Production method for wavelength conversion members

A wavelength conversion and manufacturing method technology, which is applied in chemical instruments and methods, electrical components, semiconductor devices, etc., can solve the problems of poor water resistance of resin, deterioration of inorganic nano-fluorescent particles, and discoloration of resin, so as to suppress heat energy and heat deterioration , Promote the effect of softening flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Using SnO, SnF 2 ,P 2 o 5 As a raw material, contains Sn in terms of cationic % 2+ 56.3%, P 5+ 43.8%, containing F in terms of anion % - 24.8%, O 2- The batch prepared in the 75.2% manner was put into a quartz beaker, and melted at 680° C. for 5 minutes in an electric furnace set as a nitrogen atmosphere. The obtained molten glass was molded into an ingot shape, and it pulverized with a mortar to obtain a glass powder (average particle diameter=25 μm, yield point=150° C.).

[0076] With respect to 1 g of glass powder, 100 μl of a dispersion obtained by dispersing inorganic nano phosphor particles (CdSe / ZnS, average particle diameter = about 3 nm) in hexane as a dispersion medium at a concentration of 1% by mass was added and mixed, Thereafter, vacuum drying was performed at 30° C. for 20 minutes, thereby obtaining a mixture of glass powder and inorganic nano phosphor particles.

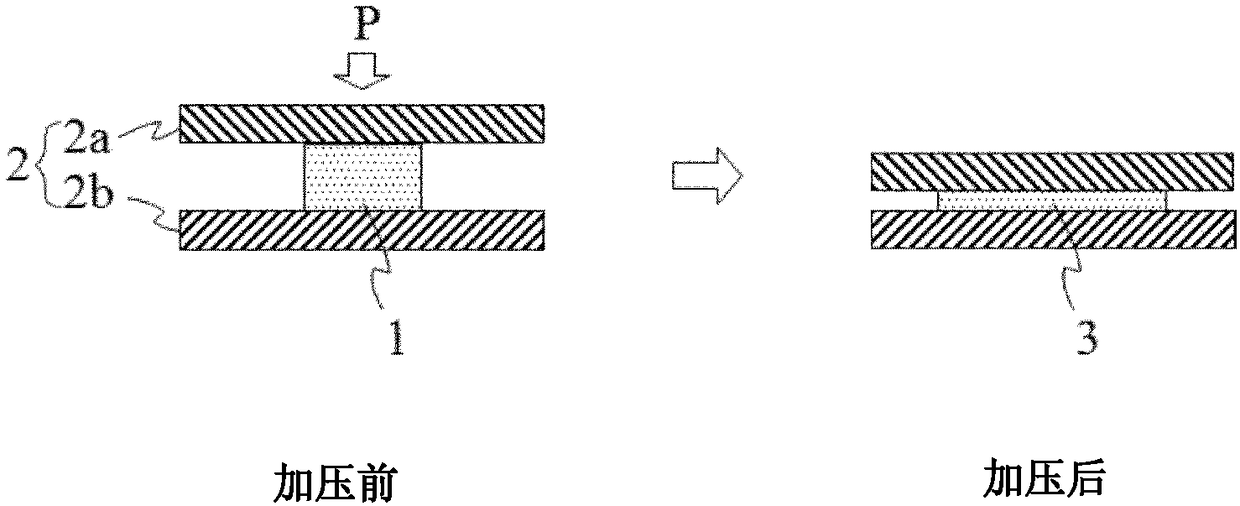

[0077] The obtained mixture was placed on the lower die of a tungsten carbide press ...

Embodiment 2

[0080] A wavelength conversion member was fabricated in the same manner as in Example 1 except that the preheating and hot pressing temperatures were set at 180°C. The light emission quantum efficiency of the obtained wavelength conversion member was measured to be 38%.

Embodiment 3

[0082] A wavelength conversion member was produced in the same manner as in Example 1 except that the preheating and hot pressing temperatures were set to 200°C. The light emission quantum efficiency of the obtained wavelength conversion member was measured to be 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com