Medical waste disposal device

A technology of medical waste and treatment equipment, applied in the field of medical waste treatment equipment, can solve the problems of poor environmental friendliness, high cost, environmental pollution, etc., and achieve the effect of thorough disinfection and high degree of killing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

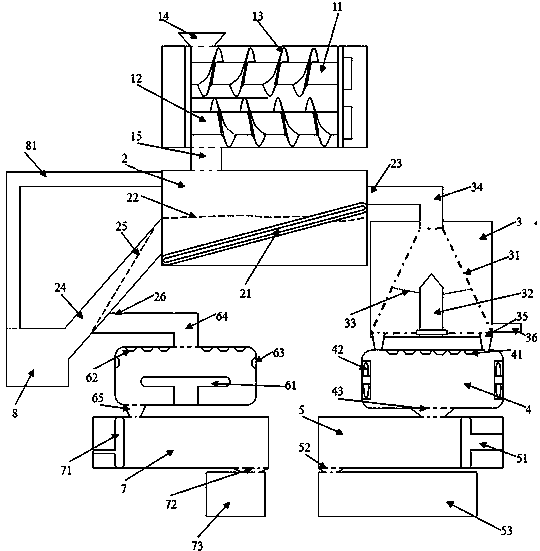

[0036] Such as figure 1 Shown: a medical waste treatment device, including a crushing chamber, a soaking chamber, a dehydration chamber, a first drying chamber, a first compression chamber, a first storage tank, a second drying chamber, a second compression chamber, a second Storage tank and sterile water collection chamber.

[0037] The crushing chamber includes a crushing chamber casing, a first crushing shaft, a second crushing shaft, a waste inlet and a crushing chamber outlet; the crushing chamber casing has a rectangular parallelepiped structure as a whole. The first crushing shaft and the second crushing shaft are arranged laterally in the shell of the crushing chamber in sequence, and single-helical crushing teeth are respectively arranged in reverse on the first crushing shaft and the second crushing shaft. The right end of the shaft is provided with a motor, which is used to drive the rotation of the two crushing shafts. A waste inlet is provided on the crushing cha...

Embodiment 2

[0055] A medical waste treatment device, comprising a crushing chamber, a soaking chamber, a dehydration chamber, a first drying chamber, a first compression chamber, a first storage tank, a second drying chamber, a second compression chamber, a second storage tank and Disinfectant water collection chamber.

[0056] The crushing chamber includes a crushing chamber housing, a first crushing shaft, a second crushing shaft, a waste inlet and a crushing chamber outlet; the first crushing shaft and the second crushing shaft are arranged laterally in the crushing chamber housing in sequence, On the first crushing shaft and the second crushing shaft, single-helical crushing teeth are respectively provided in reverse directions, and a motor is provided at the right end of the two crushing shafts to drive the rotation of the two crushing shafts, starting from the first crushing shaft The crushing chamber casing at the top of the starting end is provided with a waste inlet, and the crus...

Embodiment 3

[0074] A medical waste treatment device, comprising a crushing chamber, a soaking chamber, a dehydration chamber, a first drying chamber, a first compression chamber, a first storage tank, a second drying chamber, a second compression chamber, a second storage tank and Disinfectant water collection chamber.

[0075] The crushing chamber includes a crushing chamber housing, a first crushing shaft, a second crushing shaft, a waste inlet and a crushing chamber outlet; the first crushing shaft and the second crushing shaft are arranged laterally in the crushing chamber housing in sequence, On the first crushing shaft and the second crushing shaft, single-helical crushing teeth are respectively provided in reverse directions, and a motor is provided at the right end of the two crushing shafts to drive the rotation of the two crushing shafts, starting from the first crushing shaft The crushing chamber casing at the top of the starting end is provided with a waste inlet, and the crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com