Method for determining brake transient load position of crane (brake slip amount detection)

A determination method and crane technology, applied in the direction of measuring devices, load hanging components, instruments, etc., can solve the problems of large random time delay, large measurement error of instantaneous load position during braking, etc., to improve consistency and realize automatic high precision measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

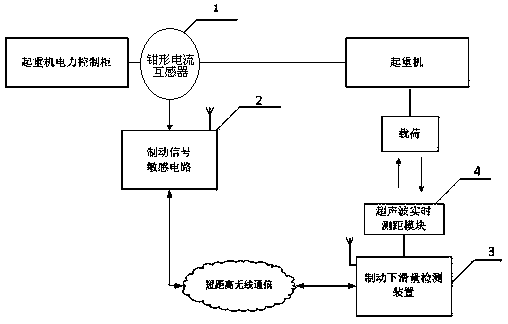

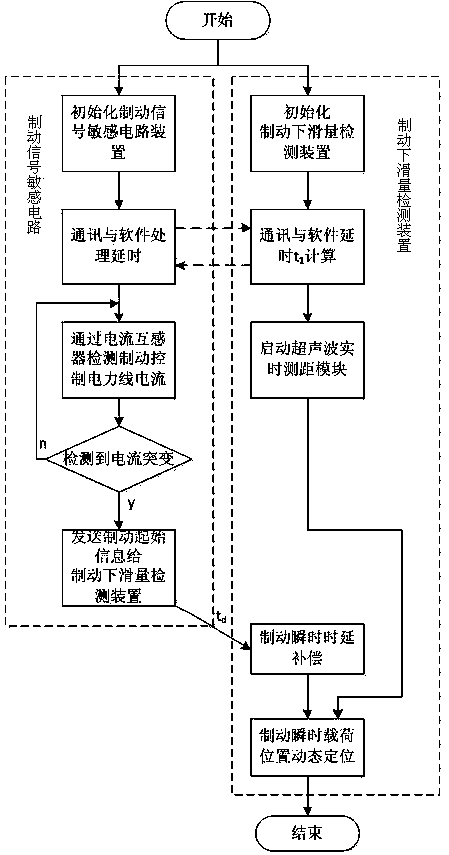

[0022] Examples of the present invention are figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it is a method for determining the instantaneous load position of the crane (brake slip detection). First, the brake signal sensitive circuit 2 monitors the current of the power cable of the crane brake through the current transformer connected to it, and identifies the brake signal. The brake signal is sent to the braking slip detection device 3 through short-distance wireless communication, and the braking slip detection device 3 obtains the instantaneous braking moment of the crane through the precise timing method of the braking instant; The dynamic positioning algorithm of the position accurately measures the braking instantaneous position of the load during the movement.

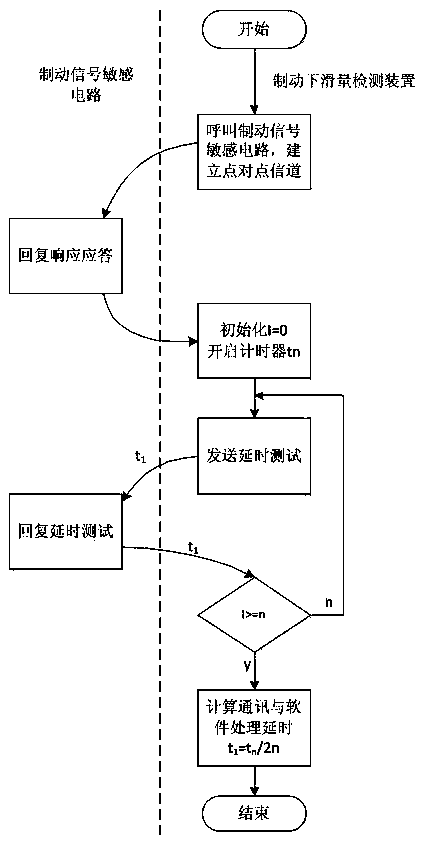

[0023] In the system initialization stage, the brakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com