Polyester type ultra-low density polyurethane resin for shoes

An ultra-low density polyurethane shoe technology, applied in footwear, applications, clothing, etc., can solve the problems of unfavorable production efficiency and economic benefits, shrinkage and deformation of insole products, slow molding, etc., achieve good appearance and surface effects, and improve product grades , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

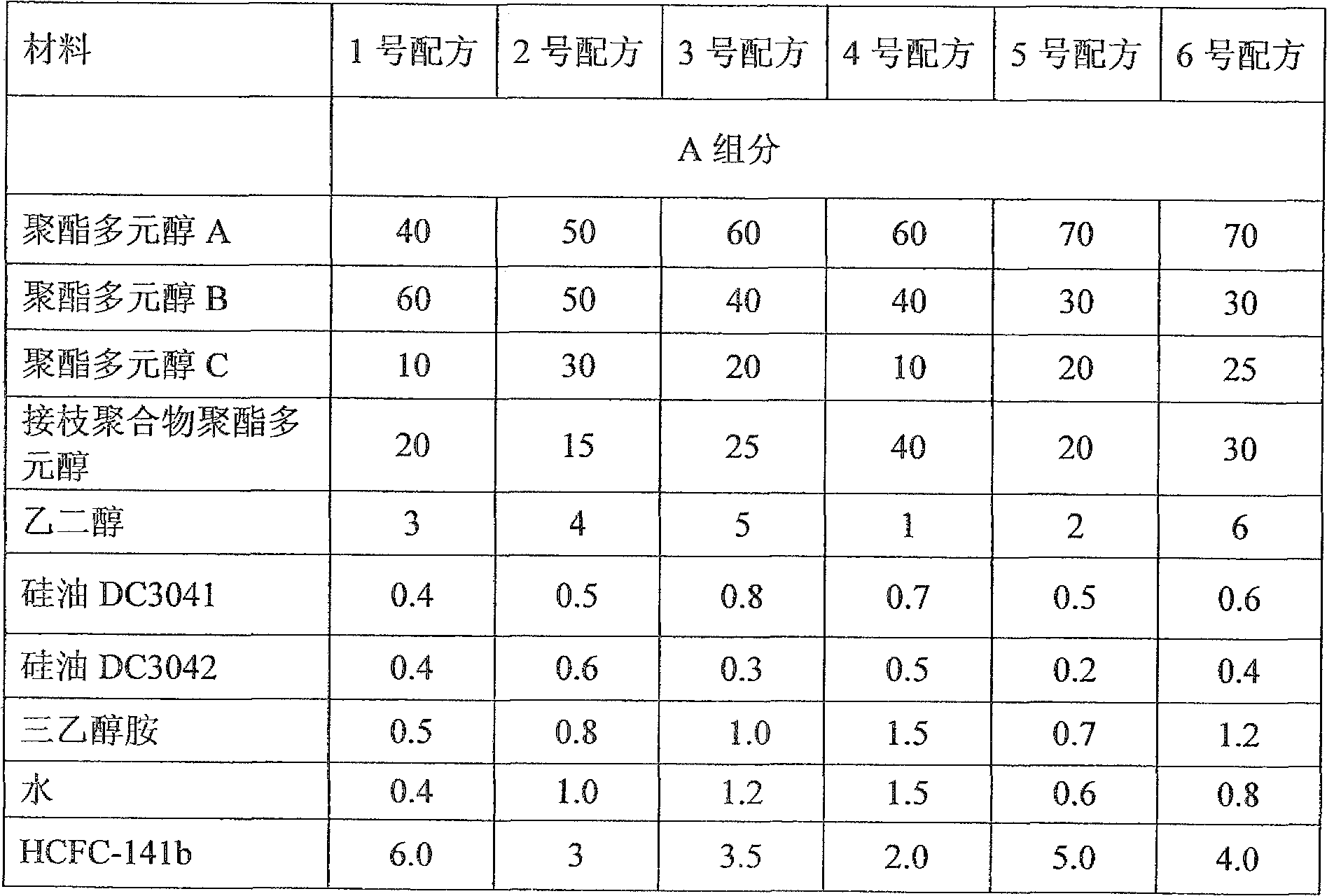

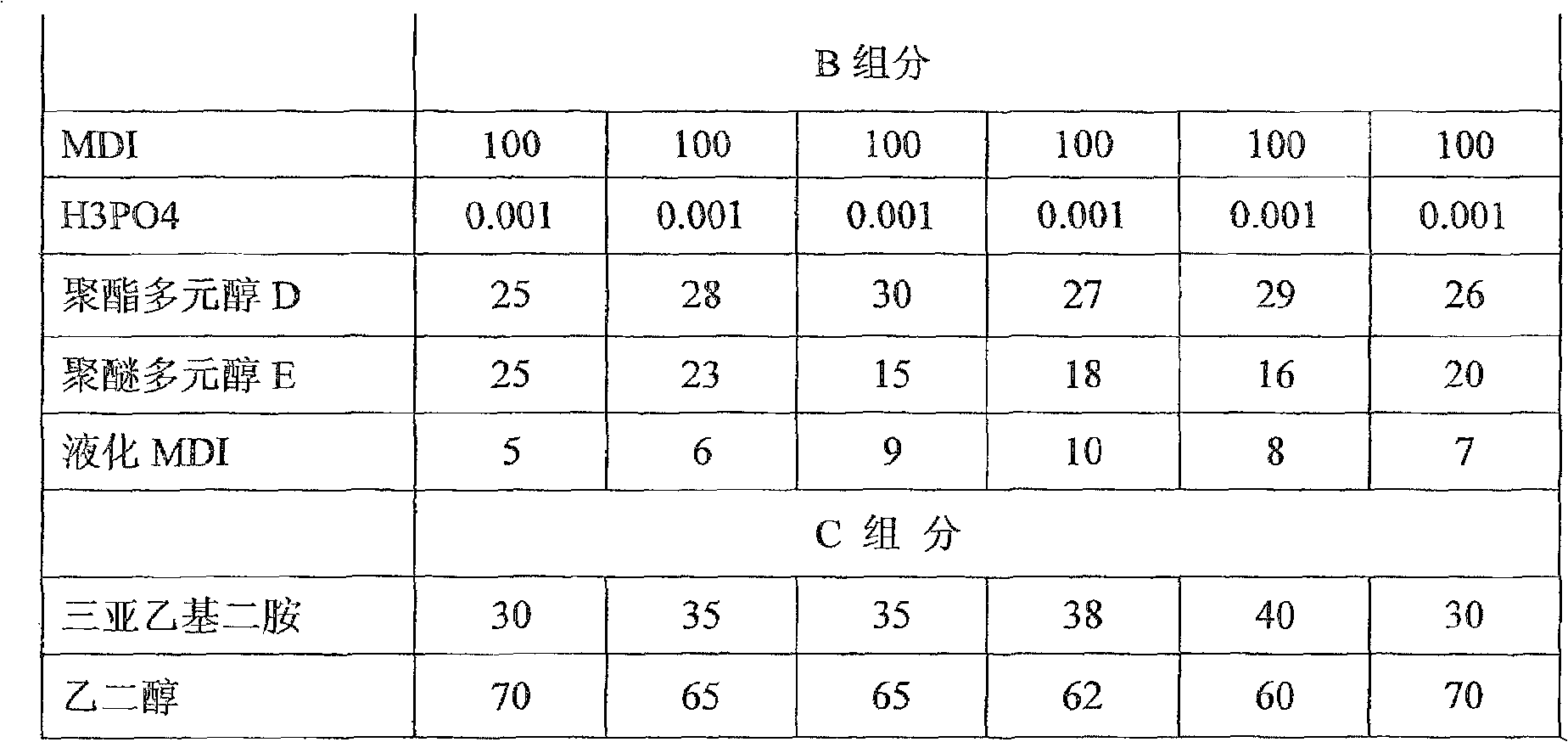

[0036] The molding and processing conditions of polyester ultra-low density polyurethane resin for shoes are as follows: component A and component B are preheated in an oven at 60±5°C for 4 to 6 hours, then take out component C and add it to component A. Make up the A component mixture. The amount of C is generally 1.22 to 1.5% of A.

[0037] (1) Manual operation: Weigh 100 parts of component A and 62 parts of component B, and pour them into the mold cavity for foaming under 2500r / min strong stirring for 5-9 seconds.

[0038] (2) Mechanical operation: pour the mixed components into material tank A of the shoe-making machine, circulate in the shoe-making machine through a metering pump, and measure during the pouring operation. Component B is poured into the material tank B of the shoe-making machine, circulated in the shoe-making machine through a metering pump, and is metered during the pouring operation.

[0039] (3) The mixing equivalent of the mixed components is about 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com