Bamboo bridge deck

A bridge deck, bamboo technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of insufficient longitudinal bearing capacity and rigidity of plank beams, affecting the overall stiffness bearing capacity of slab structures, and easy cracking and damage of bridge decks. The effect of improving bridge spanning capacity, green materials and reducing lateral span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

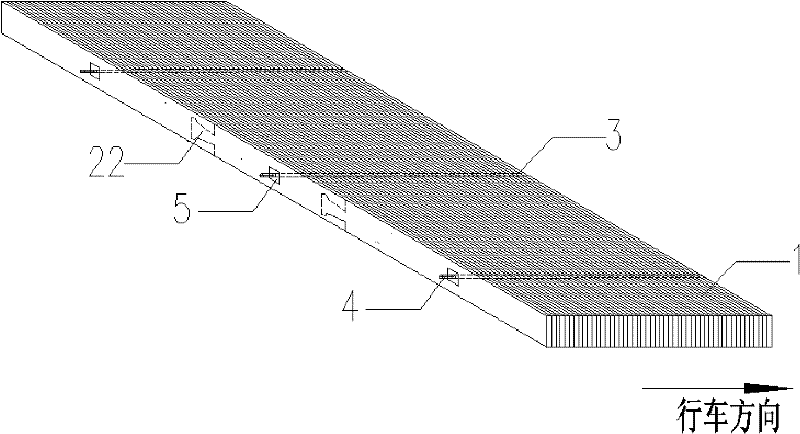

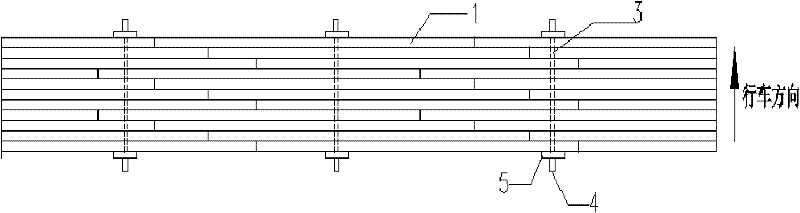

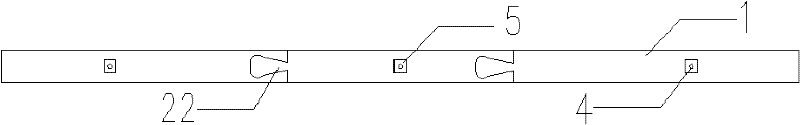

[0038] The bamboo bridge deck of the present invention comprises prestressed tendons 3 and a plurality of laminated bridge deck sheets 1, the bridge deck sheet 1 is formed by sequentially jointing the bridge deck veneers 2 made of a plurality of bamboo plywood, and the bridge deck One end of the bridge deck veneer 2 on sheet 1 is provided with a mortise 21 whose groove width gradually increases along the groove entry direction, and one end of the adjacent bridge deck veneer 2 is provided with a tenon matching the mortise 21 22. The mortise 22 is embedded in the mortise 21, and the mortise joints of two adjacent bridge deck pieces 1 are staggered. The bridge deck veneer 2 is provided with a mounting hole 23 for the prestressed tendon 3 to pass through, the prestressed tendon 3 passes through a plurality of bridge deck sheets 1 through the mounting hole 23, and the two ends of the prestressed tendon 3 pass through the backing plate 5 and are used The anchorage 4 is fixed and tau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com