Method for modifying a transparent electrode film

A transparent electrode film, modified technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of substrate deformation, insufficient production efficiency, resin deterioration and other problems, achieve high-efficiency resistivity, suppress thermal deterioration or Effects of thermal deformation and reduction of electrical resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A substrate (material: glass, thickness: 0.7 mm) was placed in a sputtering device (manufactured by FTS Corp., product name "FTS facing sputtering device"), and sputtered on the surface of the substrate under the conditions shown below. A transparent electrode film (material: ITO, thickness: 150 nm) was formed on the substrate to obtain a substrate with a transparent electrode film. The surface resistivity of the transparent electrode film on the obtained substrate with the transparent electrode film was 51.7 Ω / ㎡.

[0033] Film forming pressure: 0.5 Pa

[0034] Ar flow: 40 sec / m

[0035] Oxygen flow: 0.5 seconds / m

[0036] Input power: DC 1kW

[0037] Film formation rate: 11 nm / m

[0038] Target: ITO (10% mass SnO 2 ).

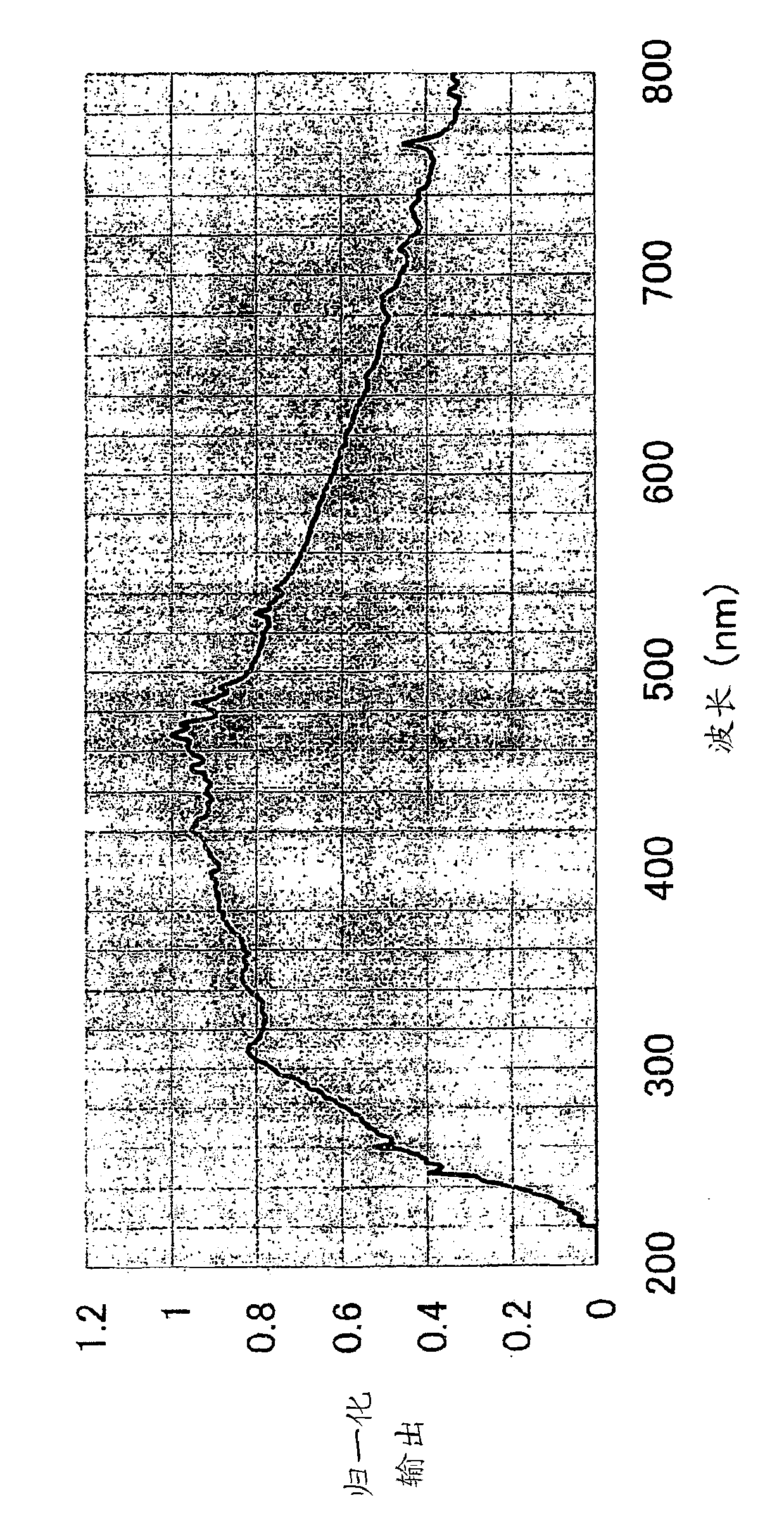

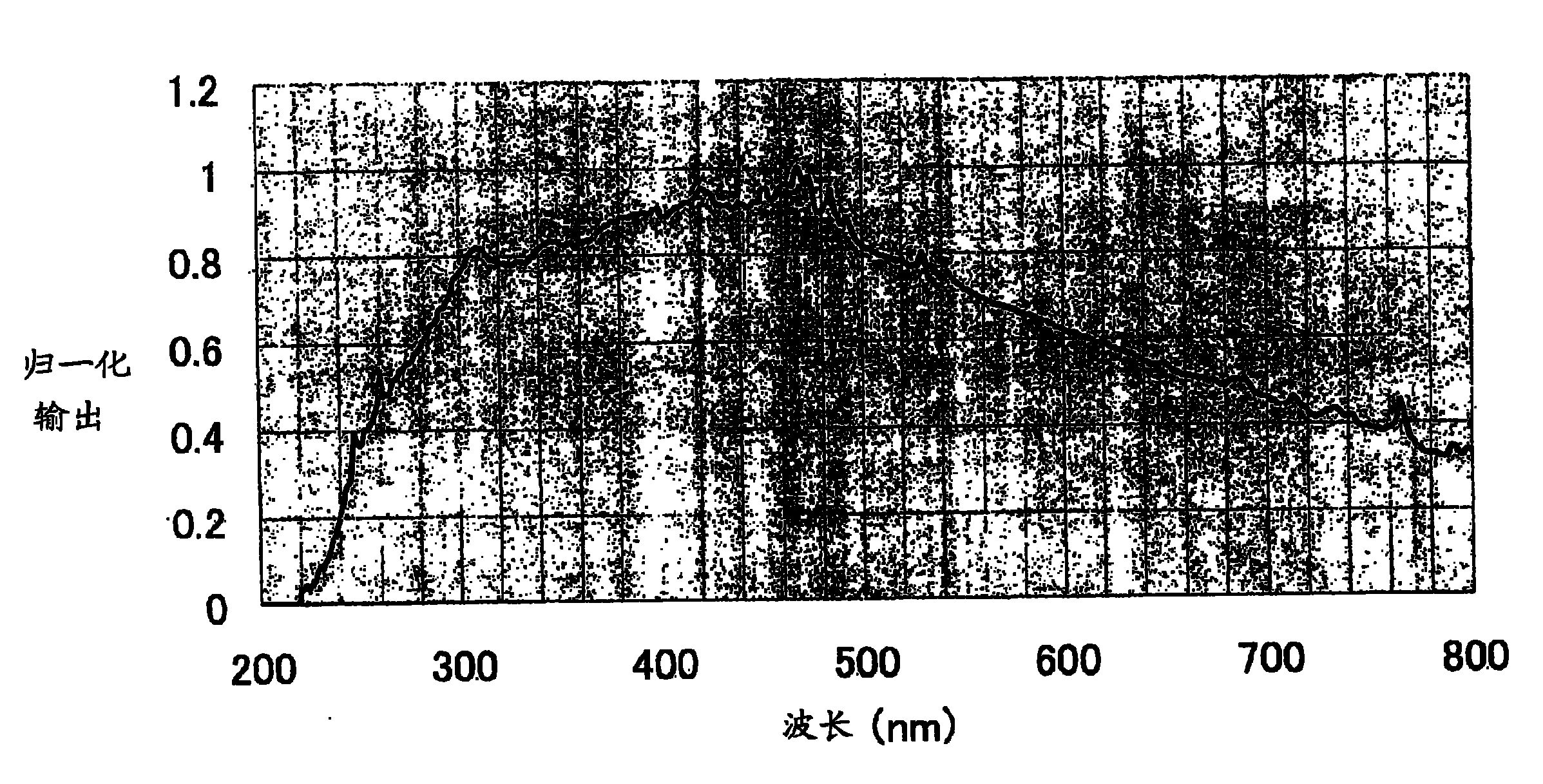

[0039] Next, using a flash annealing device manufactured by Usio Electric Co., Ltd., the surface of the transparent electrode film on the obtained substrate with a transparent electrode film was irradiated with a flash lamp, and the transparent el...

Embodiment 2

[0046] A substrate made of resin (material: polyethylene naphthalate, thickness: 125 μm) was used instead of the substrate (material: glass, thickness: 0.7 mm), and a film with a transparent electrode was obtained in the same manner as in Example 1 except that substrate, and the modified substrate with transparent electrode film. The surface resistivity of the transparent electrode film on the substrate with the transparent electrode film before modification was 53.2 Ω / μ. The surface resistivity of the transparent electrode film on the modified transparent electrode film-attached substrate was 18.4 Ω / Ω, and the substrate made of the resin was not deformed or discolored. Therefore, it was confirmed that according to the modification method of the transparent electrode film of the present invention, the surface resistivity of the transparent electrode film can be sufficiently reduced by annealing for a short time. It was also confirmed that the modification method of the transp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com