Preparation of rice hull powder/talcum powder composite reinforced starch-based degradable plastic

A technology for degrading plastics and talc, which is applied in the field of degradable material preparation, can solve the problems that have been reported and have not yet been found, such as the preparation method of rice husk powder/talc composite reinforced starch-based degradable plastics, and achieves improved degradation performance, Significant social value and economic value, easy to shape effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

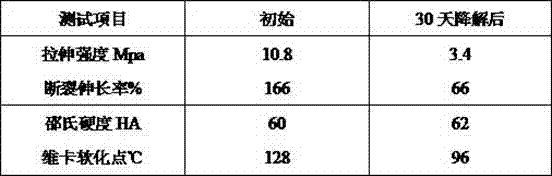

Embodiment 1

[0022] (1) Weigh the following raw materials in parts by weight: 40 parts of starch, 15 parts of rice husk powder, 6 parts of talc, 8 parts of polyvinyl alcohol, 6 parts of plasticizer, 1.2 parts of compound additives, 4 parts of water; The compound auxiliary agent is prepared by mixing polyethylene wax, stearic acid, white oil and coupling agent in a mass ratio of 30:30:30:10; the plasticizer is a triol, preferably a triol Glycerol; The coupling agent is a silane coupling agent, and the preferred silane coupling agent is silane coupling agent KH-550 (chemical name is 3-aminopropyltriethoxysilane);

[0023] (2) Add the starch, rice husk powder, talc powder, polyvinyl alcohol, plasticizer, compound additives and water weighed in step (1) into the mixer and mix uniformly to obtain a mixture;

[0024] (3) Add the mixture described in step (2) to the twin-screw extruder. The temperature of the feeding section, melting section, homogenization section and discharge section of the twin-sc...

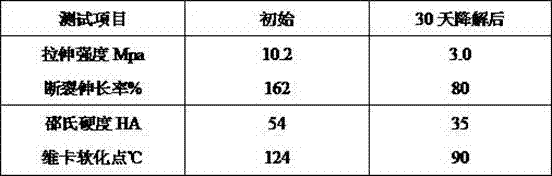

Embodiment 2

[0028] (1) Weigh the following various raw materials in parts by weight: 50 parts of starch, 10 parts of rice husk powder, 5 parts of talcum powder, 5 parts of polyvinyl alcohol, 5 parts of plasticizer, 1 part of compound additives, 3 parts of water; The compound auxiliary agent is prepared by mixing polyethylene wax, stearic acid, white oil and coupling agent in a mass ratio of 28:32:27:12; the plasticizer is a triol, preferably a triol Glycerol; The coupling agent is a silane coupling agent, and the preferred silane coupling agent is silane coupling agent KH-570 (chemical name is 3-methacryloxypropyltrimethoxysilane);

[0029] (2) Add the starch, rice husk powder, talc powder, polyvinyl alcohol, plasticizer, compound additives and water weighed in step (1) into the mixer and mix uniformly to obtain a mixture;

[0030] (3) Add the mixture described in step (2) to the twin-screw extruder. The temperature of the feeding section, melting section, homogenization section and discharge ...

Embodiment 3

[0034] (1) Weigh the following raw materials in parts by weight: 70 parts of starch, 20 parts of rice husk powder, 12 parts of talc, 7 parts of polyvinyl alcohol, 10 parts of plasticizer, 2.5 parts of compound additives, 5 parts of water; The compound auxiliary agent is prepared by mixing polyethylene wax, stearic acid, white oil and coupling agent in a mass ratio of 30:30:30:8; the plasticizer is a glycol, preferably a glycol It is 1,2-propylene glycol; the coupling agent is a silane coupling agent, and the preferred silane coupling agent is silane coupling agent KH-550 (chemical name is 3-aminopropyltriethoxysilane);

[0035] (2) Add the starch, rice husk powder, talc powder, polyvinyl alcohol, plasticizer, compound additives and water weighed in step (1) into the mixer and mix uniformly to obtain a mixture;

[0036] (3) Add the mixture described in step (2) to the twin-screw extruder. The temperature of the feeding section, melting section, homogenization section and discharge s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com