Rapid separation and integral hoisting method for pile head of cast-in-place concrete pile

An integral hoisting and concrete technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of high efficiency, high quality inconsistency, manpower and material resources, major damage to the main reinforcement, etc., to achieve the reduction of construction equipment and personnel, The effect of saving time and less supporting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiment and accompanying drawing:

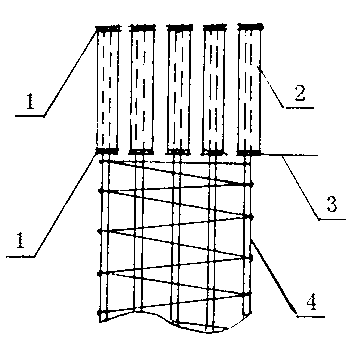

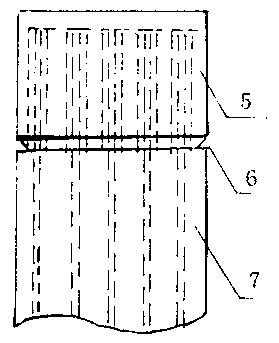

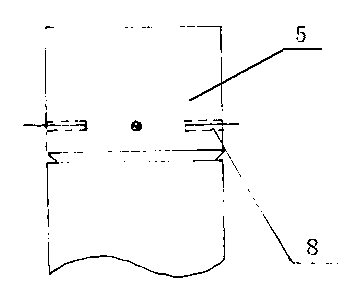

[0026] Such as figure 1 As shown, before the reinforcement cage is lowered, the elbow of the main reinforcement 4 of the reinforcement cage is not applied first (in the construction design of some cast-in-place piles, in order to strengthen the connection effect between the concrete pouring pile and the cap, the end of the main reinforcement 4 of the reinforcement cage is made into a 90° 。 Elbow), first install a plastic casing 2 (PVC casing) with a certain length, wall thickness and hardness on the top of the main reinforcement 4 of the steel cage (the pile head section needs to be chiseled), and the inner diameter is larger than the outer diameter of the main reinforcement 4 of the steel cage. The inner diameter, wall thickness and hardness of the casing 2 must meet the requirements. The length and insertion position of the plastic casing 2 must be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com