Preserved fruit making and drying device for food processing

A food processing and drying equipment technology, applied in food processing, application, food science, etc., can solve the problems of insufficient uniformity and comprehensive drying, low work efficiency, high production cost, etc., and achieve soft texture, low manufacturing cost, uniform and comprehensive drying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

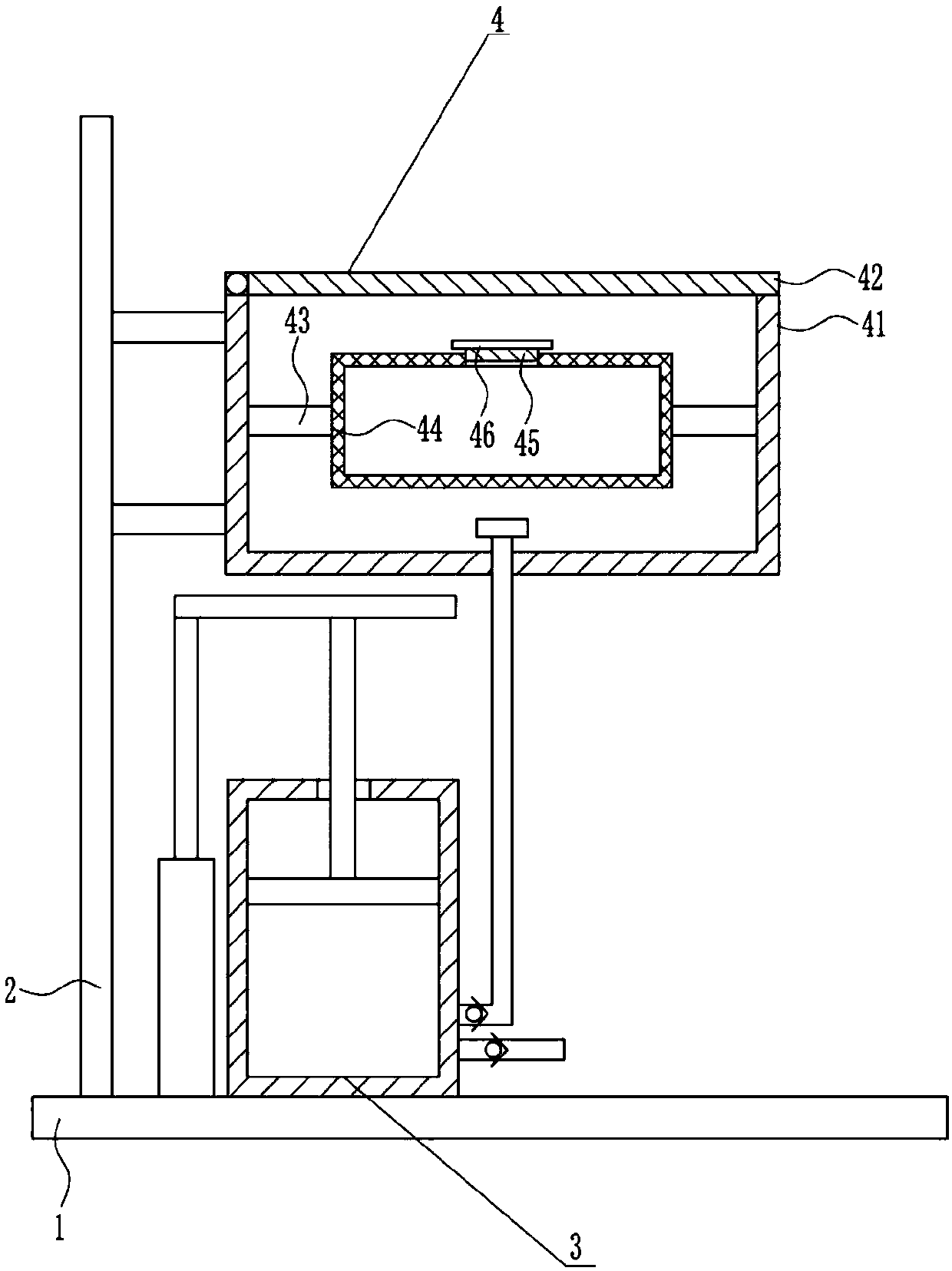

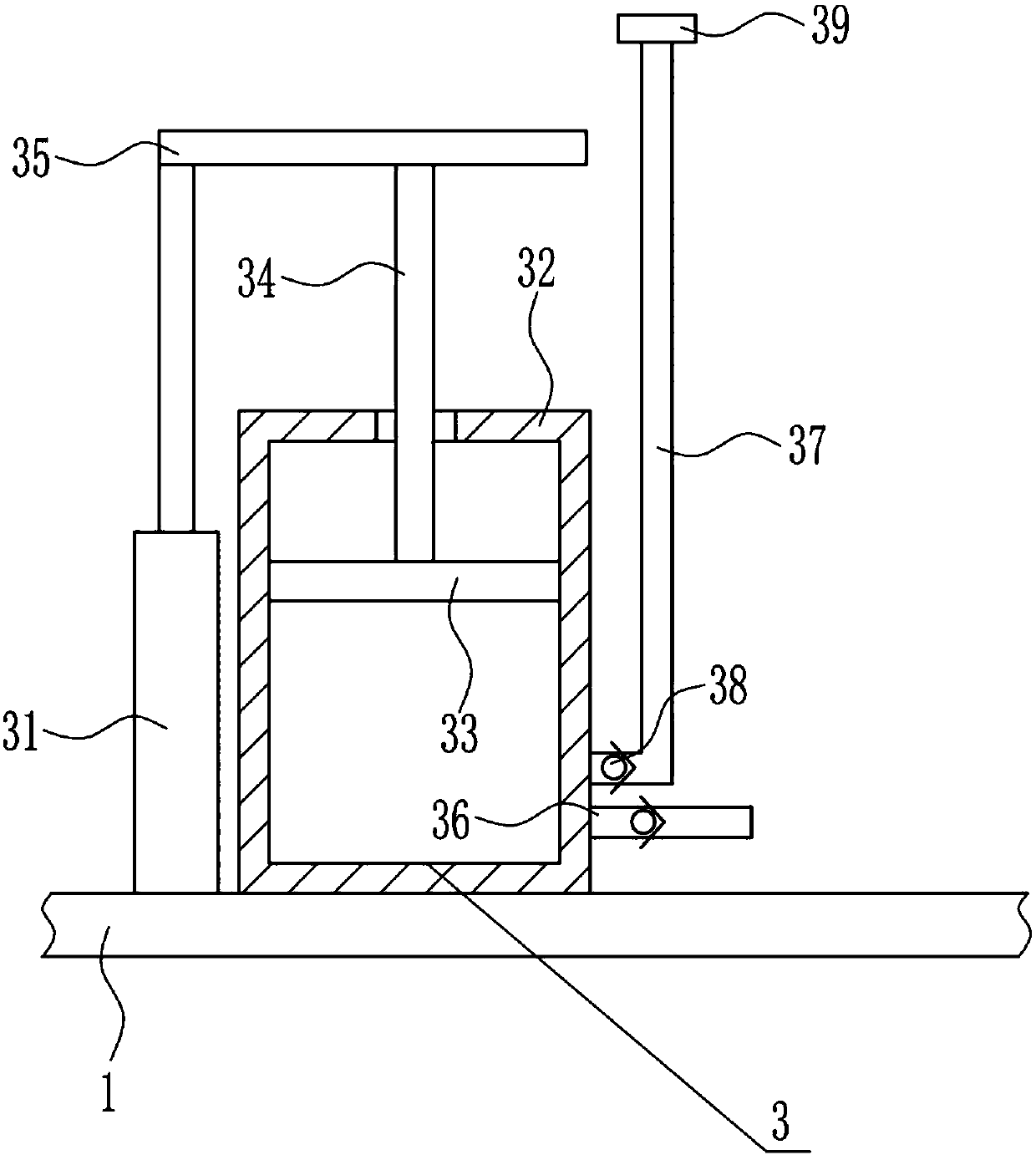

[0037] see figure 1 , a drying equipment for making preserved fruit for food processing, comprising a bottom plate 1, a support 2, an air spray device 3 and a loading device 4 for placing fruits to be processed; the support 2 is vertically arranged at one end of the bottom plate 1, and the loading The device 4 is arranged on the upper part of the bracket 2, the air injection device 3 is arranged on the base plate 1, the air injection device 3 is arranged below the loading device 4, and the air injection parts of the air injection device 3 can extend into the loading device 4.

[0038] The loading device 4 comprises a box body 41 with a box cover 42 on the top, a cross bar 43 is respectively arranged on the inner walls of both sides of the box body 41, and a net loading tube 44 is arranged between the two cross bars 43, and a mesh tube 44 There is a feeding port on the top, and a plug 45 cooperating with it is provided in the feeding port, and a horizontal plate 46 is connected...

Embodiment 2

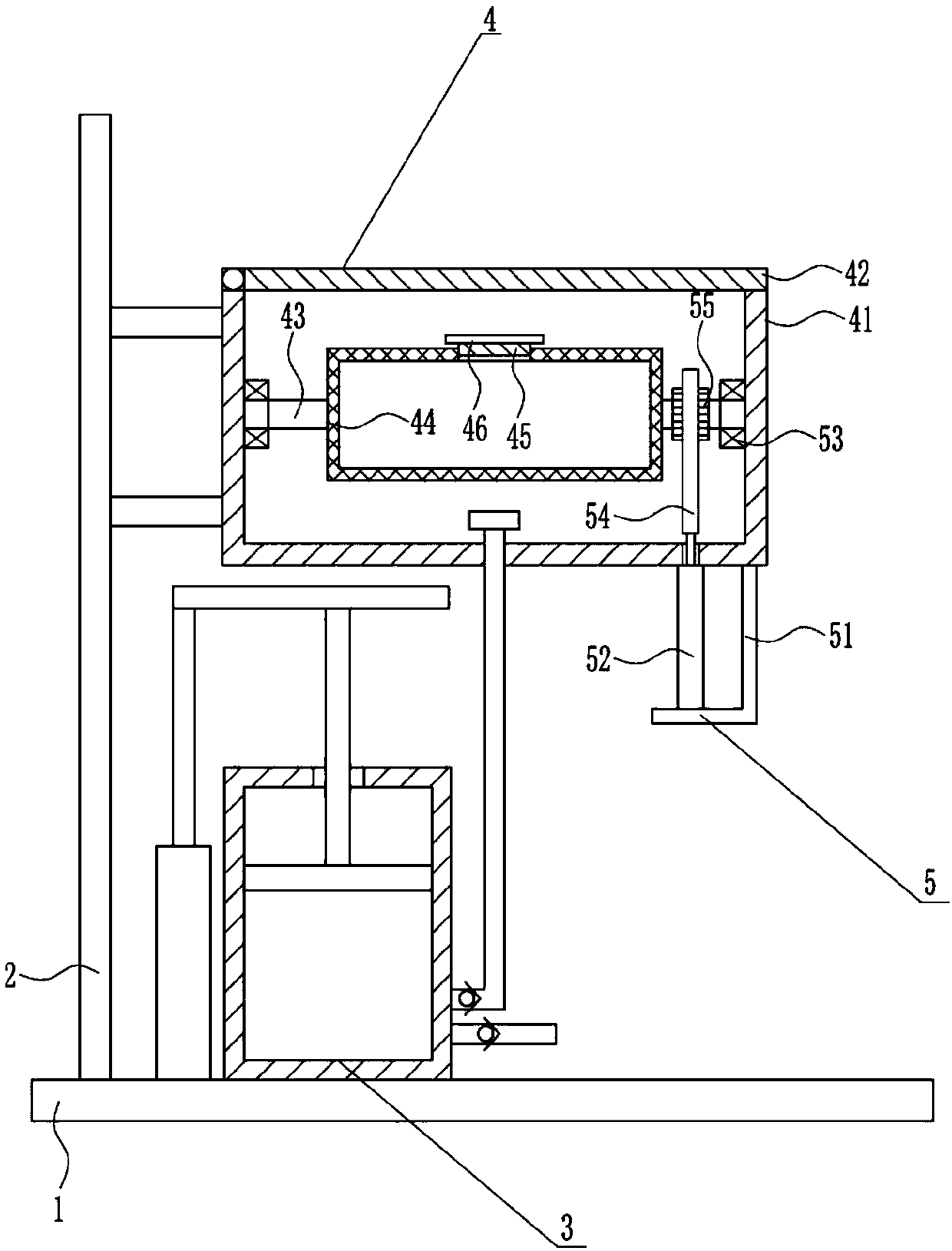

[0041] see image 3 , different from Embodiment 1, it also includes a rotating device 5, the rotating device 5 includes a mounting plate 51, a second cylinder 52, a bearing seat 53, a rack 54 and a gear 55, and the left and right sides of the box body 41 are connected symmetrically by bolts. The bearing housing 53 is installed in the above method, the outer end of the cross bar 43 is located in the bearing in the bearing housing 53, the cross bar 43 and the bearing in the bearing housing 53 are connected by interference fit, and the middle part of the right cross bar 43 is connected by a key connection There is a gear 55, and the right end of the bottom of the box body 41 is connected with a mounting plate 51 through a bolt connection mode, and a second cylinder 52 is vertically installed on the inner bottom of the mounting plate 51 through a bolt connection mode, and a second cylinder 52 is installed on the right side of the bottom of the box body 41. Hole, the second cylinde...

Embodiment 3

[0043] see Figure 4 with Figure 5 , different from Embodiment 2, it also includes a fixing device 6, the fixing device 6 includes a screw rod 62, a knob 63 and a rubber block 64, a threaded hole 61 is opened symmetrically on the horizontal plate 46, and a screw rod 62 is arranged in the threaded hole 61 , the screw 62 cooperates with the threaded hole 61, the bottom of the screw 62 is welded with a knob 63, the knob 63 is located above the horizontal plate 46, the bottom of the screw 62 is connected with a rubber block 64 horizontally, and the mesh tube 44 on the left and right sides of the feed inlet A groove 65 is formed, and the rubber block 64 corresponds to the groove 65 up and down, and the rubber block 64 cooperates with the groove 65.

[0044] see Image 6 , preferably, also includes a reinforcing rib 9, a reinforcing rib 9 is connected between the middle part of the inner right side of the mounting plate 51 and the bottom of the box body 41, the reinforcing rib 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com