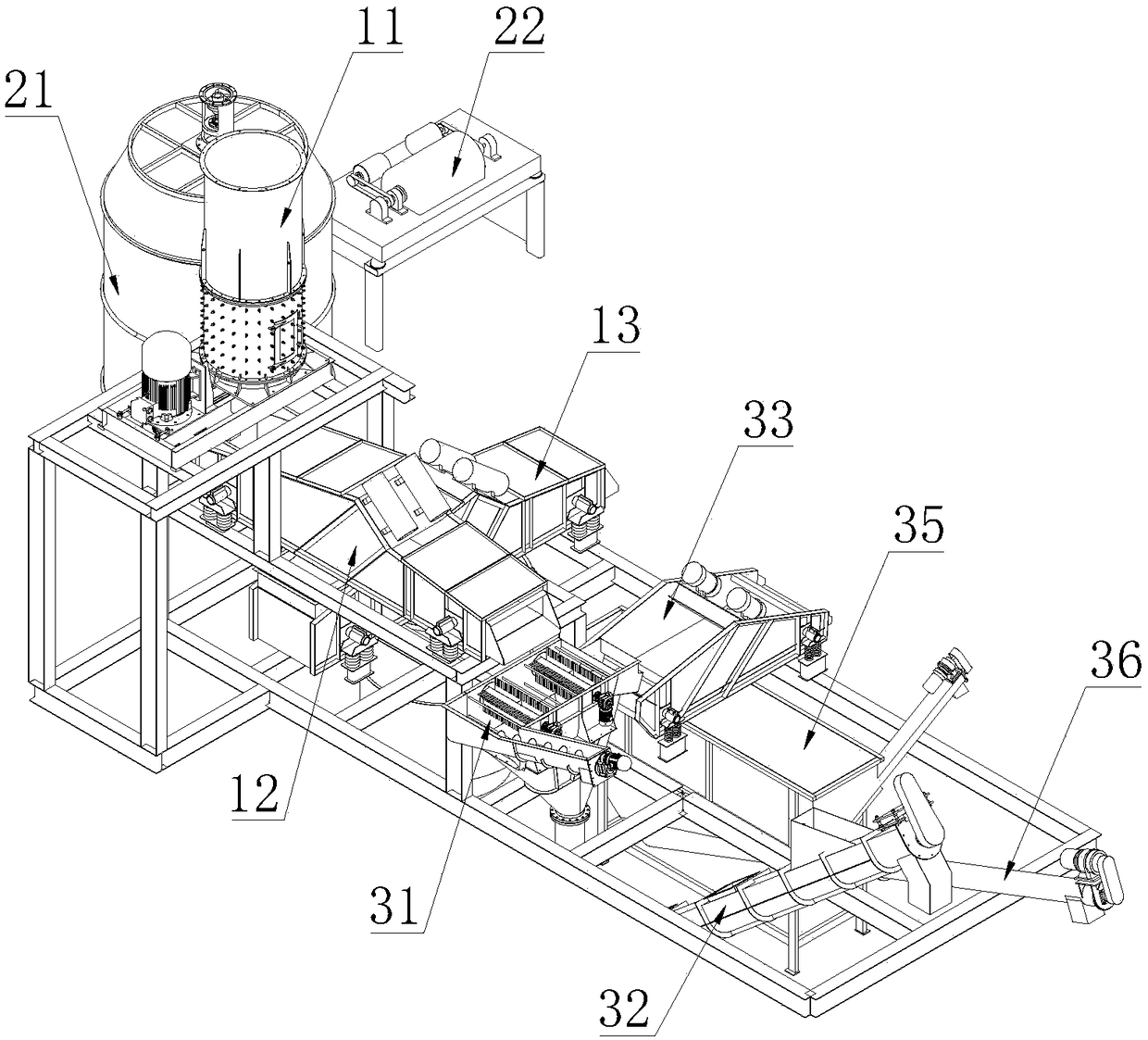

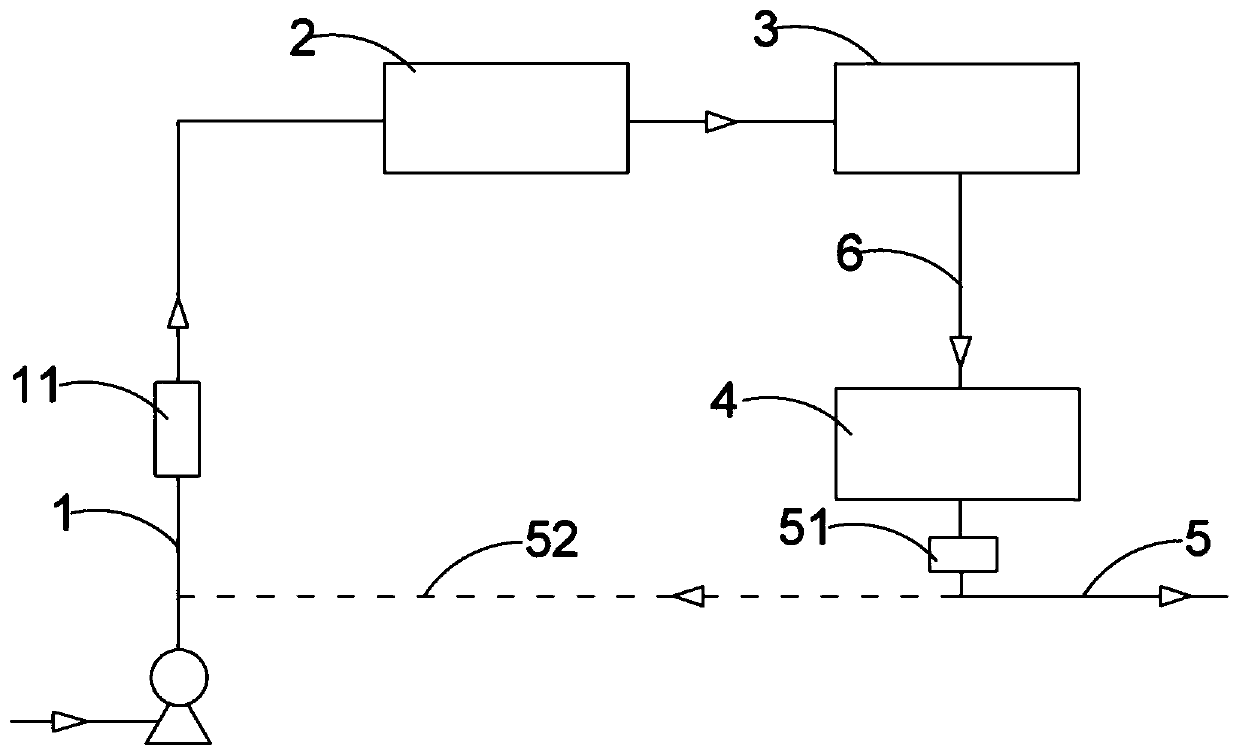

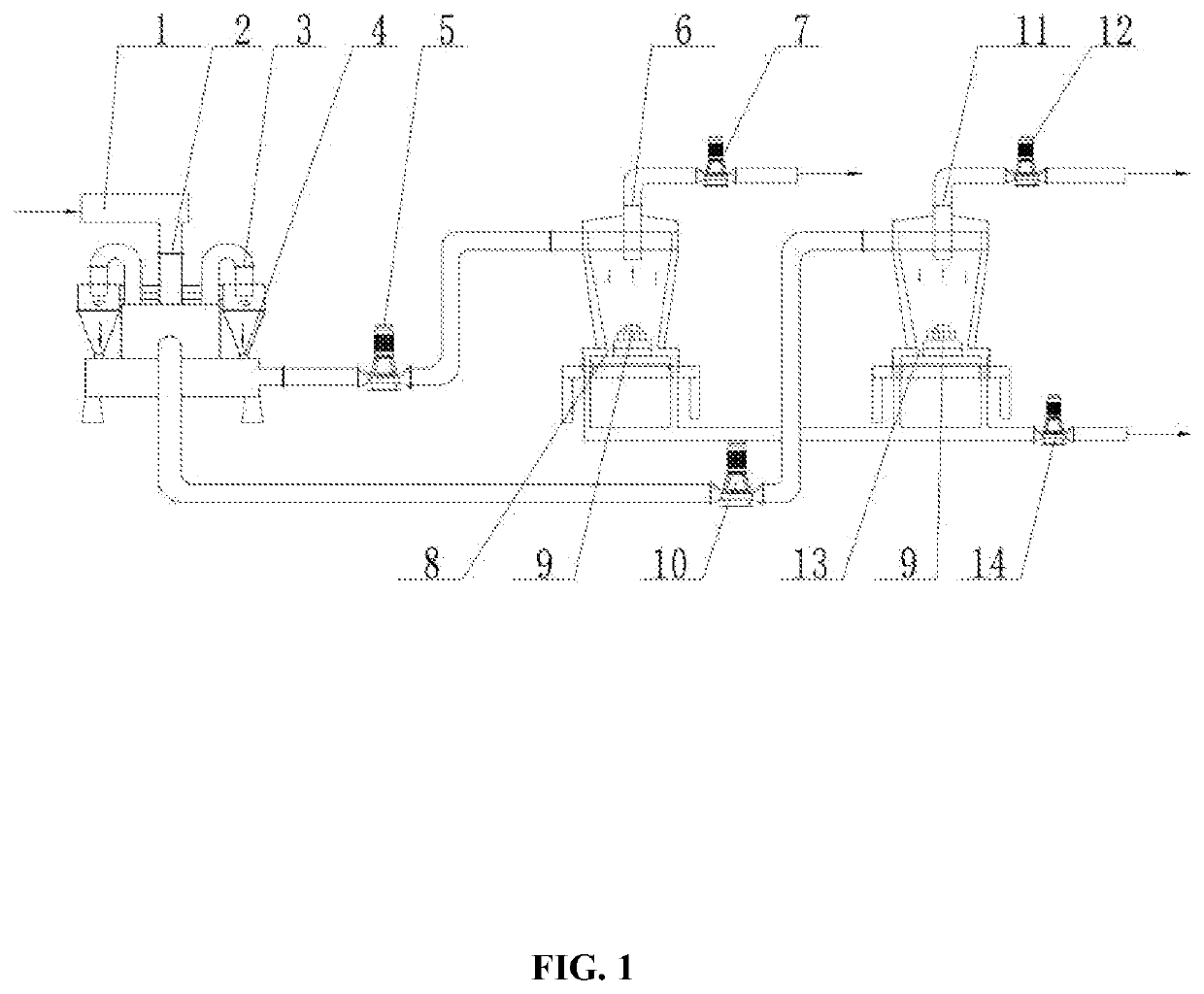

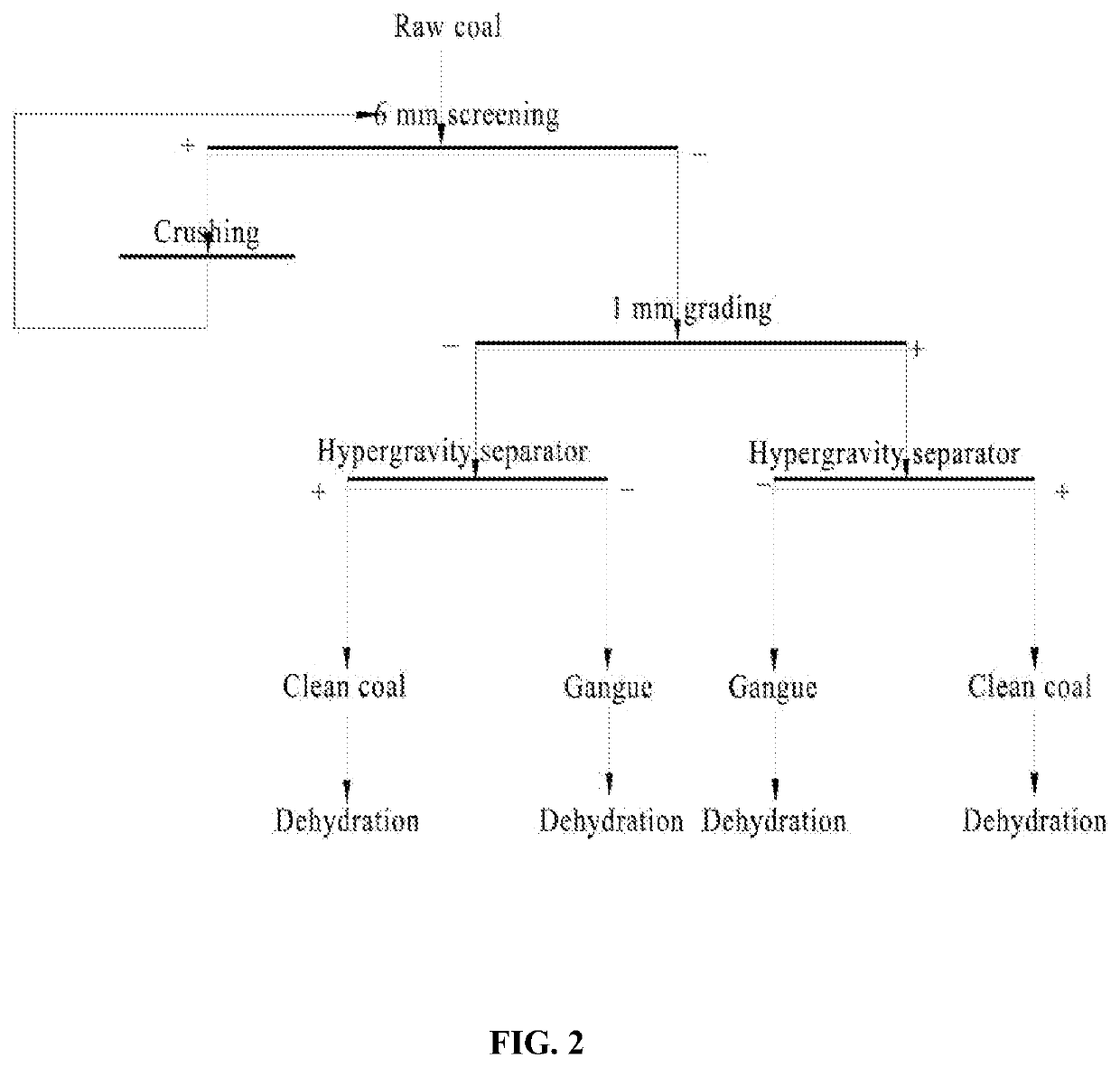

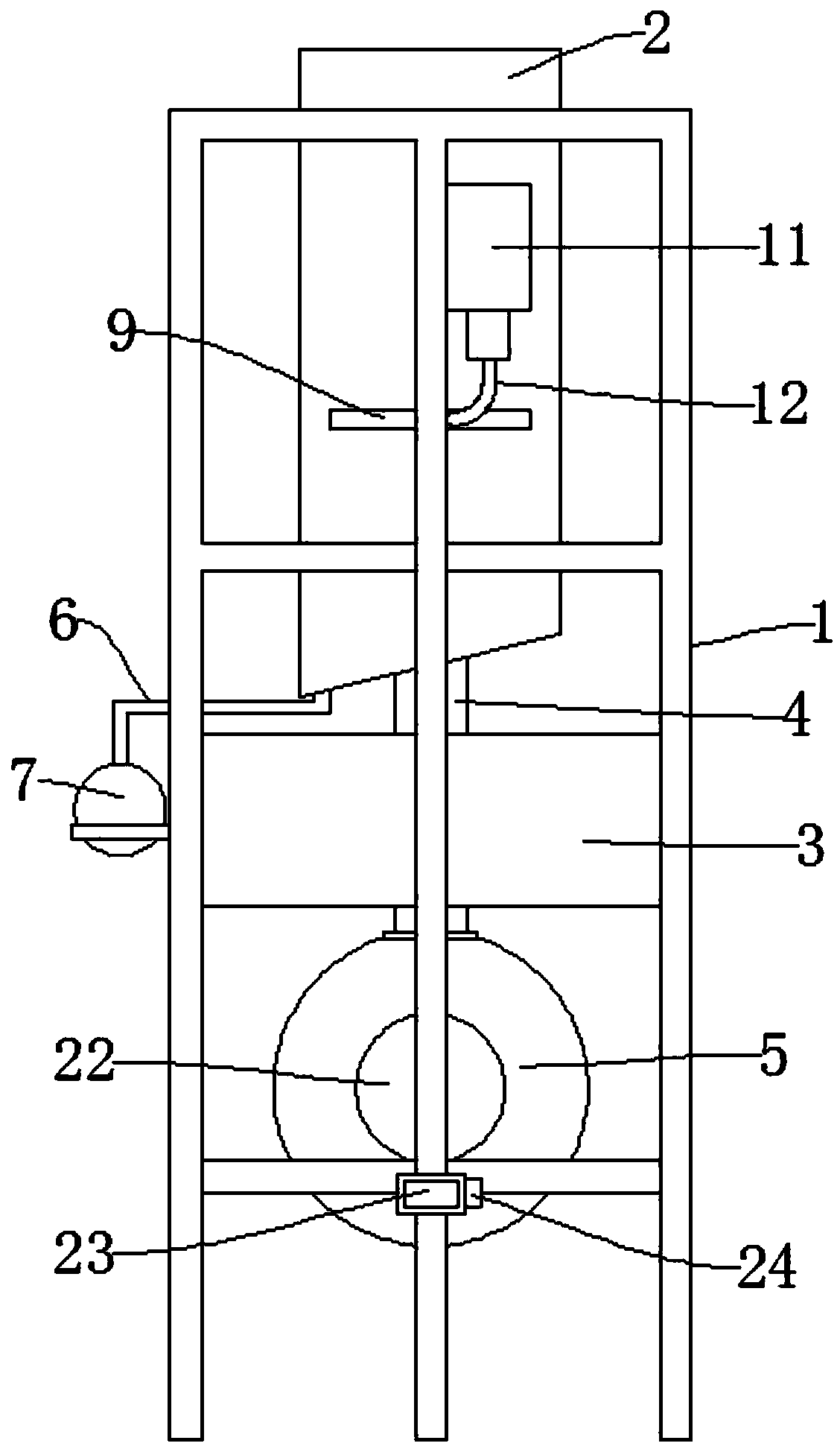

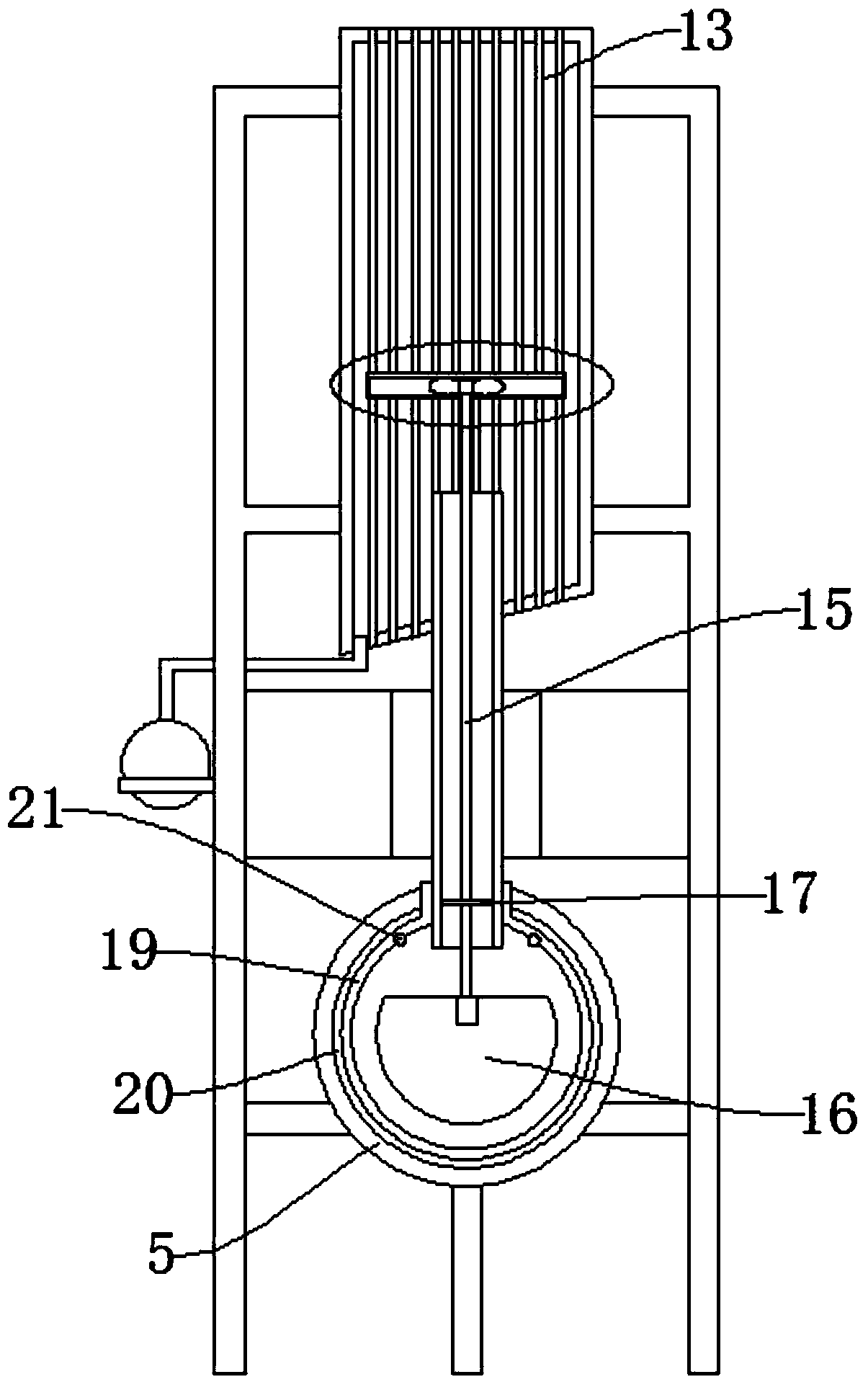

Underground coal hypergravity field separation system and separation process

PendingUS20220314233A1Less supporting equipmentSmall footprintWet separationCoal gangueProcess engineering

The present disclosure relates to the field of mineral processing and separation, and in particular, to an underground coal hypergravity field separation system and a separation process. The separation system includes a grading hydrocyclone group, hypergravity field separators, feeding pumps, and conveying pumps. Coal collected underground is graded through a grading hydrocyclone first, then is fed into the hypergravity field separators for separation, and finally, is conveyed to a next link for dehydration through the conveying pumps. The separation system of the present disclosure has less supporting equipment, small floor area, and no complex pipeline, and is suitable for a downhole operation. In addition, the hypergravity field separators can provide a high-strength centrifugal acceleration, which can realize rapid separation of coal gangue particles in a radial direction and a tangential direction, and realize effective separation of fine coal gangue particles.

Owner:CHINA UNIV OF MINING & TECH

Rotary evaporator for preparing brominated epoxy resin

The invention discloses a rotary evaporator for preparing brominated epoxy resin, wherein the rotary evaporator comprises a rack. The upper end of the rack is equipped with a condenser, the lower endof the condenser is connected with a gas pipeline, the lower end of the gas pipeline is equipped with an evaporation bottle, the inner wall of the evaporation bottle is equipped with a temperature sensor, the outer wall of the evaporation bottle is tightly jacketed with an electric heating piece, and the electric heating piece is externally sleeved with a heat shield cover; the lower end of the rack is equipped with a processor electrically connected with the temperature sensor and a displayer electrically connected with the processor; the middle part of the rack is equipped with a battery. The rotary evaporator has the beneficial effects that the rotary evaporator for preparing the brominated epoxy resin does not need water bath heating and the assistance of water cooling devices during working, has fewer supporting devices and low use cost, significantly reduces the production cost of brominated epoxy resin production enterprises, and has good practicability.

Owner:山东妙捷新型建材有限公司

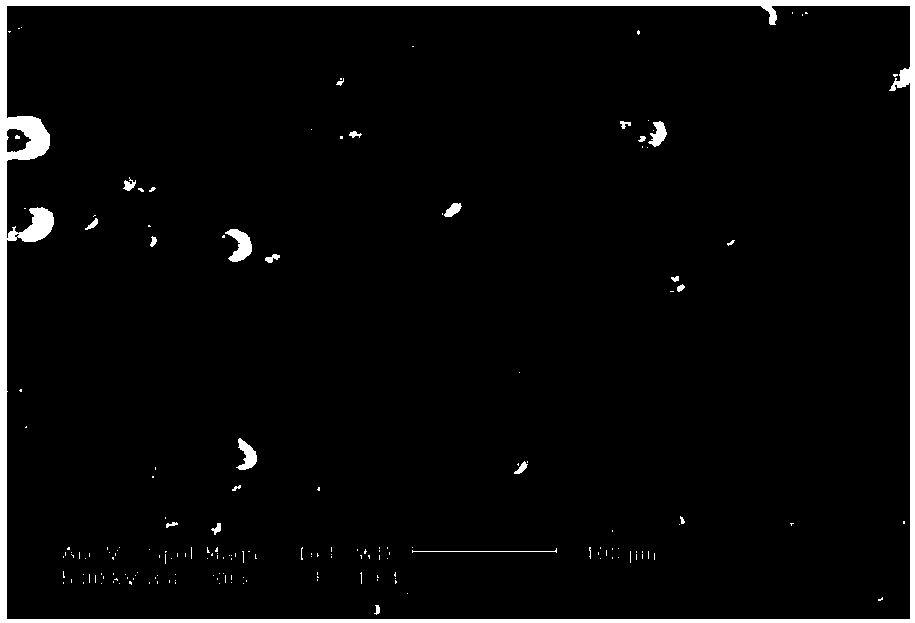

Ethylene polymerization method and polyethylene

InactiveCN108794666AGood chemical stabilityReduce accumulationBulk chemical productionPolymer scienceMagnesium salt

The invention relates to the field of polymerization and discloses an ethylene polymerization method and polyethylene prepared through the same. The ethylene polymerization method comprises, under polymerization conditions and with existence of catalysts, subjecting ethylene to polymerization, wherein the catalysts are composed of a silica-gel carrier and magnesium salt and / or titanium salt carried on the silica-gel carrier; the silica-gel carrier is prepared through the method including the following steps including (1) mixing sodium silicate, polyhydric alcohols and inorganic acids for contact, and then filtering and / or washing the obtained mixture through a ceramic film filter to obtain a silica gel filter cake, and (2) ball-milling the silica gel filter cake obtained in the step (1) and then performing spray drying to obtain the silica-gel carrier. The ethylene polymerization method is high in activity of the applied catalysts and can prepare polyethylene products low in bulk density and melt index.

Owner:CHINA PETROLEUM & CHEM CORP +1

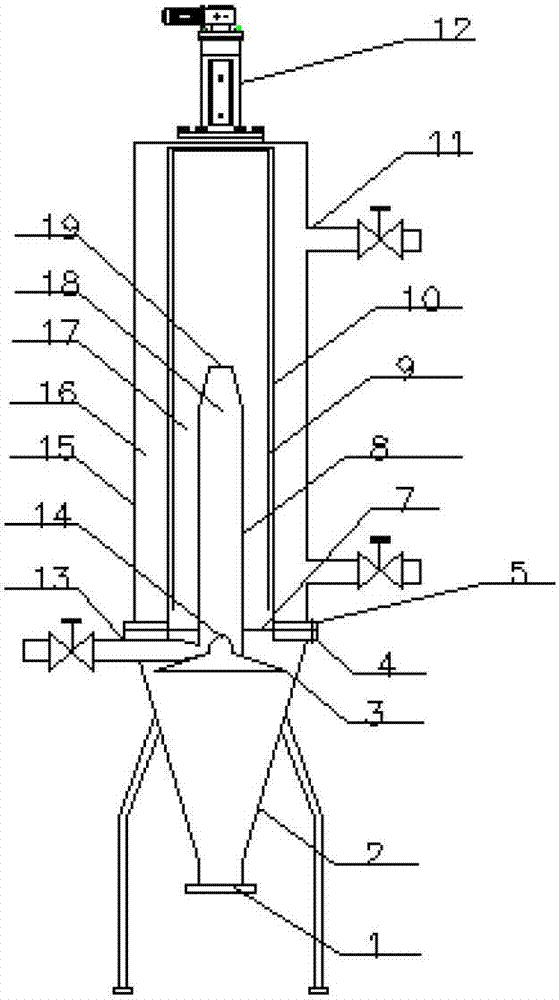

Cyclone separation filter

InactiveCN102815801AEfficient separationImprove separation efficiencyWater/sewage treatment by centrifugal separationMultistage water/sewage treatmentSedimentEnergy consumption

The invention relates to a cyclone separation filter. The cyclone separation filter comprises a raw water inlet tube, a sediment storehouse, a cyclone tube, a cyclone chamber sediment discharge port, and a sediment storehouse sediment discharge port, wherein a housing is sleeved outside the cyclone tube; the housing is provided with a purified liquid outlet; a filter screen cover is arranged between the cyclone tube and the housing; and the housing and the filter screen cover are connected with the sediment storehouse through an upper ring flange and a lower ring flange. The cyclone separation filter enables the solid-liquid separation efficiency to be improved and especially the fine particle removal efficiency to be improved, and has the advantages of simple and compact structure, reduction of conveying pipelines and matching equipment, and realization of less energy consumption, low running cost, convenient operation and convenient cleaning.

Owner:董伟

Method for transporting grouting material vertical delivery pipe used for mine

InactiveCN102720532ANot affected by interaction interferenceReduce shipping costsEarth drilling and miningUnderground transportTransport systemBrick

The invention discloses a method for transporting a grouting material vertical delivery pipe used for a mine. The method comprises the following steps of: building a delivery bore hole with a diameter of 0.5 to 0.8 meters from the ground to a underground laneway, sinking a wear-resistant sleeve in the delivery bore hole, arranging a buffer chamber and a separation chamber at the bottom of the delivery bore hole, arranging a mixing station at the lower part of the buffer chamber and the separation chamber, and arranging a separator at the openings of the buffer chamber and the separation chamber. The method is characterized in that the buffer chamber and the separation chamber are built on a cave chamber in a way that the efficient buffer height is not less than 3 meters, the two chambers are separated by a brick wall of 50 cm thickness, the separator is a forked pipe, a baffle plate capable of being opened leftward and rightward is arranged in the pipe, and the baffle plate is controlled by a hydraulic oil cylinder to distribute different types of materials to different chambers. The method adopts the independent transport system which is free of the mutual interference with the auxiliary shaft lifting system, reduces the transport cost, and works under the action of self-gravity to save the cost.

Owner:鄂托克前旗长城煤矿有限责任公司

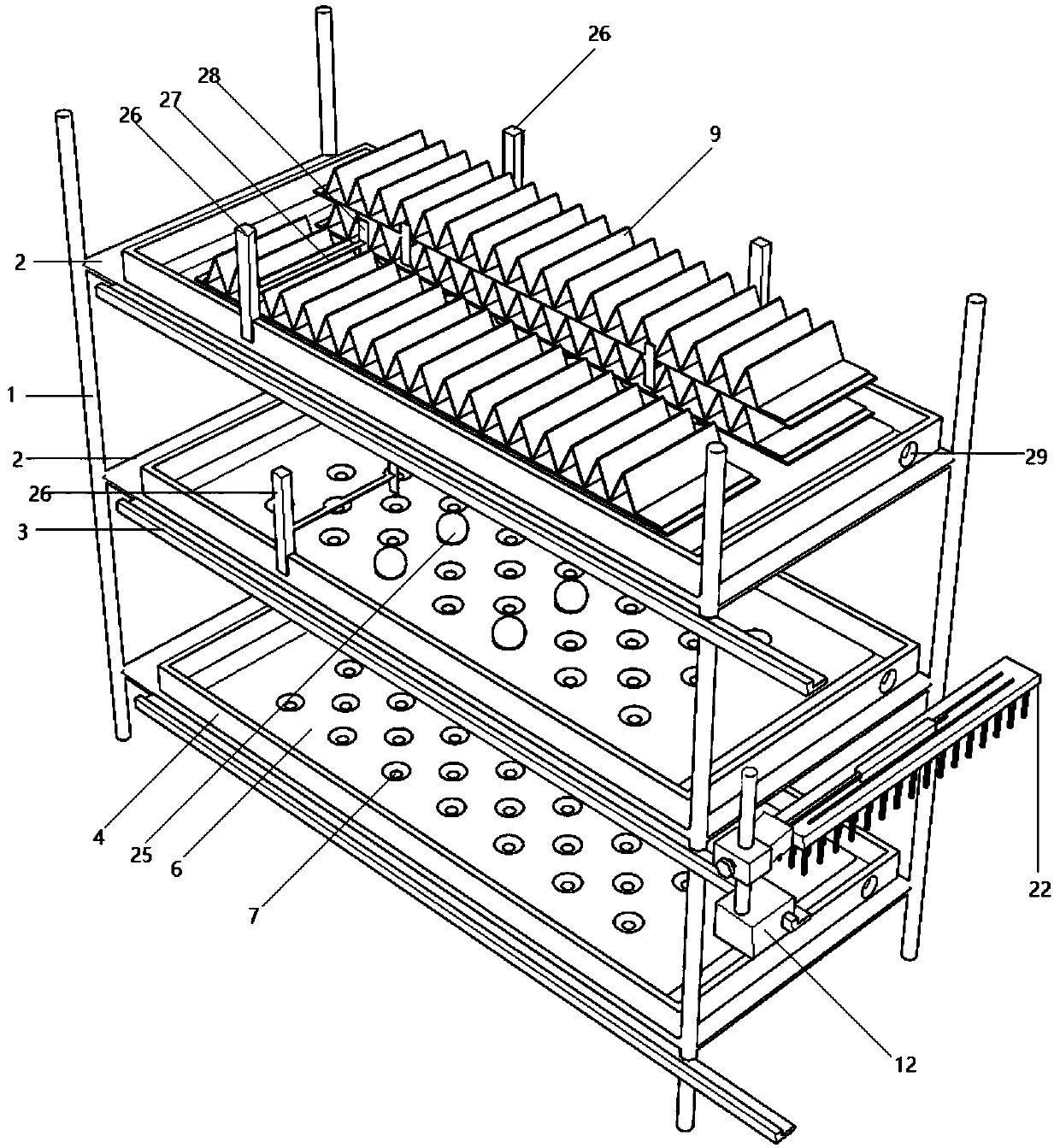

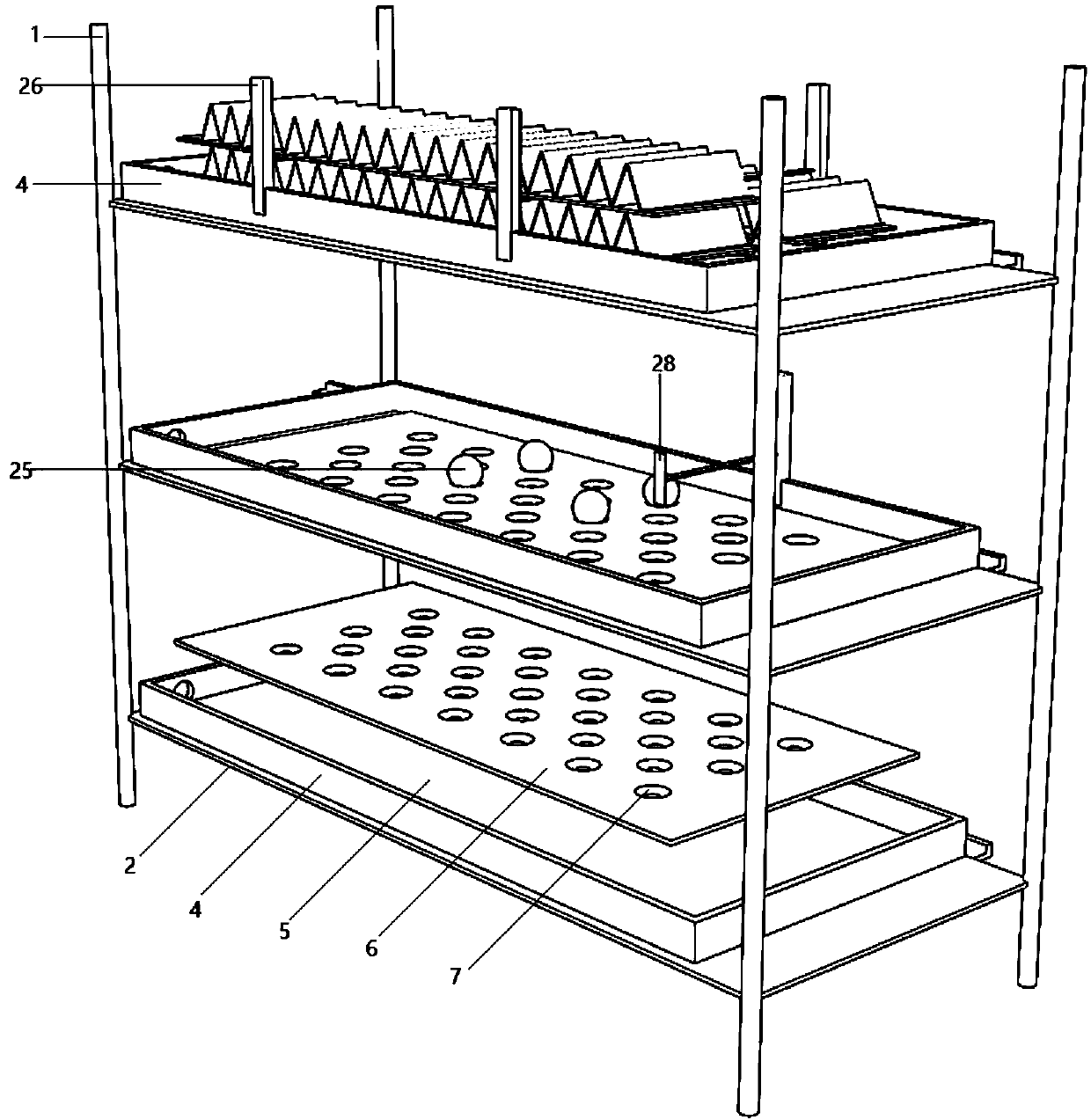

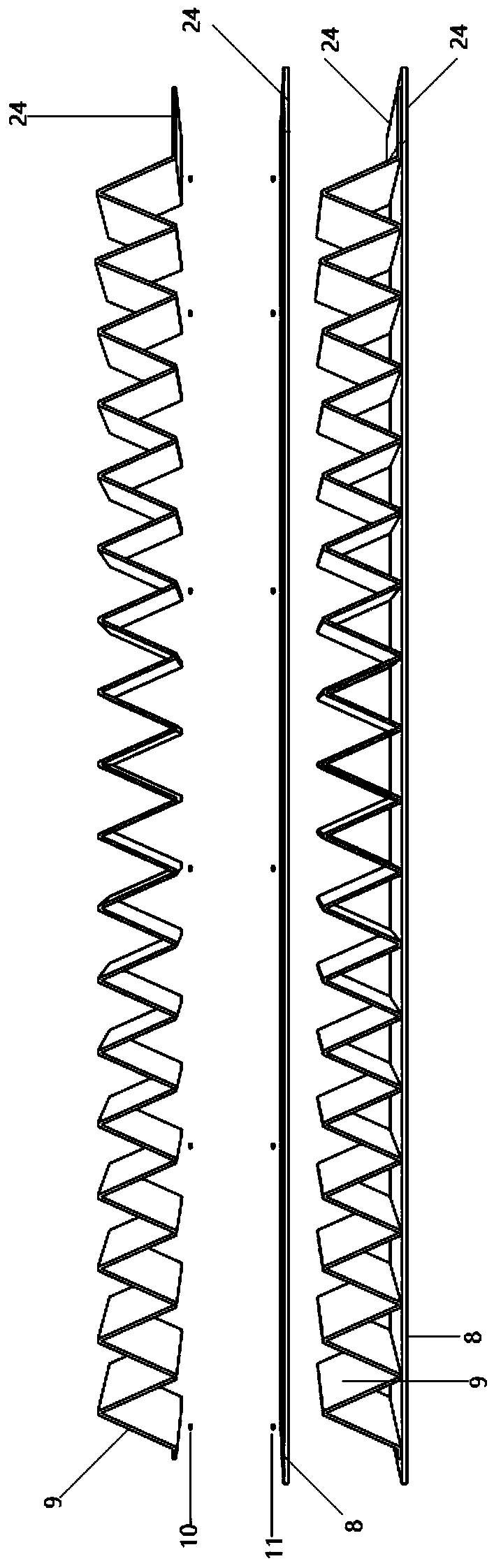

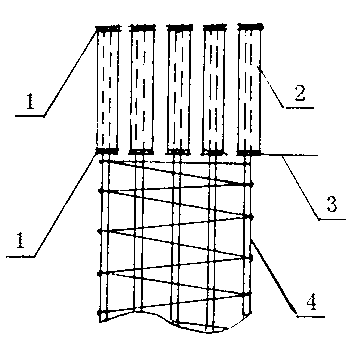

Three-dimensional silkworm breeding special device

ActiveCN109644954AClean thoroughlyFast layingCleaning using toolsAnimal husbandryDrive motorForward backward

The invention discloses a three-dimensional silkworm breeding special device and relates to the technical field of silkworm breeding equipment. The three-dimensional silkworm breeding special device comprises a support and a clean cocoon picking device; the upper end of every layer plate is provided with a breeding device, the inside of every breeding device is provided with a cocooning device, the cocooning device comprises a lower bottom belt and an upper support belt, wherein the support belt is in a continuous V shape; the clean cocoon picking device comprises a slider slidingly matched with a sliding rail; a driving motor is mounted inside a mounting tube, the output end of the driving motor is provided with a reciprocating cylindrical cam; the inside of the mounting tube is slidinglyconnected in a sleeve mode with a driving tube; a support rod is connected in a sleeve mode with a horizontal hairbrush; a brush board is provided with two cocoon picking through slots in a forward-backward direction. The three-dimensional silkworm breeding special device has the advantages of achieving cleaning of breeding grooves and picking cocoons in the cocooning devices, saving support equipment of silkworm breeding, and facilitating and accelerating arrangement of the cocooning devices and subsequent cocoon picking operation.

Owner:滨州高新材料产业园有限公司

Rapid separation and integral hoisting method for pile head of cast-in-place concrete pile

Owner:GANSU TIEKE CONSTR ENG CONSULTING +1

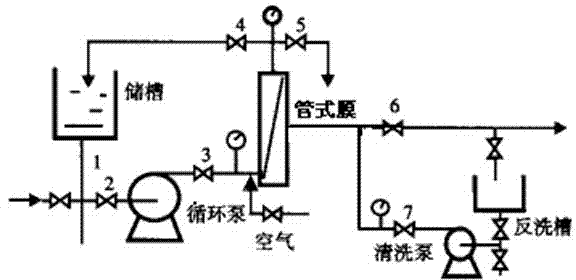

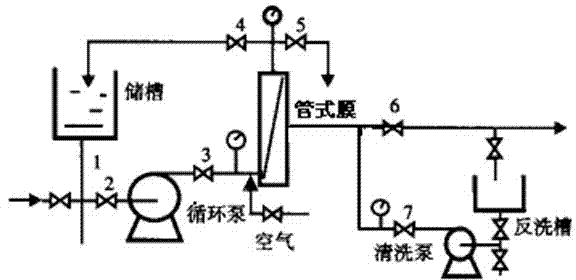

Method for fast clarification of freshly squeezed bayberry juice

InactiveCN102293431AAchieve the effect of aseptic cold fillingImprove stabilityFood scienceOrganic filmFlavor

The invention discloses a method for quickly clarifying freshly squeezed bayberry raw juice, which comprises the following steps: the first step, sorting; the second step, rinsing; the third step, denucleation; the fourth step, pressing; the fifth step, Filtration; the raw bayberry juice is first filtered through a bag-type trap, and then enters a stainless steel storage tank that has been sterilized; then the filtrate is pumped into the stainless steel container of the tubular membrane filter and passed through the tube. Type membrane filter carries out fine filtration, obtains the raw bayberry juice of aseptic clarification; Described tube type membrane filter adopts the organic membrane that molecular weight is 100000, and pore diameter is 0.1um; The 6th step, filling; The 7th step, store. The invention has fewer procedures and fewer consumables, so the loss is very small, and the production cost is 20% lower than that of the traditional method. The invention can minimize the loss of nutrients in the bayberry and preserve the unique flavor of the bayberry.

Owner:浙江聚仙庄饮品有限公司

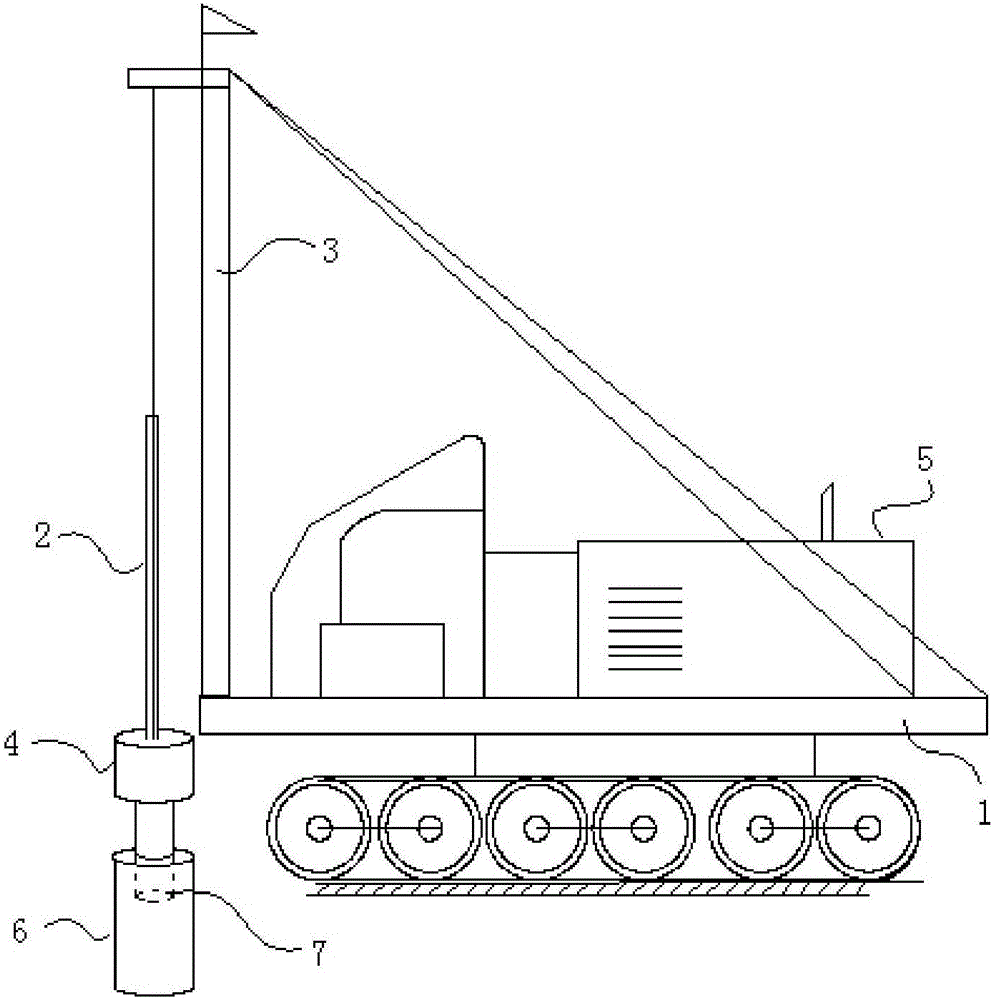

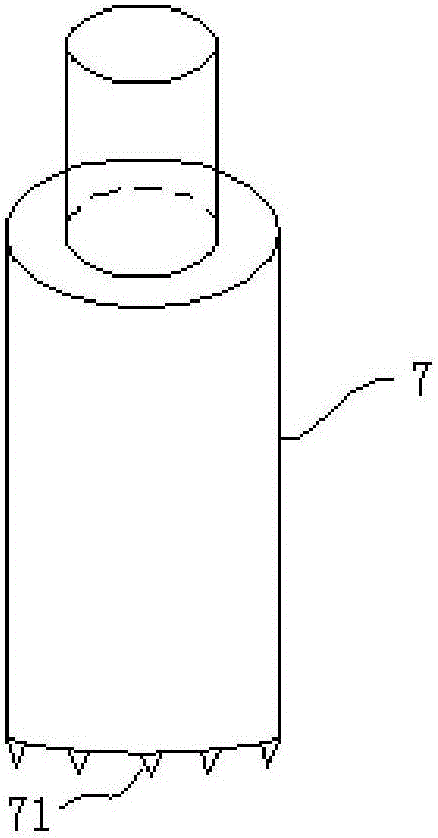

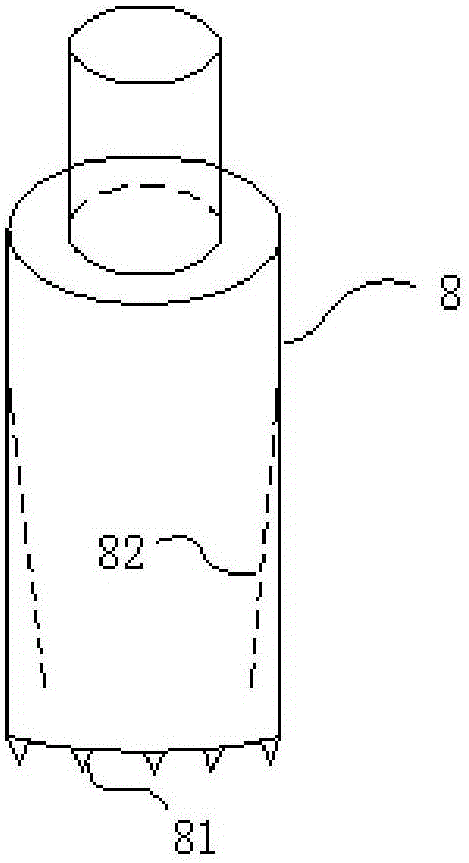

Integral type rotary obstacle clearing machine and obstacle clearing method

InactiveCN105756064AQuick clearImprove work efficiencyBulkheads/pilesPower equipmentVertical cylinder

The invention provides an integral type rotary obstacle clearing machine and an obstacle clearing method, and relates to the technical field of civil engineering construction, which aims at solving the technical problems of improving operation efficiency and saving construction occupation space. The integral type rotary obstacle clearing machine comprises a chassis, a drill pipe and a support frame, wherein the support frame is fixedly arranged on the chassis; the drill pipe is arranged on the support frame; a rotary driving base is arranged at the lower end of the drill pipe; a drill bit is arranged on the driving base; power equipment is arranged on the chassis and is used for driving the rotary driving base to rotate; a steel sleeve cylinder is fixedly arranged on the driving base, and is a vertical cylinder body of which the upper end and lower end are opened, and the drill bit is arranged in the steel sleeve cylinder, and is in clearance fit with the steel sleeve pipe; the drill bit is a vertical cylinder body which is downwards opened, and a plurality of cutting knives are fixedly arranged at the lower end of the drill bit and are distributed around a cylinder center axis of the drill bit. The integral type rotary obstacle clearing machine is suitable for clearing underground piles.

Owner:铧巍牛咨询管理(上海)有限公司

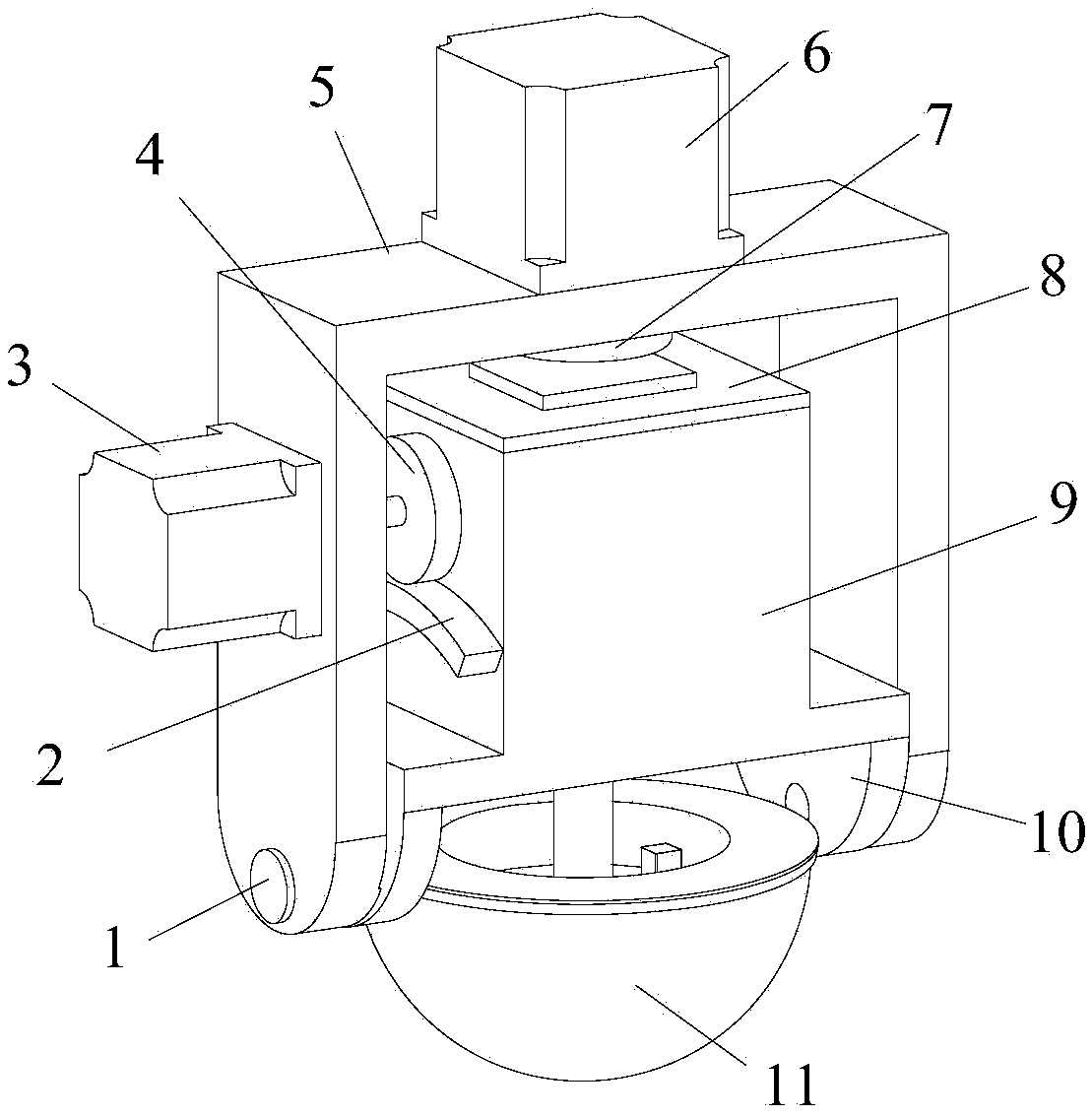

Compact type gasbag polishing precession mechanism

ActiveCN105364690ASmall footprintSimple structurePolishing machinesGrinding drivesCouplingPrecession

The invention discloses a compact type gasbag polishing precession mechanism and relates to gasbag polishing. The compact type gasbag polishing precession mechanism is provided with horizontal shafts, an arc rack, a horizontal shaft motor, a gear, a swing arm, a vertical shaft motor, a vertical shaft, an end cover, a spindle box, spindle box swing arms, a gasbag tool, a spindle motor, a coupling and a bearing. The swing arm is installed vertically. The vertical shaft motor is vertically installed at the top of the swing arm and controls the swing arm to rotate. The spindle box is installed inside the swing arm in an inlaid mode. The spindle box swing arms are connected with the lower end of the swing arm through the horizontal shafts. The arc rack is installed on the left side of the spindle box. The horizontal shaft motor is vertically fixed to the left side of the swing arm. The gear installed at the motor shaft end of the horizontal shaft motor is engaged with the arc rack. The spindle motor is of a hollow structure and is installed inside the spindle box. The gasbag tool is located at the bottom of the spindle box and connected with a spindle of the spindle motor through the coupling. According to the compact type gasbag polishing precession mechanism, a tire structure is adopted, inflation is easy, the precession mechanism can be separated from a pneumatic supply, the number of matched devices of a machine tool is reduced, and the spindle structure of the machine tool is simplified.

Owner:XIAMEN UNIV

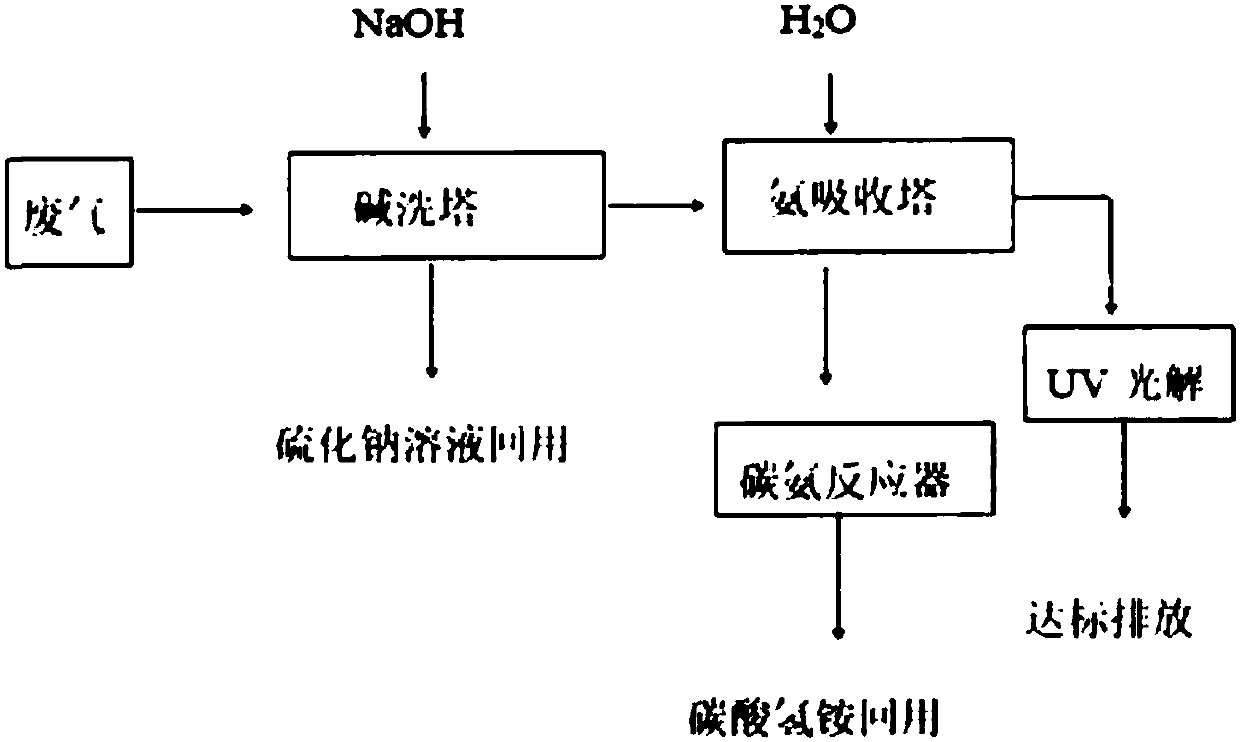

Method and system for treating exhaust gas containing ammonia and ammonium sulfide

PendingCN107754602ALarge concentration adjustment rangeEfficient and reasonable useGas treatmentDispersed particle separationHigh rateAmmonium sulfide

The invention discloses a method and system for treating exhaust gas containing ammonia and ammonium sulfide. The method comprises leaching exhaust gas containing ammonia and ammonium sulfide througha NaOH solution in an alkaline washing zone, absorbing ammonia gas in an ammonia absorption zone, oxidizing unabsorbed ammonia gas through ozone in a UV photolysis zone and carrying out discharge. Thesystem comprises the alkaline washing zone, the ammonia absorption zone, the UV photolysis zone and an ammonium bicarbonate reaction zone. One end of the ammonia absorption zone is communicated withthe alkaline washing zone. The other end of the ammonia absorption zone is communicated with the UV photolysis zone and the ammonium bicarbonate reaction zone. Compared with the prior art, the methodand system for treating exhaust gas containing ammonia and ammonium sulfide realize a low production cost. The system has low maintenance frequency, a high rate of reaching the designed standard, a low operation cost and a low ammonium bicarbonate production unit comprehensive cost, saves energy, is environmentally friendly and has high economic efficiency and social benefits.

Owner:湖南内特环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com