Atmosphere controlled joint device, method and electronic device

A technology of a bonding device and a bonding method, which is applied in the direction of assembling printed circuits, circuits, and welding equipment with electrical components, can solve problems such as component damage, and achieve the effects of reducing the bonding pressure, realizing the bonding temperature, and suppressing the deterioration of electrical characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

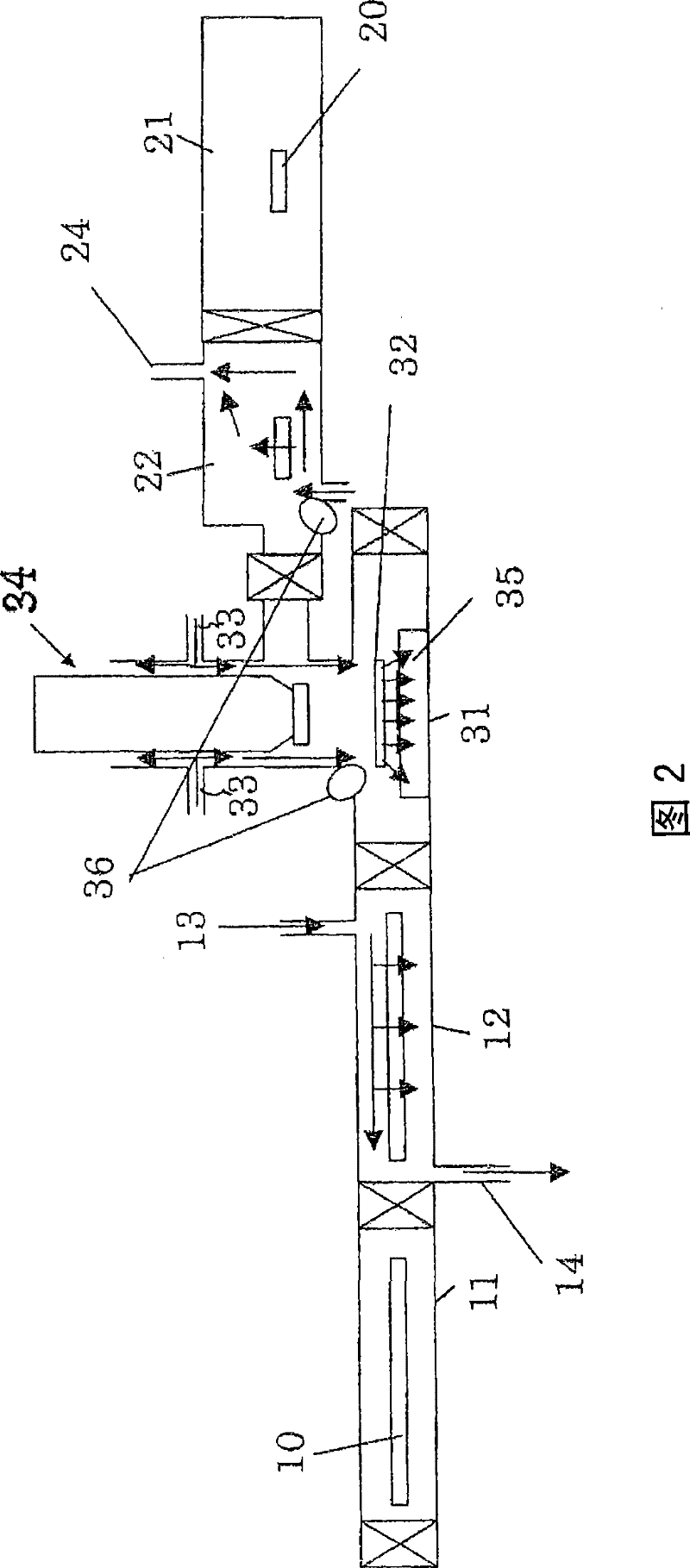

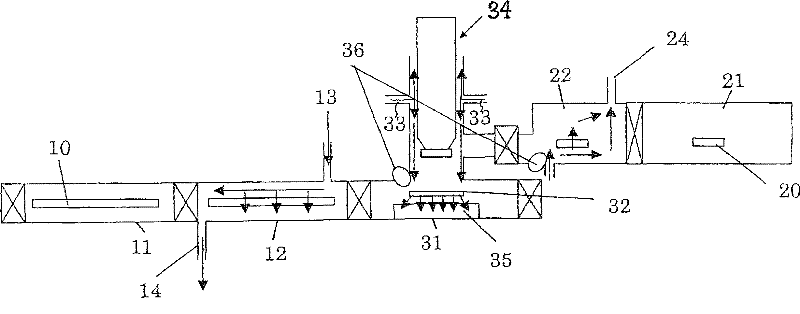

[0022] Regarding the bonding device of the embodiment of the present invention, the use figure 2 Be explained. figure 2 It is a schematic diagram showing the structure of the bonding apparatus of this embodiment. The mounting substrate 10 is introduced from the substrate introduction chamber 11, and the dry inert gas 13 is introduced into the substrate surface adsorption moisture removal chamber 12 to remove moisture.

[0023] On the other hand, the component 20 to be mounted on the mounting substrate 10 is introduced from the component introduction chamber 21 into the component surface adsorption moisture removal chamber 22, and the moisture on the surface is removed by dry inert gas. Both are crimped in a crimping chamber 31 having a crimping arm 34 and a crimping table 35 .

[0024] The bonding apparatus has a substrate conveyance mechanism not shown, a component conveyance mechanism not shown similarly, and a substrate carry-out chamber not shown. In the substrate surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com