Closed cycle two-stage drying method and drying device of 1,3-cyclohexanedione

A technology of cyclohexanedione and closed-circuit circulation, which is applied in the direction of drying gas arrangement, drying machine combination, drying solid materials, etc., can solve the problems of increasing the work intensity of workers, regular cleaning of equipment, and high temperature control requirements, so as to improve production Operating environment, reducing the possibility of dust explosion, and reducing the effect of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

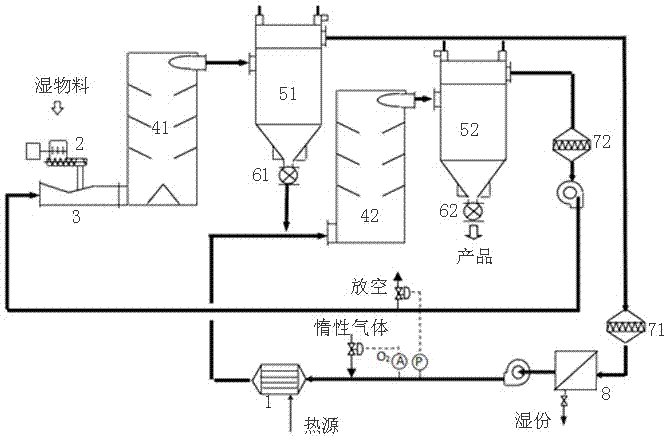

Image

Examples

Embodiment 1

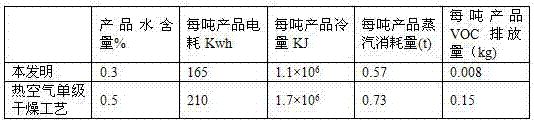

[0031] The present invention uses nitrogen as the drying carrier gas, and the water content of the 1,3-cyclohexanedione wet material is 12.3%. The baffle plate of the hole; the gas-solid separation adopts the back-blowing bag filter, the carrier gas heating and condensation water removal adopt the partition wall heat exchanger, the inert gas heater uses 0.5MPa steam as the heating source, and the cold source is cold brine temperature ≤ -10°C; the air temperature of the secondary drying is 73°C, the air temperature of the primary drying is 57°C, the water content of the product is 0.27%, and the product yield is 99.7%; the power consumption per ton of product is 149kWh, the consumption of steam is 0.49 tons, and the cooling capacity Consumes 9.06×10 5 kJ; The product is light yellow to white powdery particles without lumps and impurities.

Embodiment 2

[0033] In the present invention, argon is used as the drying carrier gas, and the water content of the 1,3-cyclohexanedione wet material is 11.3%. The first-stage dryer in the two-stage dryer adopts a flash dryer, and the second-stage dryer adopts a cyclone dryer. ;The gas-solid separation adopts the cyclone separator, the inert gas heater uses 0.5MPa steam as the heating source, and the carrier gas heating and condensation dewatering adopt the partition wall heat exchanger; the dehumidification adopts the membrane separation dehumidification device; the secondary drying air inlet temperature is at 70°C, primary drying air inlet temperature 59°C, water content 0.30%, product yield 99.5%; per ton of product consumes 160kWh of electricity, consumes 0.57 tons of steam, and consumes 9.46×10 cooling capacity 5 kJ; The product is light yellow to white powdery particles without lumps and impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com