Inorganic nanofiber and method for manufacturing same

a technology of nanofibers and nanofibers, which is applied in the field of inorganic nanofibers, can solve the problems of metal blade damage, difficult to obtain inorganic short fibers having a short fiber length of 200 m or less, and difficult to use fibers as fillers for thinner polymer films, etc., and achieves good mechanical strength and not easily deformed. , the effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0123]Tetraethyl orthosilicate, water, and hydrochloric acid were mixed at a molar ratio of 1:2:0.0025, and the mixture was heated and stirred at a temperature of 80° C. for 15 hours. The reaction mixture was concentrated using an evaporator until the silica concentration became 44 wt %, and was thickened until the viscosity became 200 to 300 mPa·s, to obtain a silica sol solution.

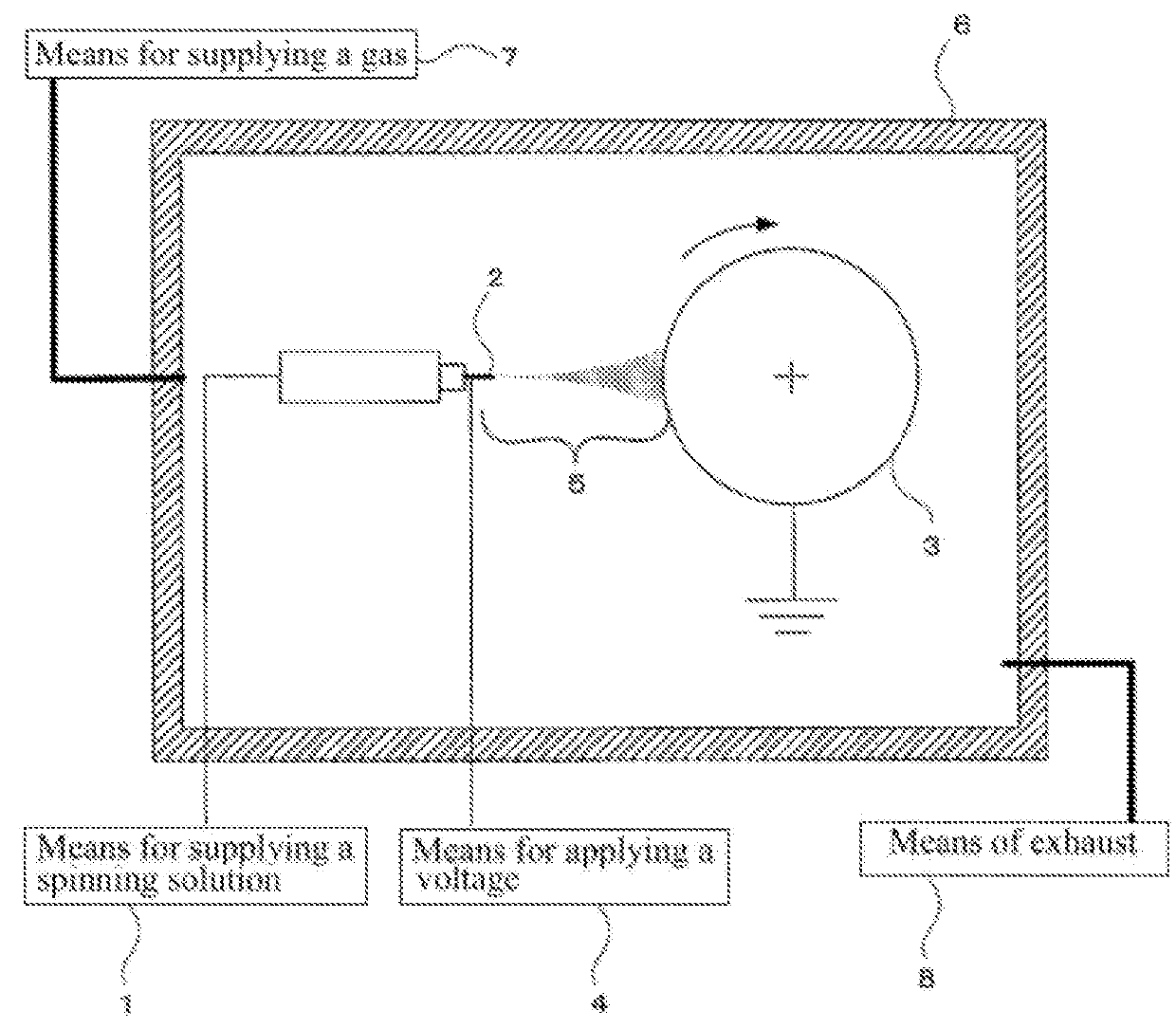

[0124]Next, spinning was carried out using the silica sol solution under the spinning conditions shown in Table 1, and sintering was carried out under the sintering conditions shown in Table 1, to obtain a silica nanofiber sheet having an average fiber diameter of 1 μm (mass per unit area: 26.0 g / m2).

TABLE 1SinteringSpinning conditionsconditions in#1#2#3#4sintering furnaceUnitg / hr.cm° C. / % RHkV° C. / hr.Example 111025 / 30+10800 / 2Example 211025 / 30+10800 / 2Example 311025 / 30+30800 / 2Example 40.2525 / 20+10800 / 2Comp.11025 / 30+10800 / 2Example 1Comp.11025 / 30+10800 / 2Example 2Comp.11025 / 30+10800 / 2Example 3#1: Amount extrud...

example 2

[0126]Approximately 1 g of a silica nanofiber sheet (mass per unit area: 26.0 g / m2), which had been prepared in a similar manner to that of Example 1, was weighed out, and the silica nanofiber sheet was stacked so that the thickness became 1.5 cm. The stacked sheet was pressed and crushed using a press machine at a pressure of 10 MPa for 30 seconds, to prepare inorganic sintered nanofibers having an average fiber diameter of 1 μm, an average fiber length of 10 μm, and a CV value of the fiber length of 0.266 (aspect ratio: 10).

example 3

[0127]Zirconium tetra-n-butoxide [Zr(OnBu)4], ethyl acetoacetate, hydrazinium chloride, and water were mixed at a molar ratio of 1:1.75:0.02:1.5, and the mixture was stirred at room temperature for 3 days. The reaction mixture was concentrated using an evaporator until the zirconia concentration became 30 wt %, and was thickened until the viscosity became 2100 to 2700 mPa·s, to obtain a zirconia sol solution.

[0128]Next, spinning was carried out using the zirconia sol solution under the spinning conditions shown in Table 1, and sintering was carried out under the sintering conditions shown in Table 1, to obtain a zirconia nanofiber sheet having an average fiber diameter of 500 nm (mass per unit area: 17.4 g / m2).

[0129]Next, approximately 1 g of the zirconia nanofiber sheet was weighed out, and the zirconia nanofiber sheet was stacked so that the thickness became 1.5 cm. The stacked sheet was pressed and crushed using a press machine at a pressure of 1 MPa for 1 second, to prepare inor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com