Patents

Literature

103results about How to "Solve the large measurement error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

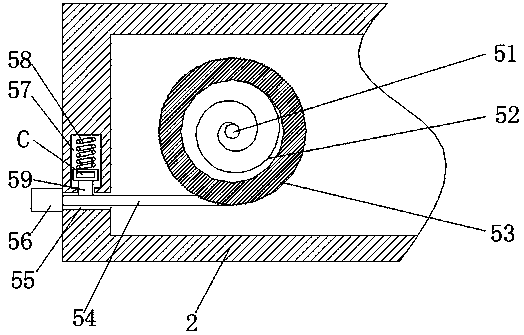

Pressure sensor for extracorporeal circulating circuit

InactiveUS20090071258A1Solve the large measurement errorPressure detectionFluid pressure measurement by electric/magnetic elementsSuction devicesExtracorporeal circulationEngineering

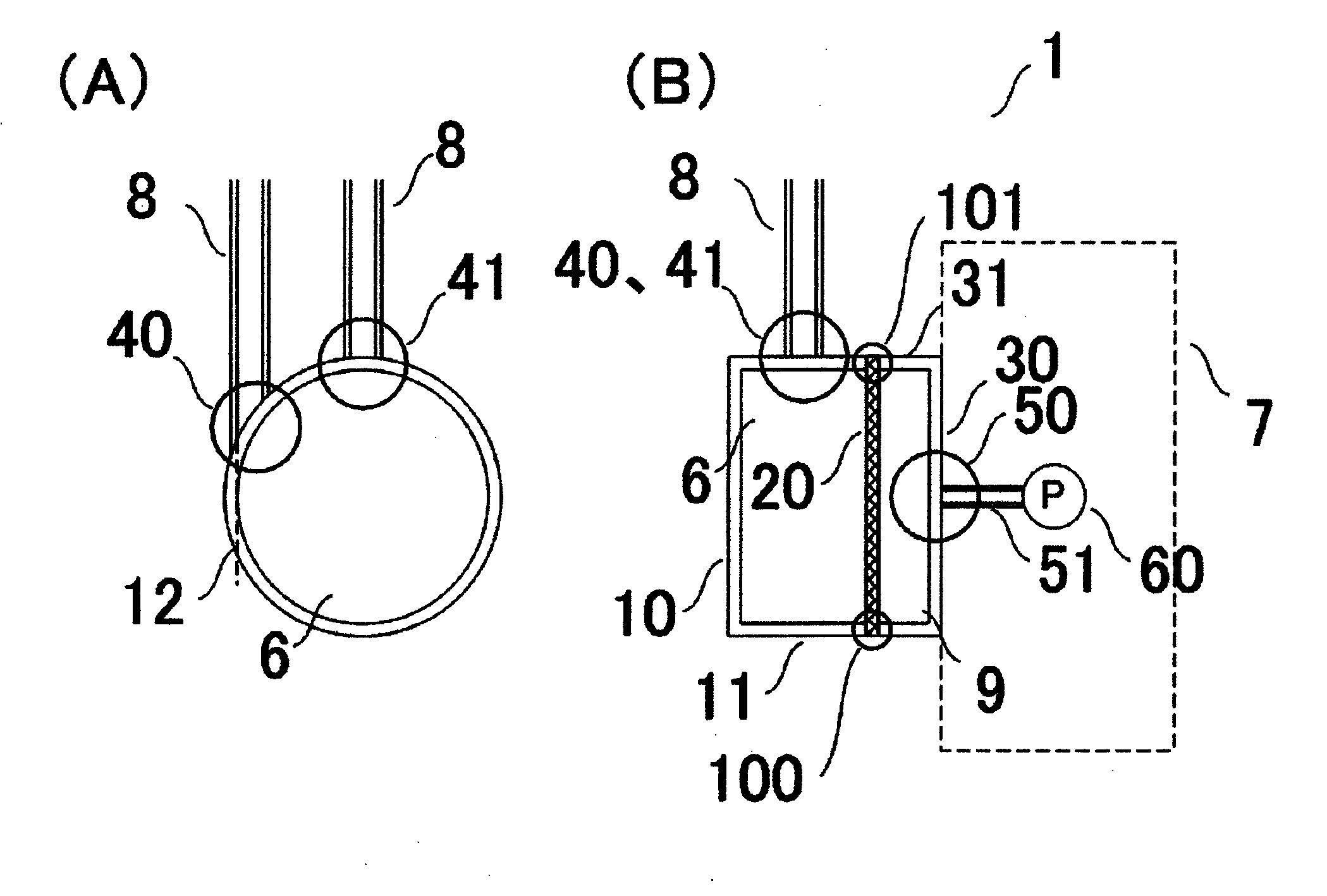

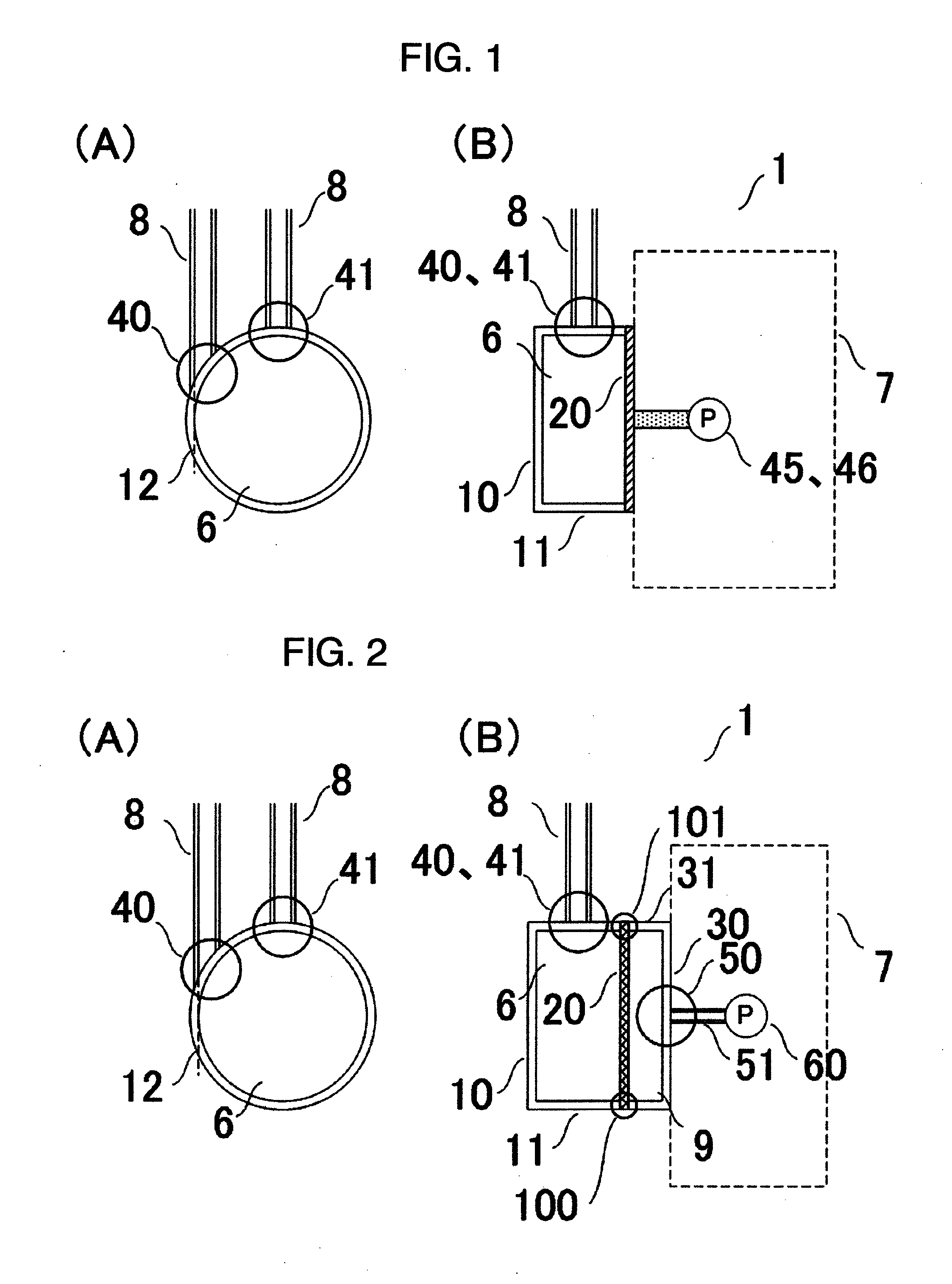

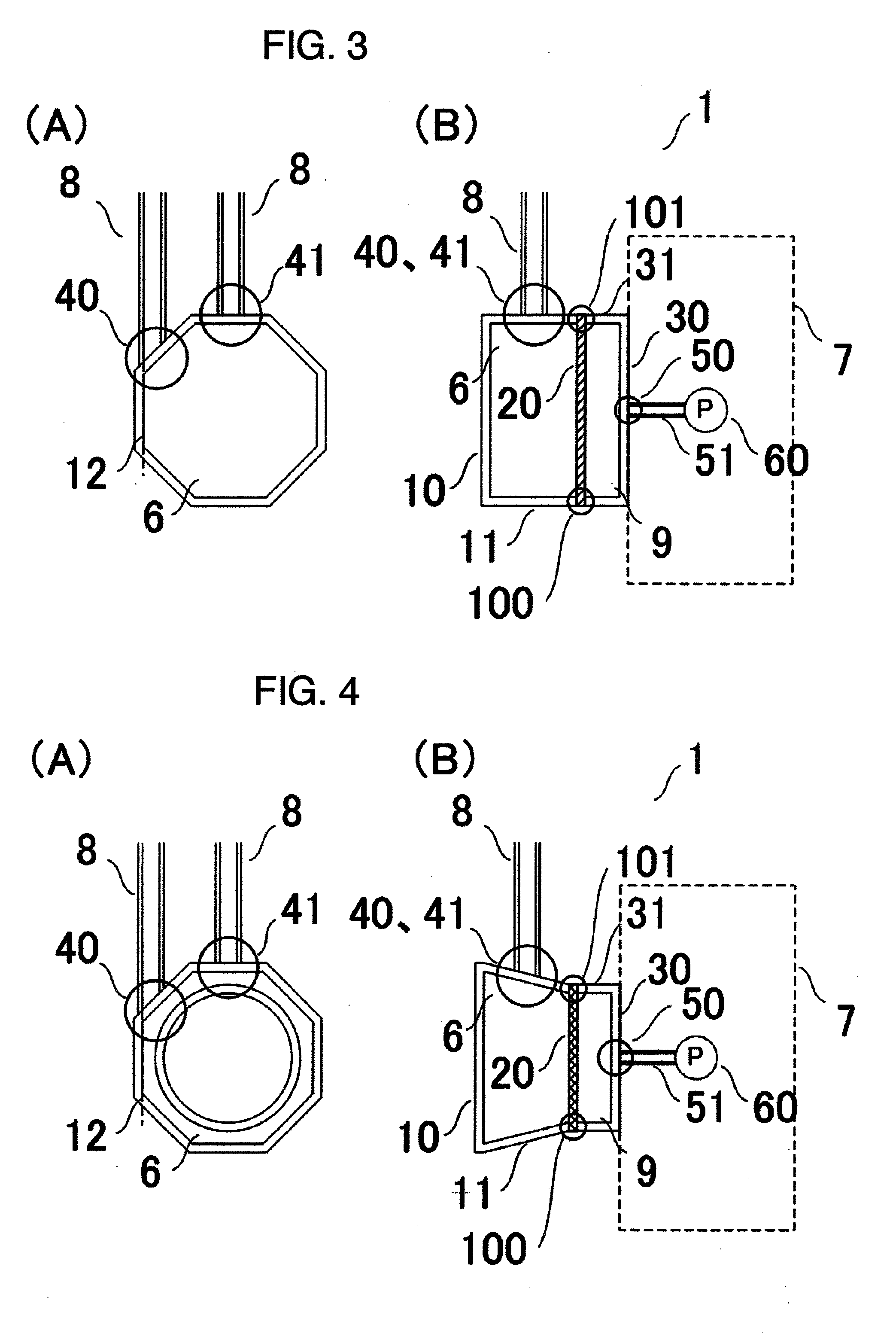

A pressure sensor for an extracorporeal circulating circuit includes a liquid chamber, a pressure measuring means, and a liquid flow path. The liquid chamber includes a reference surface not deformed by a pressure in the extracorporeal circulating circuit, a deforming surface disposed separated from the reference surface and deformed at least partially by a pressure in the extracorporeal circulating circuit, a first connection surface that joins the deforming surface with the reference surface to form a closed liquid-tight space inside them and is not deformed by a pressure in the extracorporeal circulating circuit, a liquid inflowing port provided in the side surface of the first connection surface, and a liquid outflowing port disposed away by ½ to less than one round from the inflowing port in the flowing direction of liquid introduced along the inner periphery of the side surface of the first connection surface. The pressure measuring means measures the deformation amount of the deforming surface, and is disposed outside the liquid chamber; and the liquid flow path is liquid-tightly connected with the liquid inflowing port so that liquid to be introduced into the liquid chamber flows in along the inner periphery of the side surface of the first connection surface.

Owner:ASAHI KASEI MEDICAL CO LTD

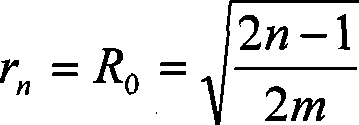

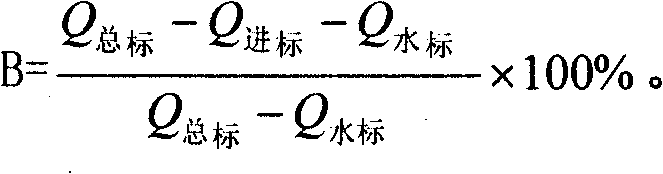

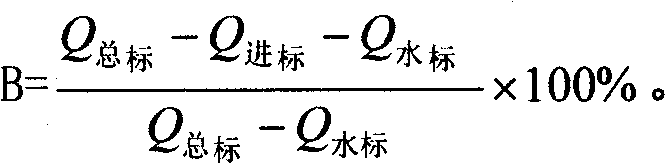

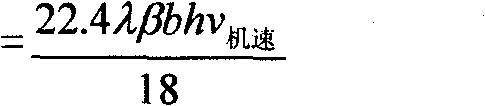

Air leakage rate measuring method of sintering machine system

InactiveCN101435711ASolve the large measurement errorReduce contentFurnace typesIndirect mass flowmetersObservational errorGas analysis

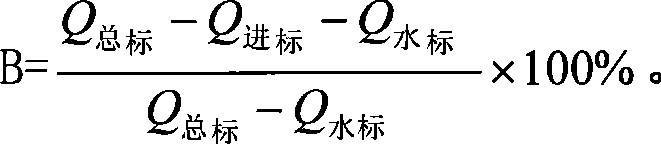

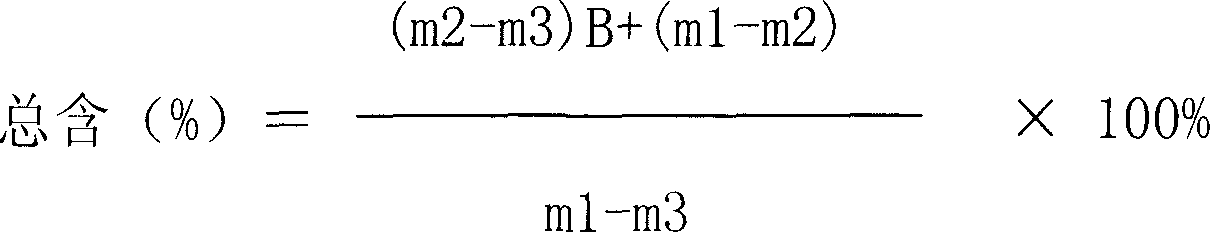

The invention relates to a method for measuring system air leakage rate of a sintering machine in metallurgy. The invention discloses a method for measuring the system air leakage rate of the sintering machine. The method comprises the following steps: firstly, by measuring charge level air speeds at different parts of a machine pallet of the sintering machine, the effective air quantity(Q[inlet]) entering a sinter layer is worked out, by measuring the air speed in a main duct in front of an electrostatic dust collector, the total air quality(Q[total]) pumped in the main duct by an air exhauster is worked out, and by the water content in mixing material, the content of the air converted into vapor is worked out; secondly, the air qualities(Q[total standard], Q[inlet standard] and Q[water standard]) at the standard state are converted all together; and finally, the air leakage rate(B) is worked out according to the formula. The measuring method has strong operability and can overcome the defects of inconvenient measurement, big measurement error and complex air analysis existing in daily production and the defect existing in prior art that the local air leakage rate can only be measured by the air leakage point air speed measuring method. In a word, the method has the advantages of easy operation, accurate measurement and good use effect.

Owner:武钢集团有限公司

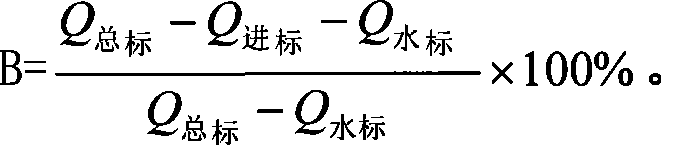

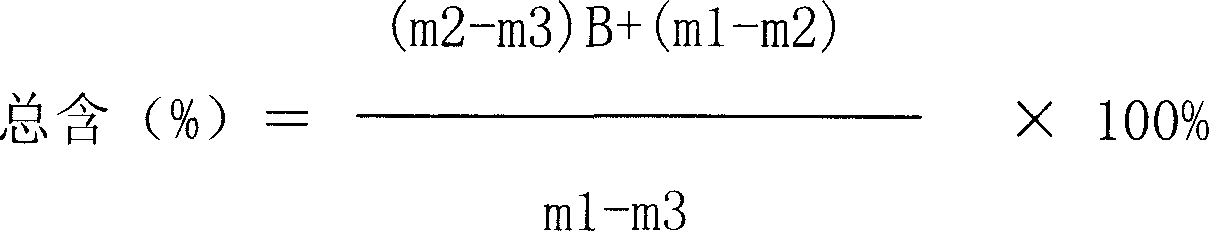

Method for detecting crude oil water content

InactiveCN1945274AImprove the measurement methodAvoid measurement errorsWeighing by removing componentPreparing sample for investigationRefrigerated temperatureWater content

The present invention is method of determining water content in crude oil. The method includes cooling crude oil in a refrigerator and inclining and stirring to separate out free water from crude oil, weighing the free water in a electronic balance, determining the weight of emulsified water and suspend water in centrifugal process or distilling process, calculating the total water weight, and calculating the weight percentage of water in crude oil. The perfected method has raised determining precision.

Owner:DAQING OILFIELD CO LTD

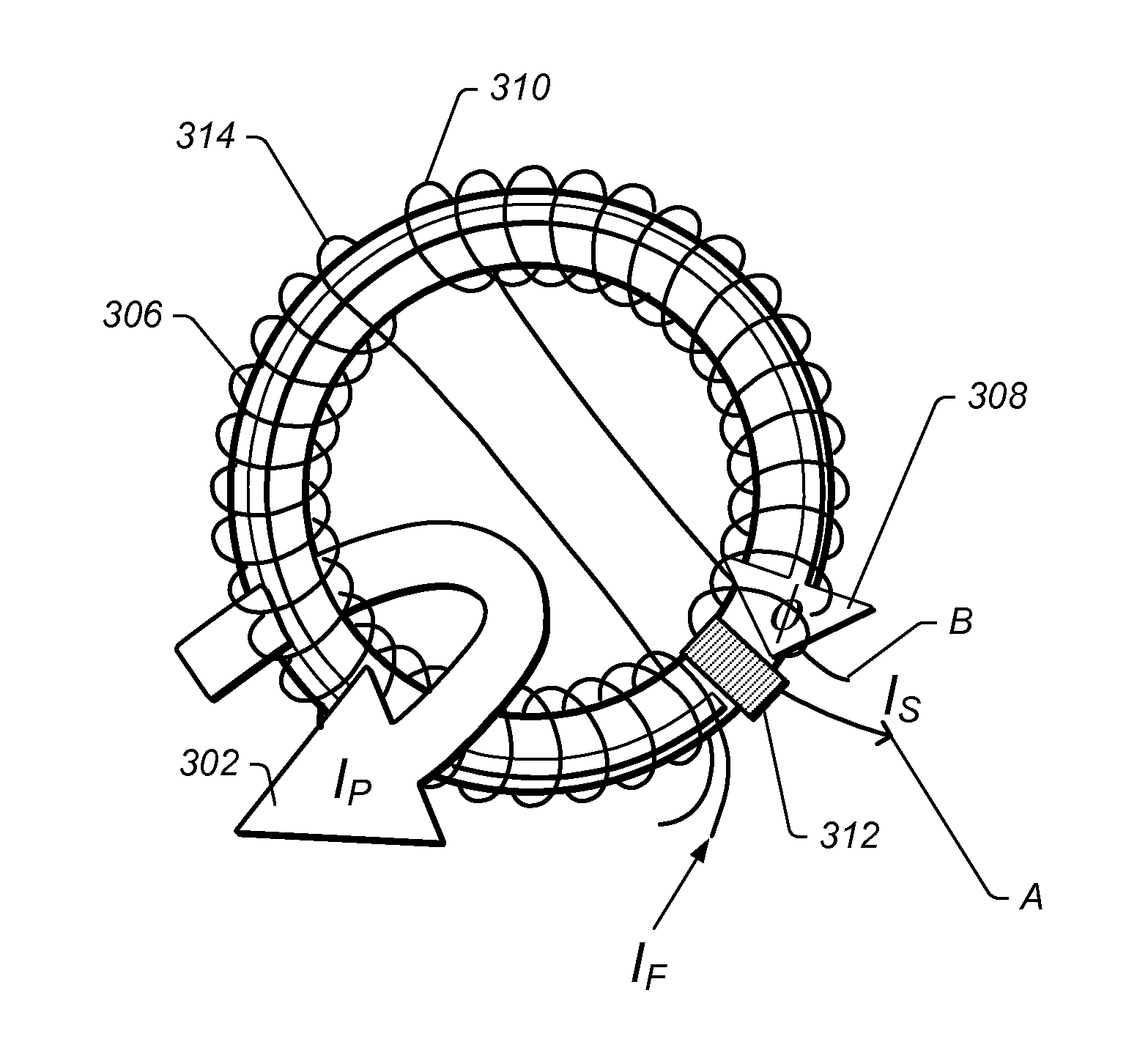

Current sensor

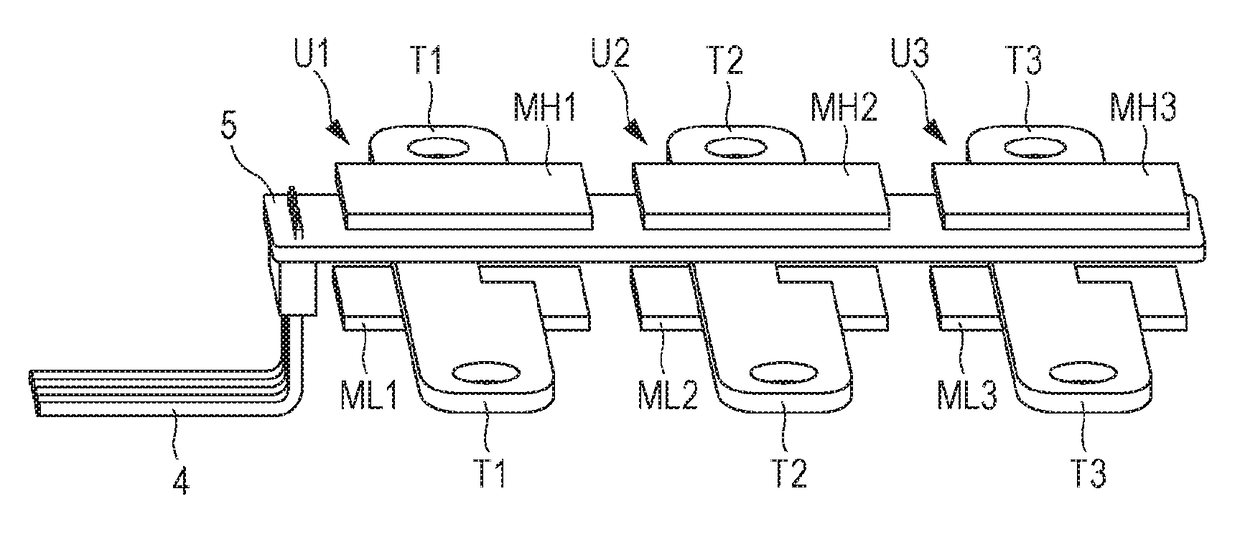

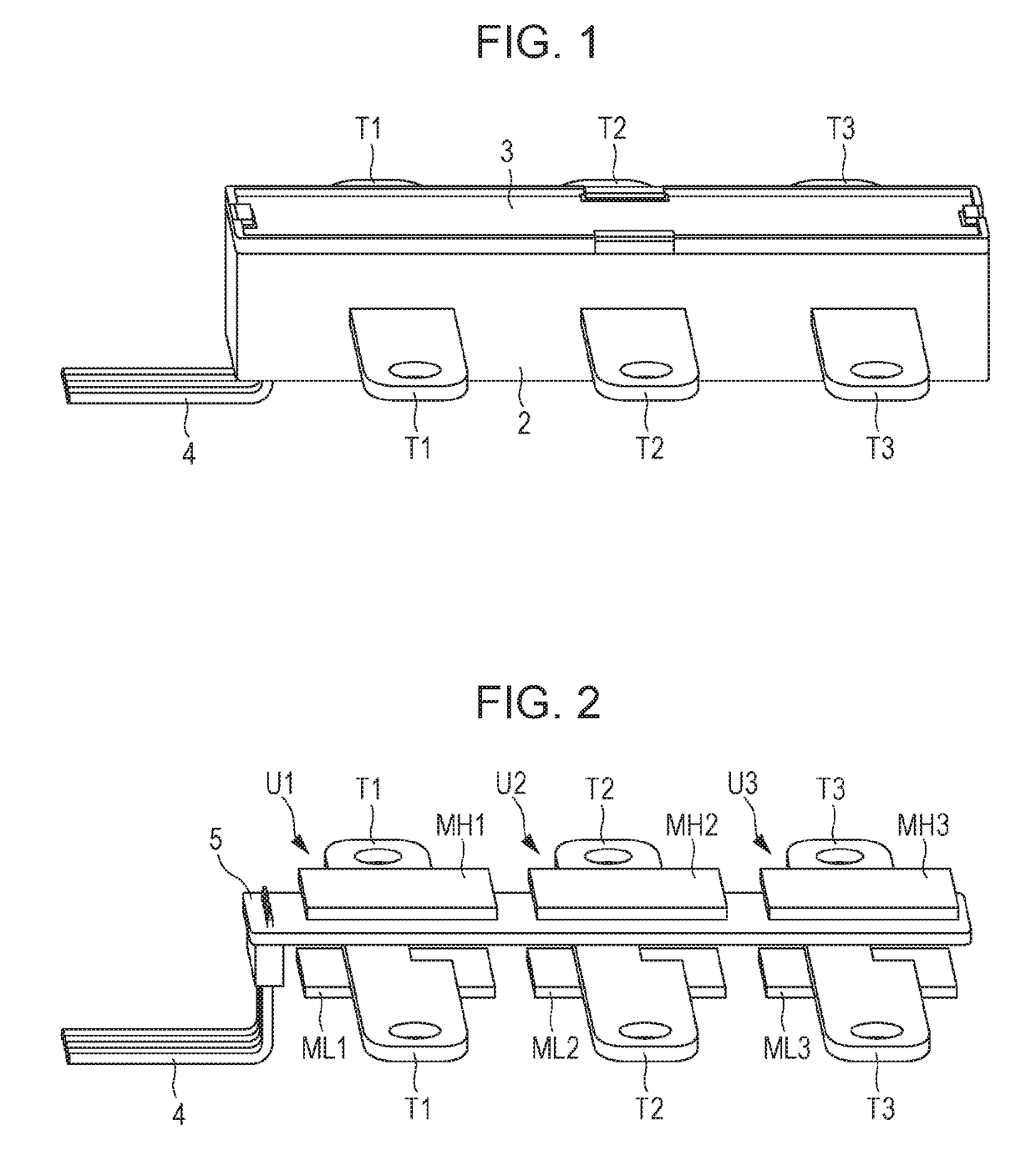

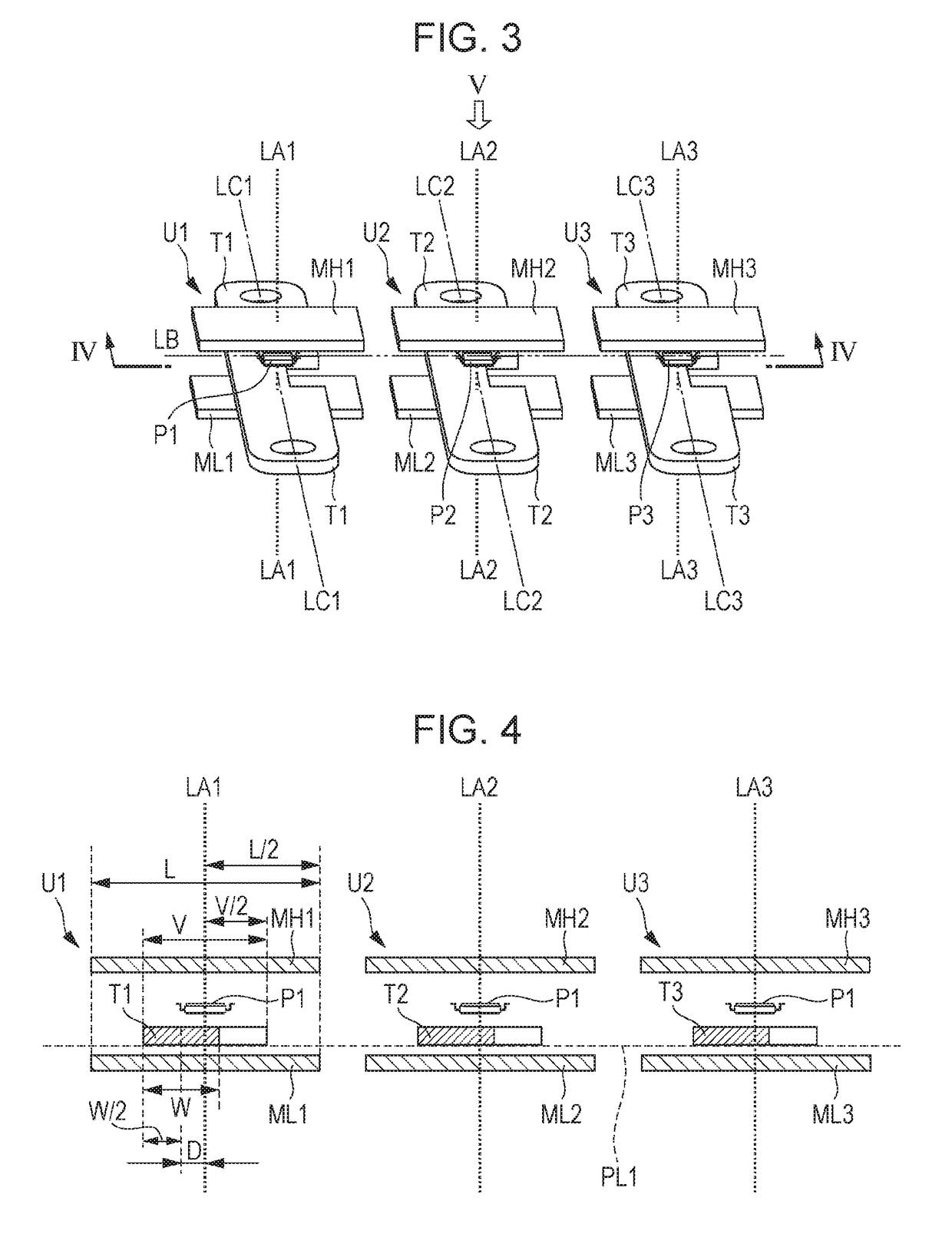

ActiveUS20170343584A1Reduce resistance lossPrecise positioningVoltage/current isolationElectrical conductorCurrent sensor

Each of three magnetic sensors is positioned on a first virtual line that passes the centers of two magnetic shields in the width direction and is perpendicular to a virtual plane, so a value detected by the magnetic sensor is less likely to be influenced by an external magnetic field. The first virtual line and the center of a conductor intersecting the first virtual line are separated from each other by a certain distance. Therefore, even if a distance from the center of the conductor in the width direction to the magnetic sensor is short, it is possible to improve, on a high-frequency side, frequency characteristics in the detection sensitivity of the magnetic sensor for the frequency of the current under measurement.

Owner:ALPS ALPINE CO LTD

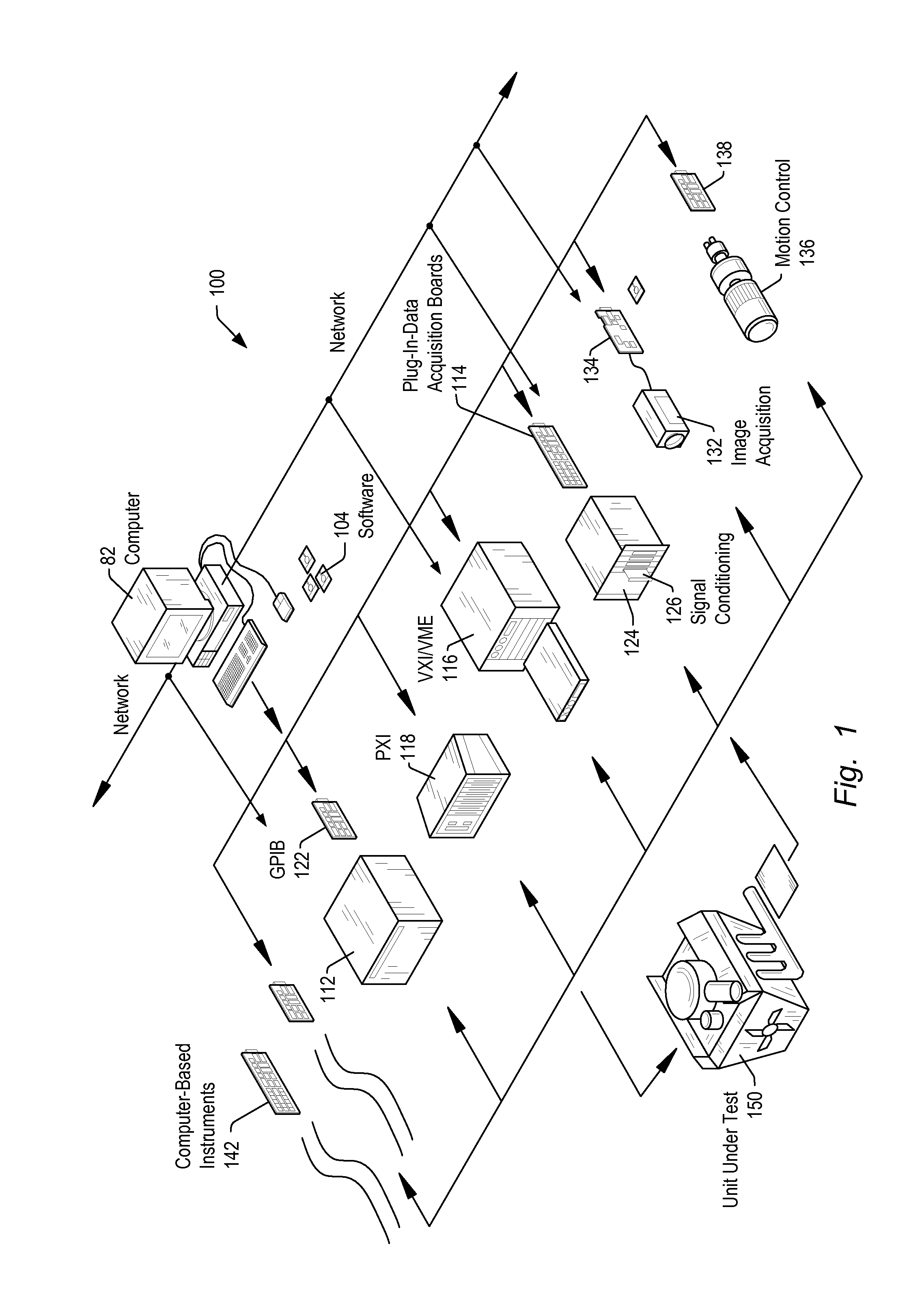

Circuit to Compensate for Inaccuracies in Current Transformers

InactiveUS20140285180A1Reduce most significant error sourceEasy to useElectric devicesTemperature compensation modificationElectric forceSignificant error

An improved measurement circuit includes a current transformer and an active feedback circuit operated as a negative resistance that matches the value of the winding resistance of the current transformer. An amplifier in the feedback circuit provides power to drive a secondary current through a sense resistor and the transformer winding resistance, reducing the most significant error source in a current transformer circuit by presenting a negative impedance to the current transformer. Combined with the positive resistance of the transformer's winding, the negative impedance results in a net burden of zero on the current transformer, which eliminates the need for the transformer having to provide power to drive the secondary current. This facilitates the use of smaller transformers while achieving reduced measurement errors. Thus, a single, compact measurement device may be used in a wide range of applications with high measurement performance.

Owner:NATIONAL INSTRUMENTS

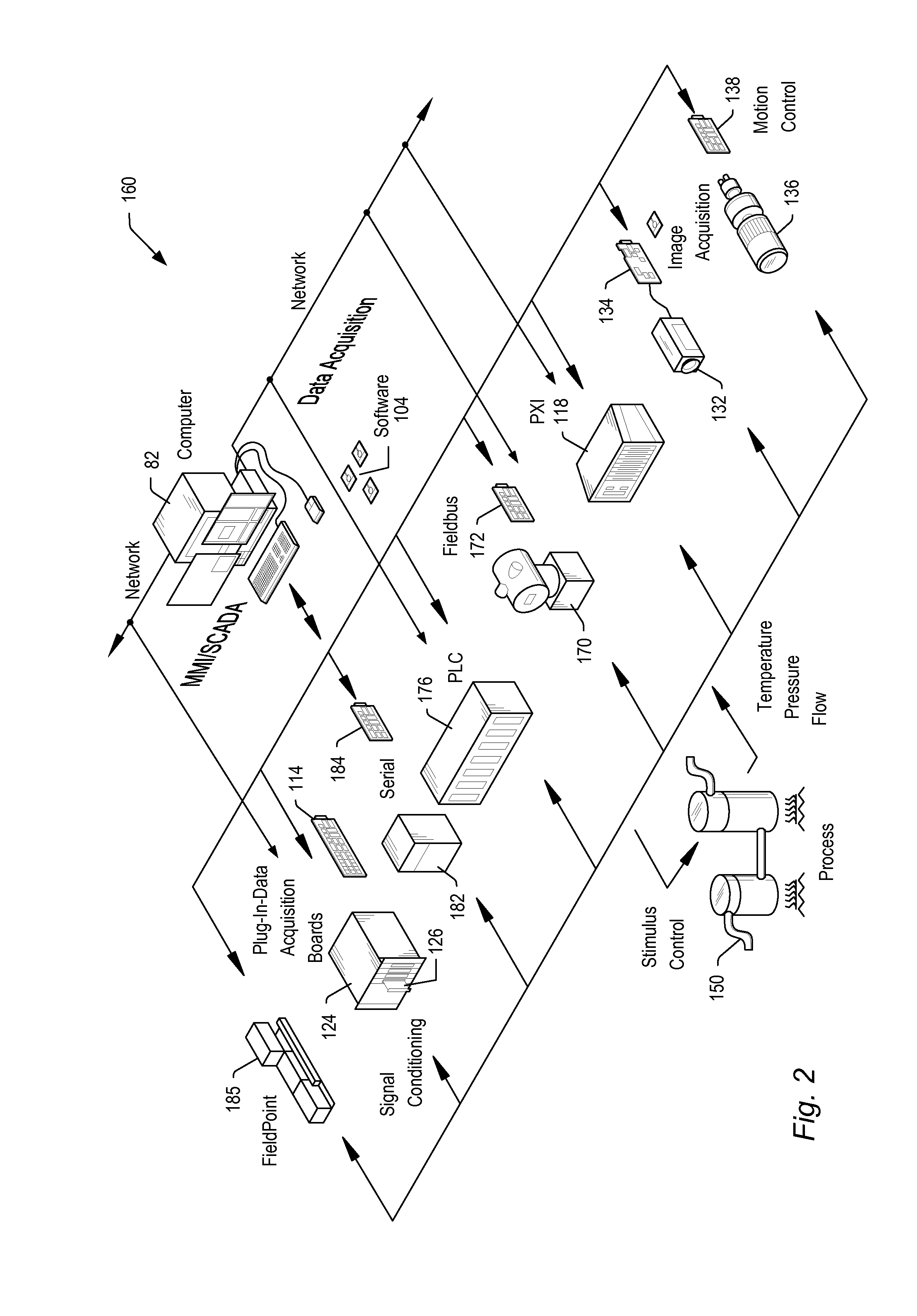

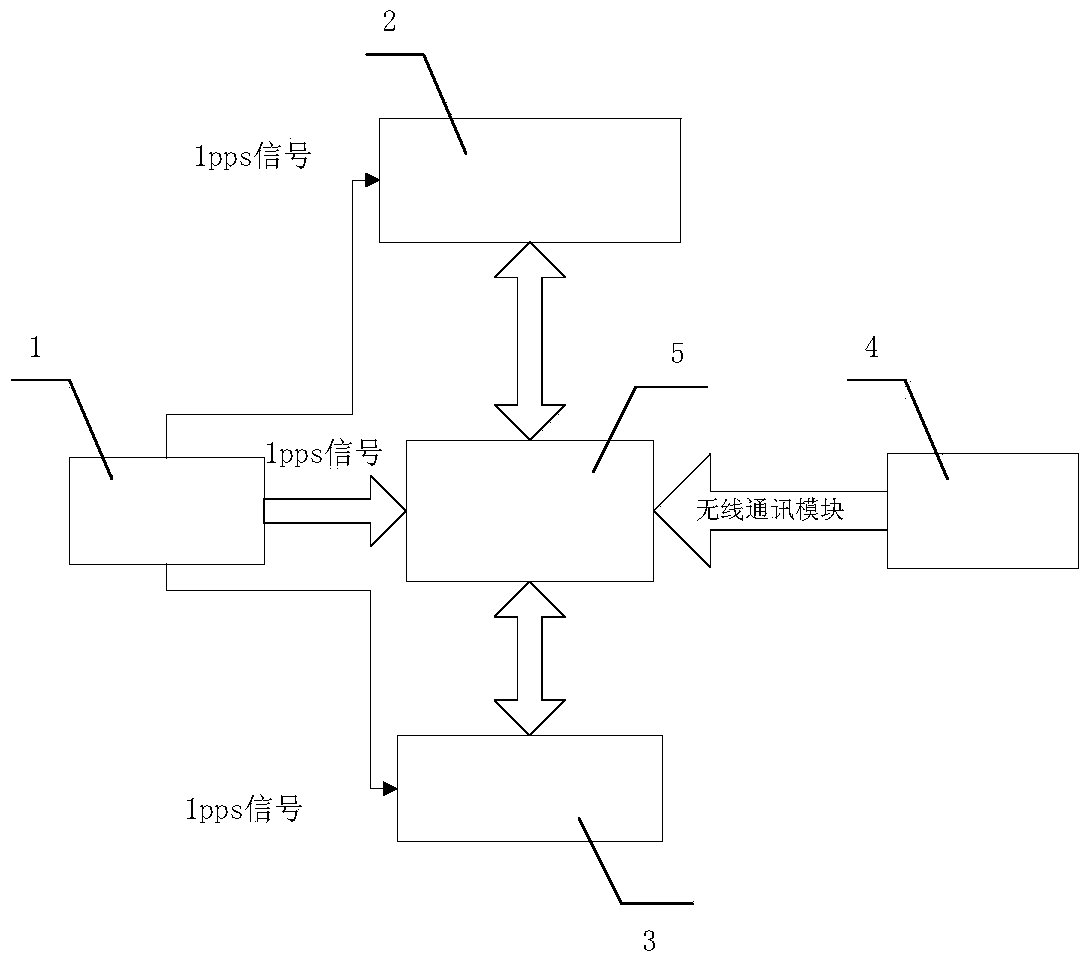

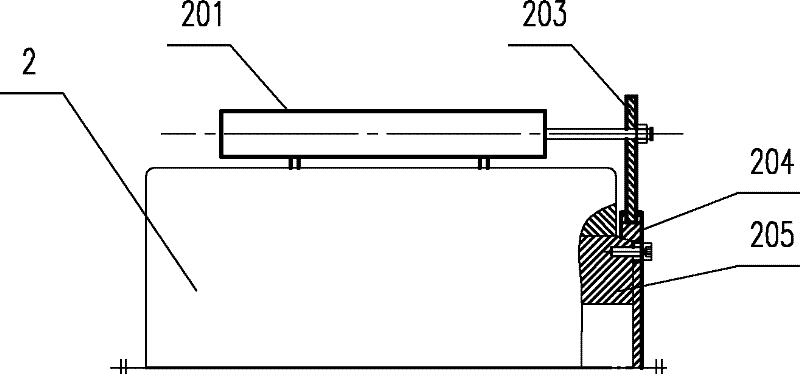

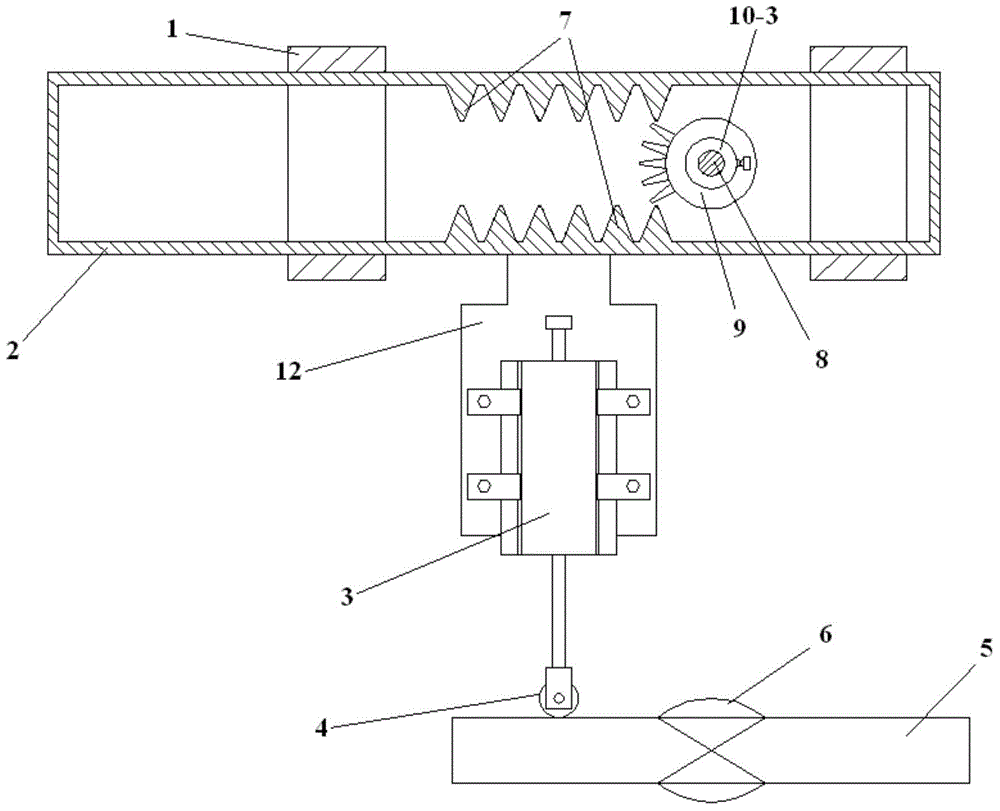

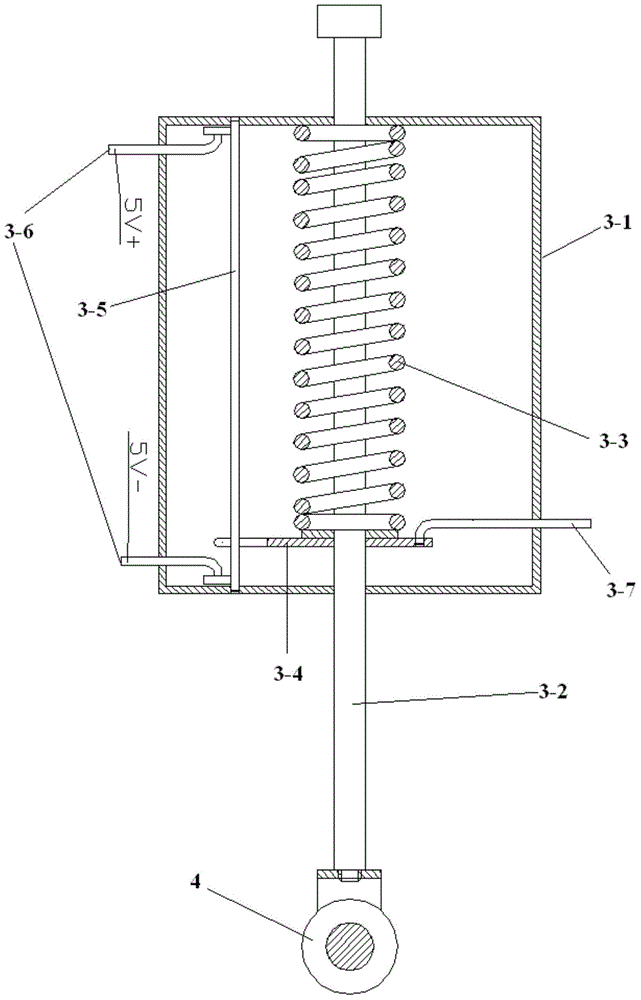

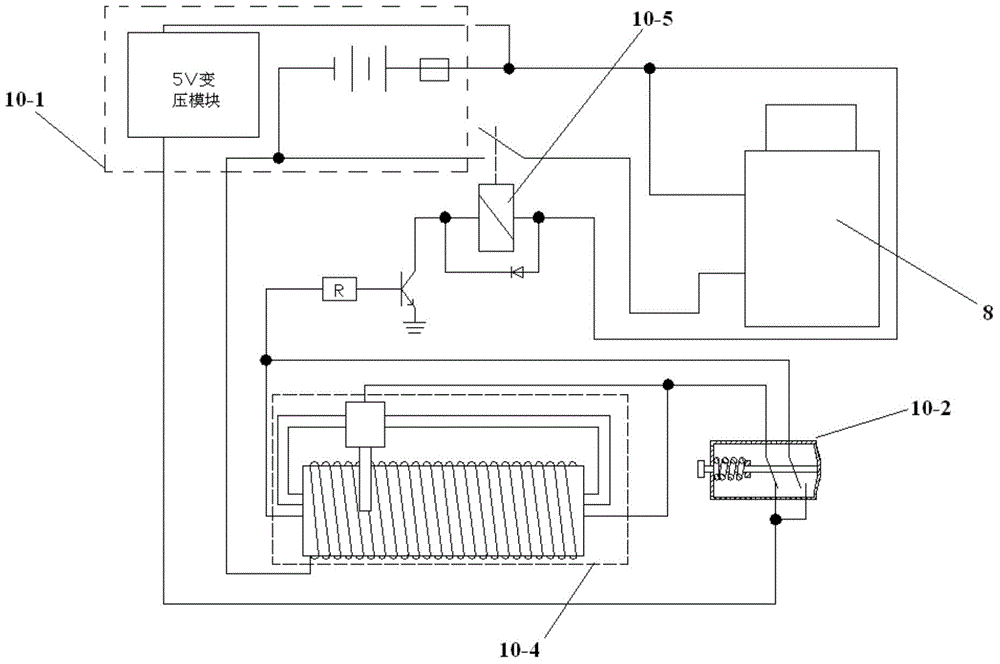

Real-time course precision detection system and method for inertial navigation system for ships

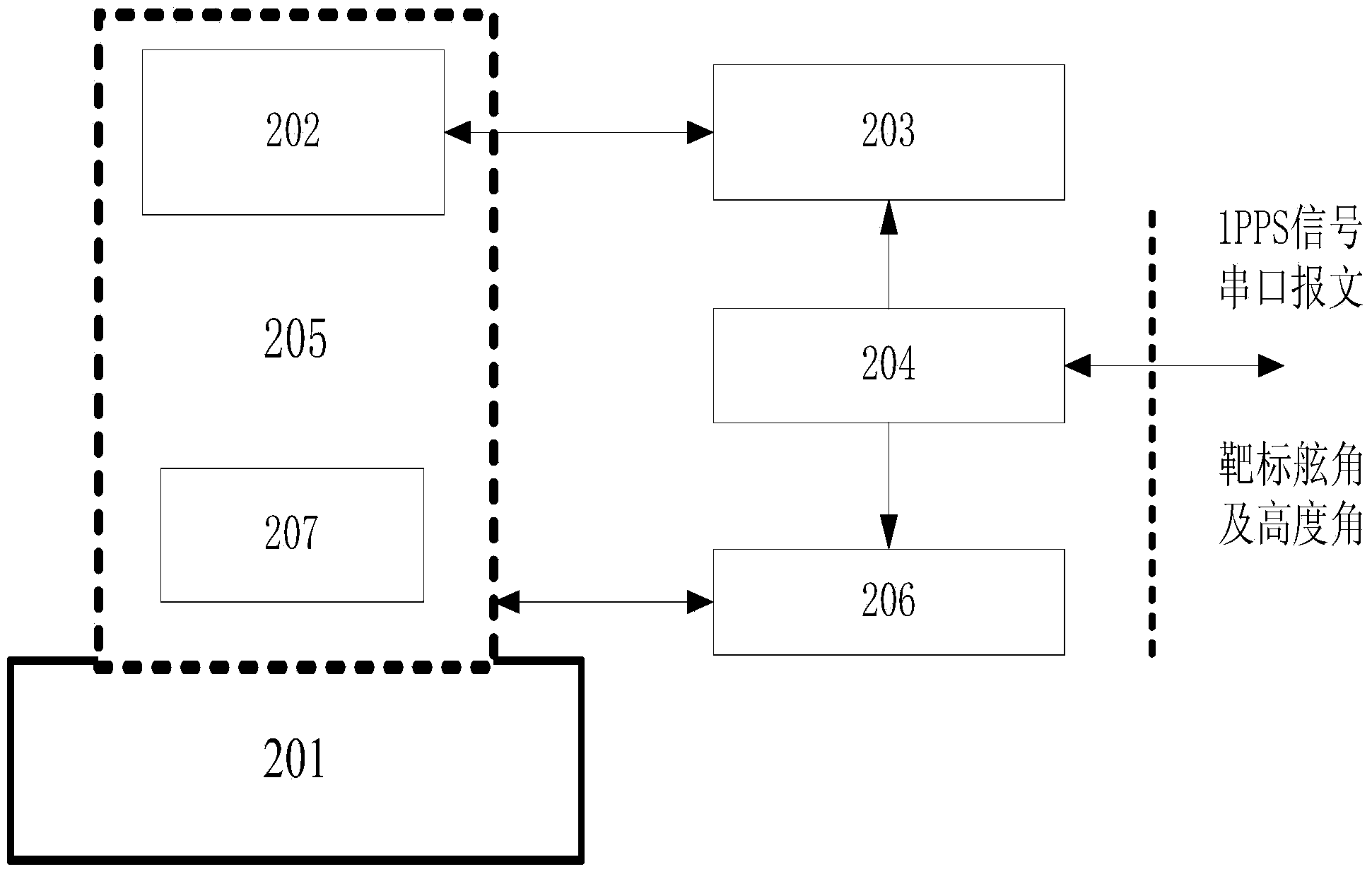

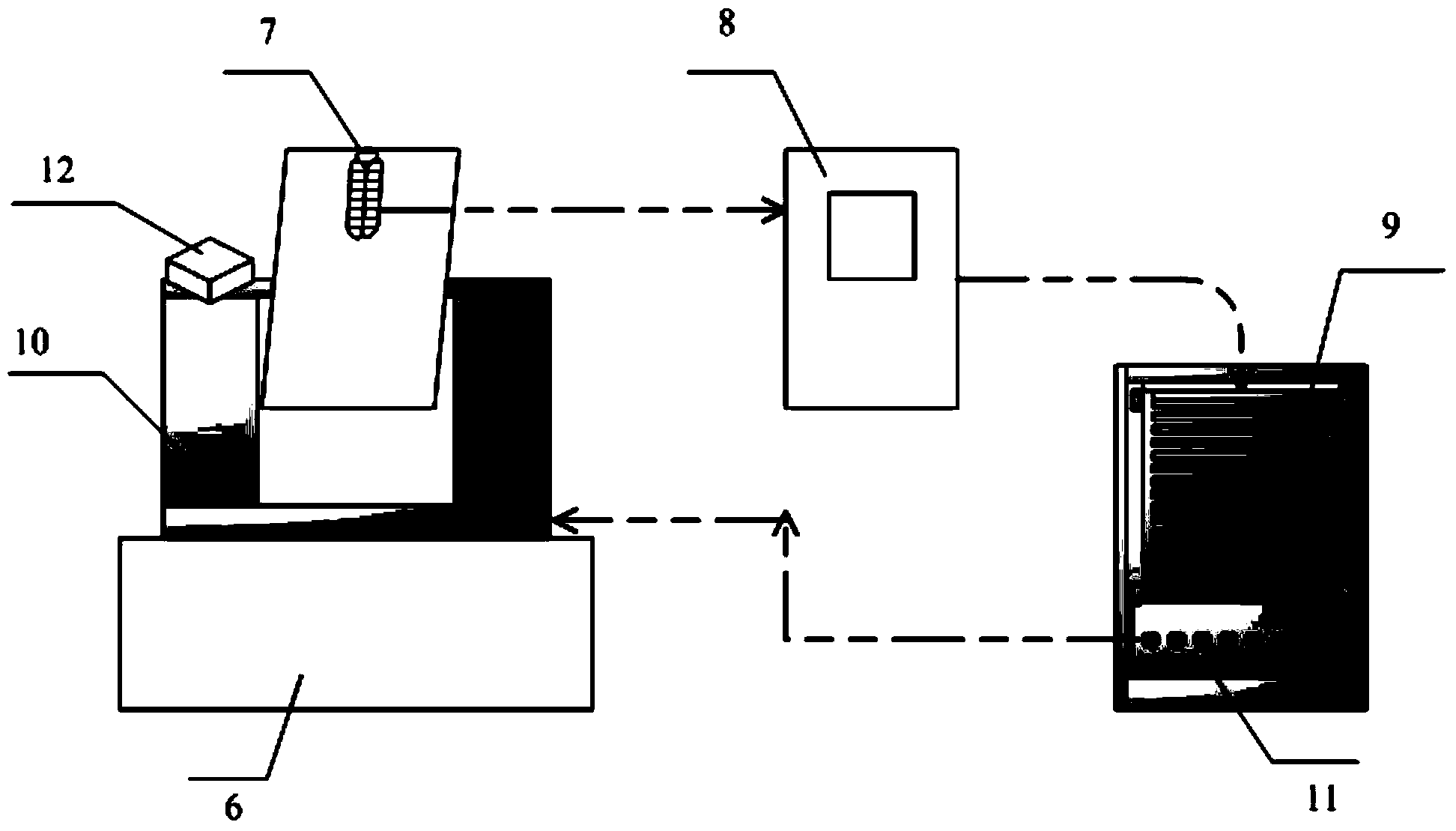

InactiveCN103900609ASolve the large measurement errorReliable data supportMeasurement devicesTime courseTheodolite

The invention provides a real-time course precision detection system and a real-time course precision detection method for an inertial navigation system for ships. The system comprises a ship differential global positioning system unit 1, an electro-optic theodolite unit 2, an attitude information interface unit 3, a target unit 4 and a data acquisition processing unit 5, wherein the ship differential global positioning system unit 1 is used for guaranteeing time synchronization and acquiring accurate position information of the electro-optic theodolite unit 2 and the target unit 4; the electro-optic theodolite unit 2 and the target unit 4 are used for measuring relative bearing of the ship; the attitude information interface unit 3 can acquire the attitude course information of the ship and calculates to obtain the course precision of inertial navigation equipment for ships through the data acquisition processing unit 5. According to the device and the method provided by the invention, real-time course precision measurement can be realized, the dynamic course precision measurement errors are reduced, and the measurement precision of the electro-optic theodolite is improved.

Owner:HARBIN ENG UNIV

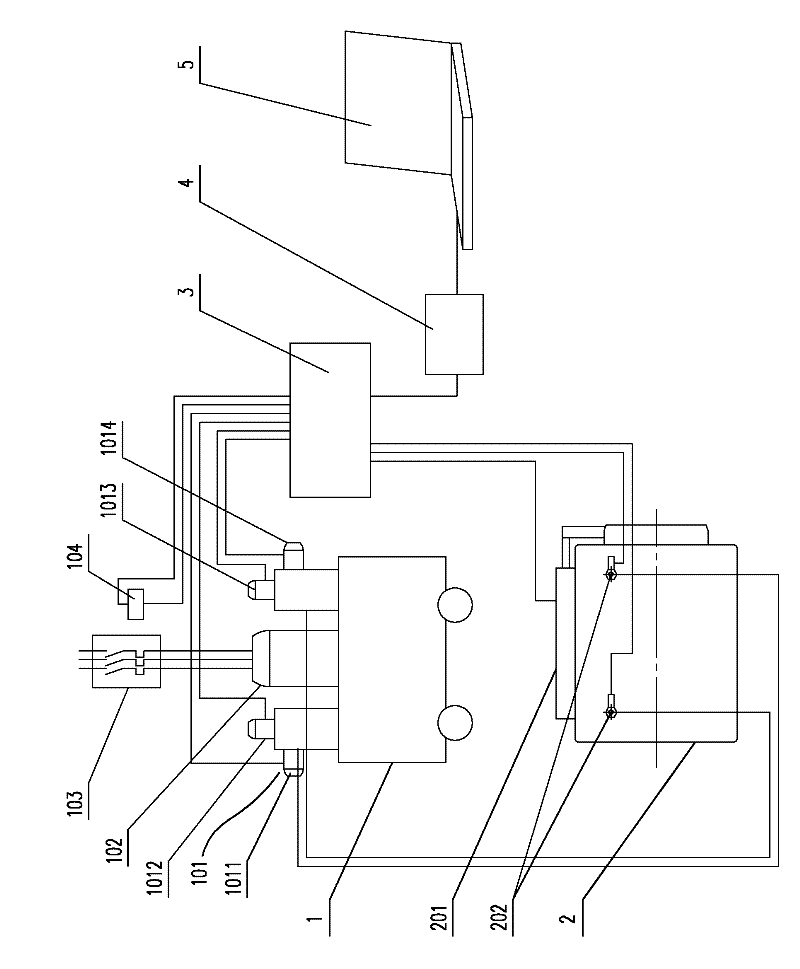

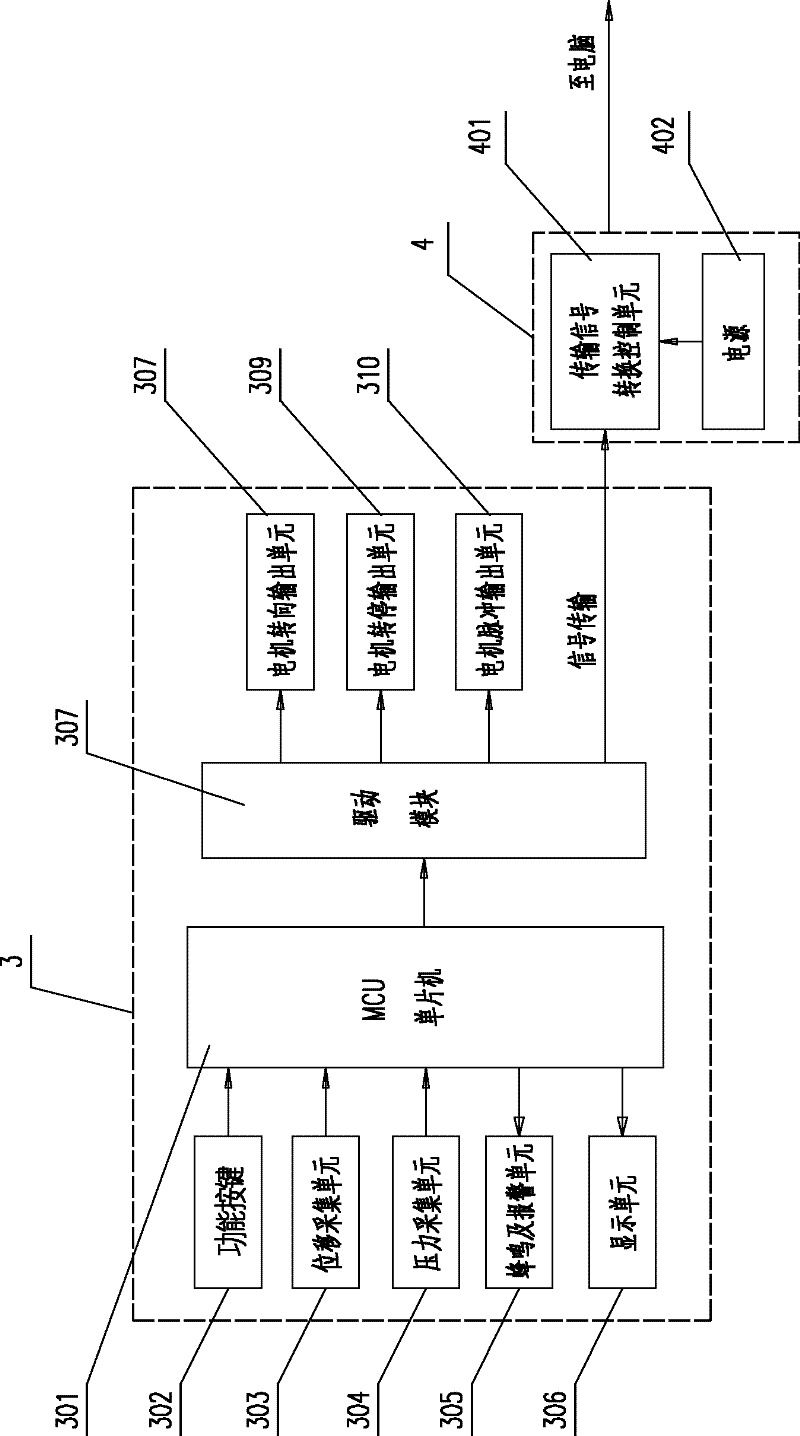

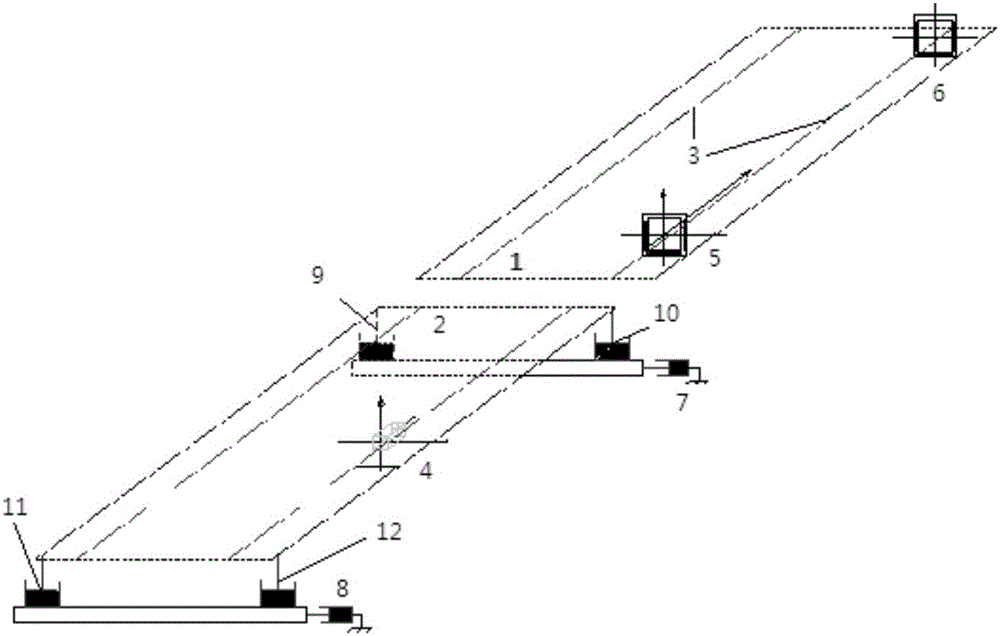

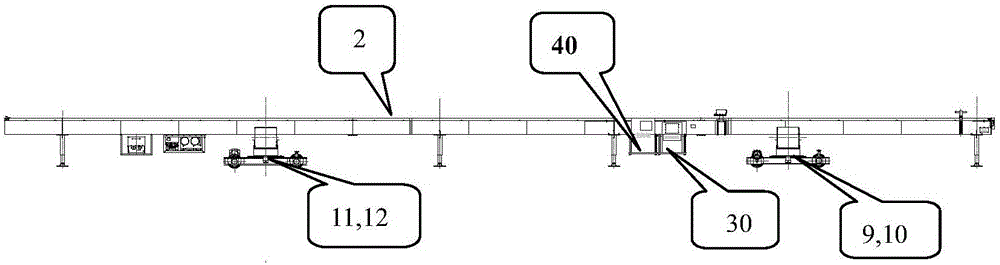

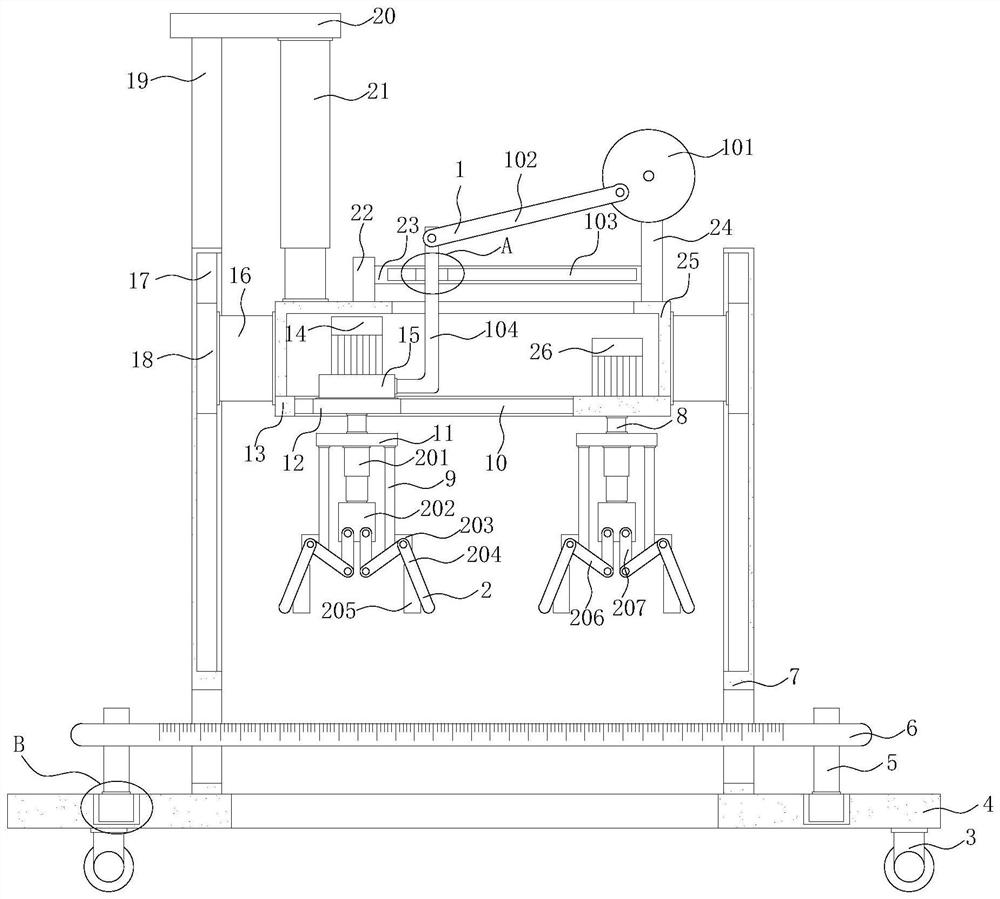

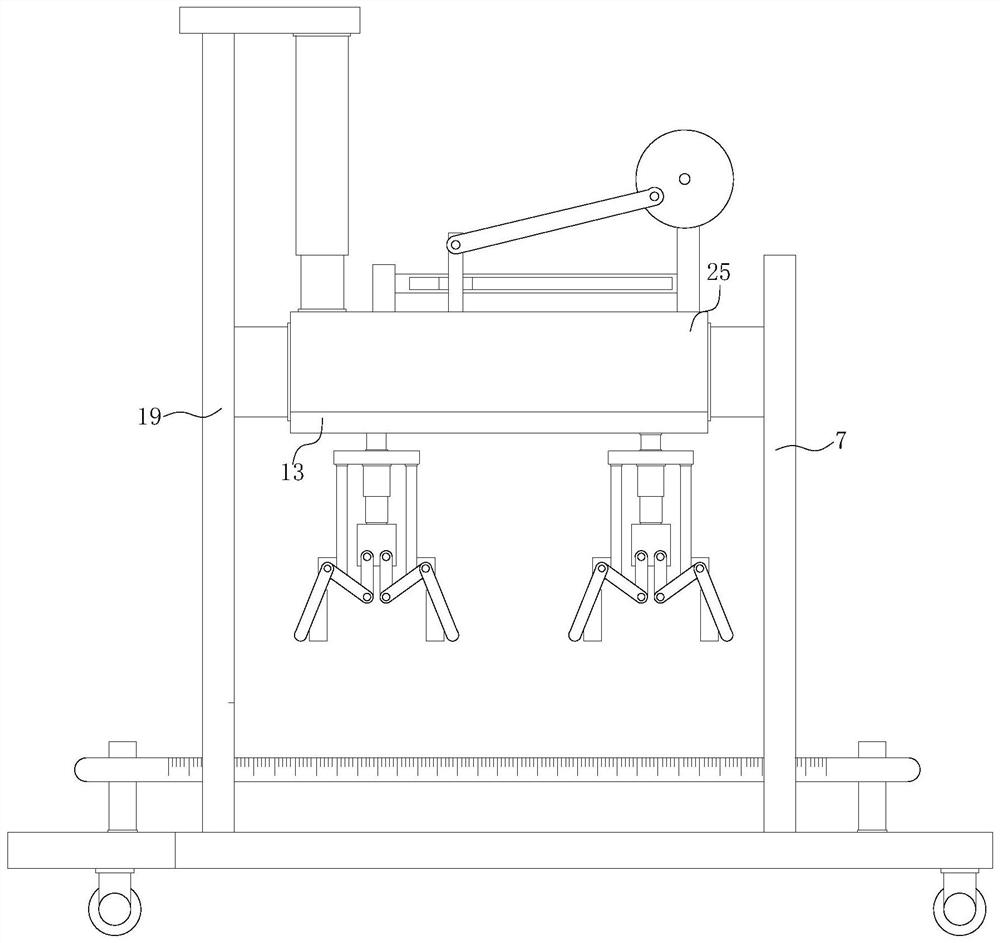

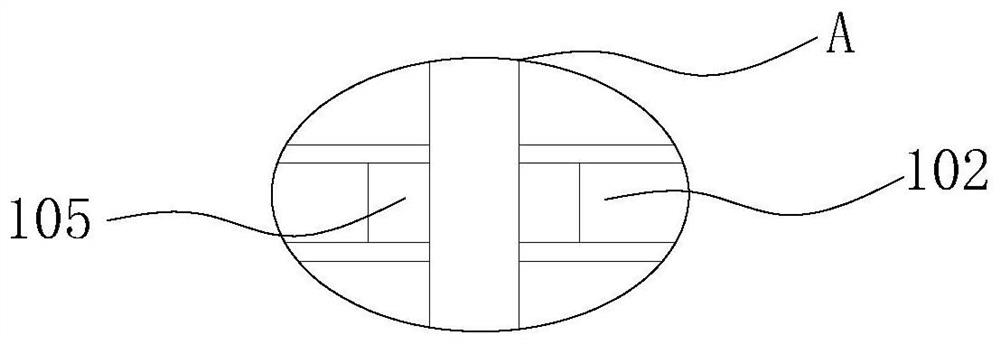

Automatic tension control system and method thereof

ActiveCN102444290AImprove tensioning accuracyFast monitoringBuilding material handlingMechanical pressure/force controlAutomatic controlPre stressing

The invention relates to an automatic tension control system and a method thereof, relating to a system and a method for applying pre-stress on a pre-stressed component in civil engineering. The system comprises an electric oil pump, a hydraulic jack, a controller of the automatic tension control system, a data relay controller and a computer. A pull rod type displacement sensor and a pressure sensor are arranged on the hydraulic jack. Control valve rods of left and right control valves of the electric oil pump are connected with a stepping motor. The controller of the automatic tension control system comprises a MCU (Micro-programmed Control Unit) single chip microcomputer, functional keystrokes, a displacement collection unit, a pressure collection unit, a buzzing and alarming unit, a display unit, a driving module, a motor steering output unit, a motor steering and stopping output unit and a motor pulse output unit. The method comprises the steps of tensioning, unloading and the like. According to the system and the method disclosed by the invention, the tension precision can be increased; the tension uncontrolled accident of the pre-stressed reinforcing steel can be effectively avoided; the system and the method have the characteristics of being simple in structure, low in cost, safe, reliable, low in quality monitoring difficulty, simple in method and convenient for operation; and the system and the method are applied to various fields.

Owner:柳州市建桥预应力智能设备有限公司

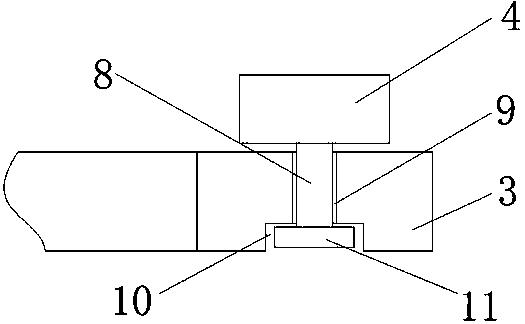

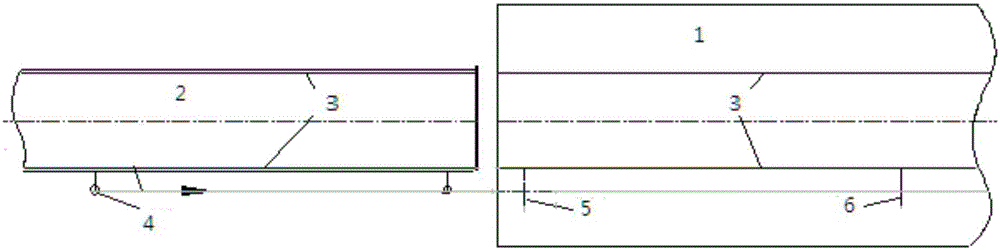

Contact type inter-plate welding line surplus height measuring device

InactiveCN104801874AImprove adaptabilityIncrease productivityElectrical/magnetic thickness measurementsWelding apparatusEngineeringDrive motor

The invention provides a contact type inter-plate welding line surplus height measuring device. The device comprises a guide sleeve, wherein a movement guide cylinder which can move along the guide sleeve is arranged in the guide sleeve; a displacement sensor is fixedly arranged on the movement guide cylinder; a rolling wheel contacted with a workpiece is arranged on the end part of the displacement sensor and is driven by the movement guide cylinder to move along the surface of the workpiece. When the rolling wheel is in contact with a bump on the surface of a welding line on the workpiece, the height of the rolling wheel is changed, the surplus height of the bump on the surface of the welding line is converted into the change of an output signal of the displacement sensor, and the inter-plate welding line surplus height is obtained according to the change of the output signal of the displacement sensor; rotary movement of a driving motor is changed into the left and right movement of the displacement sensor along the welding line measuring direction, the numerical value of the welding line surplus height is converted into a certain electric signal, and welding line surplus height data is acquired by using the displacement sensor, the device has the characteristics of accurate measurement, high precision and capability of measuring welding lines with different widths and heights, and the width of the welding line can be 0.01mm.

Owner:CHANGAN UNIV

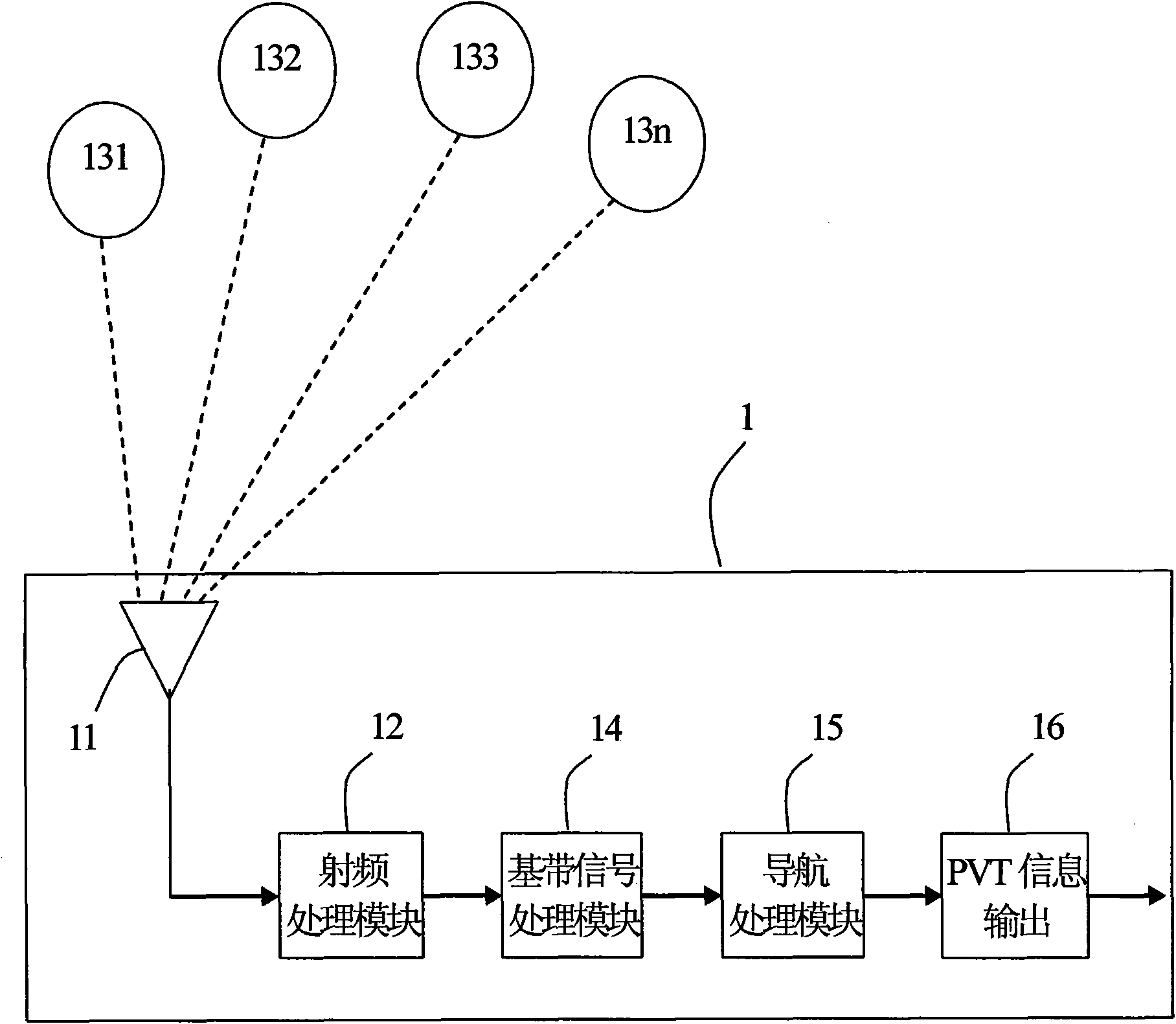

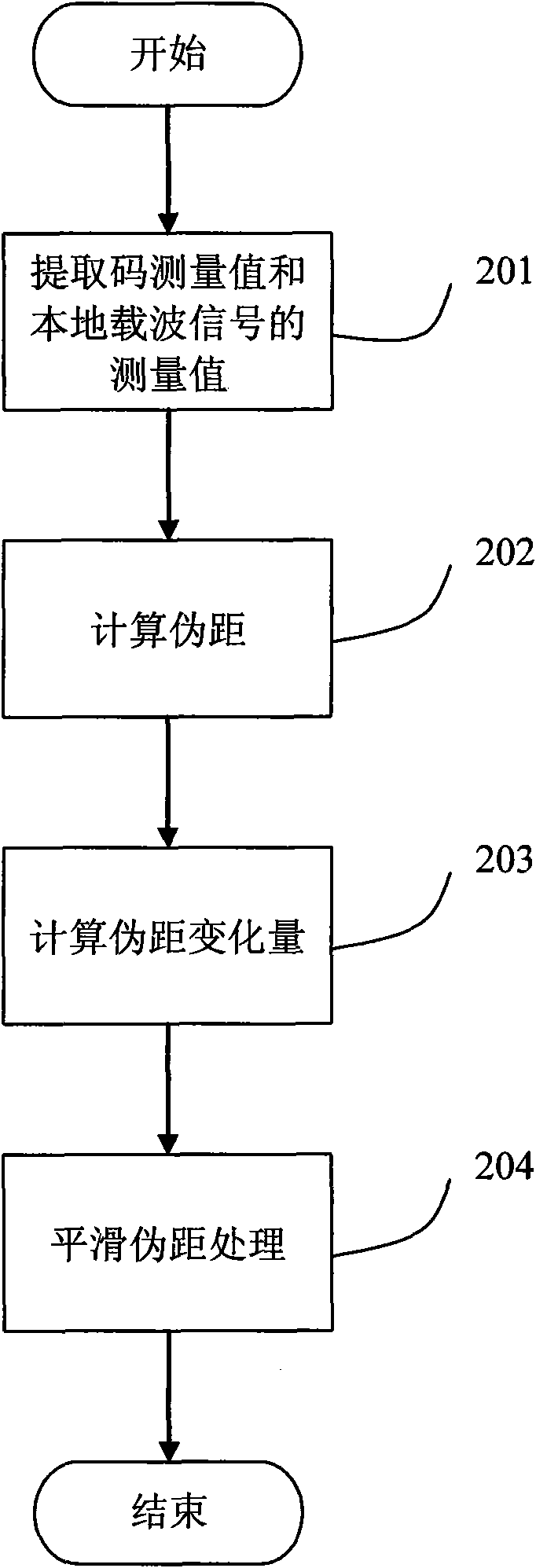

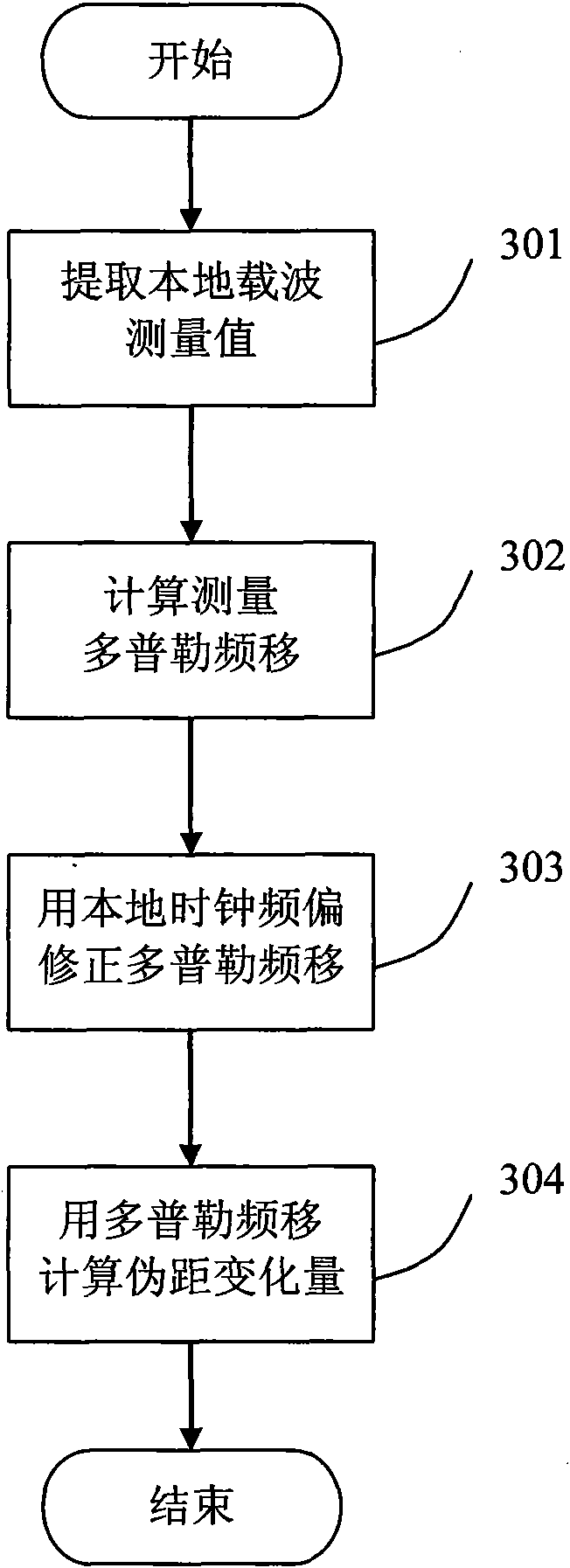

Method for smoothing pseudo range by using Doppler frequency shift

ActiveCN101865992AReduce mistakesHigh precisionPosition fixationComputational physicsErrors and residuals

The invention discloses a method for smoothing the pseudo range by using a Doppler frequency shift, comprising the following steps: calculating the pseudo range of a measured epoch by using the code phase measurement value; calculating the change rate of the pseudo range of the measured epoch by using the Doppler frequency shift; calculating the estimation value of the pseudo range of the current epoch by using the smoothed value of the last epoch and the change rate of the pseudo range of the current measured epoch; and endowing the measurement value and the estimation value of the pseudo range of the current epoch with different weight to obtain the smoothed value of the pseudo range of the current epoch. Because the error on the pseudo range measured by using the code phase in single time is great, the Doppler frequency shift is used for smoothing the pseudo range. Therefore, the error on the pseudo range can be reduced effectively, and further the positioning accuracy of the GPS can be improved.

Owner:杭州中科微电子有限公司

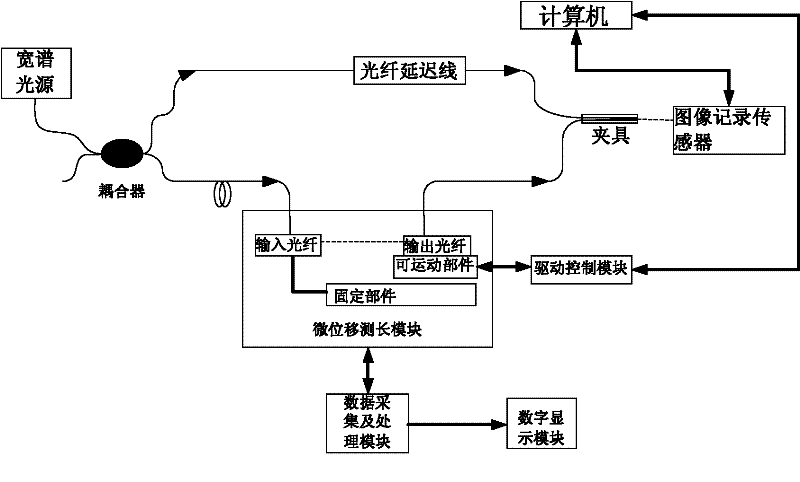

Delay amount measuring method applied for fiber delay line measuring system and realization apparatus thereof

InactiveCN102353520ASolve the large measurement errorProcessing speedTesting optical propertiesObservational errorFiber

The invention, which belongs to the fiber measurement technology field, disclose a delay amount measuring method applied for a fiber delay line measuring system and a realization apparatus thereof. The measuring method comprises the following steps that: a light that is emitted by a broadband light source passes through a 3dB coupler and is divided into two paths of lights, wherein a first path of the light passes through a fiber and a second path of the light passes through a micro displacement measurement length module; and a delay amount of a to-be-detected fiber is obtained according to two interference conditions of the two paths of the light. According to the realization apparatus, an employed image recording sensor is used not only as an image recording sensor but also as an imaging screen, so that a substantial measurement error that is caused by a problem of a recording direction can be avoided; and then the result is sent to a computer to carry out processing. According to the invention, feedback control is employed; and an interference result of an image recording sensor is utilized to control a moving state of a micro displacement measurement length module; moreover, the processing speed is fast and the precision is high; automatic adjustment can be realized and high-precision measurement is easy to realize.

Owner:BEIHANG UNIV

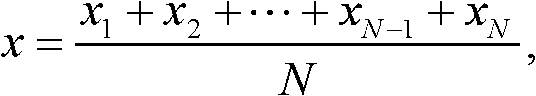

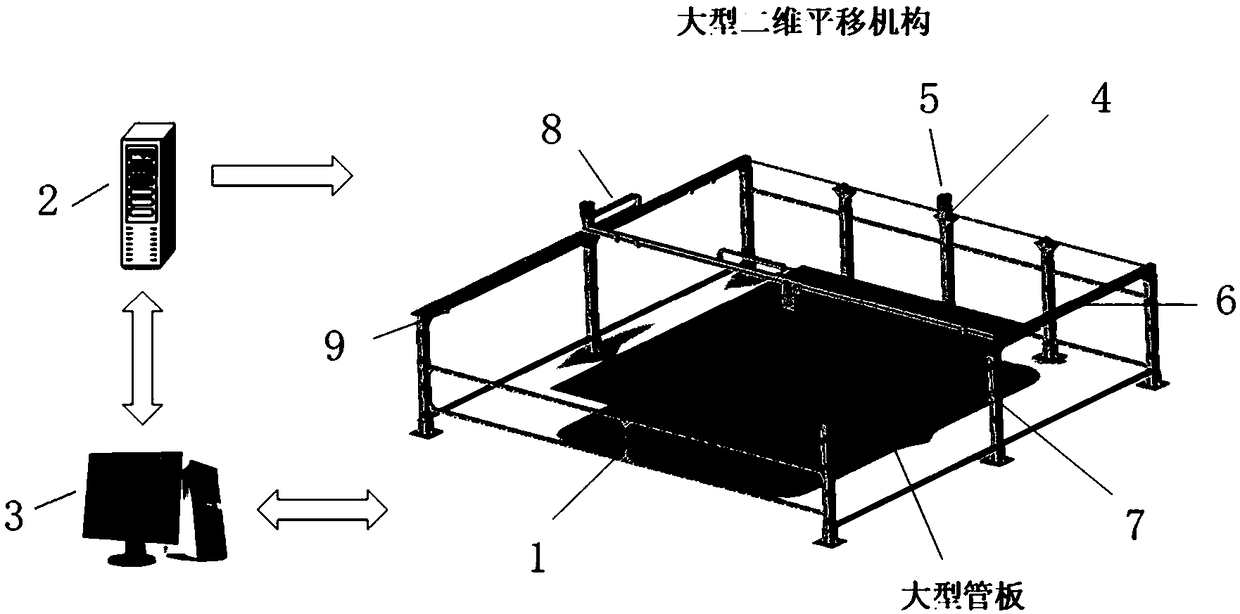

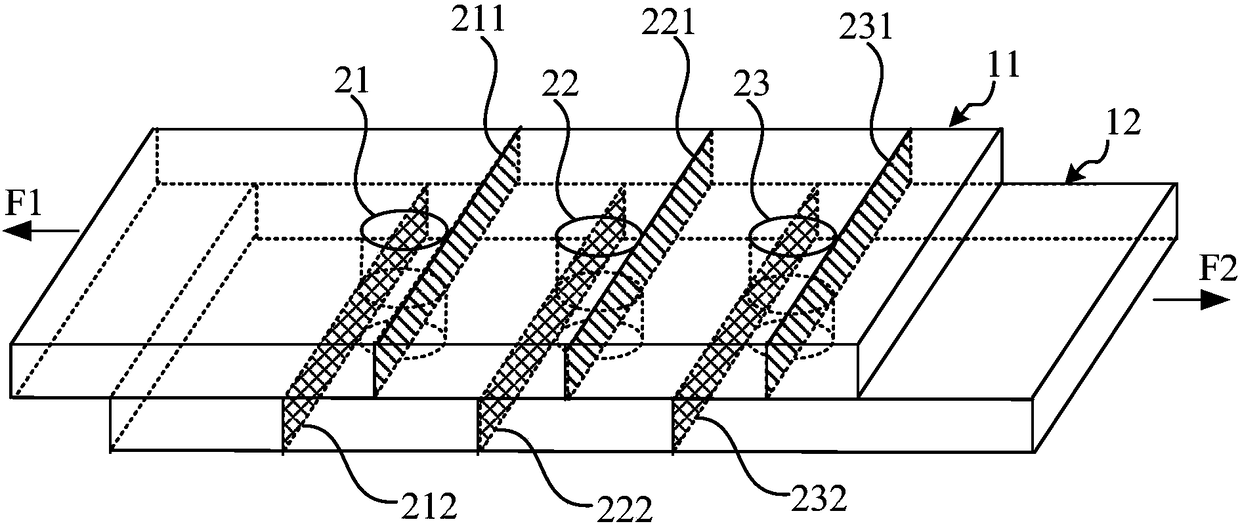

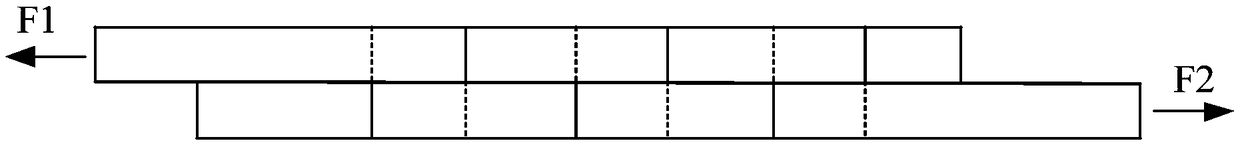

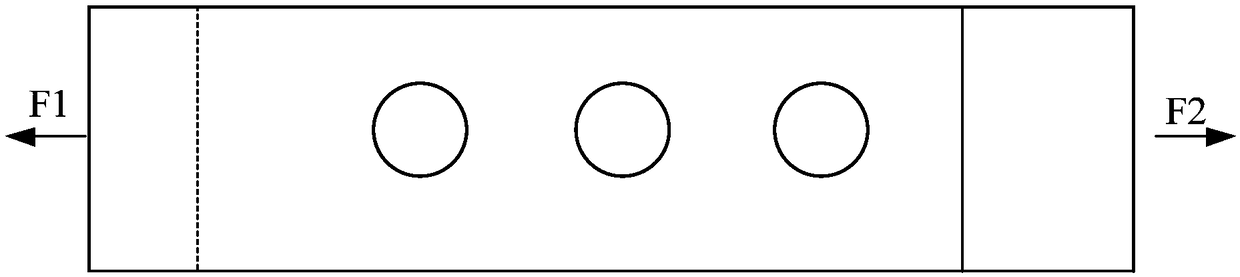

Aperture and pitch measuring device and measuring method for large-sized tube sheet

ActiveCN109405755AGuaranteed uptimeHigh positioning accuracyUsing optical meansMeasurement deviceEdge extraction

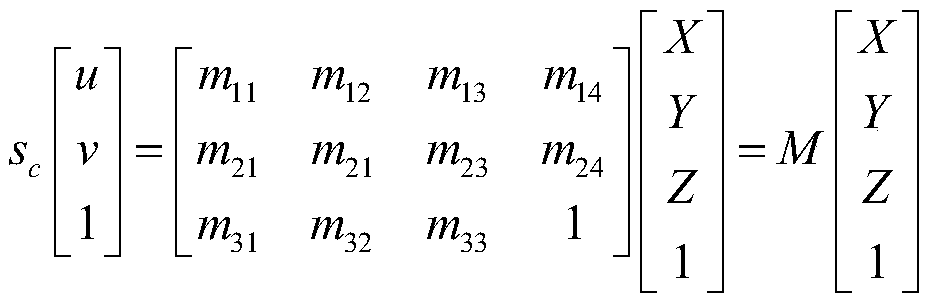

Provided in the invention is an aperture and pitch measuring device and measuring method for a large-sized tube sheet. The measuring device comprises a two-dimensional translation mechanism, a measuring head mechanism, a controller and a computer. The two-dimensional translation mechanism moves according to a path planned in advance; the measuring head mechanism completes image collection and uploads the image to the computer; and the computer processes the image information to obtain the aperture of a tube sheet and pitch data of adjacent holes, and then displays a measuring result and completes storage and printing outputting of a detection report. In addition, the measuring method includes: step one, carrying out identification and separation of a target hole; step two, extracting the edge of the target hole by using a sub-pixel edge extraction method and carrying out fitting of the centers of all holes by using hole edges; step three, on the basis of plane projection transformationand polar line constraint, carrying out target hole matching; step four, carrying out local plane determination; step five, carrying out three-dimensional coordinate calculation of hole edges; ad step six, selecting and determining an aperture and a pitch preferably by using a redundant measurement result. The aperture and pitch measuring device and measuring method have advantages of high reliability and high measurement result accuracy.

Owner:XI AN JIAOTONG UNIV

Pin load measurement method and device, measuring instrument and storage medium

ActiveCN108444629ASolve the large measurement errorLow costApparatus for force/torque/work measurementMeasuring instrumentProjection line

The embodiment of the invention discloses a pin load measurement method and device, a measuring instrument and a storage medium. The method includes the following steps: under two circumstances of notapplying a load to a composite material connecting piece and applying a specific load, obtaining three-dimensional position coordinates of each projection line, on a first surface of a connecting plate, of a cross section tangent with side walls of each pair of connecting holes in the connecting piece to obtain initial position parameters and extrusion position parameters; according to the difference values of extrusion position parameters and the initial position parameters of the projection lines corresponding to each pair of connecting holes and the sum of the difference values of the extrusion position parameters and the initial position parameters of the projection lines corresponding to all the connecting holes, determining a deformation ratio of each pair of connecting holes; and according to the deformation ratio and the applied load, obtaining a pin load value of each pair of connecting holes. By adoption of the abovementioned technical scheme, a noncontact mode is adopted todirect measure pin load distribution in the composite material connecting piece, a measuring error is reduced, cost of pin load measurement is reduced, and thus wide-range use is facilitated.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

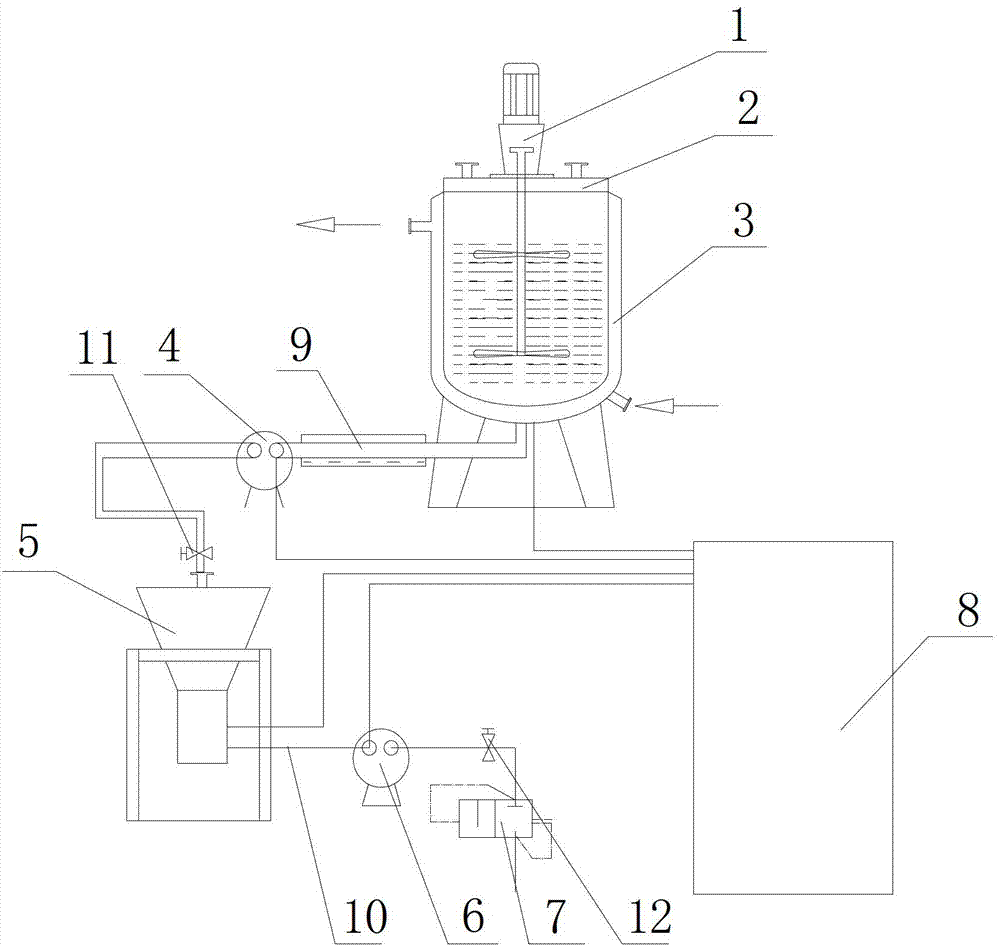

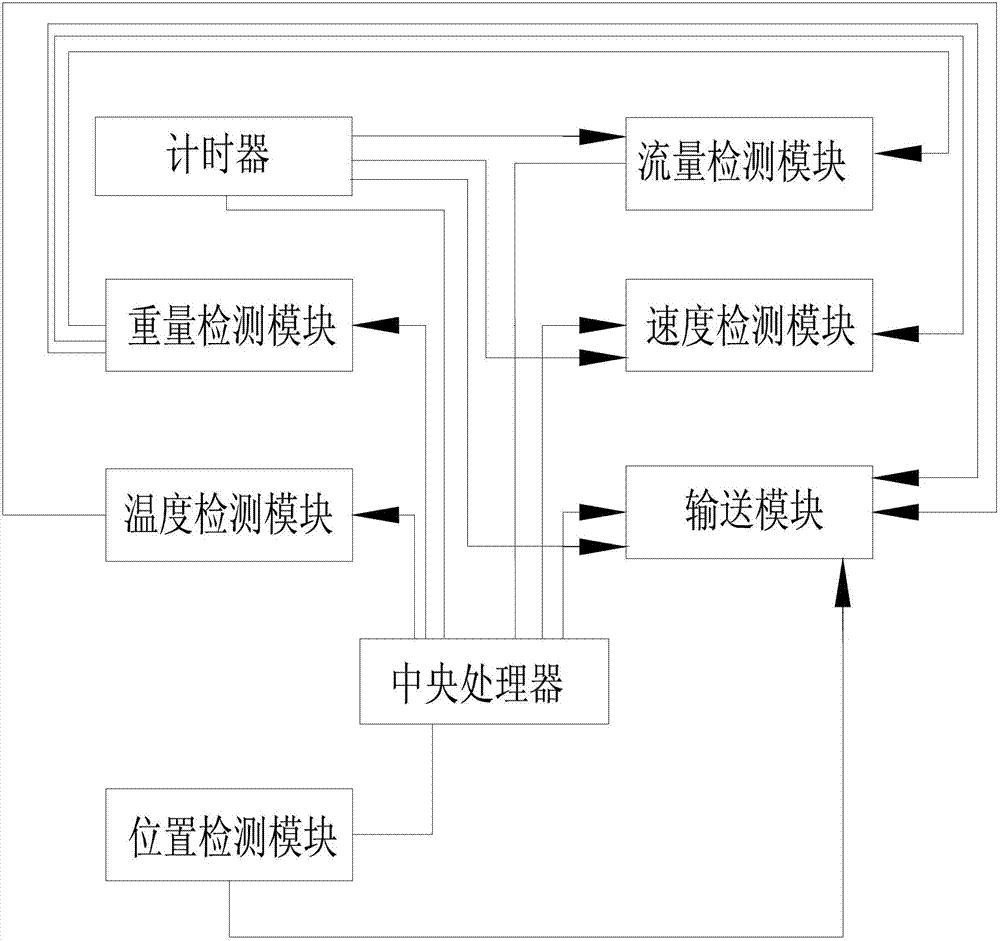

Multi-batch metering oil injection system and method

The invention discloses a multi-batch metering oil injection system and a multi-batch metering oil injection method. The system comprises an oil storage tank, a batch metering balance and an electrical control cabinet, wherein a first oil pump is arranged on a first pipeline for connecting the oil storage tank and the batch metering balance; a second oil pump is arranged on a second pipeline of an internal mixer externally connected to the batch metering balance; the oil storage tank, the first oil pump, the second oil pump and the batch metering balance are electrically connected with the electrical control cabinet respectively; the oil storage tank comprises an inner container and a preheating sleeve; the inner container is arranged in the preheating sleeve; a heat medium is filled between the inner container and the preheating sleeve; the batch metering balance comprises an oil barrel and a weight detector; and the weight detector is arranged at the bottom of the oil barrel. The method comprises the following steps of: under the control of the electrical control cabinet, preheating oil in the oil storage tank by the heat medium; conveying the oil from the first oil pump into the batch metering balance; weighing the oil by the batch metering balance according to weights of corresponding batches; and conveying the weighed oil to the internal mixer through the second oil pump. By the system and the method, the oil can be automatically injected into the internal mixer; the oil injection amount is accurate; and the labor intensity of a user is low.

Owner:KINGFA SCI & TECH CO LTD +1

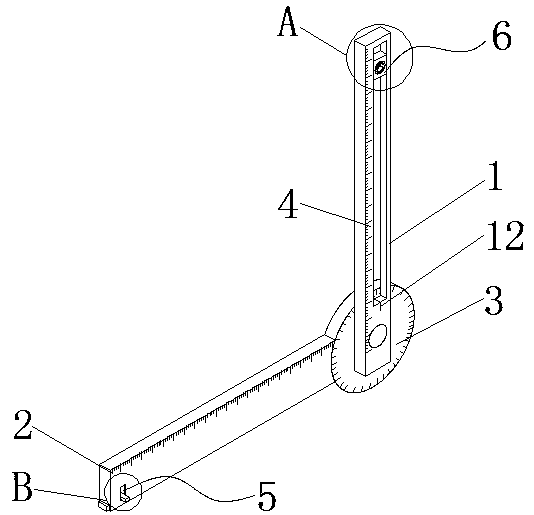

Scribing and distance measuring device

InactiveCN109278448ADrawn preciselyReduce contactWriting aidsMechanical measuring arrangementsObservational errorStraightedge

The invention discloses a scribing and distance measuring device. The scribing and distance measuring device comprises a scribing and distance measuring device body, a straight ruler, an angle disc, arotating ruler, a measuring tape assembly, a sliding scribing assembly and a chalk clamping assembly, wherein the straight ruler is arranged on one side of the scribing and distance measuring devicebody, the angle disc is fixedly welded to the outer wall of one end of the straight ruler, the rotating ruler is arranged on one side of the angle disc, a first rotating shaft is fixedly welded to theouter wall of one end of the rotating ruler, a rotating shaft hole is formed in the portion, corresponding to the first rotating shaft, of the center of the outer wall of one side of the angle disc,and the first rotating shaft penetrates through the rotating shaft hole. Various combinations of lengths, angles and the like can be carried out, single-hand operation can be carried out more conveniently and quickly when the straight ruler and the angle disc are matched for measuring, and the rotating ruler is rotated to be overlapped with the straight ruler, so that folding of the device is achieved, and storage and carrying are convenient to achieve; and when some long objects are measured, measurement can be carried out through a measuring tape, and the problem that the measurement error is large due to multi-section measurement of the straight ruler is solved.

Owner:周婷婷

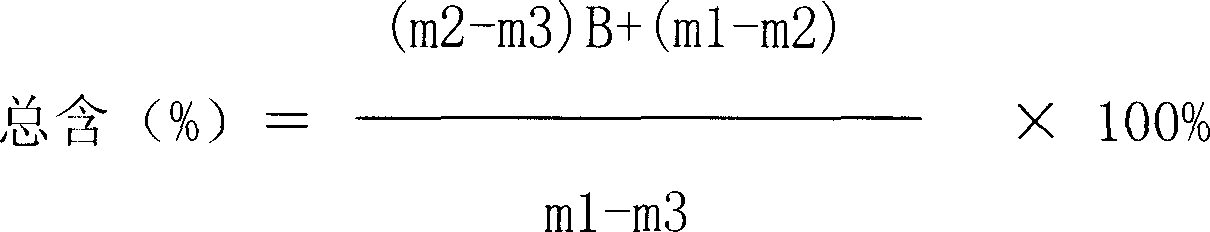

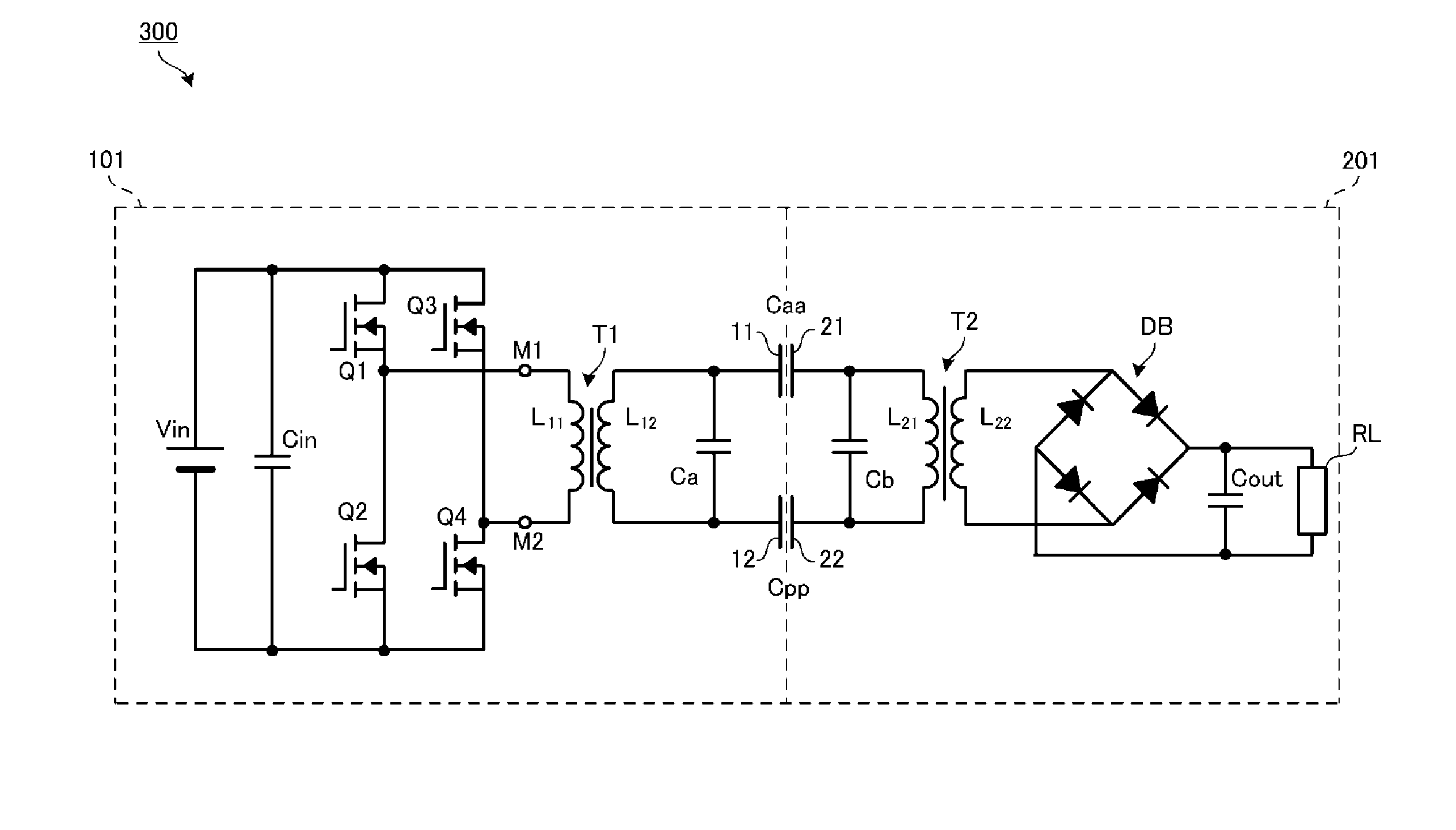

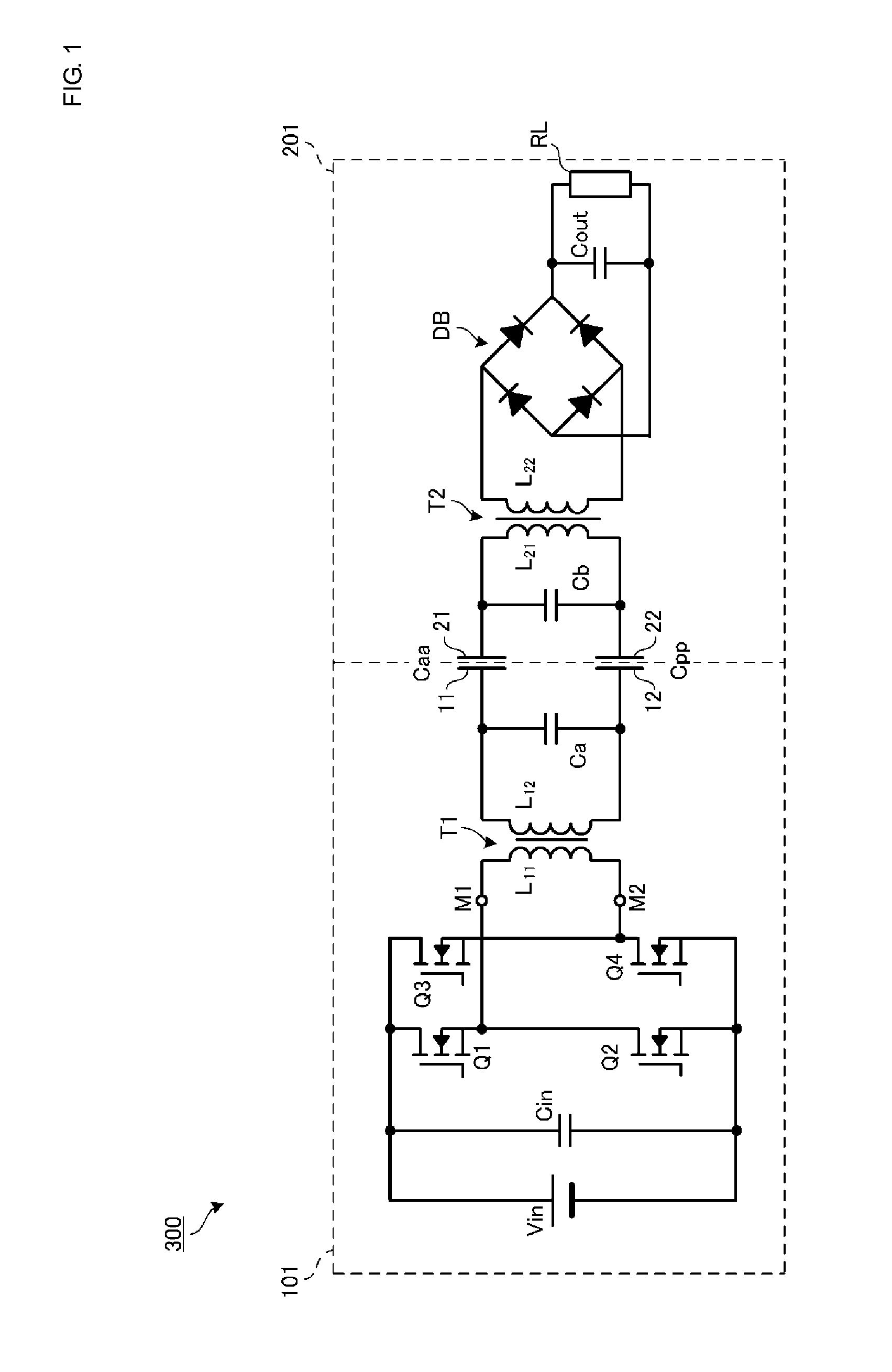

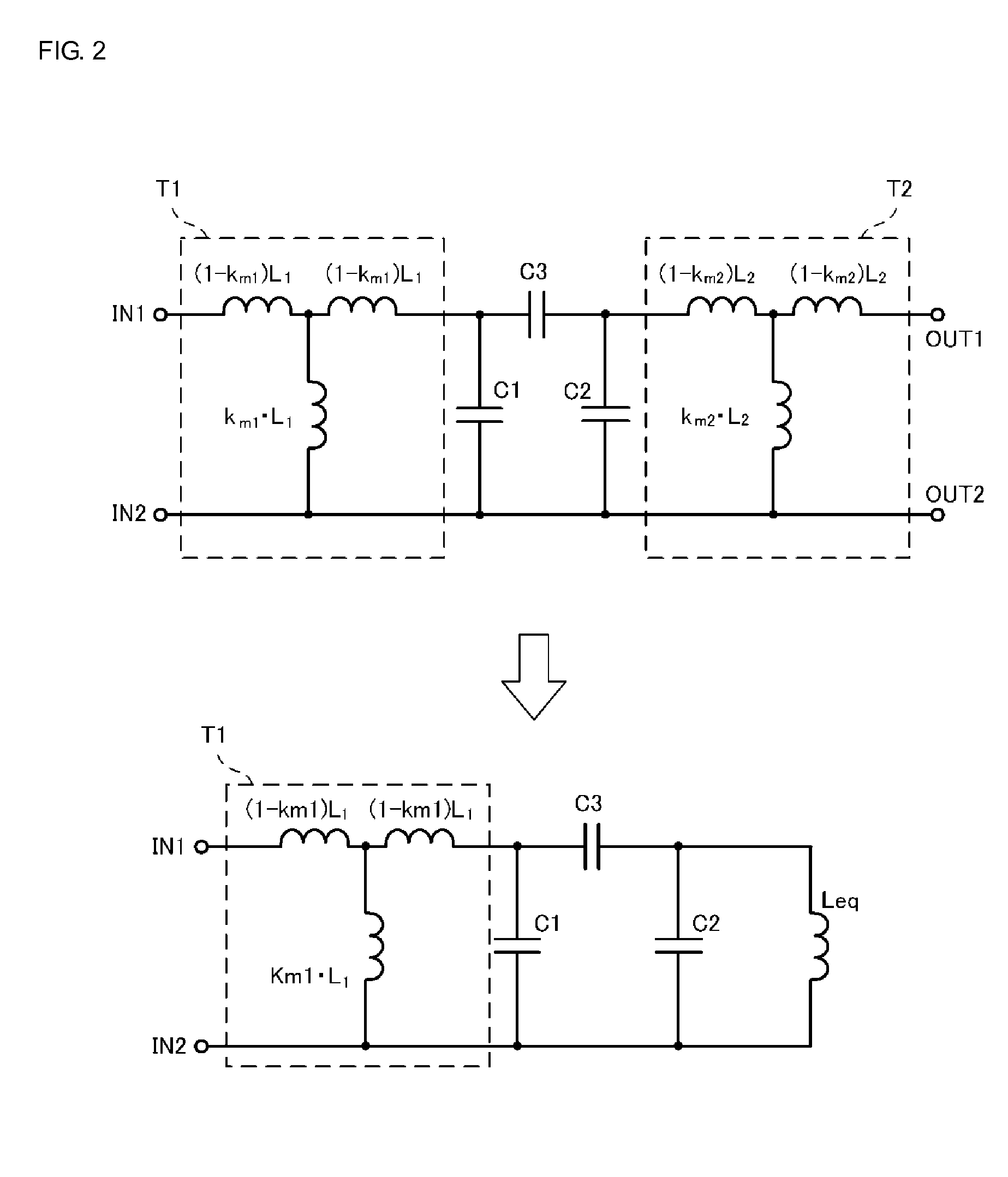

Parameter derivation method

ActiveUS20150285845A1Easy to shapeSmall sizeNear-field transmissionBatteries circuit arrangementsElectric power transmissionCoupling

A method for determining parameters of a wireless power transmission system is disclosed where the wireless power transmission system transmits power from a power transmission device to a power reception device via electric field coupling. The parameters include a coupling coefficient ke of an electric field coupling unit that is formed of active electrodes and passive electrodes of the power transmission device and the power reception device.

Owner:MURATA MFG CO LTD

Measuring device for sealing ring of three-eccentric center butterfly valve

ActiveCN102706251ASimple and accurate measurementSolve the large measurement errorMechanical measuring arrangementsObservational errorSection plane

The invention relates to a measuring device for a sealing ring of a three-eccentric center butterfly valve. The device is characterized by comprising a fixture body arranged on a vertical lathe, wherein the rotation center of the fixture body is overlapped with the rotation center of the vertical lathe; a positioning body is obliquely arranged on the fixture body; a workpiece is clamped on the positioning body; a measuring rod frame is arranged in the rotation center of the fixture body; a measuring rod is horizontally arranged on the top of the measuring rod frame; the rotation center of the fixture body equally divides an included angle formed between the two sides of the axial section of the machined workpiece; an included angle is formed between the rotation center of the vertical lathe and the vertical center line of the workpiece and is equal to an included angle formed between the rotation center of the vertical lathe and the center line of a butterfly valve installation pipeline; one end of the measuring rod stretches out of the measuring rod frame; and the end part of the stretching end of the measuring rod is provided with a tool setting point of a turning tool of the vertical lathe. The device solves the problem that the measuring error of the sealing ring is large, ensures the actually measured size of the sealing ring, simply and accurately measures the sealing ring, and well ensures a sealing effect.

Owner:无锡宝牛阀业有限公司

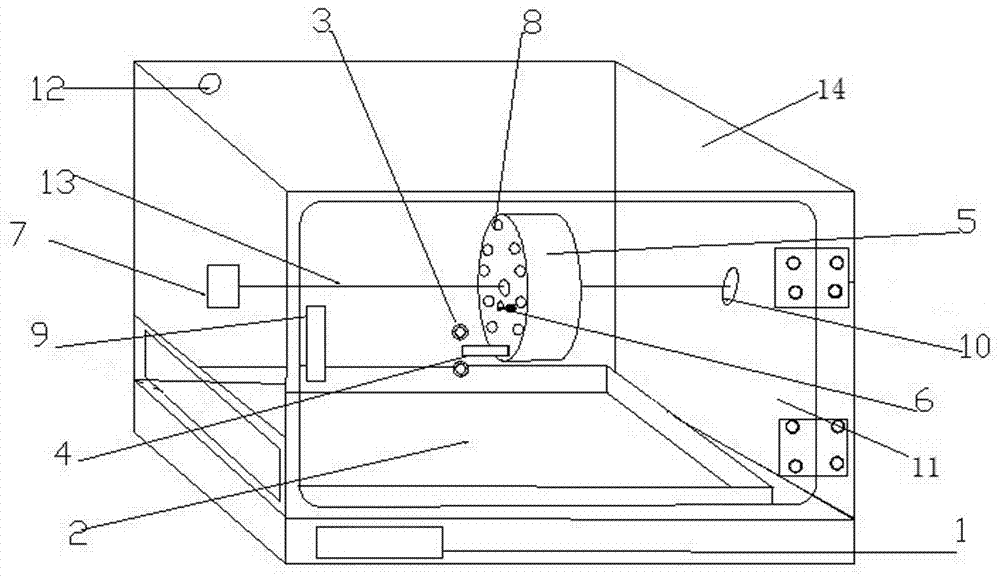

Cigarette smoldering detector

ActiveCN106885869ASolve the large measurement errorAvoid scatterChemical analysis using combustionUsing optical meansObservational errorEngineering

The invention relates to the field of cigarette detection device and in particular relates to a cigarette smoldering detector. The cigarette smoldering detector comprises a smoldering rack for mounting cigarettes. A cigarette mounting position is arranged on the cigarette rack. The cigarette smoldering detector also comprises a photoelectric detection device for detecting whether the cigarette mounting length in the cigarette mounting position meets the requirement or not. The photoelectric detection device comprises an emitter which emits a detection signal. The cigarette smoldering detector provided by the invention detects whether cigarette mounting length is qualified or not through the photoelectric detection device and solves the problem that the measuring error of the existing cigarette smoldering detection device which mainly performs manual detection is great.

Owner:CHINA TOBACCO HENAN IND

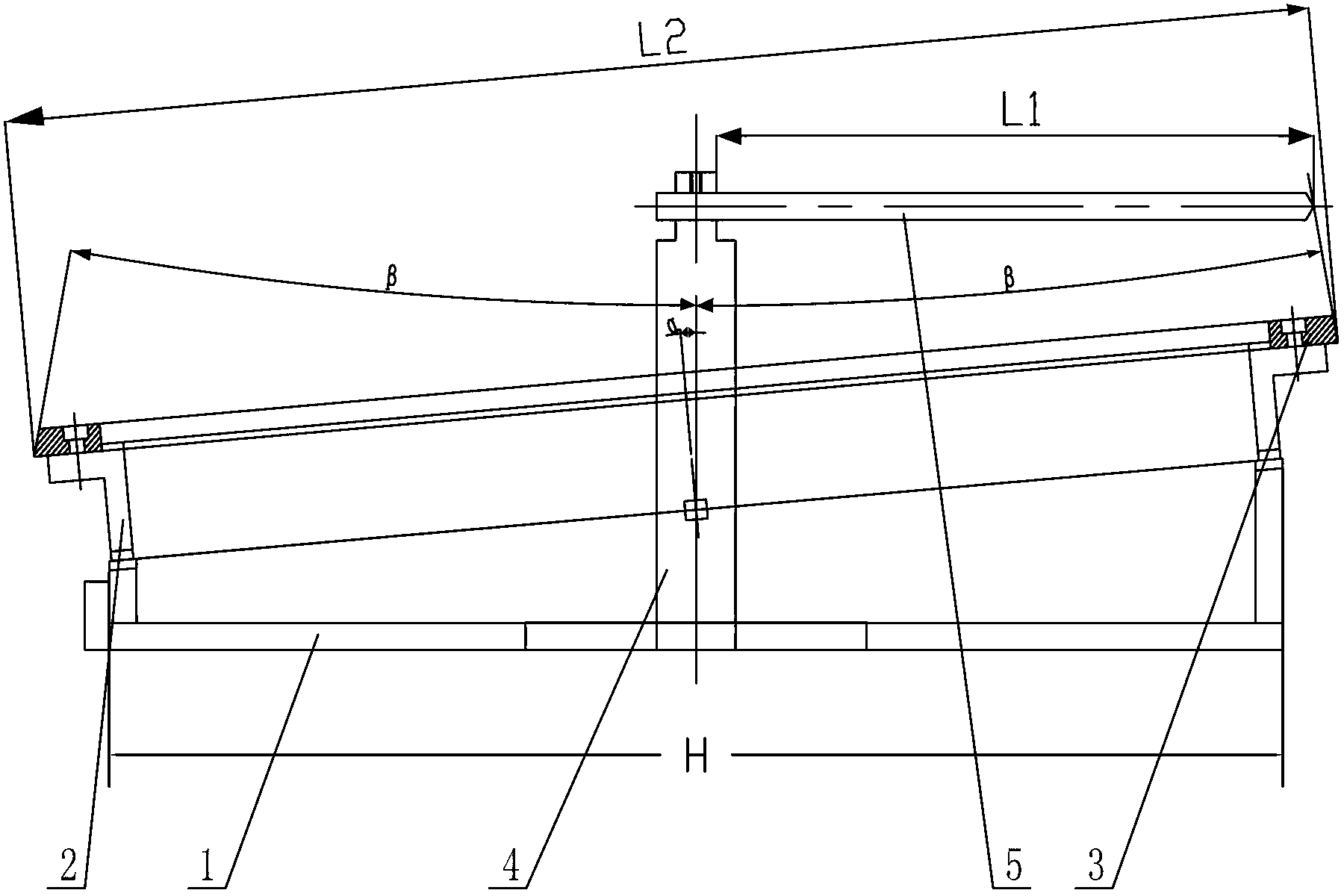

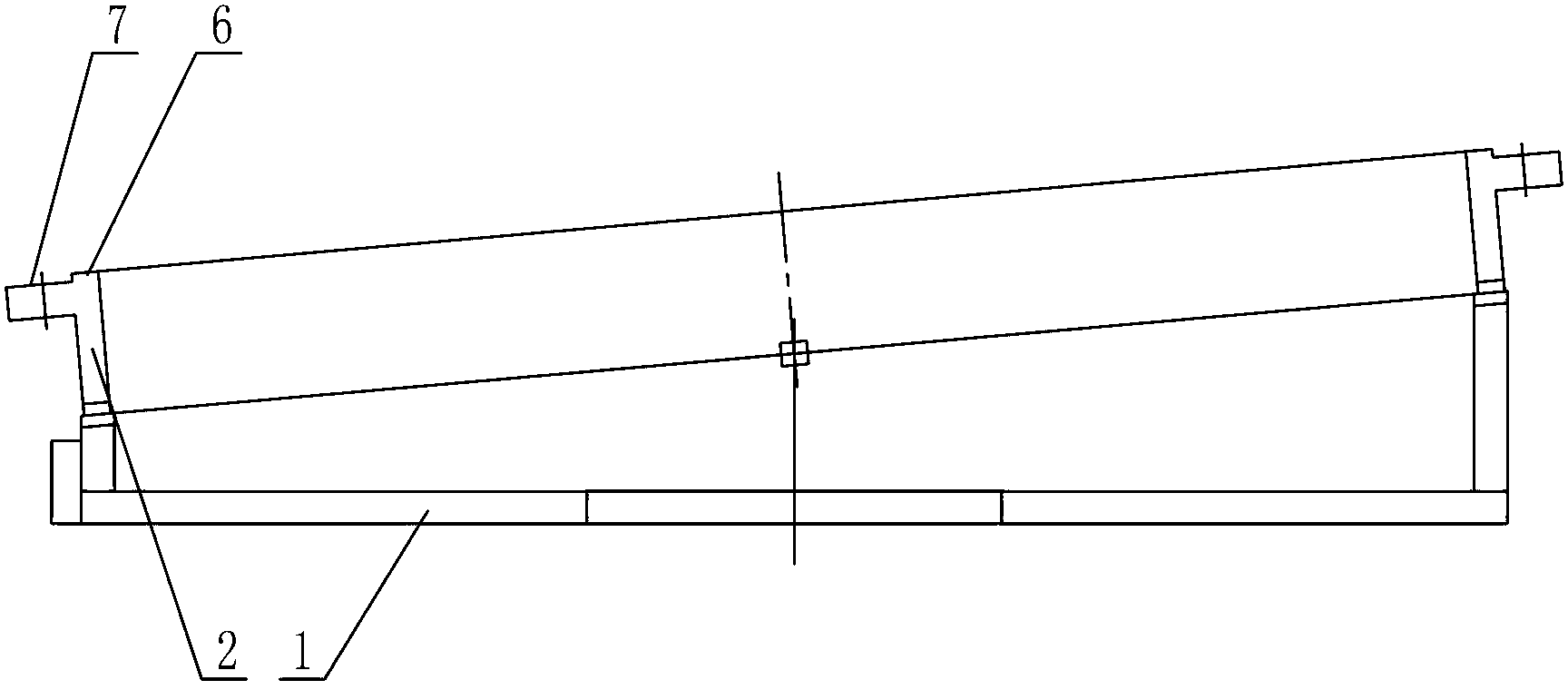

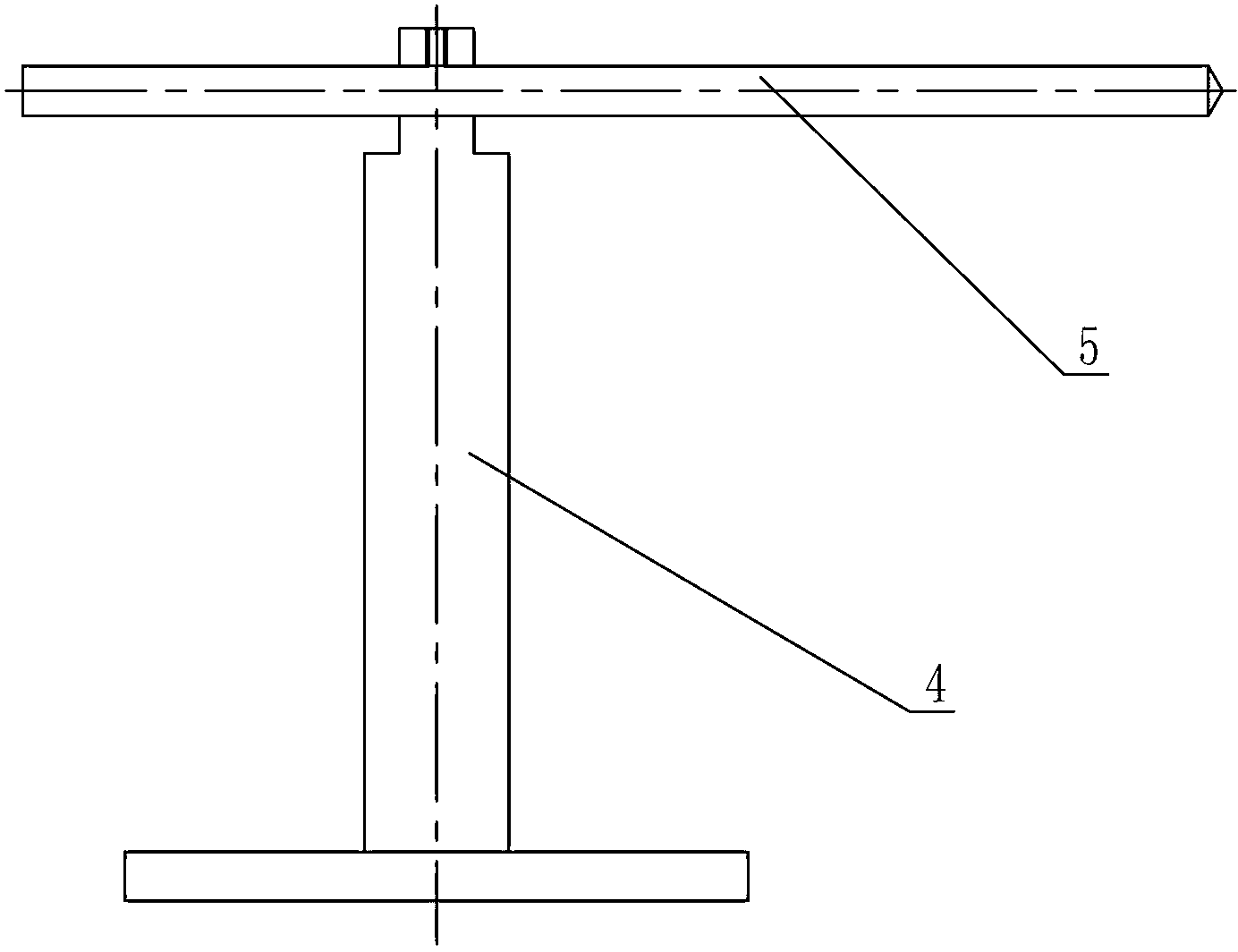

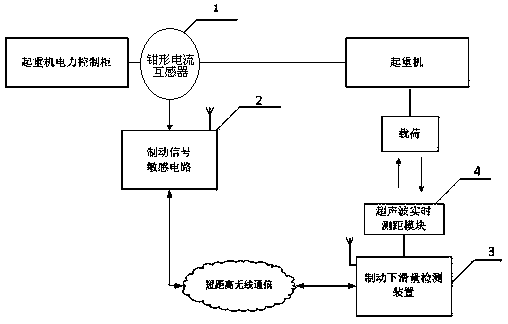

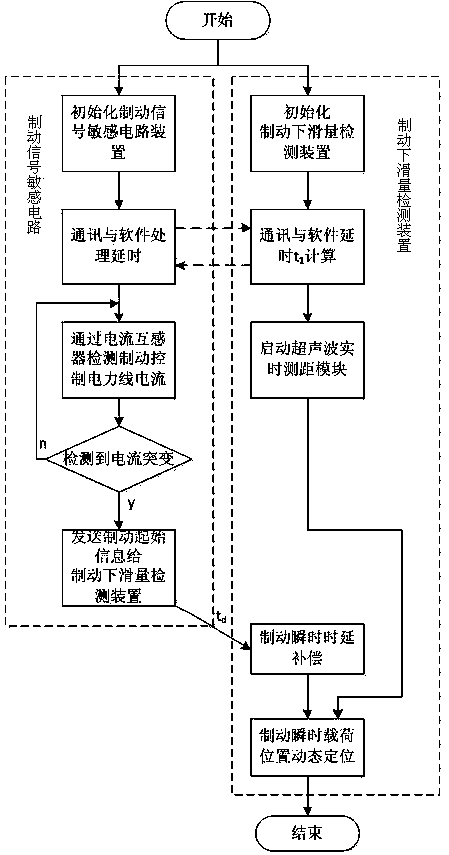

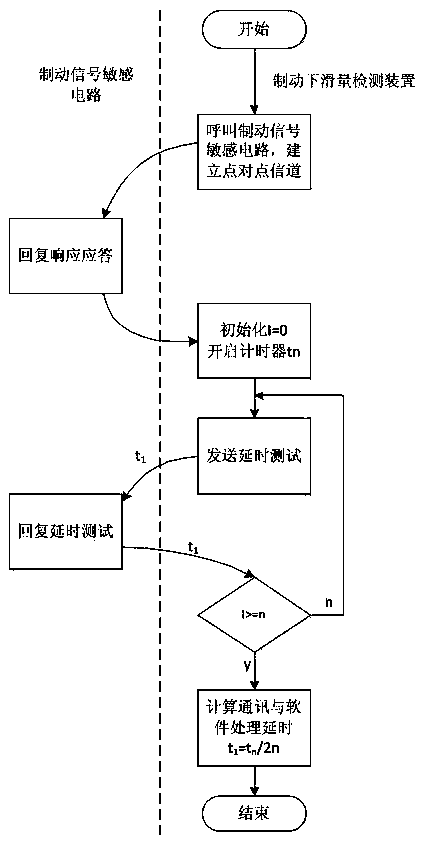

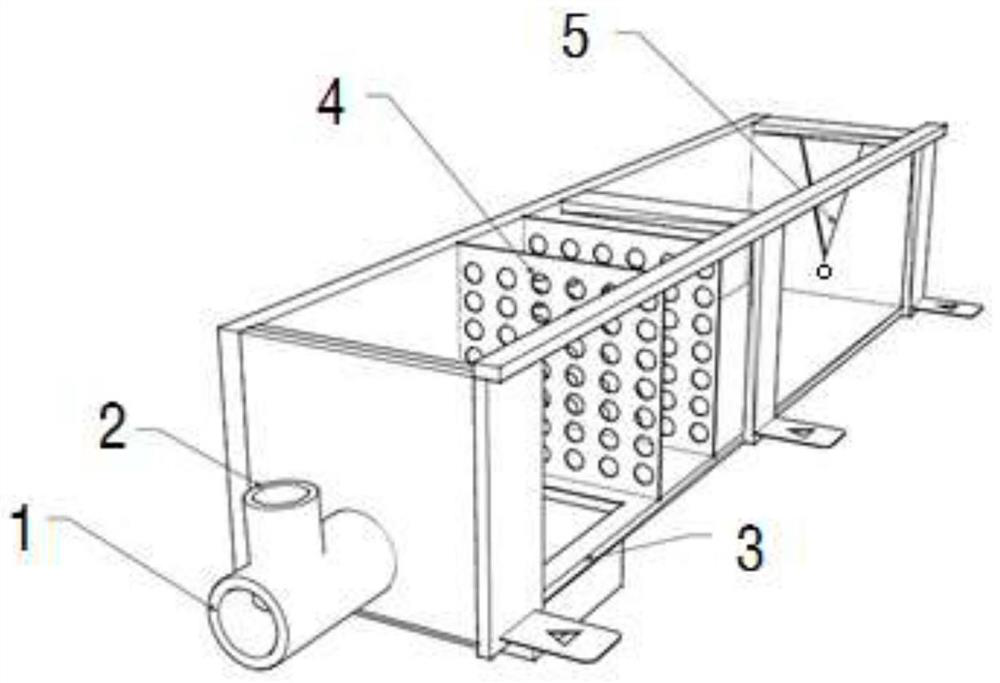

Method for determining brake transient load position of crane (brake slip amount detection)

InactiveCN103708353ASolve the problem of timing with large random delaySolve the large measurement errorMeasurement devicesLoad-engaging elementsShortest distanceEngineering

The invention discloses a method for determining a brake transient load position of a crane (brake slip amount detection). The method is characterized by comprising the following steps of receiving a moment of brake information transmitted by a brake signal sensitive circuit through a short-distance wireless communication way by a brake slip-amount detection device, subtracting the communication transmission and software processing delay time and the brake signal detection circuit hardware delay time to obtain a real brake transient moment of the crane, and accurately measuring a brake transient position of a load in the movement process through a dynamic positioning algorithm of the brake transient load position. By adopting the method, the problem of the traditional crane brake slip-amount detection method that the timing of the real brake transient moment is severely delayed can be solved, and the brake slip-amount detection consistency can be improved; the problem that the error in measuring the brake transient down load position of the crane is large in the dynamic measurement process based on an ultrasonic ranging sensor can be solved, and the automatic high-precision measurement of the brake slip-amount detection brake transient down load position can be realized.

Owner:SOUTHEAST UNIV +1

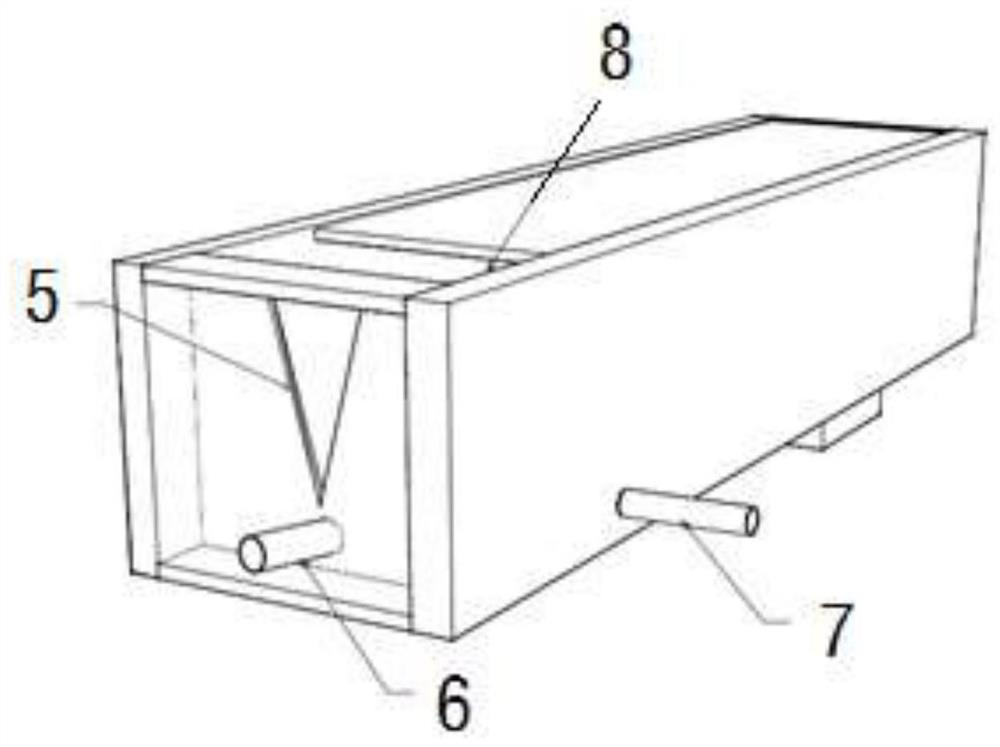

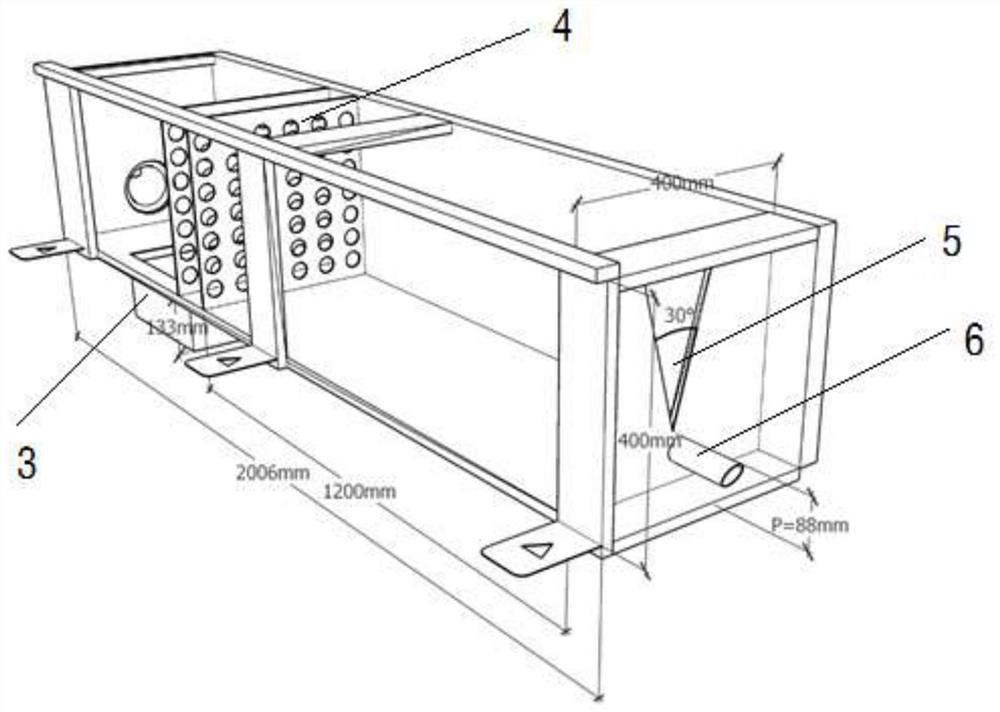

Farmland runoff monitoring device suitable for paddy fields and dry lands

PendingCN111983187AClear timeAvoid oversamplingEarth material testingStream flowEnvironmental engineering

The invention discloses a farmland runoff monitoring device simultaneously suitable for dry land and paddy fields. The device comprises a water inlet, a grit chamber, a steady flow plate, a triangularweir, a float-type water level sensor and a water outlet. A movable sampling frame is arranged in the grit chamber; farmland drainage settles silt through the grit chamber and stably enters a triangular weir for flow measurement through a steady flow plate; the float-type water level sensor is communicated through a hole in the right side of the weir trough, the float in the instrument rises andfalls along with the fluctuation of the water level, the water level change in the triangular weir is measured, and water level data is transmitted to automatic sampling equipment to calculate the weir flow; when the water level exceeds the height of the weir crest of the triangular weir, sampling is triggered so as to compare changes of runoff pollutant concentrations generated in different stages. By utilizing the agricultural non-point source pollution runoff monitoring device, the problems of small agricultural non-point source pollution runoff flow, much silt and difficulty in accurate measurement can be solved, and a reliable basis is provided for agricultural non-point source pollution control and ecological environment protection.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

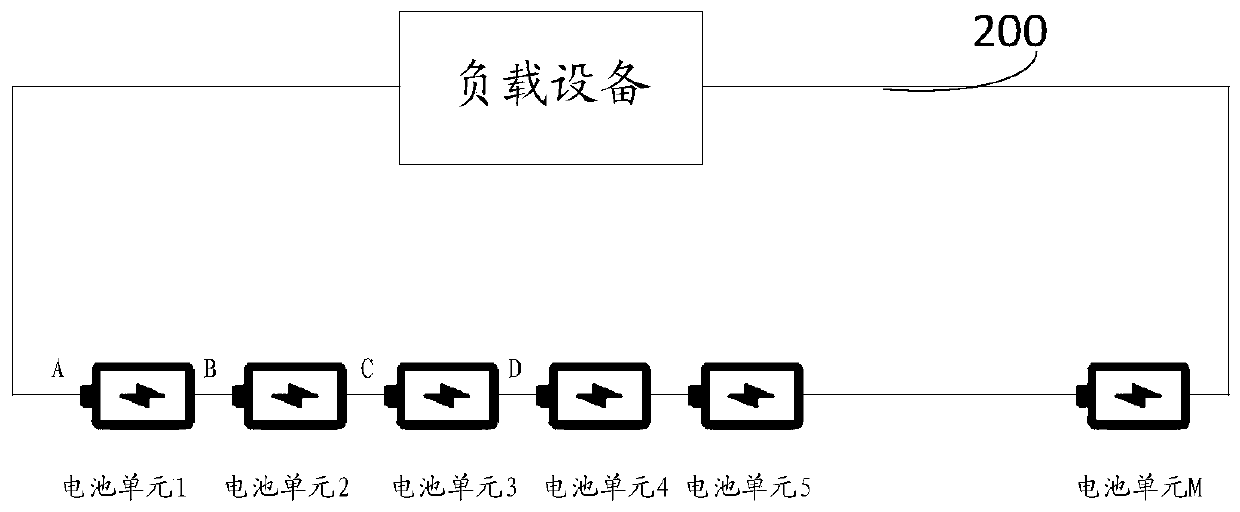

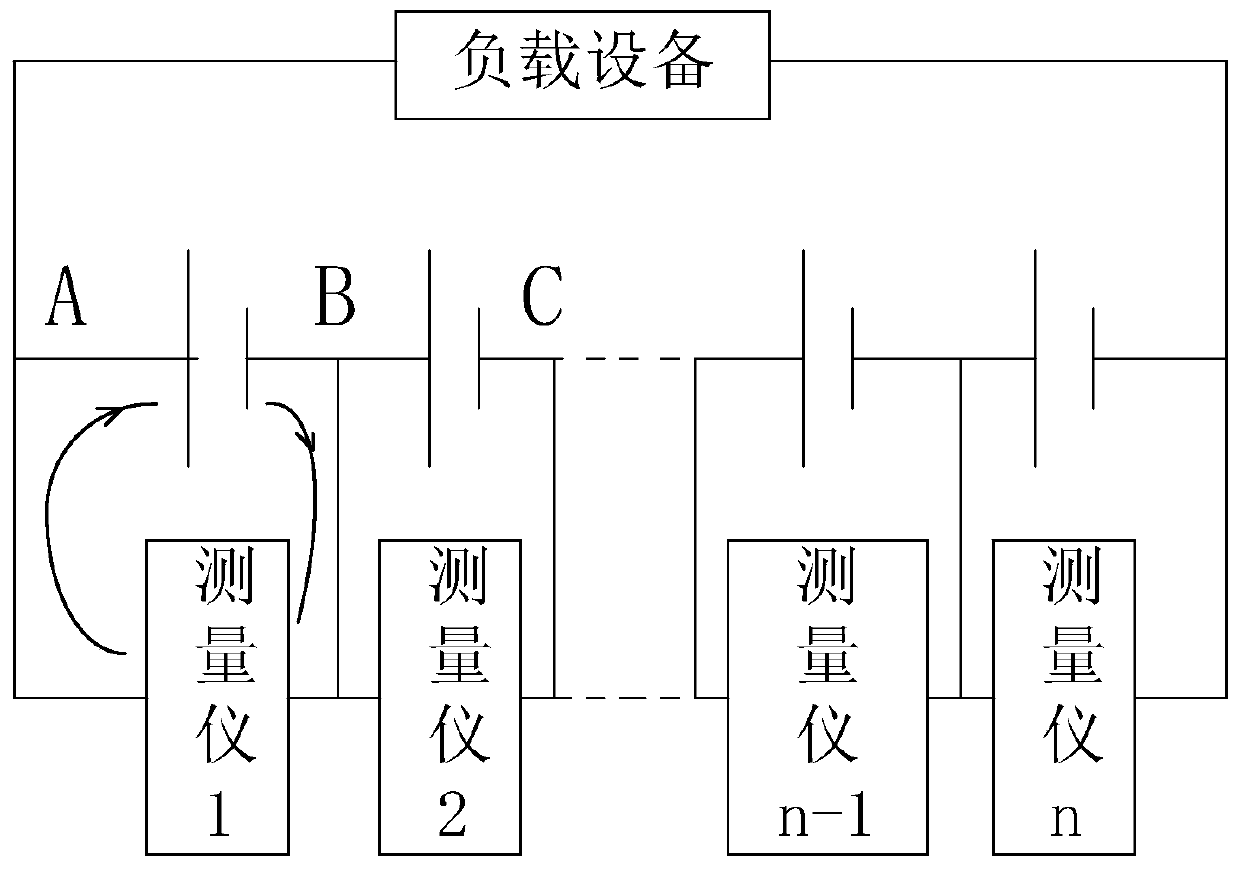

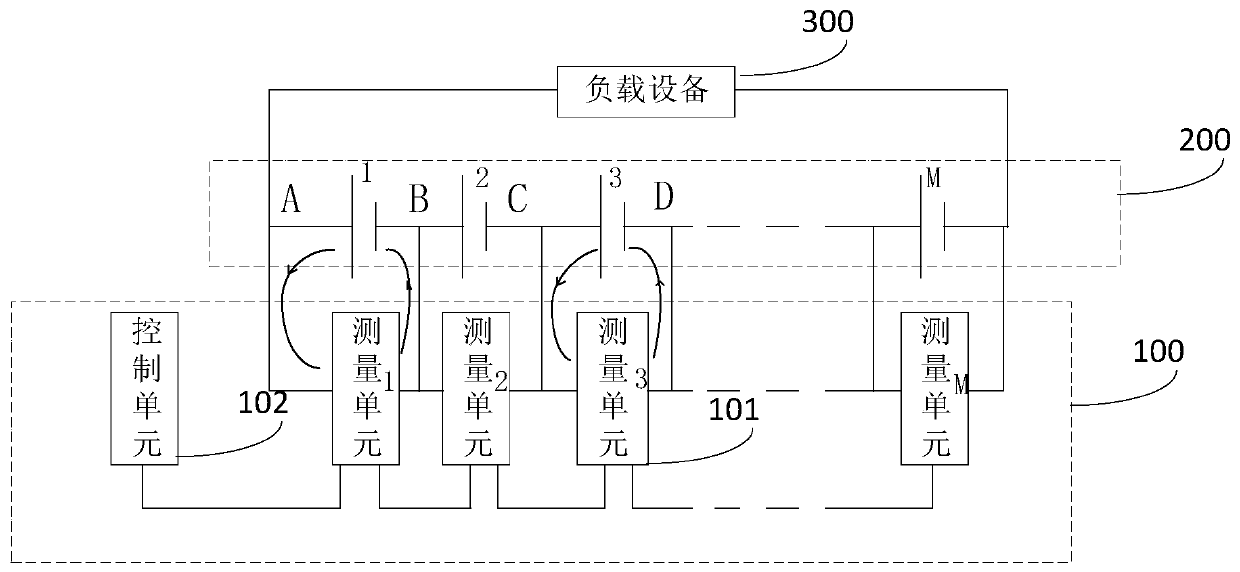

Method and device for measuring internal resistance of battery pack

InactiveCN110716147ASolve the large measurement errorSolve the problem that the measurement speed is too slowElectrical testingInternal resistanceControl engineering

The invention discloses a method and device for measuring the internal resistance of a battery pack, and relates to the technical field of power electronics. The device for measuring the internal resistance of the battery pack includes N sets of measuring units and a control unit, each measuring unit is used for measuring the internal resistance of one battery unit, wherein N is bigger than or equal to 2, each set of the measuring units includes at least one measuring unit, at least one of set of the N sets of measuring units includes more than two measuring units, and the number of the measuring units in any two sets of the measuring units is equal or in one-difference; the control unit is in communication connection with the N sets of measuring units, and is used for controlling the N sets of measuring units to start measuring one by one; and the measuring units in the same set start measurement at the same time, and after the measurement of one set of measuring units is completed, the next set of measuring units starts to measure until the N sets of measuring units complete the measurement. The embodiments of the method and device are applied to measure the internal resistance of the battery pack.

Owner:云蜂数智物联网有限公司

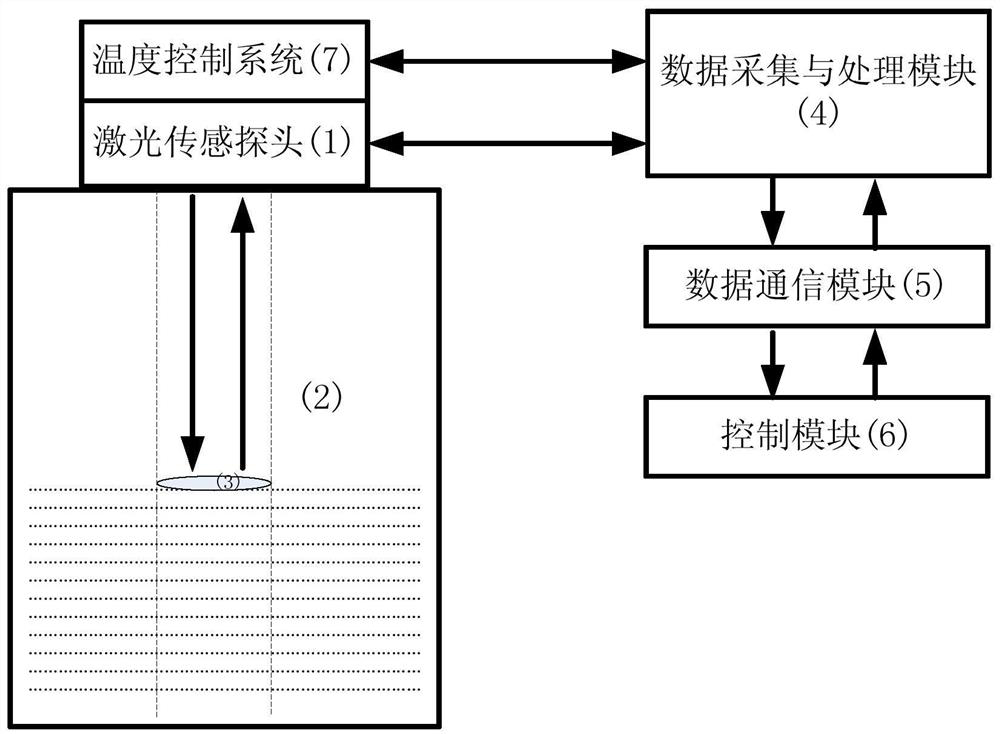

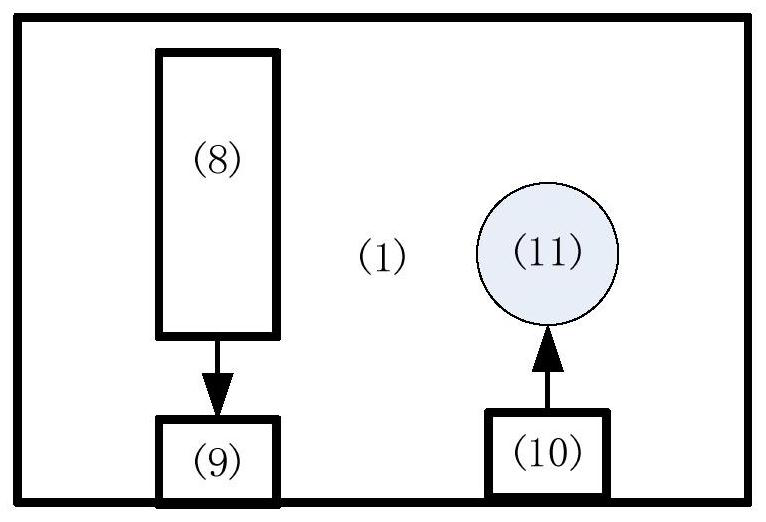

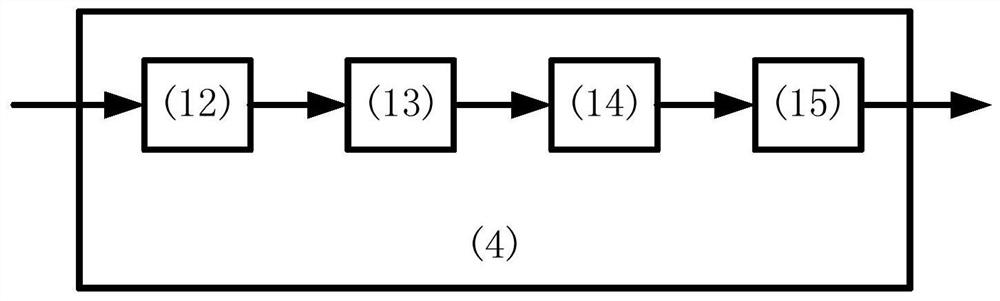

Device and method for measuring rocket fuel liquid oxygen liquid level through laser ranging

InactiveCN111623852ASolve the accuracy problemSolution rangeMachines/enginesLubrication indication devicesCapacitanceDielectric

The invention discloses a device and method for measuring the rocket fuel liquid oxygen liquid level through laser ranging. The device comprises a control module which is used for transmitting a lasertriggering signal through a data communication module, and updating the liquid level information in real time according to the liquid level height; a laser sensing probe which is used for emitting measurement laser, and transmitting the reflected laser to a data acquisition and processing module; a reflection floating plate which is used for reflecting the measurement laser and outputting the reflected laser; a data acquisition and processing module which is used for recording initial data information and analyzing the reflected laser to obtain measurement data information; and a data communication module which is used for calculating the liquid level height according to the initial data information and the measurement data information. The problems that a traditional rocket low-temperature fuel liquid oxygen liquid level monitoring scheme is affected by low temperature, capacitance dielectric constant, in-tank pressure intensity, electromagnetic wave interference and the like, so that measurement precision is low, the range is small, reliability is poor, the safety coefficient is low, and installation is complex are solved.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Large-scale equipment automatically centering method

ActiveCN105059564ASolve the large measurement errorThe principle is simpleAircraft assemblyObservational errorControl system

The present invention discloses a large-scale equipment automatically centering method. The method comprises a step of placing centering equipment and target equipment into place; a step of inputting deviation measurement data of a measuring system into a control system; a step that the control system judges if rolling, swaying, pitching, lateral moving and lifting adjustments are needed, calculates an adjustment amount after the adjustments are judged to be needed, drives adjusting devices to complete corresponding adjustment actions, and sends a next-time measuring command to the measuring system according to an adjustment in-place signal until criteria are met; and a step of completing butt joint of the centering equipment and the target equipment after centering. The large-scale equipment automatically centering method is advantageous in that a straight line centering method is adopted, thereby solving the problem of large measuring errors of end face centering adopted by large-scale equipment with small end faces. The method is simple in principle, few in assorted equipment, easy to realize, automatic in execution of all links such as deviation measurement, recognition, resolving, execution, control and feedback, free of manual intervention in the whole process, and high in centering efficiency.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

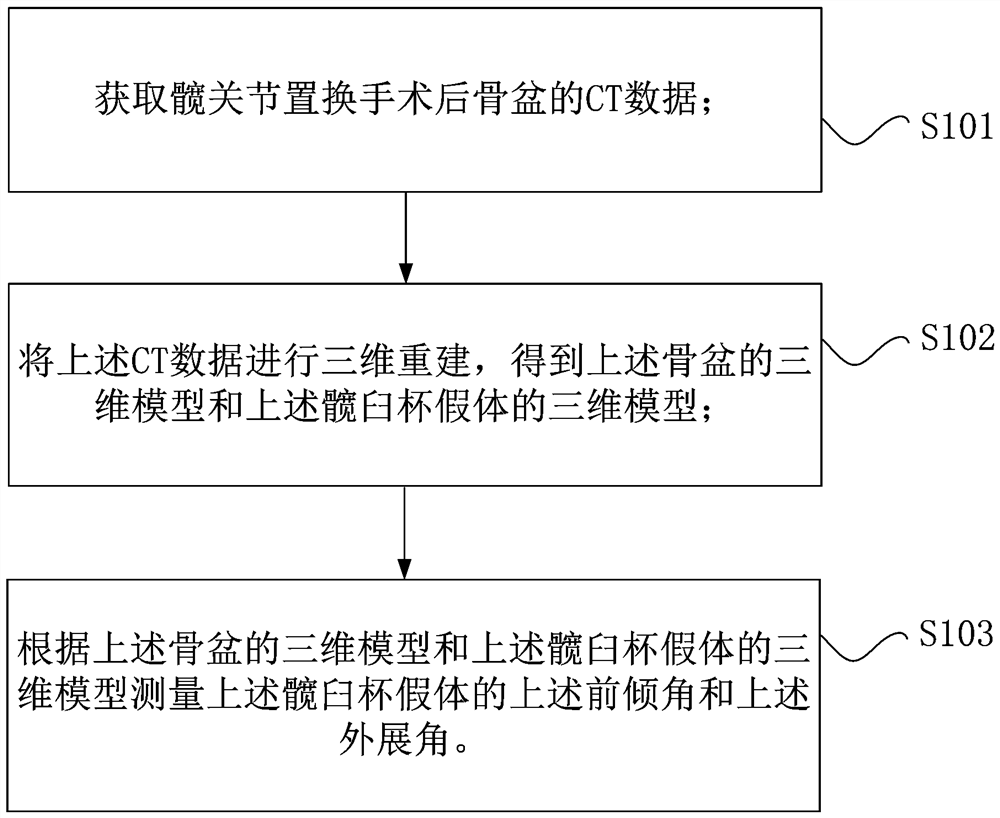

Method, device and system for measuring angle of acetabular cup prosthesis

ActiveCN114259330ASolve the large measurement errorReduce mistakesJoint implantsHip joint replacement operationPhysical medicine and rehabilitation

The invention provides a method, a device and a system for measuring the angle of an acetabular cup prosthesis. The method comprises the following steps: acquiring CT data of a pelvis after a hip replacement operation; performing three-dimensional reconstruction on the CT data to obtain a three-dimensional model of the pelvis and a three-dimensional model of the acetabular cup prosthesis; and according to the three-dimensional model of the pelvis and the three-dimensional model of the acetabular cup prosthesis, measuring the front rake angle and the abduction angle of the acetabular cup prosthesis. According to the method, three-dimensional reconstruction is carried out through CT data to obtain a three-dimensional model of a pelvis and a three-dimensional model of an acetabular cup prosthesis, and therefore the front rake angle and the abduction angle of the acetabular cup prosthesis are measured according to the three-dimensional model of the pelvis and the three-dimensional model of the acetabular cup prosthesis. Compared with the prior art that the anteversion angle and abduction angle of the acetabular cup prosthesis are measured through a two-dimensional X-ray film, errors are greatly reduced, and the problem that in the prior art, an acetabular cup angle measuring method is large in measuring error is solved.

Owner:BEIJING YIDIANLINGDONG TECH CO LTD

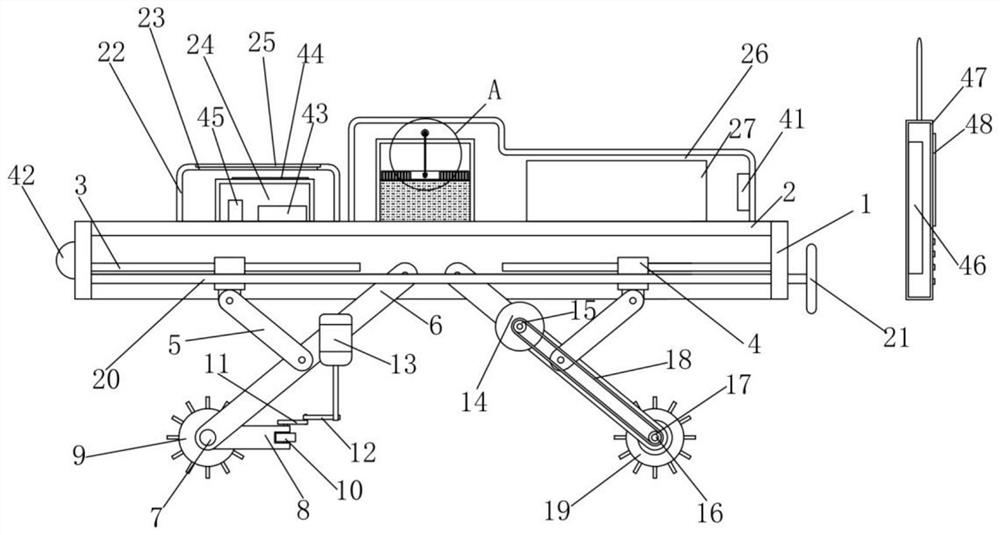

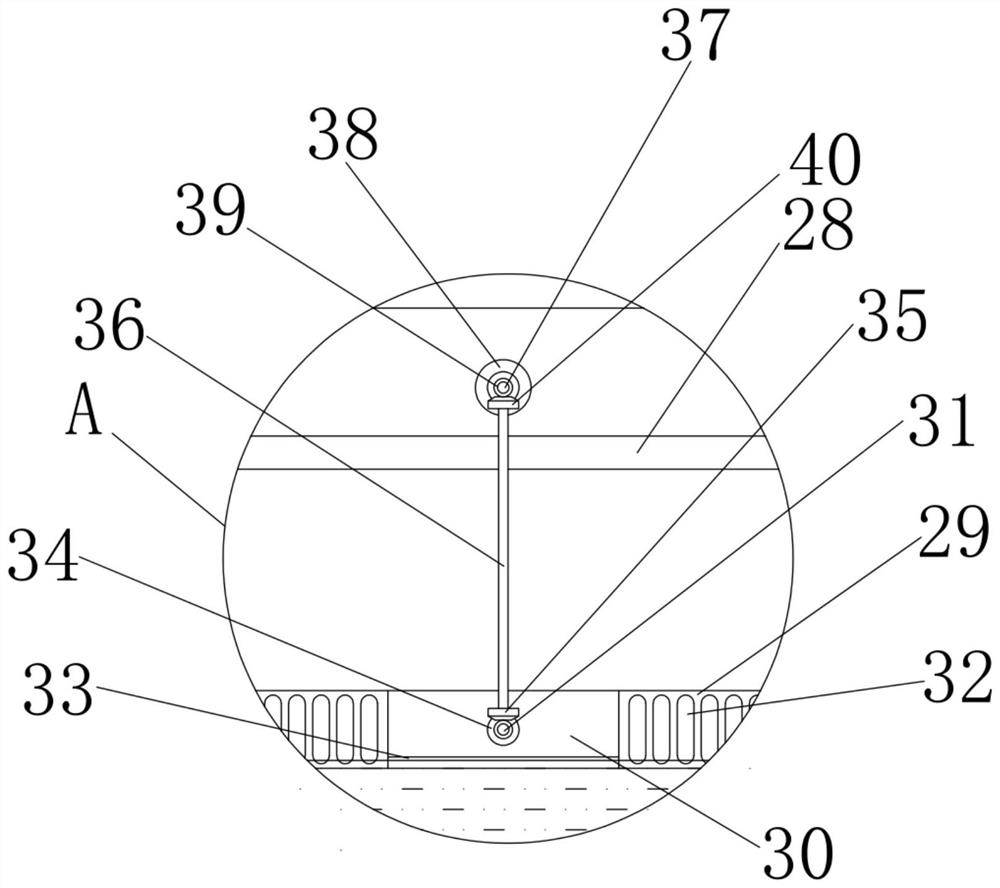

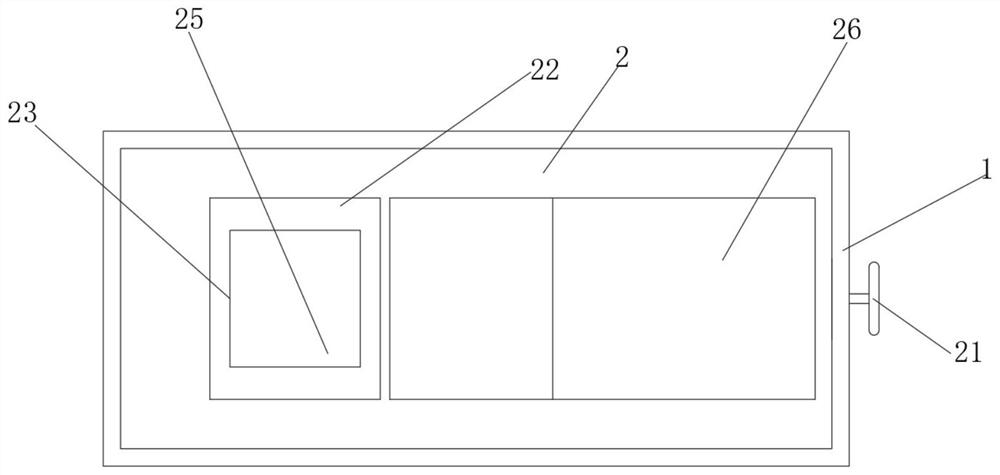

Portable land area measuring instrument for land planning and design

ActiveCN113048936ACause fatigue problemsMeet the needs of steeringMeasurement devicesMeasuring instrumentFixed frame

The invention relates to the technical field of land planning, in particular to a portable land area measuring instrument for land planning design, which comprises a fixed frame, roller mounting rods are symmetrically and rotatably mounted on two side walls of an inner cavity of the fixed frame, and fixed rods are fixedly mounted at one ends, far away from the fixed frame, of the two groups of roller mounting rods on the left side. Adjusting rods are rotatably mounted at the two ends of the fixing rod correspondingly, rotating rollers are rotatably mounted at the ends, away from the fixing rod, of the two adjusting rods correspondingly, a first traction rod is rotatably mounted on the right side between the two rotating rollers, and a steering mechanism is arranged on one side of each adjusting rod. Wheel shafts are rotationally mounted at the ends, away from the fixed frame, of the two groups of roller mounting rods on the right side. Compared with the prior art, the problem that a traditional land area measuring instrument only carries out area measurement calculation according to the longitude and the latitude, and the measurement error is large when the land with the gradient is handled is solved.

Owner:安徽中汇规划勘测设计研究院股份有限公司

Precise steel pipe quick diameter measuring device for auto spare parts

InactiveCN112066849AFast approachFull clamping workMechanical diameter measurementsEngineeringSteel tube

The invention discloses a precise steel pipe rapid diameter measuring device for auto spare parts, and relates to the technical field of auto spare parts. The precise steel pipe rapid diameter measuring device for the auto spare parts comprises a bottom plate, rolling wheels are rotationally installed on the outer surface of the bottom of the bottom plate, a first side rack and a second side rackare welded to the outer surface of the top of the bottom plate, and second sliding grooves are formed in the first side rack and the second side rack correspondingly; and second sliding blocks are slidably mounted in the second sliding grooves, the number of the second sliding blocks is two, connecting blocks are welded to the adjacent side walls of the two second sliding blocks, and a U-shaped box is arranged between the first side rack and the second side rack. According to the precise steel pipe rapid diameter measuring device, lifting work can be carried out, a steel pipe can be conveniently clamped, steel pipes of different lengths can be clamped, stable and effective clamping work is provided for the steel pipe, and accurate diameter measuring work can be carried out on the steel pipe.

Owner:湖州爆米花信息科技有限公司

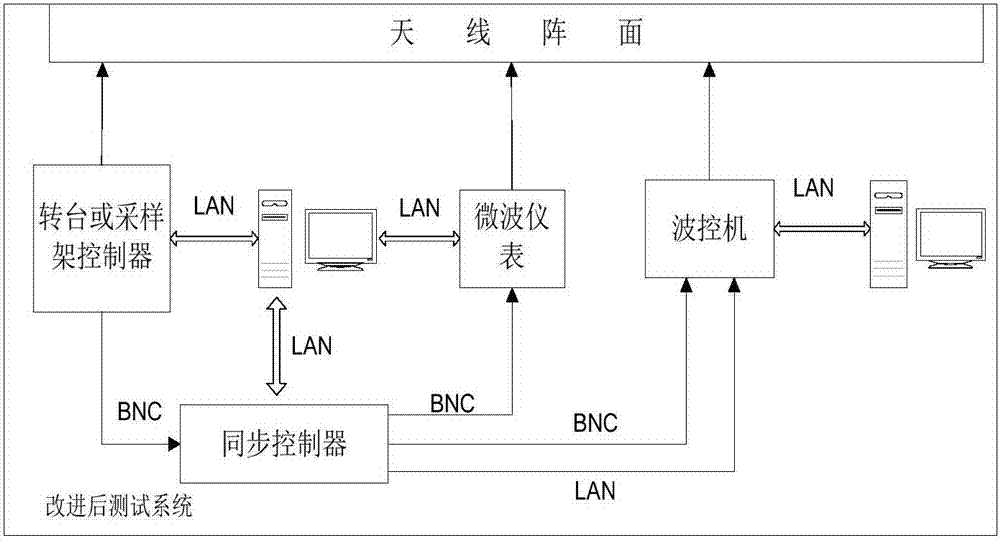

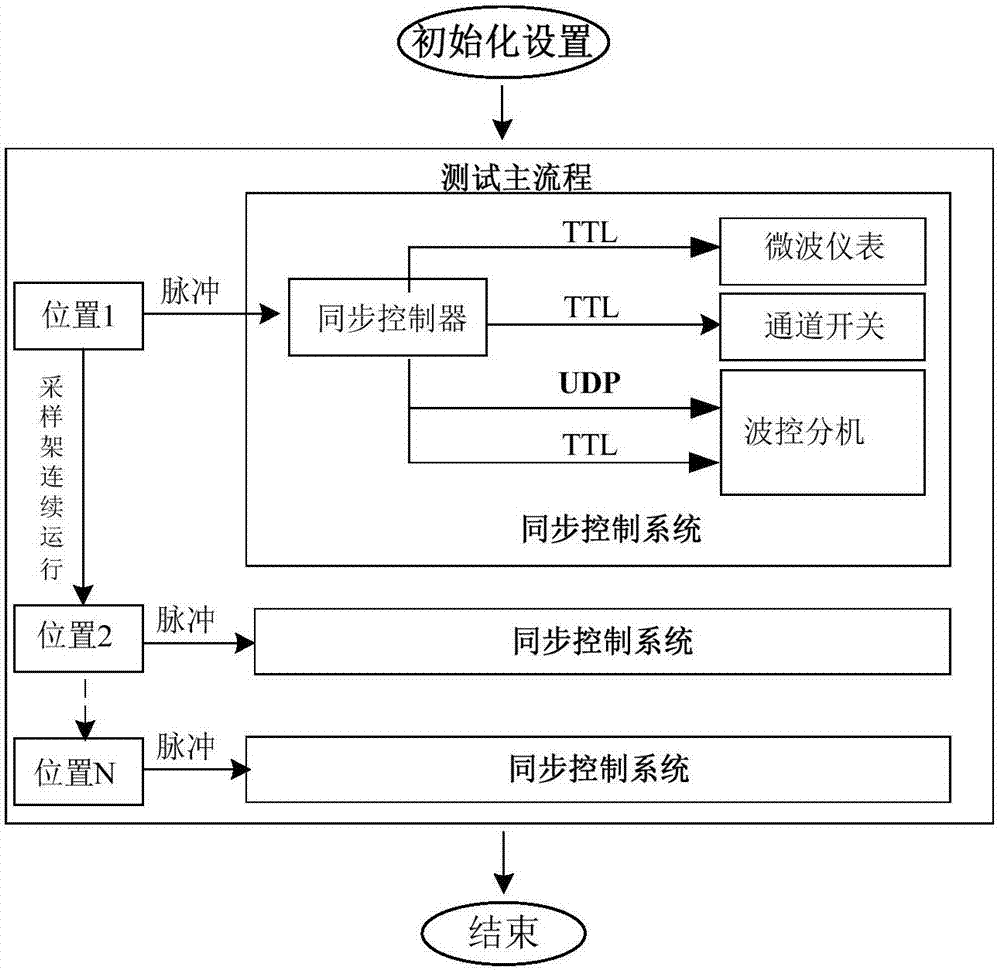

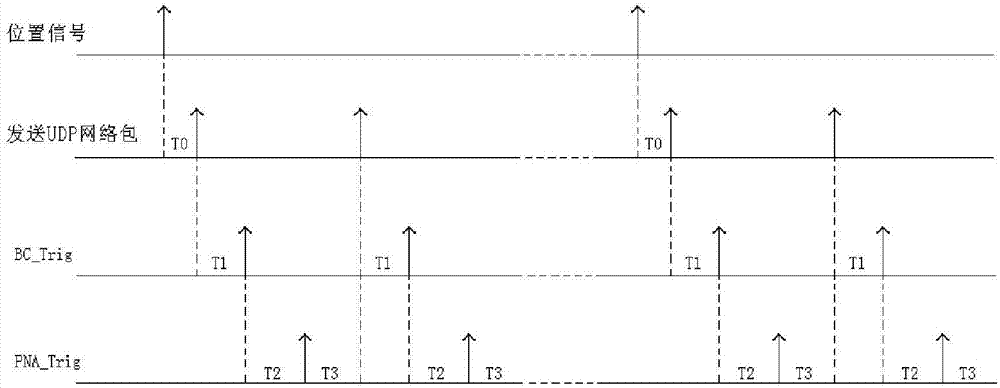

Near-field antenna emission unit level measurement system

InactiveCN108008206AReduced measurement timeReduce labor costsAntenna radiation diagramsTest efficiencyObservational error

The invention discloses a near-field antenna emission unit level measurement system which includes a master control machine used for sending an initialization command, a sampling frame controller usedfor controlling the operation of a sampling frame according to the initialization command, and a wave control machine used for data acquisition. The measurement system further includes a synchronization controller used for synchronizing the sampling frame controller and the wave control machine. By using the system of the invention, the problem that the measurement error is large due to large environmental temperature difference caused by too long time is avoided, and the test progress and the near-field test efficiency are improved. Moreover, there is no need for a calibration link on the basis of the prior art, and the measurement cost and the labor cost are greatly saved.

Owner:BEIJING INST OF RADIO MEASUREMENT

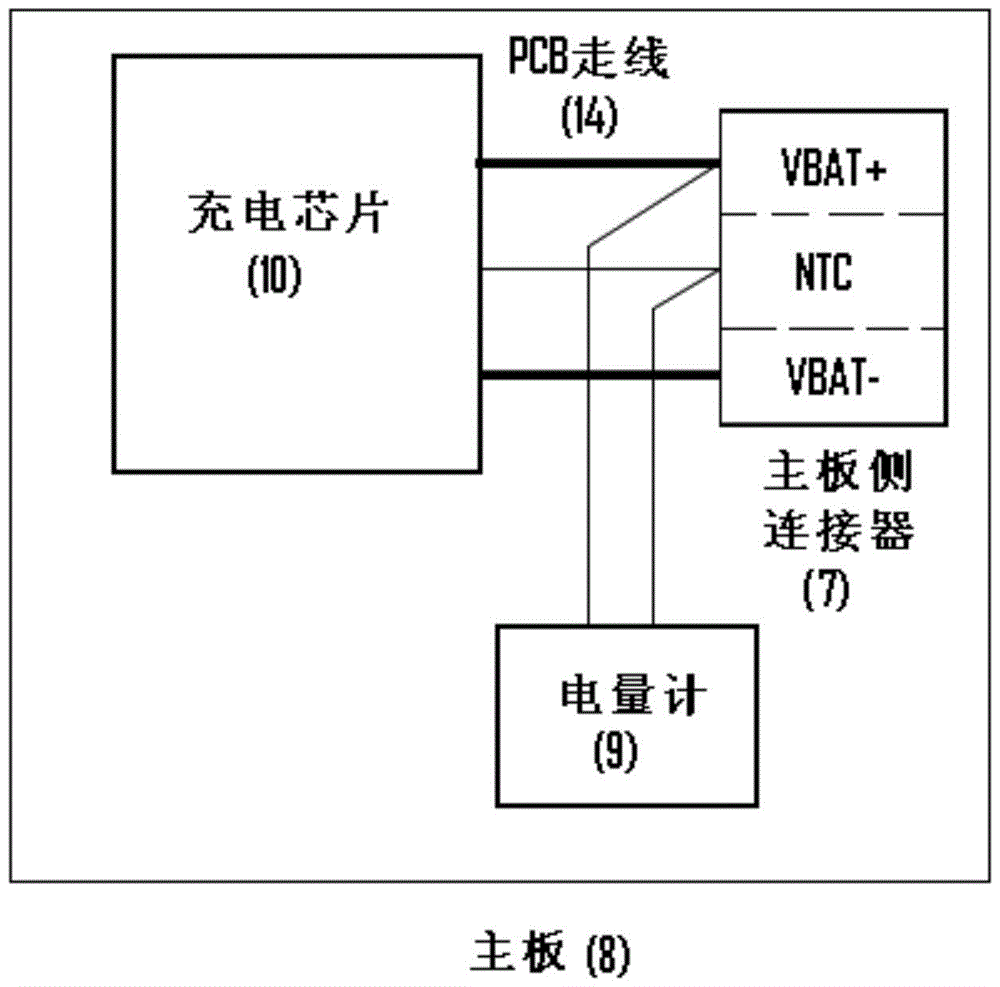

Voltage measuring method and voltage measuring device

InactiveCN106324317ASolve the large measurement errorReduce measurement errorBatteries circuit arrangementsCurrent/voltage measurementMeasurement precisionBattery cell

The invention provides a voltage measuring method and a voltage measuring device. According to the method, the voltage between the electrodes of a battery cell is measured by two detection signal lines arranged on a battery-side connector, wherein the two detection signal lines are respectively connected to the electrode lead ends of the battery cell. Through the voltage measuring method and the voltage measuring device of the invention, the problem of large battery voltage measurement error in the related technology is solved, and furthermore, the battery voltage measurement error is reduced, the measurement precision is improved, and the charging time is reduced.

Owner:ZTE CORP

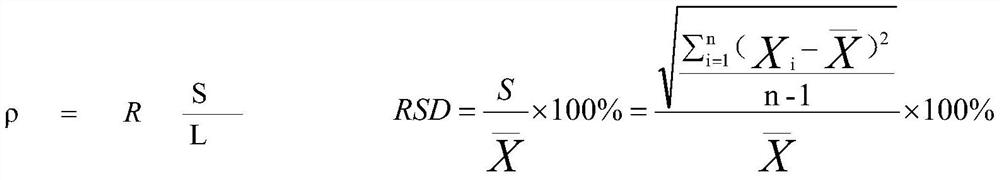

Pole piece resistivity test method

PendingCN112683958ASolve the large measurement errorReduce measurement errorResistance/reactance/impedencePreparing sample for investigationElectrical batteryPole piece

Owner:东莞维科电池有限公司

Air leakage rate measuring method of sintering machine system

InactiveCN101435711BSolve the large measurement errorReduce contentFurnace typesIndirect mass flowmetersAir velocityAir volume

The invention relates to a method for measuring system air leakage rate of a sintering machine in metallurgy. The invention discloses a method for measuring the system air leakage rate of the sintering machine. The method comprises the following steps: firstly, by measuring charge level air speeds at different parts of a machine pallet of the sintering machine, the effective air quantity(Q[inlet]) entering a sinter layer is worked out, by measuring the air speed in a main duct in front of an electrostatic dust collector, the total air quality(Q[total]) pumped in the main duct by an air exhauster is worked out, and by the water content in mixing material, the content of the air converted into vapor is worked out; secondly, the air qualities(Q[total standard], Q[inlet standard] and Q[water standard]) at the standard state are converted all together; and finally, the air leakage rate(B) is worked out according to the formula. The measuring method has strong operability and can overcome the defects of inconvenient measurement, big measurement error and complex air analysis existing in daily production and the defect existing in prior art that the local air leakage rate can only be measured by the air leakage point air speed measuring method. In a word, the method has the advantages of easy operation, accurate measurement and good use effect.

Owner:武钢集团有限公司

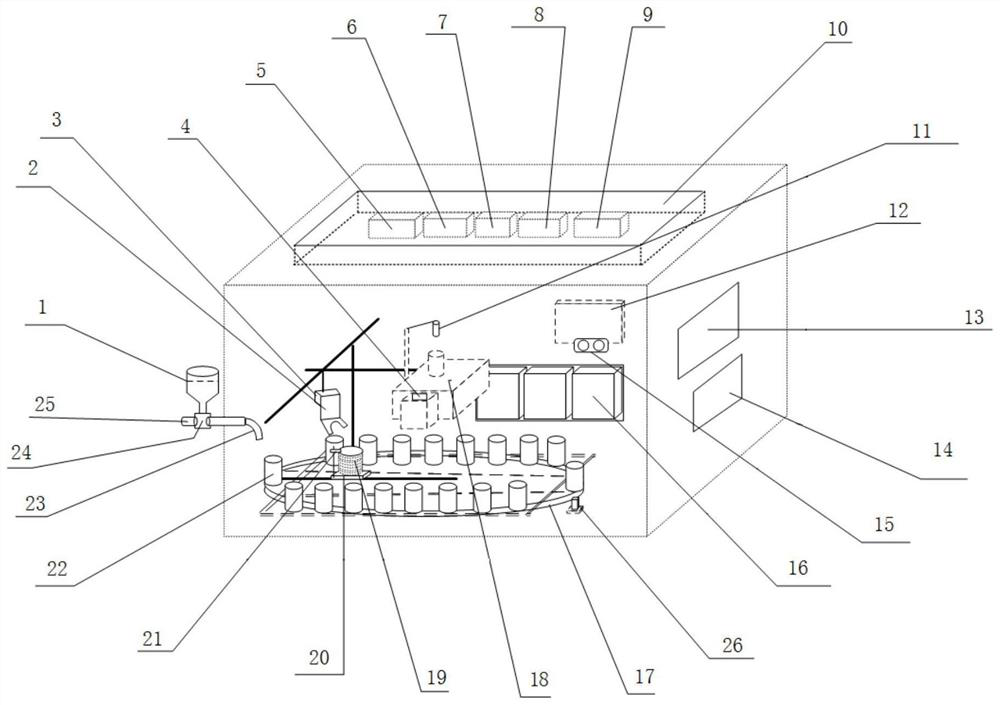

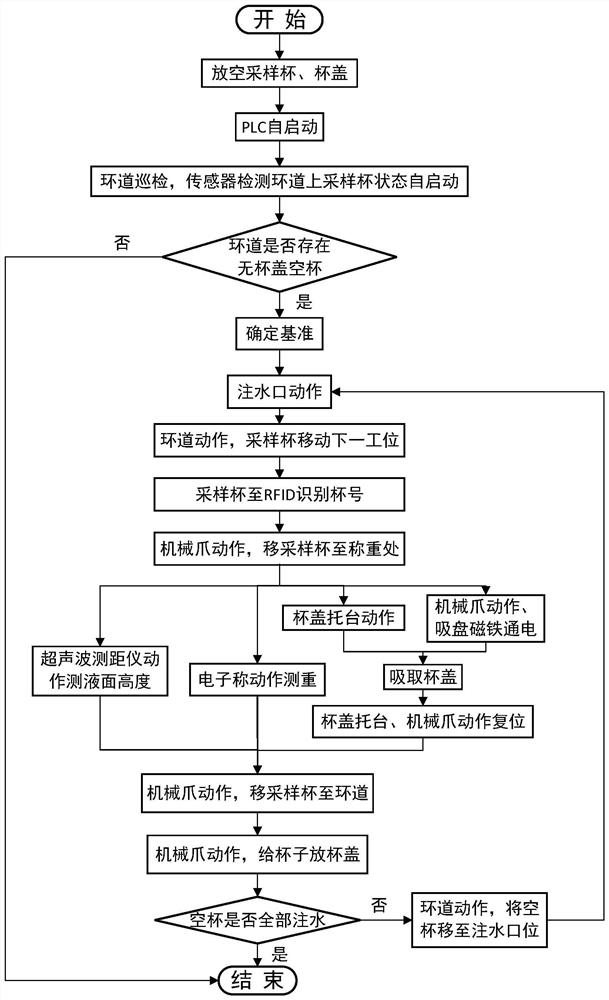

Device and method for measuring runoff sediment in whole scene

ActiveCN113933201AFlexible measurementAdjustable sampling intervalMaterial weighingEngineeringHydrology

The invention discloses a device and method for measuring runoff sediment in a full scene, the device comprises a box body, and a control part and a power supply part which are arranged at the top of the box body, a sampling assembly is arranged in the box body corresponding to the control part, the sampling assembly comprises a loop slide rail, a plurality of sampling cups are mounted on the loop slide rail, and a cup cover assembly is arranged in a ring of the loop slide rail. The first side wall of the box body is provided with a sampling assembly corresponding to the sampling cups, an electronic scale corresponding to the control part is arranged above the plurality of sampling cups, one side of the electronic scale is connected with a card identifier, an ultrasonic range finder is arranged above the electronic scale, and the plurality of sampling cups are further provided with mechanical claw assemblies; the side wall of the box body is provided with an operation control assembly corresponding to the control part, and the side wall of the box body is provided with a sampling observation window. The invention further discloses a method for measuring runoff sediment in whole scene. The device is used for measuring the runoff sediment in whole scene, and the measuring precision and efficiency are improved.

Owner:XIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com