Air leakage rate measuring method of sintering machine system

A technology of a sintering machine system, measuring method, applied in the direction of mass flow measurement device, furnace type, furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

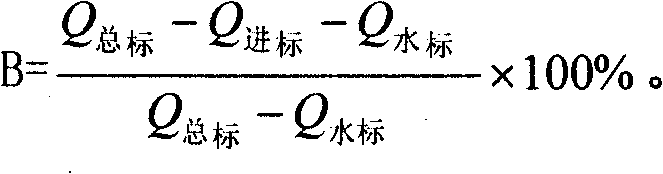

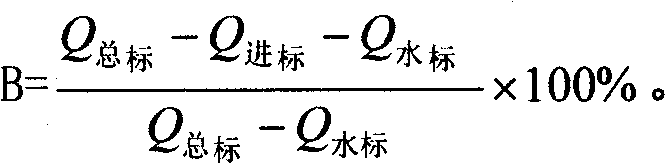

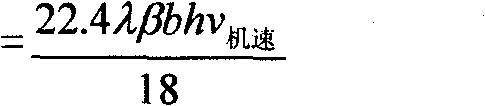

[0072] The wind in the sintering process is drawn into the sintering material layer by the exhaust fan. The sintering process is to use the oxygen in the air to burn with the carbon in the mixture to generate heat to cause physical and chemical reactions inside the sintered material, so that the mixture is sintered into blocks. The total air volume Q in the large flue under working conditions 总 It consists of three parts: one is the effective air intake Q of the sintered material surface under working conditions 进 ; The second is the harmful air leakage Q of the sintering system 漏 ; The third is the additional amount of gas Q added by physical and chemical reactions during the sintering process 额 . The additional amount of gas is the difference between the amount of water vapor in the mixture that changes from liquid to gas and the amount of gas produced by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com