Brown coal drying and dehydrating device

A dehydration equipment, lignite technology, applied in dryer combination, drying solid materials, lighting and heating equipment, etc., can solve the problems of increased operating costs, high costs, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

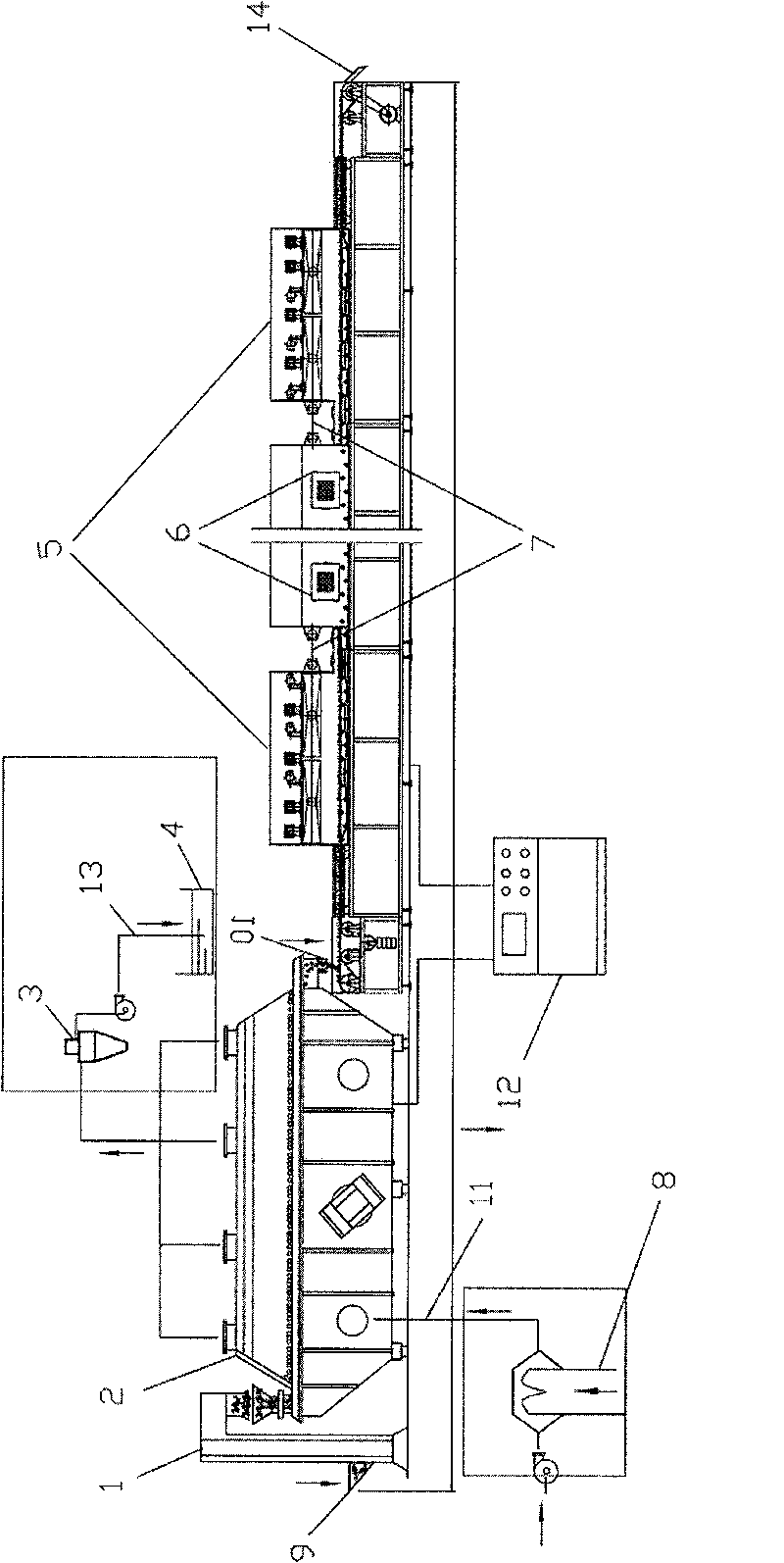

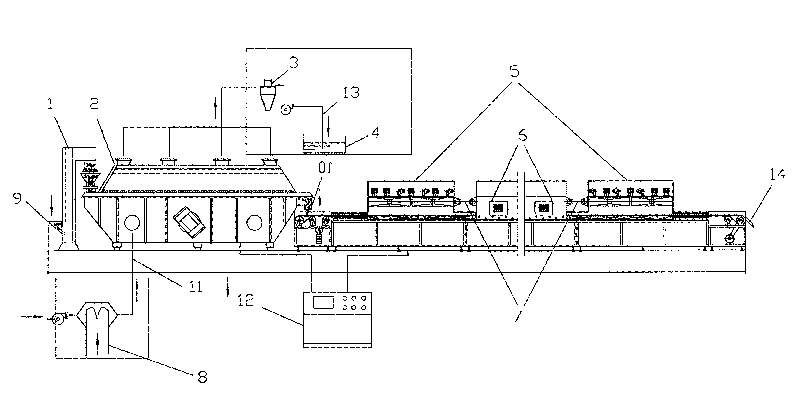

Method used

Image

Examples

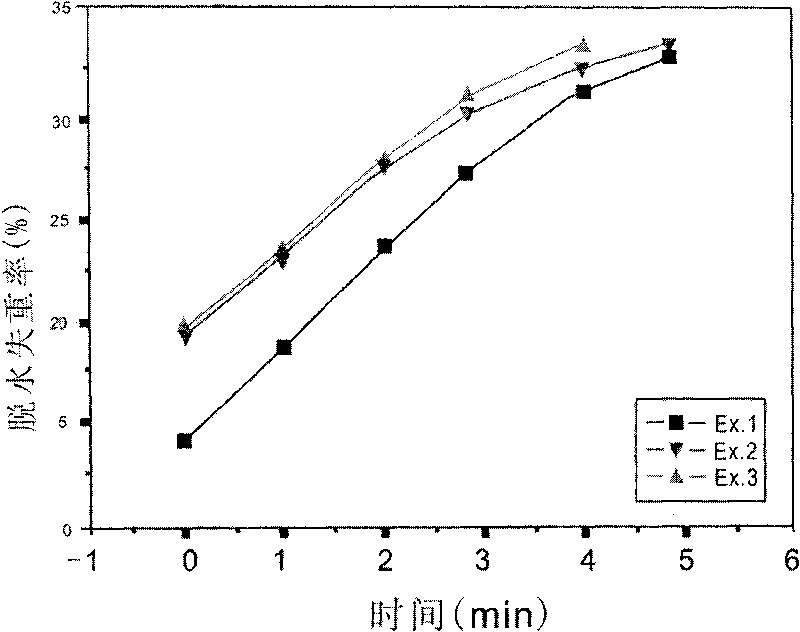

Embodiment 1

[0025] Weigh 500g of raw coal that has been crushed, firstly pass through the pretreatment of rotary blast drying equipment at 115°C, and then use microwave treatment, the microwave frequency is 2450MHz, the output power is 700K, after 5min, the weight loss rate of coal is 32.25%, and the moisture content About 0.8%. After testing, the calorific value of this coal has increased from 3750 kcal of raw coal to 6000 kcal.

Embodiment 2

[0027] Weigh 500g of crushed raw coal, adopt the steps of Example 1, and after vibrating fluidized bed treatment at 125°C, use microwave treatment, microwave frequency is 915MHz, output power is 700K, after 5min, the coal weight loss rate is 32.85 %, the moisture content is about 0.35%. After testing, the calorific value of this coal has increased from 3750 kcal of raw coal to 6080 kcal.

Embodiment 3

[0029] Weigh 600g of crushed raw coal, adopt the steps of Example 1, heat-treat with rotary blast at 140°C, and then use microwave treatment with a microwave frequency of 915MHz and an output power of 750K. After 4min, the coal weight loss rate is 32.5%. , the moisture content is about 0.7%. After testing, the calorific value of this coal has increased from 3750 kcal of raw coal to 6045 kcal.

[0030] 3 example result data charts are attached figure 2 . In the accompanying drawings, the ordinate corresponding to the 0 point of the abscissa is the percentage of dehydration of lignite after pretreatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com