Multifunctional vacuum vertical spiral stirring, drying and pouring machine

A spiral stirring and multi-functional technology, applied in the field of unloaders, can solve the problems of uneven drying, sticking to the wall, affecting the appearance of products, etc., to achieve the effect of convenient drying and stirring, reducing difficulty and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

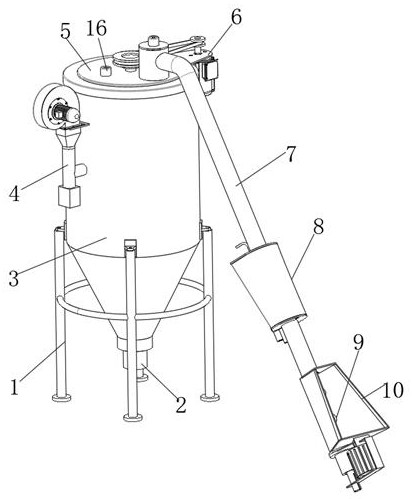

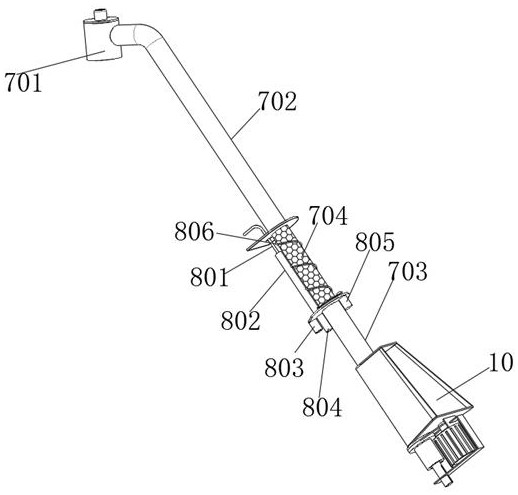

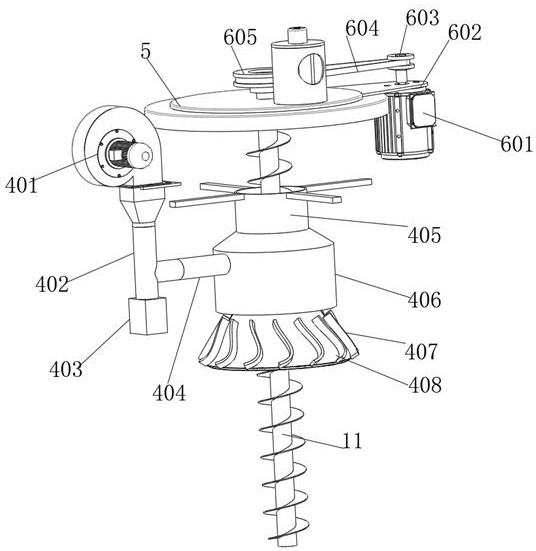

[0030] Example 1, refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 , discloses a multi-functional vacuum vertical screw stirring and drying unloading machine, including a pouring assembly, a feeding assembly is arranged on one side of the feeding assembly, and the upper part of the feeding assembly is communicated with the upper part of the feeding assembly, and the feeding assembly is Including a feeding pipe assembly 7, the feeding pipe assembly 7 includes a feeding pipe 701, the feeding pipe 701 is communicated with the upper part of the feeding assembly, and the outer peripheral surface of the feeding pipe 701 is connected with a second conveying section 702, so One end of the second conveying section 702 away from the feeding pipe 701 is connected with a metal mesh cylinder 704, and one end of the metal mesh cylinder 704 away from the second conveying section 702 is fixed with a first conveying sectio...

Embodiment 2

[0035] Example 2, refer to figure 1 , figure 2 , image 3 , Figure 4 ,rabbit, Figure 5 , Image 6 , Figure 7 , Figure 8 and Figure 9 , discloses a multi-functional vacuum vertical screw stirring and drying unloading machine, one side of the unloading assembly is provided with a feeding assembly, and the upper part of the feeding assembly is communicated with the upper part of the unloading assembly, and the feeding assembly includes a feeding pipe assembly 7. The feeding pipe assembly 7 includes a feeding pipe 701, which is communicated with the upper part of the feeding assembly, and the outer peripheral surface of the feeding pipe 701 is connected with a second conveying section 702. The second conveying section 702 is connected with a metal mesh cylinder 704 at one end away from the feeding pipe 701, and a first conveying section 703 is fixed at one end of the metal mesh cylinder 704 away from the second conveying section 702, and the lower end of the first con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com