Machining method of small titanium and titanium alloy rod wire

A processing method and technology of titanium alloy, applied in the direction of manufacturing tools, metal rolling, furnace types, etc., can solve the problem of inability to directly produce bright and pollution-free finished rods and wires, uneconomical production of rare metals, and high investment in high-speed finishing mills. and other problems, to achieve the effect of being conducive to grain refinement, elimination of dynamic recrystallization, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

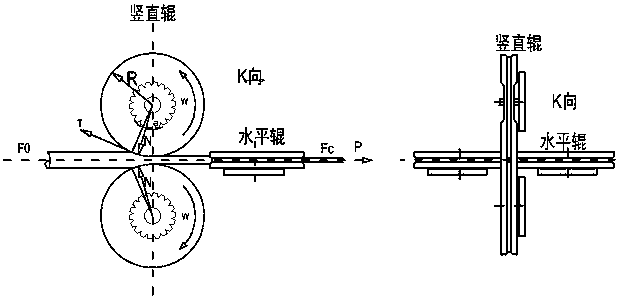

Image

Examples

Embodiment 1

[0034] First take the titanium and titanium alloy bar blanks with a specification of Φ15mm, and use a coreless lathe to remove the 1mm thick surface oxide layer and defects to obtain bright, pollution-free and defect-free bright blanks. Then put the processed billet into a vacuum furnace for vacuum heating and heat preservation for 60 minutes, and then cool down to room temperature naturally with the furnace and leave the furnace. The titanium and titanium alloy rods with a diameter of Φ10mm are cold-rolled by the cold rolling unit, and the Φ10mm rods are placed in a vacuum furnace for 60 minutes of vacuum heating, and then naturally cooled to room temperature with the furnace and released from the furnace. Then the vacuum annealed Φ10mm bar is cold-rolled by a cold rolling mill, and rolled into a Φ7.5mm finished bar with a bright surface, no pollution, and no oxide layer. If the finished product needs to be annealed, it can be put into vacuum heating for 40 minutes, and then ...

Embodiment 2

[0036] First take titanium and titanium alloy bar blanks with a specification of Φ12mm, and use a coreless lathe to remove the surface oxide layer and defects with a thickness of 1mm to obtain bright, pollution-free and defect-free bright blanks. Then put the processed billet into a vacuum furnace for vacuum heating and heat preservation for 60 minutes, and then cool down to room temperature naturally with the furnace and leave the furnace. The titanium and titanium alloy rods with a diameter of Φ8mm are cold-rolled by the cold rolling unit, and the Φ8mm rods are placed in a vacuum furnace for 60 minutes of vacuum heating, and then naturally cooled to room temperature with the furnace and released from the furnace. Then the vacuum annealed Φ8mm bar is cold-rolled by a cold rolling mill, and rolled into a Φ6.0mm finished bar with a bright surface, no pollution, and no oxide layer. If the finished product needs to be annealed, it can be put into vacuum heating for 30 minutes, an...

Embodiment 3

[0038] First take the titanium and titanium alloy bar blanks with a specification of Φ10mm, and use a coreless lathe to remove the 1mm thick surface oxide layer and defects to obtain bright, pollution-free and defect-free bright blanks. Then put the processed billet into a vacuum furnace for vacuum heating and heat preservation for 60 minutes, and then cool down to room temperature naturally with the furnace and leave the furnace. The titanium and titanium alloy rods with a diameter of Φ7mm are cold-rolled by the cold rolling unit, and the Φ7mm rods are placed in a vacuum furnace for 60 minutes of vacuum heating, and then naturally cooled to room temperature with the furnace and released from the furnace. Then the vacuum annealed Φ7mm bar is cold-rolled by a cold rolling mill, and rolled into a Φ5.0mm finished bar with a bright surface, no pollution, and no oxide layer. If the finished product needs to be annealed, it can be put into vacuum heating for 30 minutes, and then coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com