Pole piece resistivity test method

A test method and resistivity technology, applied in the field of electrode resistivity testing, can solve the problems of large measurement error, large difference in resistivity, and large difference in contact between the upper and lower probe indenters and the pole piece, and achieve low measurement error. , The effect of solving the large measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

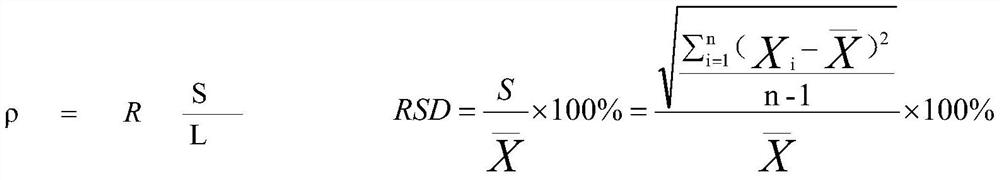

Method used

Image

Examples

Embodiment 1

[0031] 1. The polar piece with the formula of binder PVDF: conductive agent SP: lithium cobaltate at 2:2:96 is facing the glass plate (100mm×50mm) with high-strength double-sided adhesive (10mm×50mm), Use a 10kg roller to roll on the pole piece 50 times. The part of the pole piece that exceeds the double-sided adhesive tape is turned over at 180°C along the edge of the double-sided adhesive tape width direction. The current collector is separated from the coating layer to prepare the coating layer to be tested.

[0032] 2. Use an alligator clip with a bite force of 10kg (clamp width: 5mm) to clamp at 5mm positions at both ends of the length direction of the paint layer to be tested (the upper and lower metal sheets of the crocodile clip are respectively in contact with the paint layer to be tested and the glass plate), and the paint layer to be tested The length of the material is 40mm, and the width is 10mm.

[0033] 3. Connect the alligator clip to the electrochemical workst...

Embodiment 2

[0035] 1. The formula is binder PVDF: conductive agent SP: lithium cobaltate is 2:2:96 pole piece after rolling (the compaction density of the pole piece is 4.0g / cm3), and the high-strength double-sided adhesive ( 10mm×40mm) on a glass plate (100mm×40mm), use a 10kg roller to roll on the pole piece 50 times, and the part of the pole piece beyond the double-sided adhesive is folded at 180°C along the edge of the double-sided adhesive width direction, and the current collector and The coating layer is separated to prepare the coating layer to be tested.

[0036] 2. Use an alligator clip with a bite force of 10kg (clamp width: 5mm) to clamp at 5mm positions at both ends of the length direction of the paint layer to be tested (the upper and lower metal sheets of the crocodile clip are respectively in contact with the paint layer to be tested and the glass plate), and the paint layer to be tested The length of the material is 30mm, and the width is 10mm.

[0037] 3. Connect the al...

Embodiment 3

[0039] 1. The polar piece with the formula of binder PVDF: conductive agent SP: lithium cobaltate at 2:2:96 is facing the glass plate (100mm×30mm) with high-strength double-sided adhesive (10mm×30mm), Use a 10kg roller to roll on the pole piece 50 times. The part of the pole piece that exceeds the double-sided adhesive tape is turned over at 180°C along the edge of the double-sided adhesive tape width direction. The current collector is separated from the coating layer to prepare the coating layer to be tested.

[0040] 2. Use an alligator clip with a bite force of 10kg (clamp width: 5mm) to clamp at 5mm positions at both ends of the length direction of the paint layer to be tested (the upper and lower metal sheets of the crocodile clip are respectively in contact with the paint layer to be tested and the glass plate), and the paint layer to be tested The length of the material is 20mm, and the width is 10mm.

[0041] 3. Connect the alligator clip to the electrochemical workst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com