Method for forming field isolation

A field isolation and isolation layer technology, which is applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., can solve the problems of high cost, high process cost, and high manufacturing cost, and achieve low temperature, simple process steps, and high production cost. The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, a Si sheet is selected as the substrate.

[0040] First, the substrate 1 is cleaned, and the cleaning process includes first using H 2 SO 4 and H 2 o 2 The mixed solution cleans the substrate, where H 2 SO 4 :H 2 o 2 =10:1, the temperature is set at 120°C, and the time is 10min; then the surface of the substrate 1 is rinsed with deionized water; and then cleaned with hydrofluoric acid solution, wherein HF:H 2 O=1:50, the temperature is set at 25°C, and the time is 1min; finally, rinse with deionized water. After the cleaning is completed, the surface of the substrate 1 is dried.

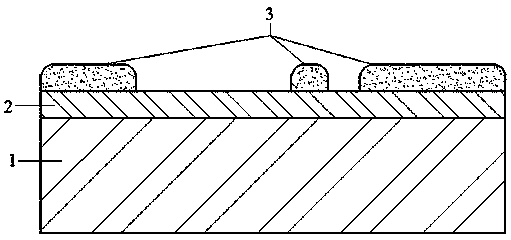

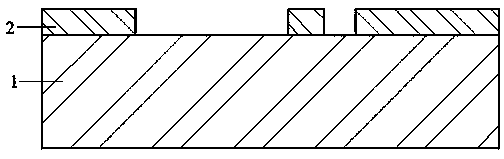

[0041] Reference attached figure 1 As shown, an isolation layer 2 with a thickness of 1 nm is grown on the surface of the substrate 1 after drying by the method of plasma enhanced chemical vapor deposition (Plasma Enhanced Chemical Vapor Deposition); in this embodiment, the isolation layer 2 for SiO 2 Floor.

[0042] Reference attached figure 1 As shown, after ...

Embodiment 2

[0046] In this embodiment, a GaN sheet is selected as the substrate.

[0047] First, the substrate 1 is cleaned, and the cleaning process includes first using H 2 SO 4 and H 2 o 2 The mixed solution cleans the substrate, where H 2 SO 4 :H 2 o 2 =10:1, the temperature is set at 120°C, and the time is 10min; then the surface of the substrate 1 is rinsed with deionized water; and then cleaned with hydrofluoric acid solution, wherein HF:H 2 O=1:50, the temperature is set at 25°C, and the time is 1min; finally, rinse with deionized water. After the cleaning is completed, the surface of the substrate 1 is dried.

[0048] Reference attached figure 1 As shown, an isolation layer 2 with a thickness of 1mm is grown on the surface of the substrate 1 after drying by the method of low pressure chemical vapor deposition; in this embodiment, the isolation layer 2 is SiN x Floor.

[0049] Reference attached figure 1 As shown, after the isolation layer 2 is prepared on the substrat...

Embodiment 3

[0053] In this embodiment, a Si sheet is selected as the substrate.

[0054] First, the substrate 1 is cleaned, and the cleaning process includes first using H 2 SO 4 and H 2 o 2 The mixed solution cleans the substrate, where H 2 SO 4 :H 2 o 2 =10:1, the temperature is set at 120°C, and the time is 10min; then the surface of the substrate 1 is rinsed with deionized water; and then cleaned with hydrofluoric acid solution, wherein HF:H 2 O=1:50, the temperature is set at 25°C, and the time is 1min; finally, rinse with deionized water. After the cleaning is completed, the surface of the substrate 1 is dried.

[0055] Reference attached figure 1 As shown, an isolation layer 2 with a thickness of 1 mm is deposited on the surface of the substrate 1 after drying by a precipitation method; in this embodiment, the isolation layer 2 is Al 2 o 3 Floor.

[0056] Reference attached figure 1 As shown, after the isolation layer 2 is prepared on the substrate 1, the photoresist l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com