Low-temperature grain storage double-layer wall square silo and silo entering and exiting method

A double-layer, silo technology, applied in the field of grain storage, can solve the problems of high building structure requirements, poor practicability, high engineering cost, etc., and achieve the effect of low personnel cost, small storage capacity and large storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

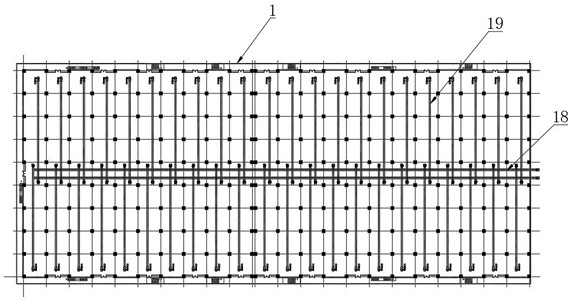

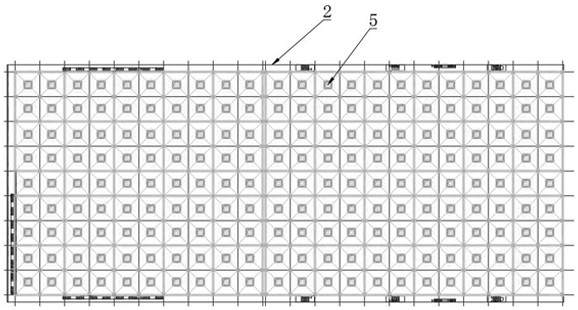

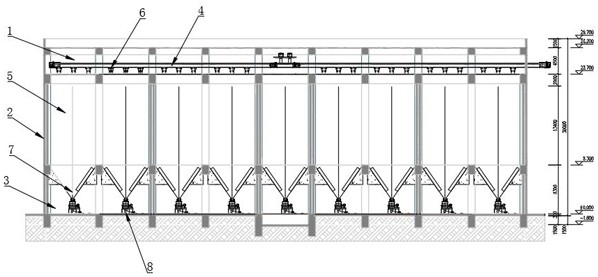

[0037] like Figure 1-5 As shown, a double-walled square silo for low-temperature grain storage includes a storage device layer 1 , a grain storage layer 2 and a storage device layer 3 . Grain conveyors 4 are arranged in the warehousing equipment layer 1, and the grain storage layer 2 includes a plurality of vertically and horizontally arranged grain storage units 5, the bottom is a cone bottom, and the number of 6 inlets at the top is 2 to reduce grain grading; The warehouse outlet 7 is connected to the scraper 8 in the warehouse outlet equipment layer 3 .

[0038] The distribution of the grain conveyors in the warehousing equipment layer 1 of the present application is as follows figure 1 As shown in the figure, it includes a multi-point unloading belt conveyor 1 18 horizontally distributed in the middle of the warehousing equipment layer 1 and a multi-point unloading belt conveyor 2 19 longitudinally connecting each grain storage unit 5. This distribution method can be aut...

Embodiment 2

[0047] Embodiment 2 is based on Embodiment 1, and a refrigeration device (air conditioner) is installed in the grain storage unit 5 , wherein the air outlet of the refrigeration device is communicated with the air outlet one 13 . Therefore, mechanical ventilation or cooling, or a combination of the two can be used as needed to achieve low-temperature grain storage.

[0048] In addition, this embodiment also adopts an intelligent ventilation control system, that is, multiple temperature and humidity sensors are installed in the grain storage unit 5, and the temperature and humidity sensors, the fan drive control circuit and the refrigeration equipment drive control circuit are all connected to the control unit. For example, the grain temperature is set to 14°C, the average moisture content is 13%, and the upper and lower temperature limits are set. Once the feedback data of the temperature and humidity sensor exceeds the upper limit, start the fan or air conditioner for ventilat...

Embodiment 3

[0060] The difference between this example and Example 2 is that the asphalt composite material is made of the following raw materials by weight: 65 parts of asphalt, 10 parts of polyurethane elastomer, 7 parts of rosin resin, 7 parts of phenolic resin, 10 parts of phase change material, 2.5 parts of calcium carbonate whiskers, 2.5 parts of lignin fibers, and 11 parts of volcanic stone powder.

[0061] The phase change material is prepared from porous material loaded with paraffin, and the specific steps are:

[0062] (1) Preparation of porous materials: steel slag powder, clay and fly ash are mixed uniformly in a weight ratio of 4:1:2, 6% starch and 6% calcium carbonate in the total amount of the above raw materials are added and ball milled uniformly, and then water is added to mix and granulate. The particle size is 1-1.5mm, bake at 60-70°C for 2h, then heat up to 800°C at 1.5°C / min, hold for 30min, then heat up to 1200°C and hold for 2.5h to obtain a porous material;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Tensile properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com