Low-temperature oxidation isolation technology for field isolation

A field isolation and low temperature technology, applied in the field of low temperature oxidation isolation technology, can solve the problems of high cost, high cost and complexity of the process, and achieve the effect of easy industrialization development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The Si substrate is selected in this embodiment.

[0043] First, the surface of the substrate 1 is cleaned, and the cleaning process includes first using H 2 SO 4 and H 2 o 2 The mixed solution cleans the substrate, where H 2 SO 4 :H 2 o 2 =10:1, the temperature is set at 120°C, and the time is 10min; then the surface of the substrate 1 is rinsed with deionized water; and then cleaned with hydrofluoric acid solution, wherein HF:H 2 O=1:50, the temperature was set at 25°C, and the time was 1min; finally, rinsed with deionized water and dried.

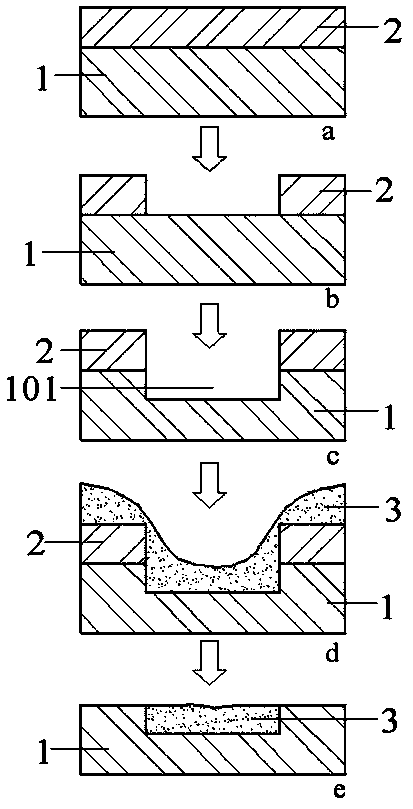

[0044] Reference attached figure 1 In part a, drop an appropriate amount of positive photoresist on the center of one surface of the substrate 1, apply the positive photoresist evenly with a spin coater to form a photoresist layer 2, and pre-baked it after coating evenly, so that Prevent the positive photoresist from sticking to other devices during operation, and remove excess positive photoresist at the edge; the positi...

Embodiment 2

[0051] In this embodiment, a GaN substrate is selected.

[0052] First, the surface of the substrate 1 is cleaned, and the cleaning process includes first using H 2 SO 4 and H 2 o 2 The mixed solution cleans the substrate, where H 2 SO 4 :H 2 o 2 =10:1, the temperature is set at 120°C, and the time is 10min; then the surface of the substrate 1 is rinsed with deionized water; and then cleaned with hydrofluoric acid solution, wherein HF:H 2 O=1:50, the temperature was set at 25°C, and the time was 1min; finally, rinsed with deionized water and dried.

[0053] Reference attached figure 1 In part a, drop an appropriate amount of positive photoresist on the center of one surface of the substrate 1, apply the positive photoresist evenly with a spin coater to form a photoresist layer 2, and pre-baked it after coating evenly, so that Prevent the positive photoresist from sticking to other devices during operation, and remove excess positive photoresist at the edge; the positi...

Embodiment 3

[0060] The Si substrate is selected in this embodiment.

[0061] First, the surface of the substrate 1 is cleaned, and the cleaning process includes first using H 2 SO 4 and H 2 o 2 The mixed solution cleans the substrate, where H 2 SO 4 :H 2 o 2 =10:1, the temperature is set at 120°C, and the time is 10min; then the surface of the substrate 1 is rinsed with deionized water; and then cleaned with hydrofluoric acid solution, wherein HF:H 2 O=1:50, the temperature was set at 25°C, and the time was 1min; finally, rinsed with deionized water and dried.

[0062] Reference attached figure 1 In part a, drop an appropriate amount of negative photoresist on the center of one surface of the substrate 1, apply the negative photoresist evenly to form a photoresist layer 2 with a spin coater, and pre-baked it after coating evenly, so as to Prevent negative photoresist from sticking to other devices during operation and remove excess negative photoresist at the edges. After the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com