Solid oxide fuel cell based on proton conduction type electrolyte and preparation method

A solid oxide, fuel cell technology, used in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve problems affecting the health of environmental experimenters, achieve small interface impedance, expand application scenarios, and avoid internal carbon deposition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

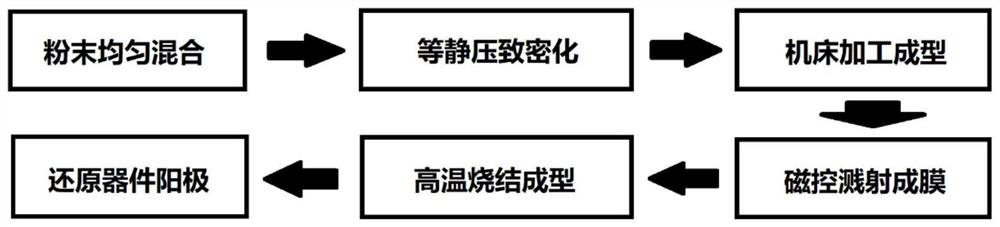

[0038] 1) Preparation of targets: prepare anode targets, electrolyte targets and cathode targets respectively;

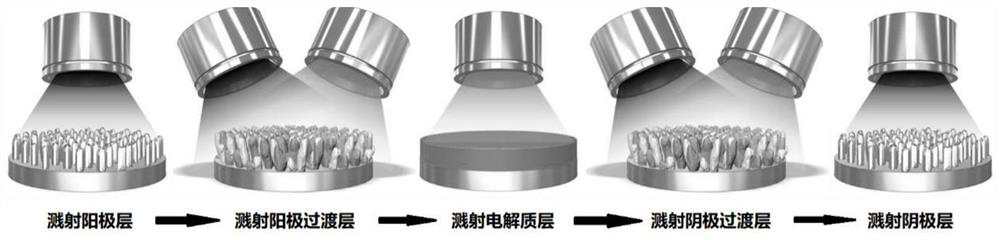

[0039] 2) On the substrate material, the anode layer, the electrolyte layer, and the cathode layer are sequentially sputtered and deposited by a magnetron sputtering process to obtain the precursor of the solid oxide fuel cell device; preferably, the anode layer and the anode layer are sequentially sputtered and deposited a transition layer, an electrolyte layer, a cathode transition layer, and a cathode layer to obtain the precursor of the solid oxide fuel cell device;

[0040] 3) Sintering the device precursor of the solid oxide fuel cell at high temperature and reducing the anode of the device to obtain the solid oxide fuel cell.

[0041] In step 1), the preparation of the target is to prepare the electrolyte target, the anode target and the cathode target containing the pore-forming agent, and the target is prepared by a two-step isostatic pressing method. Part...

Embodiment 1

[0056] Make the specific surface area 1-3m 2 NiO powder per gram and carbon powder with a particle size of 0.5-1 μm accounting for 3% by mass are uniformly mixed in a dry mixer, and then the anode NiO sputtering target is made by a two-step isostatic pressing method. During cold isostatic pressing, the pressure is maintained at 130MPa, the temperature is 100°C, and the time is 4 hours. During hot isostatic pressing, the pressure is maintained at 80MPa, the time is 3 hours, the temperature is maintained at 800°C, and argon is used as a protective gas.

[0057] Make the specific surface area 10-12m 2 / g BaCe 0.6 Zr 0.3 Y 0.1 o 3-δ The powder was fabricated into electrolyte BCZY sputtering targets using a two-step isostatic pressing method. During cold isostatic pressing, the pressure is maintained at 180MPa, the temperature is 150°C, and the time is 5 hours. During hot isostatic pressing, the pressure is maintained at 100MPa, the time is 2.5 hours, the temperature is mainta...

Embodiment 2

[0062] Make the specific surface area 3-5m 2 NiO powder per gram and carbon powder with a particle size of 0.5-1.5 μm accounting for 1% by mass are uniformly mixed in a dry mixer, and then the anode NiO sputtering target is made by a two-step isostatic pressing method. During cold isostatic pressing, the pressure is maintained at 180MPa, the temperature is 150°C, and the time is 3 hours. During hot isostatic pressing, the pressure is maintained at 130MPa, the time is 3.5 hours, the temperature is maintained at 700°C, and argon is used as a protective gas.

[0063] Make the specific surface area 12-15m 2 / g BaCe 0.5 Zr 0.4 Nd 0.1 o 3-δ The powder was fabricated into an electrolyte BCZN sputtering target using a two-step isostatic pressing method. During cold isostatic pressing, the pressure is maintained at 200MPa, the temperature is 160°C, and the time is 4 hours. During hot isostatic pressing, the pressure is maintained at 140MPa, the time is 3 hours, the temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com