Supported metallocene catalyst, preparation method and application thereof and methyl acrylate preparation method

A technology of metallocene catalysts and metallocene compounds, applied in the direction of catalyst activation/preparation, preparation of organic compounds, chemical instruments and methods, etc., can solve the problem of insufficient catalytic activity, achieve strong regeneration ability, improve product purity, reduce powder The effect of group reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] In the preparation method of the silica gel carrier in the prior art, the step of removing the template agent after spray drying is usually included, for example, the template agent is removed by a calcination method. Since the method of the present invention uses a ceramic membrane for filtration and / or washing treatment, the method for preparing the silica gel carrier of the present invention may not include the step of calcination to remove the template agent.

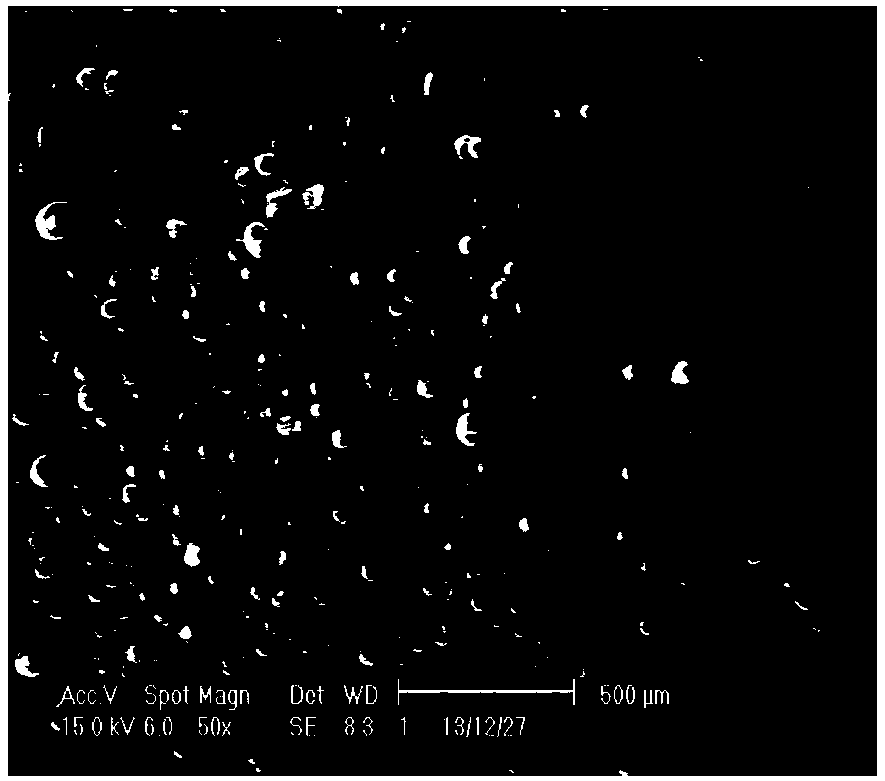

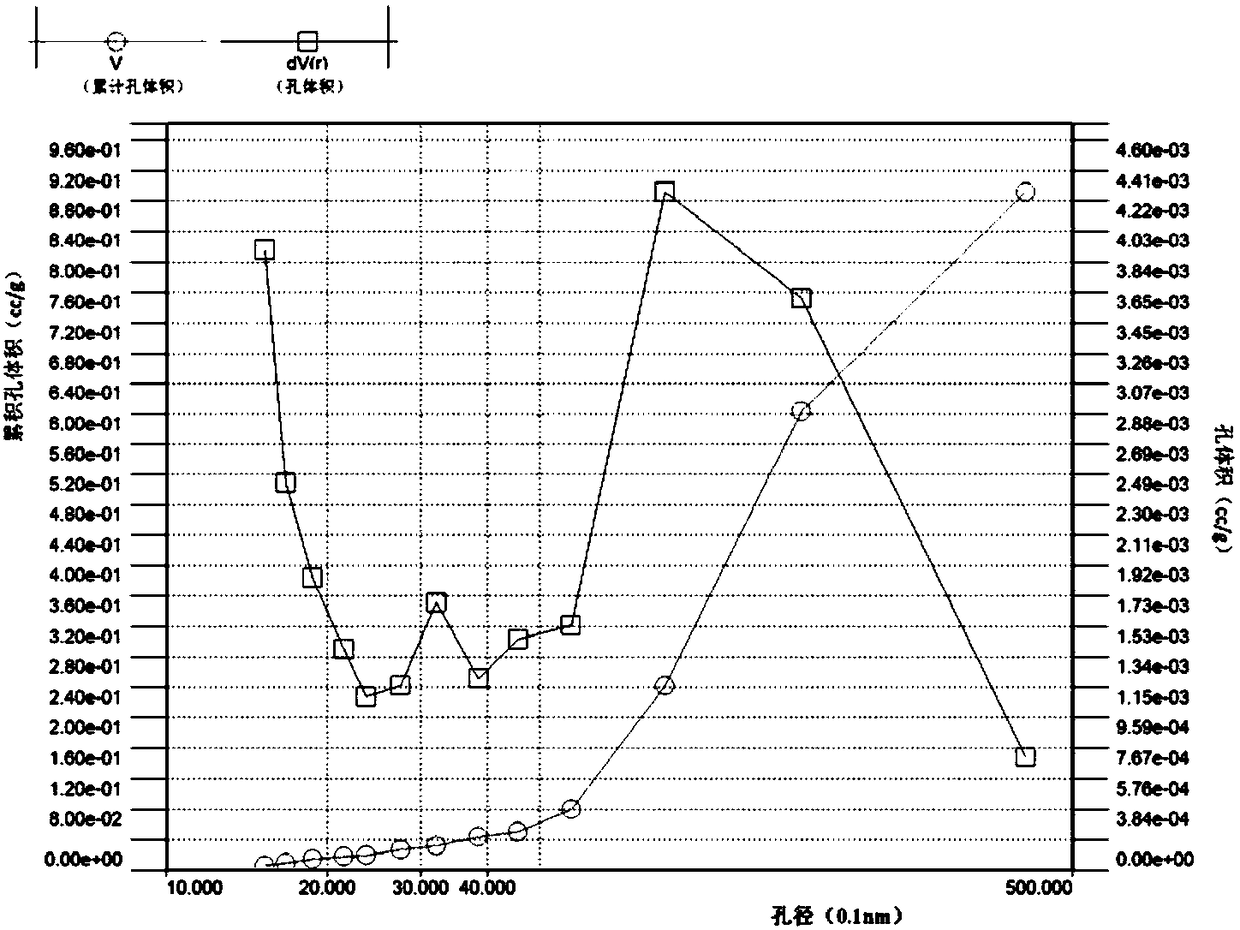

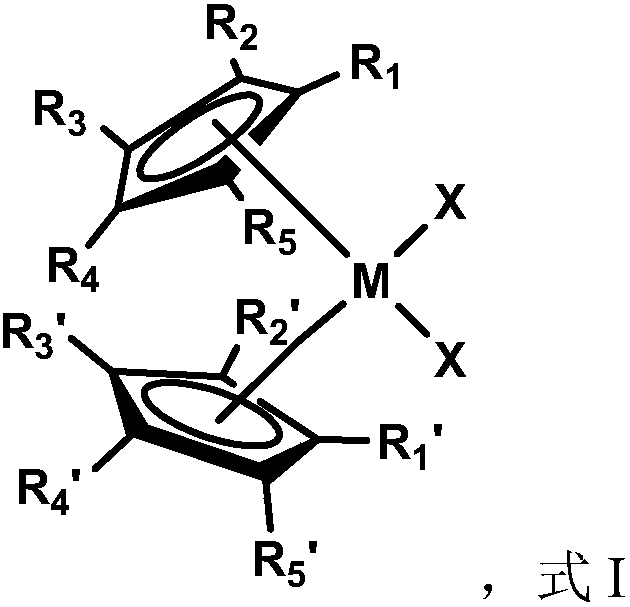

[0048] In the present invention, the average particle diameter of the silica gel carrier is 30-60 μm, and the specific surface area is 150-600 m 2 / g, the pore volume is 0.5-2.5mL / g, the pore size distribution is bimodal, and the most probable pore diameters corresponding to the bimodal are 1-4.5nm and 20-50nm.

[0049] Preferably, the silica gel carrier has an average particle diameter of 30-60 μm and a specific surface area of 200-400 m 2 / g, the pore volume is 1-2mL / g, the pore diameter distribution is ...

Embodiment 1

[0072] This example is used to illustrate the supported metallocene catalyst of the present invention and its preparation method

[0073] (1) Preparation of silica gel carrier

[0074] Concentration is that the water glass of 15% by weight, the sulfuric acid solution of 12% by weight, n-butanol and glycerol are mixed with the weight ratio of 5:1:1:1 and contact reaction at 20 ℃ for 1.5 hours, then use Sulfuric acid with a concentration of 98% by weight adjusted the pH value to 3, and then the obtained reaction material was suction-filtered and washed with a ceramic membrane filter until the sodium ion content was 0.02% by weight to obtain a silica gel filter cake. Among them, the operating pressure of the membrane module is 3.3bar, the inlet membrane pressure of the circulation side is 4bar, the outlet membrane pressure of the circulation side is 2.5bar, the membrane surface velocity of the circulation side is 4m / s, the pressure of the permeation side is 0.3bar, and the temper...

Embodiment 2

[0086] This example is used to illustrate the supported metallocene catalyst of the present invention and its preparation method

[0087] (1) Preparation of silica gel carrier

[0088] Concentration is that the water glass of 15% by weight, the sulfuric acid solution of 12% by weight, n-butanol and glycerol are mixed with the weight ratio of 6:3:1:1 and contact reaction at 60 ℃ for 3 hours, then use Sulfuric acid with a concentration of 98% by weight adjusted the pH value to 3, and then the obtained reaction material was suction-filtered and washed with a ceramic membrane filter until the sodium ion content was 0.02% by weight to obtain a silica gel filter cake. Among them, the operating pressure of the membrane module is 3bar, the inlet membrane pressure of the circulation side is 3.5bar, the outlet membrane pressure of the circulation side is 2.5bar, the membrane surface velocity of the circulation side is 4.5m / s, the pressure of the permeation side is 0.4bar, and the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com