Preparation method and application of graphene/carbon nanotube composite porous membrane

A carbon nanotube composite, carbon nanotube technology, applied in the directions of graphene, nanocarbon, carbon compounds, etc., can solve the problem of high requirements for preparation process, and achieve the effects of reducing reflection loss, simple preparation, and lowering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Disperse 15 mg of cross-linked polystyrene (PS) microspheres (particle size 1-10 μm), 0.15 g of graphene oxide, and 0.15 g of carboxylated carbon nanotubes in 100 mL of deionized water by ultrasonic and magnetic stirring to obtain a suspension ; 50mL suspension was suction filtered to obtain a filter membrane; the filter membrane was placed in an oven and dried at 90°C for 6 hours to obtain a graphene oxide / carbon nanotube / PS microsphere composite membrane; the graphene oxide / carbon nanotube / PS microsphere composite film is sandwiched between graphite plates, placed in an atmosphere furnace for carbonization treatment under an inert atmosphere, the temperature is 700°C, the heating rate is 3°C / min, and the treatment time is 1h, the required graphite can be obtained ene / carbon nanotube composite porous membrane.

[0030] The raw materials used in the present invention are all commercially available products.

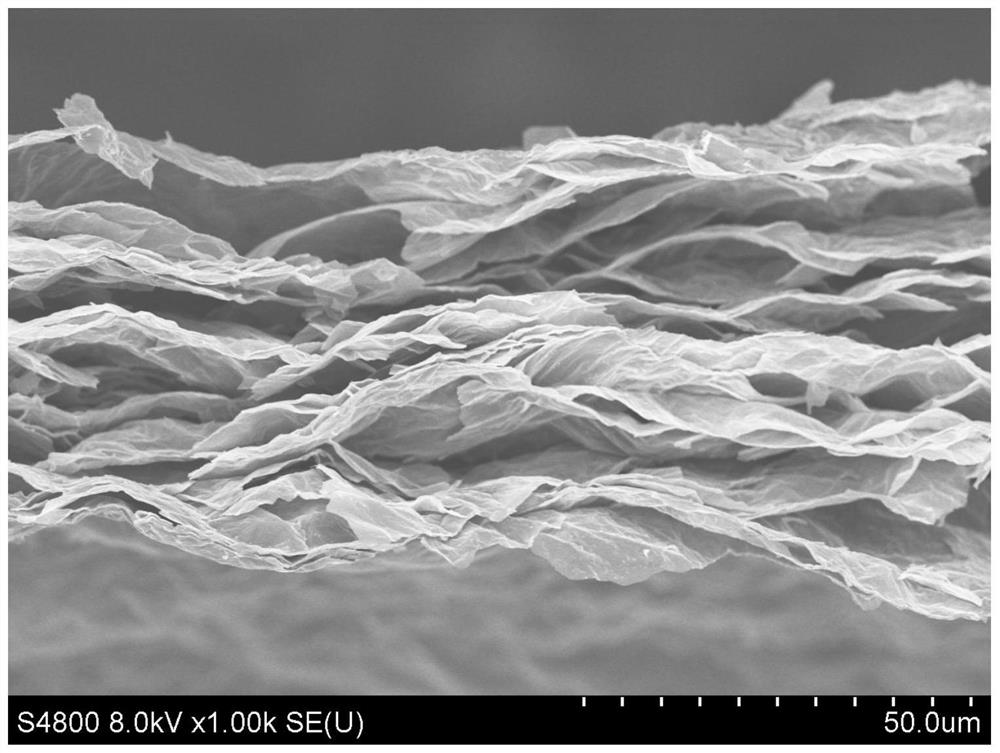

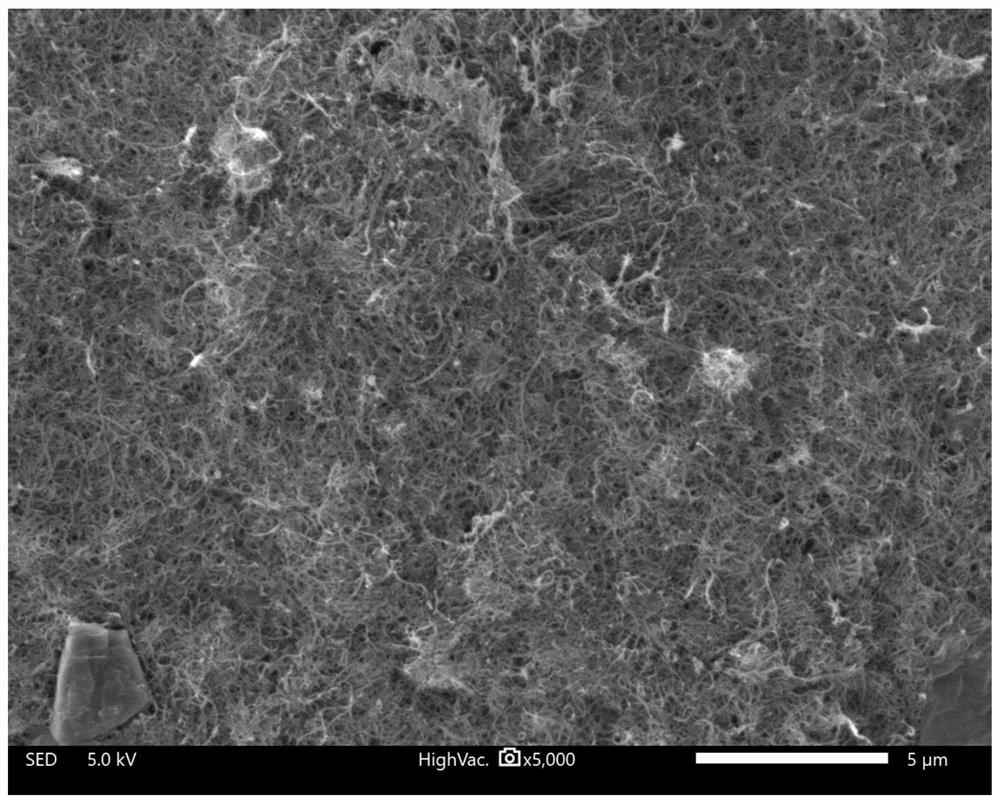

[0031] Such as figure 1 and 2 As shown, the prepared grap...

Embodiment 2

[0033] Disperse 0.3g graphene oxide and 0.05g carboxylated carbon nanotubes in 100mL deionized water by ultrasonic and magnetic stirring to obtain a suspension; filter 50mL of the suspension to obtain a filter membrane; place the filter membrane in an oven Dry at 85°C for 5 hours to obtain a graphene oxide / carbon nanotube composite film; the graphene oxide / carbon nanotube-composite film is sandwiched between graphite plates, placed in an atmosphere furnace for carbonization treatment under an inert atmosphere, the temperature 400°C, the heating rate is 2°C / min, and the treatment time is 0.5h, the desired graphene / carbon nanotube composite porous membrane can be obtained.

[0034] The prepared graphene / carbon nanotube composite porous membrane has a thickness of about 50 μm and a density of 0.16 g / cm 3 . The electromagnetic shielding performance in the X-band is tested by the waveguide method on a vector network analyzer, and the obtained electromagnetic shielding effectivenes...

Embodiment 3

[0036] Disperse 50 mg of cross-linked polystyrene (PS) microspheres (with a particle size of 1-10 μm), 0.3 g of graphene oxide, and 0.15 g of carboxylated carbon nanotubes in 100 mL of deionized water by ultrasonic and magnetic stirring to obtain a suspension ; 50mL suspension was suction filtered to obtain a filter membrane; the filter membrane was placed in an oven and dried at 95°C for 7 hours to obtain a graphene oxide / carbon nanotube / PS microsphere composite membrane; the graphene oxide / carbon nanotube / PS microsphere composite film is sandwiched between graphite plates, placed in an atmosphere furnace for carbonization treatment under an inert atmosphere, the temperature is 1000°C, the heating rate is 4°C / min, and the treatment time is 1.5h, the desired Graphene / carbon nanotube composite porous membrane.

[0037] The prepared graphene / carbon nanotube composite porous membrane has a thickness of about 70 μm and a density of 0.07 g / cm 3 . The electromagnetic shielding pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com