Peroxide pre-crosslinked low smoke zero halogen flame retarding irradiation crosslinking polyolefin composite and preparation method thereof

A technology of cross-linking polyolefin and peroxide, which is applied in the field of flame-retardant polyolefin materials to achieve the effects of good flame-retardant performance, reduced smoke generation, and excellent smoke-suppressing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

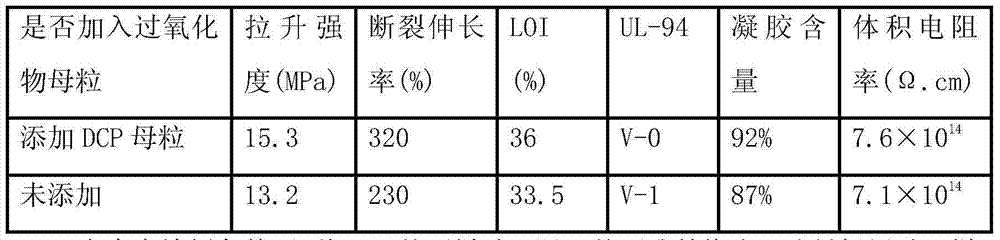

[0026] Take by weight 35 parts of ethylene-vinyl acetate copolymers, 15 parts of maleic anhydride grafted ethylene-vinyl acetate copolymers, 0.5 parts of organically modified montmorillonite, and knead for 10 minutes at 140 ° C in an internal mixer, Then add 50 parts of aluminum hydroxide, 1.5 parts of trimethylolpropyl trimethacrylate, 0.4 parts of antioxidant 300, and 0.4 parts of antioxidant DLTP. granulated into electron beam irradiation cross-linked polyolefin cable material, and then 100 parts of the polyolefin cable material and 2 parts of DCP masterbatch (wherein the mass ratio of DCP to ethylene-vinyl acetate copolymer is 2:8) at 160 Under the condition of high temperature, it is extruded and coated on the conductive core of the wire and cable, and finally irradiated and cross-linked under the electron beam with power and energy of 10KW and 10MeV respectively, and the radiation dose is 100KGy.

[0027] In order to further verify the comprehensive properties of the low...

Embodiment 2

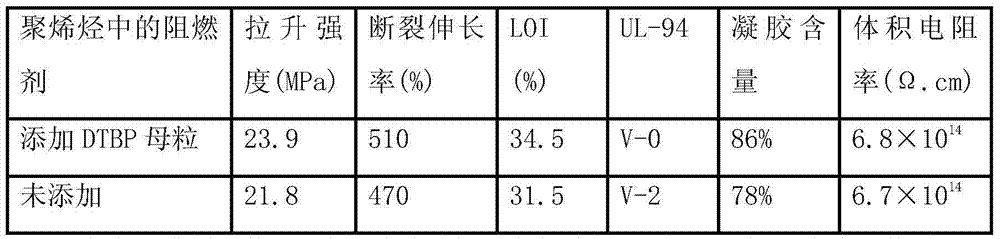

[0031]Weigh 60 parts of ethylene-vinyl acetate copolymer, 10 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer and 5 parts of zinc aluminate in parts by weight, knead in an internal mixer at 140°C for 10 minutes, then add 5 parts of macromolecular triazine-based char-forming agent, 5 parts of melamine cyanurate, 15 parts of silane microencapsulated ammonium polyphosphate, 0.5 part of triallyl isocyanurate, 0.4 part of antioxidant 300, anti-oxidant Take 0.4 part of the oxygen agent DLTP, mix the components of the raw materials evenly, extrude and granulate at 160°C to form an electron beam irradiation cross-linked cable material, and then 100 parts of the polyolefin cable Material and 5 parts of DTBP masterbatch (the mass ratio of DTBP to ethylene-vinyl acetate copolymer is 1:9) is extruded and coated on the conductive core of the wire and cable under the condition of 160 degrees, and then the power and energy are respectively Irradiation and crosslinking under...

Embodiment 3

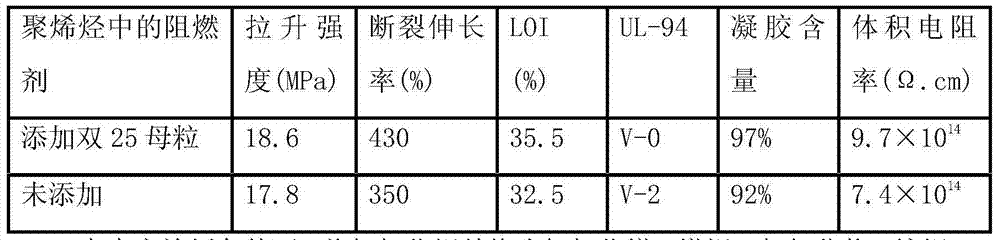

[0036] Weigh 55 parts of ethylene-vinyl acetate copolymer, 5 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, and 4.5 parts of red phosphorus in parts by weight, mix in an internal mixer at 155°C for 10 minutes, and then add hydrogen 20 parts of magnesium oxide and 40 parts of aluminum hydroxide, 0.05 part of antioxidant 300, and 0.05 part of antioxidant DLTP. After mixing the components of the raw materials evenly, extrude and granulate at 160°C to form electron beam irradiation crosslinking Cable material, then 100 parts of the polyolefin cable material and 1 part of double 25 masterbatch (the mass ratio of double 25 to ethylene-vinyl acetate copolymer is 3:7) is extruded and coated on the wire under the condition of 160 degrees On the conductive core of the cable, and then irradiate cross-linking under the electron beam with power and energy of 10KW and 10MeV respectively, and the radiation dose is 180KGy.

[0037] In order to further verify the comprehen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com