Large-aperture directional blasting method and cartridge bag

A directional blasting and large-aperture technology, which is applied in blasting, blasting barrels, weapon accessories, etc., can solve problems such as potential safety hazards, difficulties in processing charge packs, and difficulties in manufacturing special-shaped materials, and achieve the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

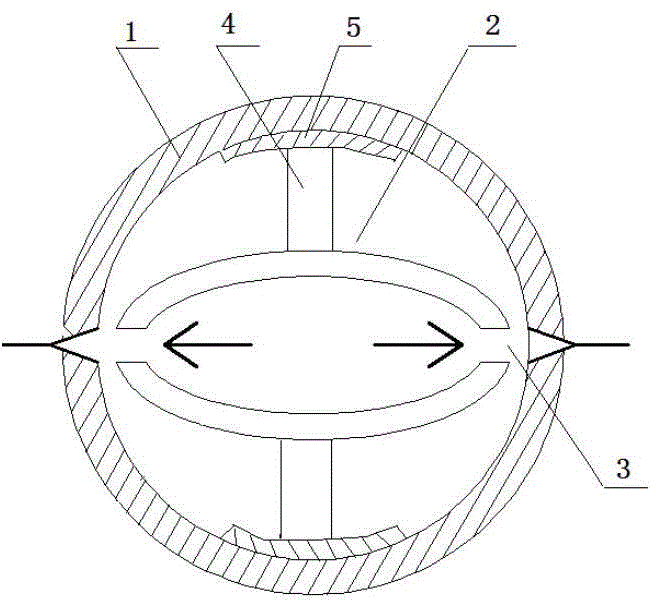

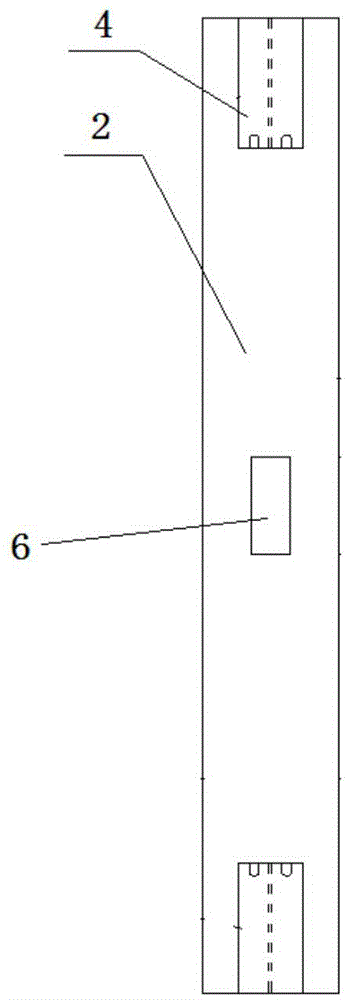

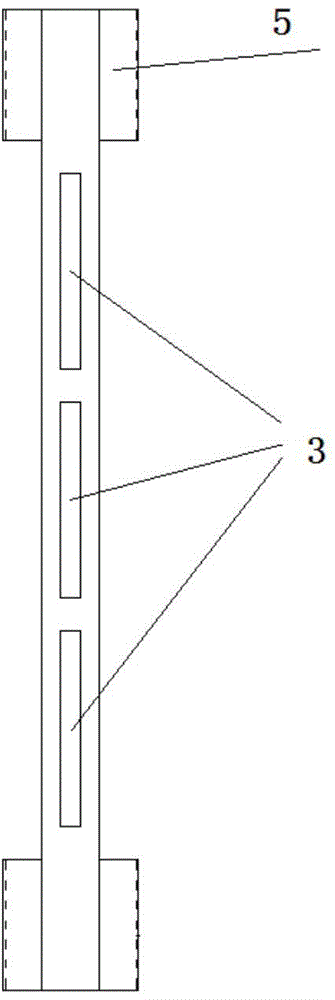

[0025] A large-aperture directional blasting method, using a cylindrical blasthole, with the center of the cross-section of the blasthole as the origin, placing an elliptical cylindrical charge with an elliptical cross-section in the cylindrical blasthole, along the long axis of the elliptical cross-section , multiple slits are opened from top to bottom on both sides of the drug pack, and the cross-section of the drug pack satisfies the equation The eccentricity satisfies e=0.92, the radial uncoupling coefficient of the cross-sectional area of the blast hole and the cross-section of the charge is K=3.9, and the open-air emulsion explosive is built in the charge, and the linear density of the open-air emulsion explosive in the cylindrical blast hole is calculated to be 8~ 10kg / m. The cross-sectional diameter of the blasthole is 25cm. In the cross-sectional ellipse equation of the charge, a is 10cm, b is 4cm, the major axis is 20cm, and the minor axis is 8cm.

[0026] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com