Preparation method of phenolic resin used for hand lay-up fiberglass-reinforced plastic

A technology of phenolic resin and glass fiber reinforced plastic, applied in the field of glass fiber reinforced plastic, can solve the problems of slow curing speed of phenolic resin and prolong the production cycle of phenolic glass fiber reinforced plastic products, so as to achieve the effect of increasing curing speed, shortening curing time and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

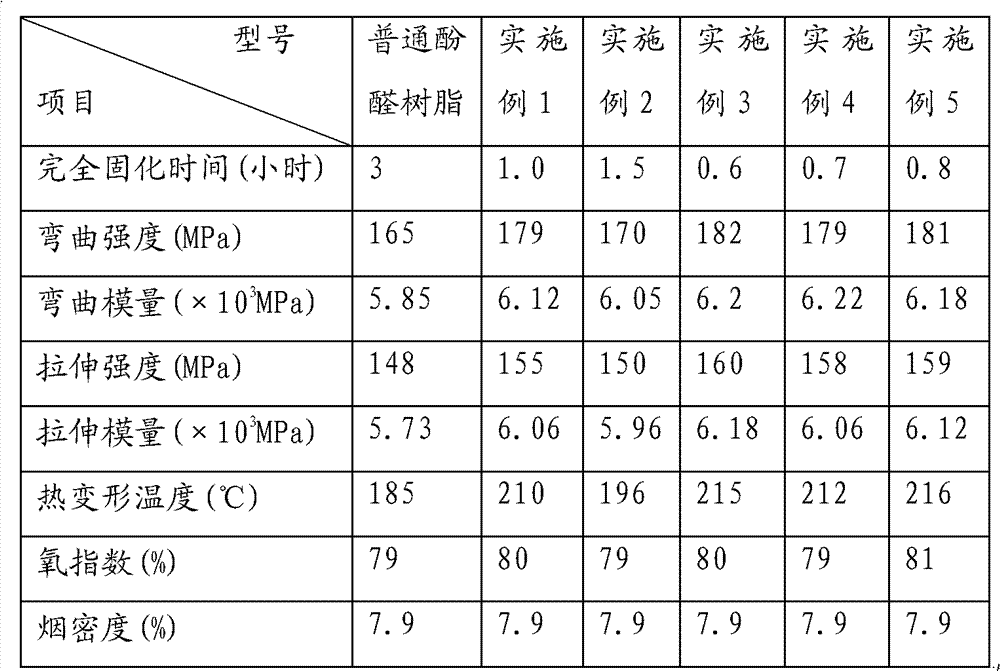

Examples

Embodiment 1

[0018] Add phenol, catechol, formaldehyde and sodium hydroxide into the reactor at a molar ratio of 1.0:0.5:2.0:0.03, raise the temperature to 40°C, react at constant temperature for 5 hours, raise the temperature to 85°C and continue the reaction for 2 hours; The obtained mixture was distilled under reduced pressure to remove part of the water: the distillation temperature was 40°C, the pressure was 0.5MPa, and the viscosity of the liquid was adjusted to 8000MPa·s / 25°C.

[0019] The phenolic resin produced in this embodiment has a solid content of 65-70%, a water content of 10-15%, and a free phenol content of 3-6%.

Embodiment 2

[0021] Add phenol, hydroquinone, formaldehyde and potassium hydroxide into the reactor at a molar ratio of 1.0:0.3:2.0:0.05, raise the temperature to 50°C, react at constant temperature for 6 hours, raise the temperature to 90°C and continue the reaction for 2 hours; The resulting mixture was distilled under reduced pressure to remove part of the water. The distillation temperature is 50°C, the pressure is 0.6MPa, and the viscosity of the liquid is adjusted to 9000MPa·s / 25°C.

[0022] The phenolic resin produced in this embodiment has a solid content of 67-72%, a moisture content of 5-13%, and a free phenol content of 7-10%.

Embodiment 3

[0024] Add phenol, resorcinol, formaldehyde and sodium bicarbonate in a molar ratio of 1.0:0.8:1.5:0.06 to the reactor, raise the temperature to 55°C, react at constant temperature for 4 hours, raise the temperature to 95°C and continue the reaction for 3 hours; The resulting mixture was distilled under reduced pressure to remove part of the water. The distillation temperature is 50°C, the pressure is 0.8MPa, and the viscosity of the liquid is adjusted to 10000MPa·s / 25°C.

[0025] The phenolic resin produced in this embodiment has a solid content of 70-75%, a water content of 4-10%, and a free phenol content of 5-8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com