Waterborne quick-drying anticorrosive and rustproof paint for high-speed rail chassis

An anti-corrosion, anti-rust and anti-rust pigment technology, applied in anti-corrosion coatings, chitin polysaccharide coatings, hyaluronic acid coatings, etc. The effect of low displacement, good impact resistance and fast drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

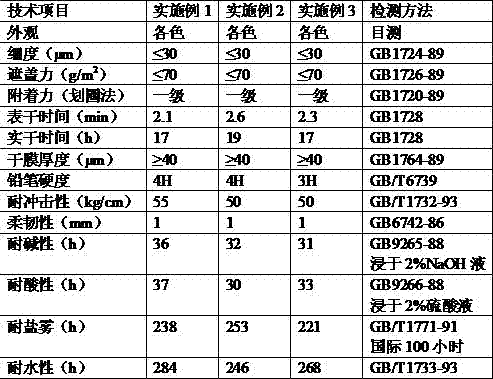

Examples

Embodiment 1

[0020] Raw material composition: 10 parts of water-based methacrylic epoxy resin, 20 parts of water-based fluorosilicone resin, 4 parts of chitosan, 11 parts of antirust pigment, 18 parts of talcum powder, 0.1 part of cationic FM emulsifier, sodium polycarboxylate 0.1 part of powder, 1 part of sodium nitrite, 0.1 part of water-based acrylic drier, 0.3 part of pH regulator, and 40 parts of deionized water.

[0021] Preparation method steps: antirust pigment, talcum powder, 1 / 2 cationic FM emulsifier, 1 / 2 polycarboxylate sodium salt dispersant, sodium nitrite, 1 / 2 water-based acrylic drier and pH regulator Stir evenly after mixing; disperse the mixed slurry at high speed, and then grind until the fineness of the slurry is ≤30μm; then add water-based methacrylic epoxy resin, water-based fluorosilicone resin, and the remaining cationic FM to the slurry The emulsifier, the remaining polycarboxylate sodium salt dispersant, the remaining water-based acrylic acid drier and water are s...

Embodiment 2

[0023] Raw material composition: 30 parts of water-based methacrylic epoxy resin, 22 parts of water-based fluorosilicone resin, 4 parts of chitosan, 9 parts of antirust pigment, 17 parts of talc powder, 0.2 parts of cationic FM emulsifier, sodium polycarboxylate 0.1 part of powder, 1 part of sodium nitrite, 0.1 part of water-based acrylic drier, 0.2 part of pH regulator, 40 parts of deionized water.

[0024] The preparation method is the same as in Example 1.

Embodiment 3

[0026] Raw material composition: 10 parts of water-based methacrylic epoxy resin, 25 parts of water-based fluorosilicone resin, 4 parts of chitosan, 13 parts of antirust pigment, 18 parts of talcum powder, 0.1 part of cationic FM emulsifier, sodium polycarboxylate 0.1 part of powder, 2 parts of sodium nitrite, 0.2 part of water-based acrylic drier, 0.2 part of pH regulator, 40 parts of deionized water.

[0027] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com