Compact type gasbag polishing precession mechanism

A kind of airbag polishing and compact technology, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding drive devices, etc. It can solve the problems of easy deformation of the swing arm, large space occupation, high cost, etc., and reduce the supporting equipment of machine tools device, increase structural rigidity, and save space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

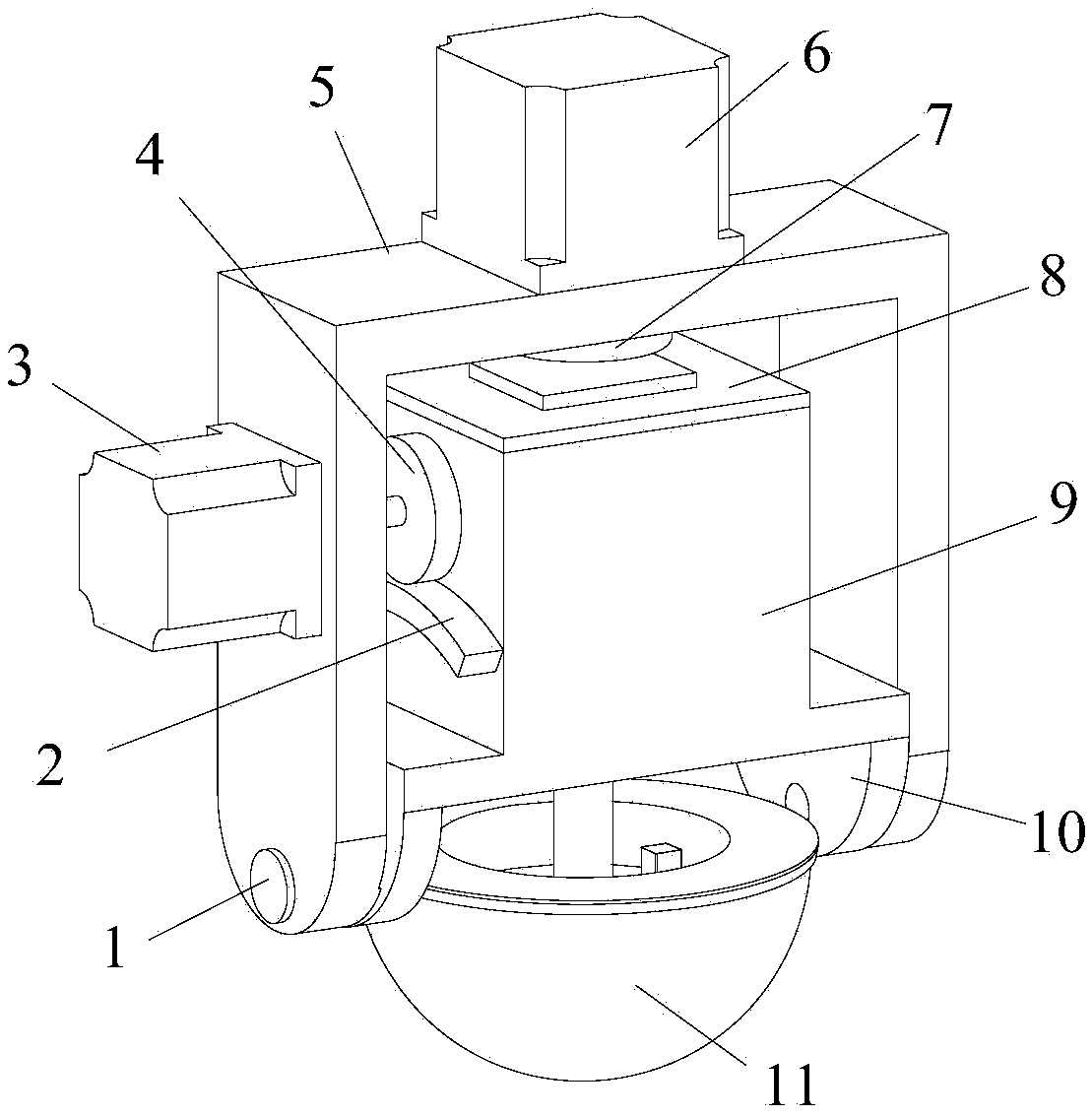

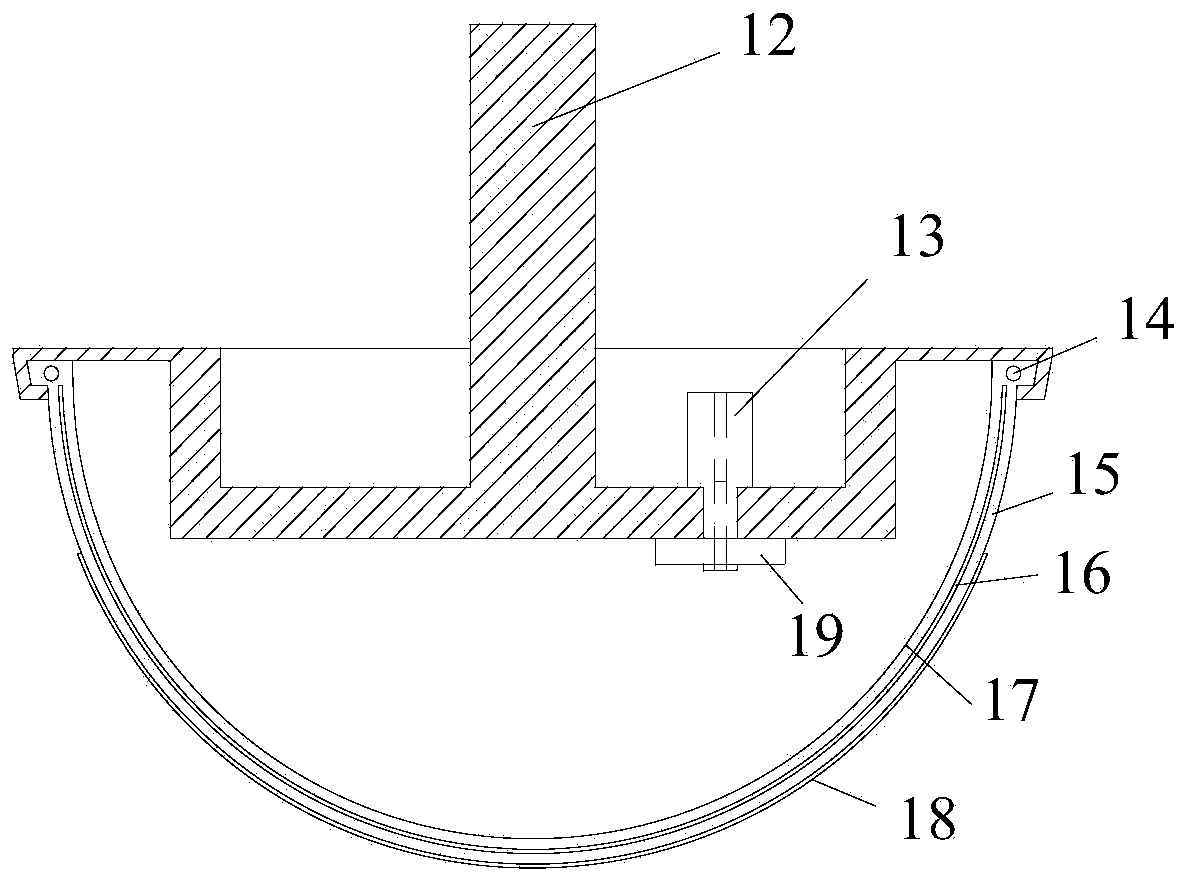

[0016] Such as figure 1 and 2 As shown, the embodiment of the present invention is provided with a horizontal axis 1, an arc rack 2, a horizontal axis motor 3, a gear 4, a swing arm 5, a vertical axis motor 6, a vertical axis 7, an end cover 8, a headstock 9, and a headstock Swing arm 10, airbag tool 11, spindle motor, coupling and bearing.

[0017] Described swing arm 5 is vertically installed, and vertical shaft motor 6 is vertically installed on swing arm 5 tops, controls swing arm 5 to rotate, and headstock 9 is nestedly installed in swing arm 5 inside, and headstock swing arm 10 passes horizontal axis 1 and The lower end of the swing arm 5 is connected, the arc rack 2 is installed on the left side of the headstock 9, the horizontal axis motor 3 is vertically fixed on the left side of the swing arm 5, and the gear 4 and the arc rack 2 installed on the motor shaft end of the horizontal axis motor 3 Engaging; the main shaft motor is a hollow structure, the main shaft motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com