Multi-stock-column type industrial furnace for chemical vapour infiltration densification

A chemical vapor infiltration and industrial furnace technology, applied in the field of multi-material column industrial furnaces for chemical vapor infiltration densification, can solve the problems of increased input-output ratio, limited production capacity, high energy consumption, etc., and achieve uniform flow field distribution, Uniform gas flow and efficient vapor deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

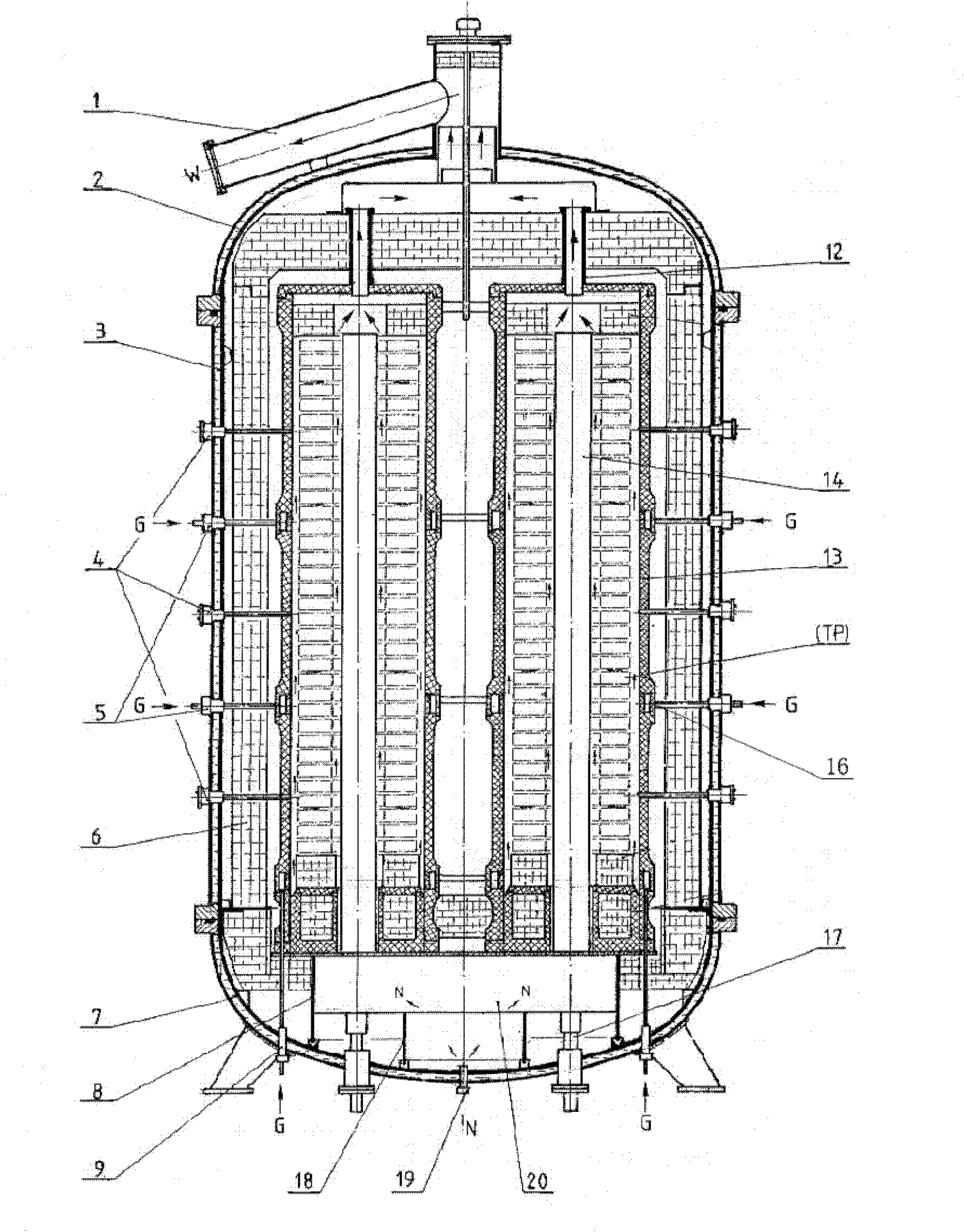

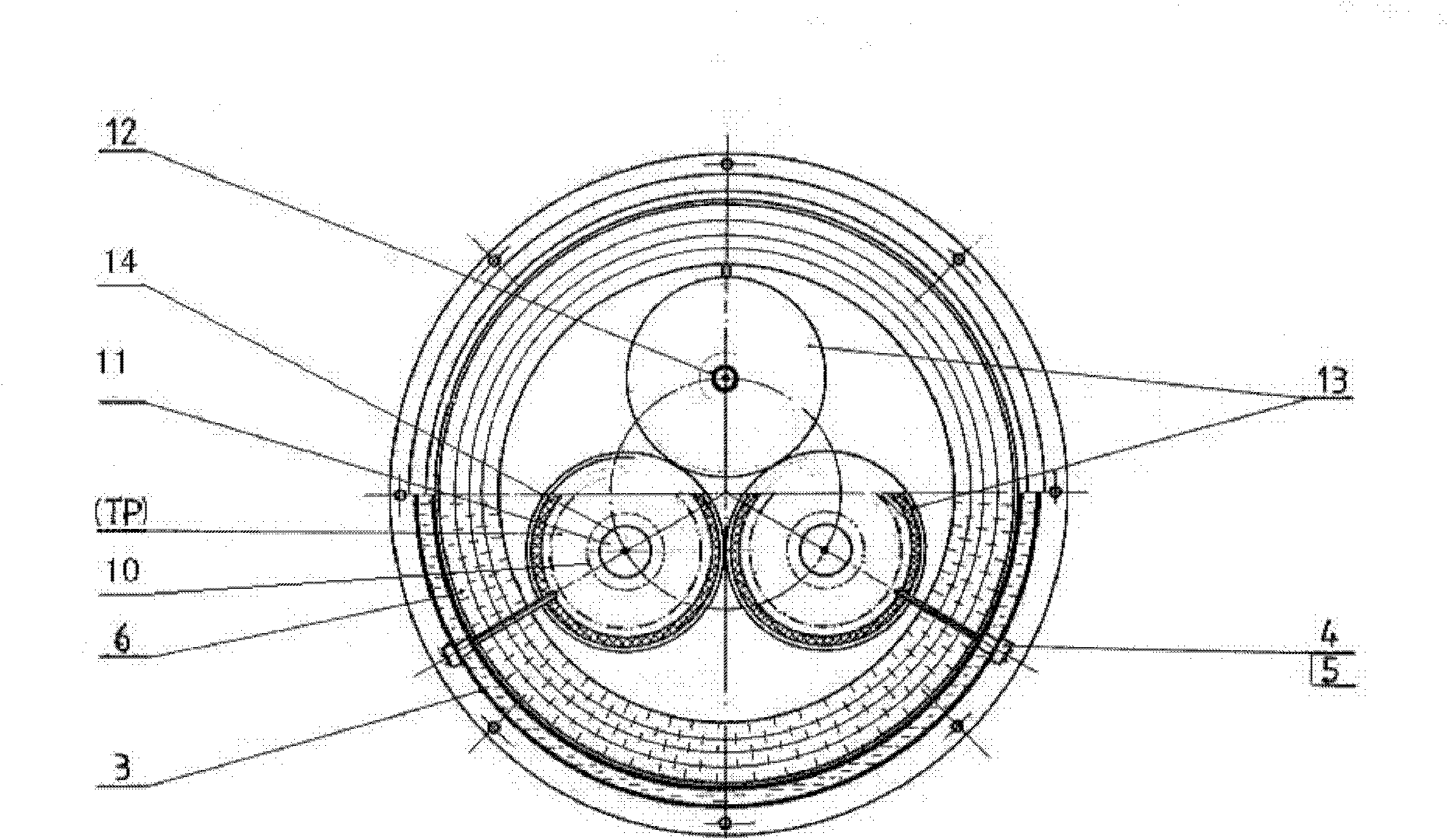

[0126] See attached figure 1 , 2 , 4, 6, a kind of multi-material column industrial furnace for chemical vapor infiltration densification of the present invention comprises a furnace cover, a furnace body and a furnace seat, and the furnace body and the furnace cover adopt a stainless steel water-cooled shell, and the whole furnace shell includes a furnace cover (2), body of furnace (3), furnace seat (7), described furnace lid and body of furnace can be separated also can be connected as a whole, be fixed on body of furnace in described furnace lid (2), body of furnace (3) (3) A heat preservation cover (6) is placed on it, thus forming a bell jar structure and being mounted on the furnace base (7) as a whole (can be lifted at any time); in the furnace base (7), place There is a large support platform (8) of rigid stainless steel quality, and the large support platform (8) is installed on the positioning ring groove of the inner wall of the furnace seat (7); There are three m...

Embodiment 2

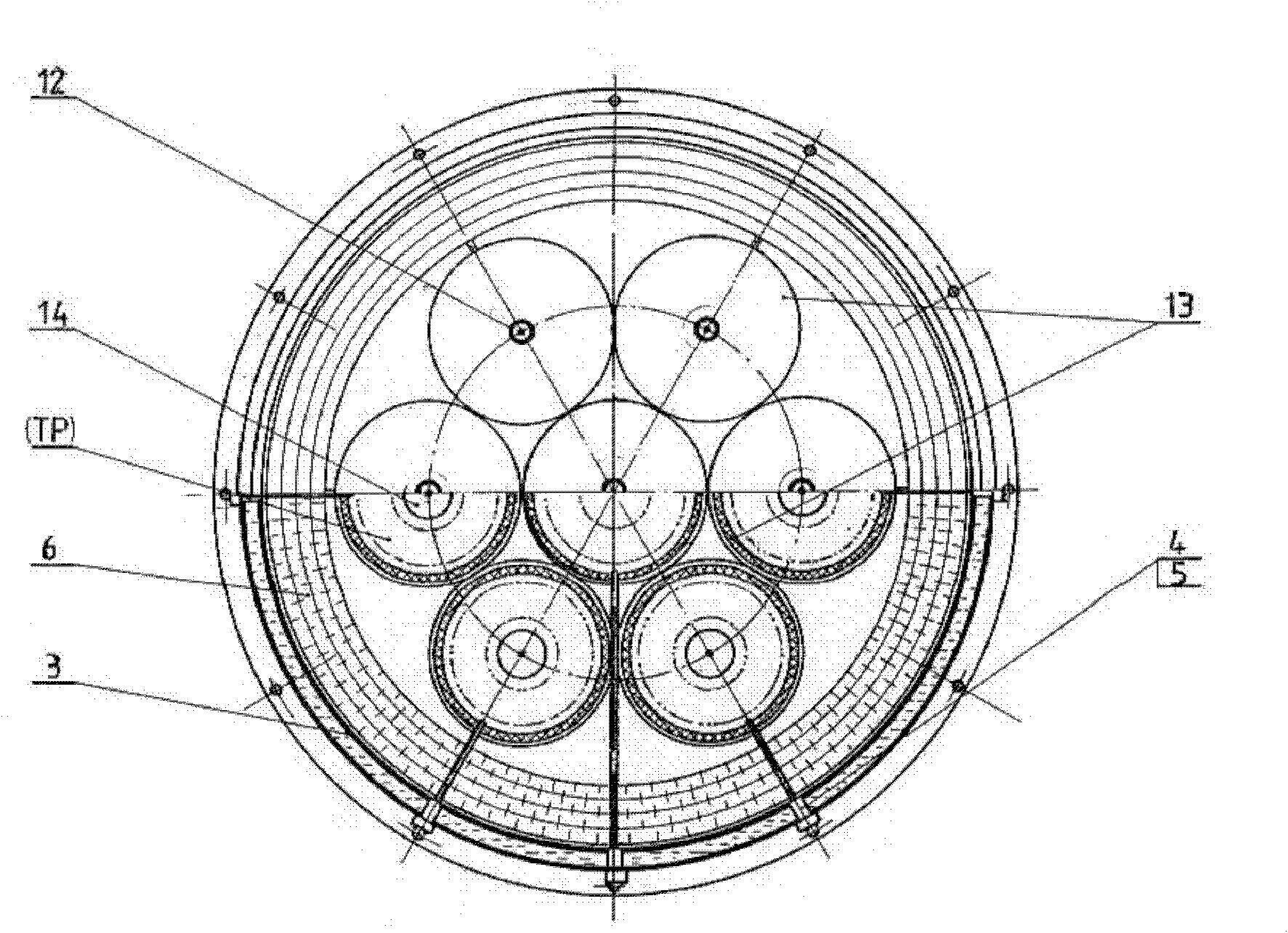

[0128] Embodiment 2 of the present invention is to increase the three vertical heating elements (14) in embodiment 1 to six vertical heating elements (14), and the six vertical heating elements (14) are evenly distributed on the same circumference ; Six independent material column chambers are provided in the heat preservation cover 6, and the six vertical rod heating elements (14) are placed in the material column chamber, and the six vertical rod heating elements (14) are in the On the axis of the material column chamber; in the middle space surrounded by the six independent material column chambers in the heat preservation cover 6, there is also a material column chamber of the same structure, that is, the seventh material column chamber, No vertical rod heating element is set in the seventh material column chamber; the power supply of the six vertical rod heating elements (14) is to first connect two adjacent vertical rod heating elements 14 in parallel and then adopt a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com