Method for transporting grouting material vertical delivery pipe used for mine

A material conveying pipe and spraying technology, applied in the field of spraying material transportation, can solve the problems of low safety, low transportation capacity, many transportation accidents, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

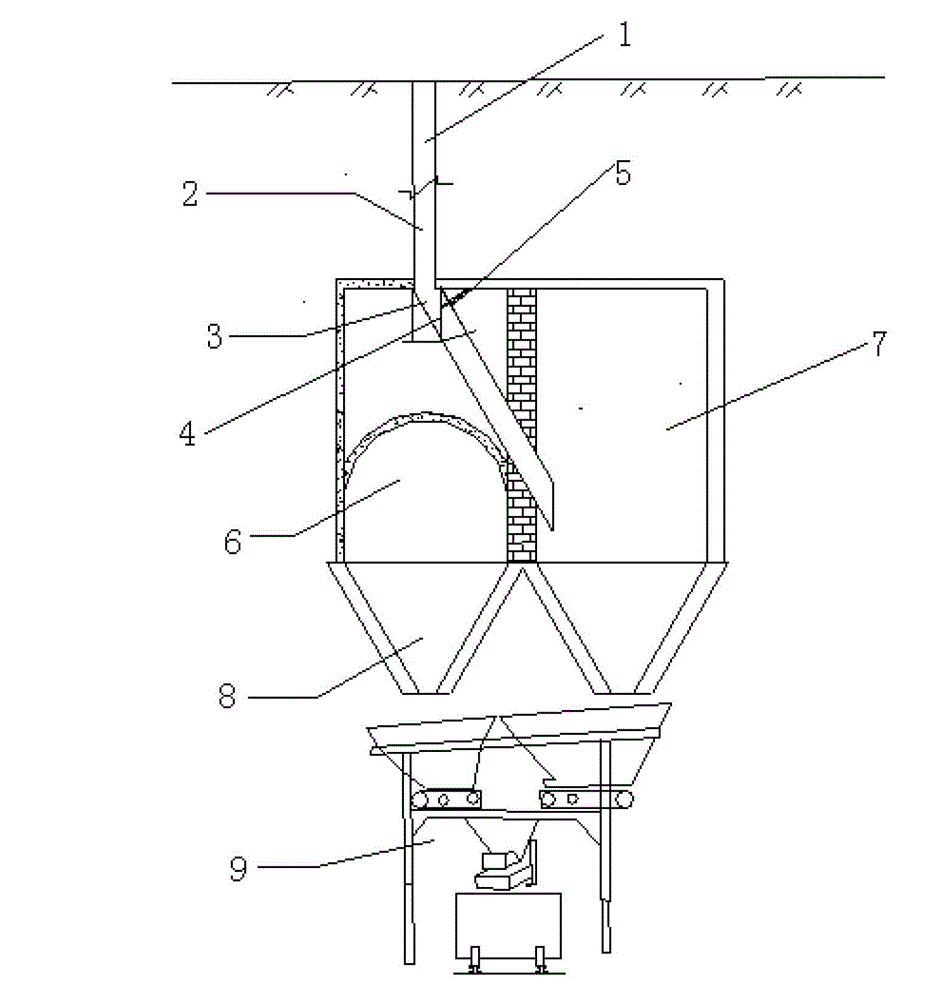

[0019] Such as figure 1 As shown, during implementation, a material delivery borehole 1 with a diameter of 0.5-0.8 meters is first constructed on the ground facing the underground roadway, the wear-resistant bushing 2 is sunk in the material delivery borehole 1, and a buffer is set at the bottom of the material delivery borehole 1 Storehouse 6 and separation storehouse 7, buffer storehouse 6 and the bottom of separate storehouse 7 are provided with mixing station 9; The upper mouth of the two storehouses of buffer storehouse 6 and separate storehouse 7 is provided with separator, and separator is a pants pipe 3, and the underpants Inside the pipe 3, there is a baffle 4 that opens and closes left and right, and the baffle 4 is controlled by a hydraulic cylinder 5 to realize the separation of different materials.

[0020] The above-mentioned feeding drill 1 is a vertical borehole with a diameter of 0.5 meters. The bushing pipe is a 20mm thick cast iron bushing, and the inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com